ToyREP

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Release status: working

| Description | Printer inspired by Prusa i3 Y-frame, CARP Box X and Y axis and Z axis of Printrbot or Wallace. Extruder is based on Wade's Geared Extruder.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | none

|

| External Link |

Contents

Introduction

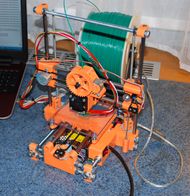

ToyREP is a tiny and inexpensive FFD 3D printer designed mostly as a technology demonstrator or child's toy. The print volume is 100x100x100mm (125x125x100mm with some upgrades) with a cold bed made of polyacrylate. Hot end is a E3D clone for 1.75 PLA or ABS filament. Using very cheap 28BYJ-48 stepper motors (with bipolar motor hack) in all axis and geared extruder, Arduino Mega 2560 with Ramps 1.4, DRV8825 and modular RepRap construction based on Mendel, Printerbot, Cherry, Prusa i3 and CARP Box ideas. It is designed to use 12V 40W PSU for LED lights that should fit under bed. Power consumption is currently ca 40W when heating hotend and 15W-20W when printing. ToyREP was released in July 2015.

Dimensions

The external dimensions of the ToyREP are 255x245x295mm and print volume 100x100x100mm (WxDxH). Optionally bigger version with external dimensions 265x265x295mm and print volume 125x125x100mm (WxDxH) is possible to build.

Key features

This printer is mostly conceptual, designed to utilize 28BYJ-48 stepper motor, to test their possible future usability in 3D printers. As such it proved working, although quite slow. Right now it is usable as very cheap technology demonstrator of FFD technology or a Toy, thus the name Toy Replicator. The second part standing for Rapid Prototyping is missing as future development have to be done to increase movement speeds.

Right now the printer can do 10-12.5mm/s in X and Y axis and 0.25 mm in Z axis safely. Eventually it can reach up 30mm/s in X and Y axis but such speeds causes overheating and possible damage to the stepper motors.

Printer is made to be self replicable, cheap, easy to build, simple to be operated, with low running costs and transportable.

It is sort of a repstrap too, as the vitamins are mostly spare parts or in case of rods, leftovers from my previous projects.

Although it shows very high steps per mm ratios, precision was not a main goal when printer was designed. It is mostly a side effect of 28BYJ-48 (changed to bipolar) with 1/16 or 1/32 microstepping. Such high microstepping is used mostly to make current control less square. Extruder is rather designed for 0.4-0.6mm nozzle, so thicker layers can be used to speed up printing a bit. Theoretically the printer have a resolution up to 1.5um in X, Y axis and 24nm in Z axis but those numbers are only virtual. There is a major deviation caused by the gearbox and threaded rod backslash and melted plastic flow. Still overall performance is may be a bit better than of a common RepRap it the terms of resolution.

Mechanical Parts

Printed Parts

Most of the parts are printed. Some parts have different versions so the printer can be customized as per your needs.

List of parts:

Pictures downloaded from thingiverse are used as thumbnails.

Download the STL files at Thingiverse. Right now, there are two possible sizes of ToyREP. Smaller one with PSU 111x78x36mm and 100x100x100mm print volume or bigger one with PSU up to 129x99x38mm and 125x125x100mm print volume. Choice the parts accordingly. Also You can either suspend threaded for Z axis from the top bearings or let all the weight rest on the motors, but you will get less wobble. If you are going to use E3D clone bowden hotend there is actually no bowden extruder for 28BYJ-48 motor. You will have to use some NEMA17 extruder instead.

Vitamins

For complete list of accessories and screws see BoM in ToyREP Buyers Guide.

Electronics

Controller Electronics

Mounting is prepared for Arduino Mega 2560 with RAMPS 1.4.

Stepper Drivers

In above mentioned electronics, Pololu drivers or its clones are used. There are two most common drivers.

- Allegro A4988 based driver - up to 16 microstepping, maximal current 2A, voltage 8-35V.

- Texas Instruments DRV8825 based drivers - up to 32 microstepping, maximal current 2.5A, voltage up to 45V.

Both needs at least passive cooler for longer prints. Although DRV8825 may look like the best choice, very low current (around 100-150mA) required for 28BYJ-48 is harder to achieve.

Stepper Motors

All stepper motors are unipolar 28BYJ-48 5V, 0.15mA?, 0.03Nm with 1:64 reduction gearbox. They are changed to bipolar by a simple hack: http://www.electronicsmayhem.com/?p=13 Be carefull when removing the blue plastic cap, as you can break tiny wires coming from coils to the PCB!

Motor can operate safely at 10-12V when bipolar. After the hack, motor has ca 2048 steps per one revolution of the shaft. This number varies as many available motors do not have exactly 1:64 reduction, but rather 1:63.7 or so. This does not matter because during the calibration the amount of steps per mm will get adjusted.

Motors with 1:64 reduction are strong enough not only for movement in all axis, but even for direct drive extruder. Be careful though because high static load can damage the tiny teeth in gearbox.

The major disadvantage is their shaft turning speed around 15RPM. Although you may hand pick some that are capable of 36RPM, they cannot be used at such "high" speed for too long, as they will overheat and their coils will burn. The motor it self without the gearbox can do 960-2300RPM. Maybe motors with 1:16 reduction gearbox may be a good way to go 4 times quicker, but they will have much lover torque. This yet have to be tested..

Extruder

The printer have a remix of Wade's geared extruder adjusted for E3D clone and 28BYJ-48 motor. The gear ratio is 1:4. Fan holder at the hot end serves also as a extruder mount on X carriage. Hyena M8 hobbed bolt is used to pull the filament. Hotend have 0.4mm nozzle, 12V 40W ceramics heat cartridge and 100K Ohm thermistor. It can be operated as 10V to match motors, only heating will take a bit longer. Be careful when using original E3D, as they have a bit shorter aluminium coldend and may not fit inside this fan mount.

Heated Bed

As I am printing mostly ABS, this printer is using polycarbonate plate 120x120x3mm with mounting holes 105x105mm apart. Printer can also utilize 145x145mm plate with mounting holes 130x130mm apart. With Polycarbonate first layer have to be extruded at very low temperature (ca 205-215°C) so the model can be removed form plate when print is done. You can use your favourite print surface instead.

For hotbed 12V 40W PCB board should be just fine. This is still on the to-do list.