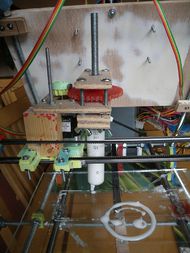

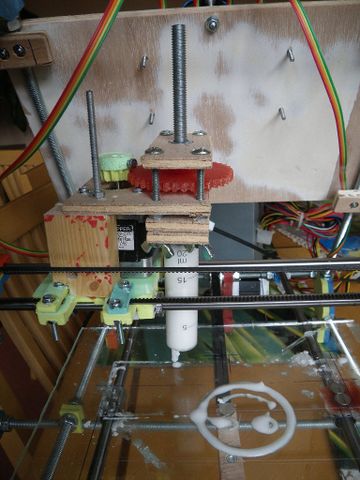

Davids Paste Extruder

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Mechanical: Overview | Mendel solid model files | Procurement | Preparation of materials | Assembly notes | Extruder | X-axis | Z-axis | Y-axis | Circuit boards | Frame | Squaring the axes

Release status: Working

| Description | Geared Nema17 Paste Extruder

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | not available

|

| External Link |

A syringe based extruder. Similar to the FrostuderMk1. Uses the gearing from Wades Extruder to rotate a nut around a threaded rod. The rod has a keyway cut down it's length, and a screw runs in this to stop the rod rotating. The rotation of the nut is thus translated into linear motion which depresses the syringe plunger. Thus unlike the frostruder2/pfiercestruder/etc, it doesn't require an air source/solenoid.

Advantages:

- It's cheap (roughly £2 for the nuts, plywood, and syringe, gears, though stepper motor is still relatively expensive - I only used NEMA17 as I had one lying around, I bet 14 would still be fine and cheaper).

- It's easy to make with handtools. I used a drill and dremel, but you could make it with just a nail and a chisel (or a sharp rock or bit of bone if you really want to be adventurous :-p)

- Its quietish (doesn't require a compressor running, but still has stepper)

- Because of cost/simplicity, it can provide a test setup which is a step beyond attaching a biro to the carriage and using it as a plotter by drawing pictures using inkscape/gcodetools (guess who tried torture testing the X/Y/Z axes with that).

Disadvantages:

- Doesn't have a sharp on/off

It can extrude any paste which won't dissolve the syringe, but I've found it doesn't like extruding playdoh - the pressure caused the plunger head to rotate 90 degs and pressure was released. This would probably be fixed with a nut at the bottom of the threaded rod, but I wasn't fussed enough to try it. (I just added a bit of water to make it slightly more paste-like, which also improved extrusion speed).

The syringe can be (relatively) rapidly switched in and out to change colors/substances. The rod has to be rewound, but this leaves the plunger in place so the contents don't get lost/air bubbles introduced. The syringe then slots out and replacement syringe can be inserted. A hook is requird to pull the plunger out of the syringe. A piece of string tied on to the plunger might work, but I didn't want to waste one (by getting it tangled and broken).

If you want to change the size of the syringe the holder can be swapped in 30secs as it's only attached to the rest of the mechanism with butterfly nuts.

I'm currently trying to figure if there is a simple electronic circuit which will activate a solenoid valve to close off the nozzle when the stepper is set to 'hold' (ie both coils activated and static). Preferably drawing power for operation from the stepper driver to avoid extra wiring. If anyone has seen anything like this, please let me know. I'm also wondering if a peristaltic pump might be better. Thats for the next trial.