Is there any alternative to Teflon?

Posted by Simba

|

Re: Is there any alternative to Teflon? October 17, 2013 08:18AM |

Admin Registered: 17 years ago Posts: 7,879 |

I think if you have a continuous force on PTFE while it is heated it will creep continuously.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Is there any alternative to Teflon? October 17, 2013 09:01AM |

Registered: 11 years ago Posts: 374 |

|

Re: Is there any alternative to Teflon? October 17, 2013 09:12AM |

Admin Registered: 11 years ago Posts: 1,063 |

crispy1 Wrote:

-------------------------------------------------------

>

> I've never needed a fan on any of my jheads,

> printing both PLA and ABS over a wide range of

> temperatures and speeds.

it'll be dependant on the pla you use, and the version of the hotend you are using, not all pla and abs is created equal

-------------------------------------------------------

>

>Quote

a jhead needs a fan...

> I've never needed a fan on any of my jheads,

> printing both PLA and ABS over a wide range of

> temperatures and speeds.

it'll be dependant on the pla you use, and the version of the hotend you are using, not all pla and abs is created equal

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Is there any alternative to Teflon? October 18, 2013 06:38AM |

Registered: 12 years ago Posts: 1,450 |

The OP (Simba) asked if there was any alternative to PTFE and I mentioned that I had tried graphite loaded PEEK, but that it had not been a success. On retrying this, I find that it was jamming because ABS filament had expanded in the melt chamber, been cooled on retract and then jammed in the graphite loaded sleeve -Tecapeek is much much harder than PTFE. I am going to retry this with a modified nozzle: My old nozzle had PTFE up to a bit where the temperature was 60 to 80C, I want to extend this to where the temperature is about 160 degrees on the entry to the chamber and also use nopheads taper - once I understood the reason for this I must try it out. Picture below.

What I am not sure of at the moment is, is160 degrees at the entry to the tapered zone O.K.? Will this cover PLA as well as ABS?

Also, any thoughts on how to machine a reverse taper like that?

Mike

What I am not sure of at the moment is, is160 degrees at the entry to the tapered zone O.K.? Will this cover PLA as well as ABS?

Also, any thoughts on how to machine a reverse taper like that?

Mike

|

Re: Is there any alternative to Teflon? October 18, 2013 07:14AM |

Admin Registered: 17 years ago Posts: 7,879 |

At the start of the taper it must be below the glass transition and at the end above the melt point so 160C is borderline for PLA as that is about the temperature it melts at. It should be OK for ABS.

I can't see the point of the PVX sleeve as it is is before the taper so the plastic should be solid at that point and a little smaller than the tube, so very little friction. If you are retracting molten filament up to there it is retracted too far. Maybe for multi head extruders you need to extract that far, in which case yes you would need something slippery. The problem is the seam would need to be perfect as plastic that had expanded to the wall and then solidified will not pass a step.

I am also not sure what the PEEK block is for as above the taper you want to cool it, not insulate it.

I have no idea how to make a blind taper like that. It would need a micro boring bar if they exist. My designs had the taper at the end of the stainless pipe, which screwed into the heater block, which was also the nozzle.

[www.hydraraptor.blogspot.com]

I can't see the point of the PVX sleeve as it is is before the taper so the plastic should be solid at that point and a little smaller than the tube, so very little friction. If you are retracting molten filament up to there it is retracted too far. Maybe for multi head extruders you need to extract that far, in which case yes you would need something slippery. The problem is the seam would need to be perfect as plastic that had expanded to the wall and then solidified will not pass a step.

I am also not sure what the PEEK block is for as above the taper you want to cool it, not insulate it.

I have no idea how to make a blind taper like that. It would need a micro boring bar if they exist. My designs had the taper at the end of the stainless pipe, which screwed into the heater block, which was also the nozzle.

[www.hydraraptor.blogspot.com]

|

Re: Is there any alternative to Teflon? October 18, 2013 07:54AM |

Registered: 12 years ago Posts: 1,450 |

Hi nophead,

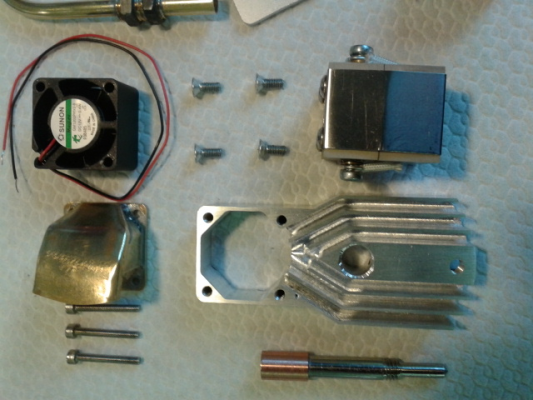

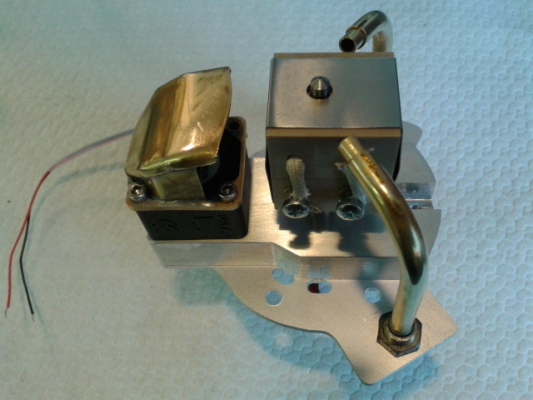

The sleeve is there just for lower friction than a drilled hole and also to allow a thin wall on the stainless steel tube, so cutting down heat loss. The top PEEK block isn't a thermal insulator but a terminal block, the cuttlefish bone below it is again to conserve heat. Pictures below of an earlier incantation, show the nozzle, the terminal block and heat sink. Heatsink fan helps area cooling of the print - local cooling of freshly printed plastic by air jets - marginally better than an area fan but an air ring is better still.

Mike

The sleeve is there just for lower friction than a drilled hole and also to allow a thin wall on the stainless steel tube, so cutting down heat loss. The top PEEK block isn't a thermal insulator but a terminal block, the cuttlefish bone below it is again to conserve heat. Pictures below of an earlier incantation, show the nozzle, the terminal block and heat sink. Heatsink fan helps area cooling of the print - local cooling of freshly printed plastic by air jets - marginally better than an area fan but an air ring is better still.

Mike

|

Re: Is there any alternative to Teflon? October 18, 2013 08:25AM |

Registered: 10 years ago Posts: 1,381 |

PEEK Graphite:

Graphite loaded PEEK is probably conducting heat into your filament.

This added heat I imagine would cause the filament to warm up and stick.

Graphite is an excellent conductor of heat, crucibles are made of it.

Teflon spray coating:

I've designed hotplate fusion welding tooling with a Teflon coating, works great.

I've conducted lots of experiments with different exotic coatings, and settled on Teflon, the same stuff on your pots and pans at home.

The Teflon coating eventually wears off, but it's cheap enough to sandblast off, and reapply. Coating the inside of a DIA 1.75 mm to 3 mm hole is not a realistic option for the hacker or for production (pita). I'm fairly confident the mfg would reject the work. It's a spray process, and the Teflon spray can't reach very far down a DIA 1/4” hole. In addition, the edge of the filament would chew up the Teflon quickly, this would necessitate recoating.

Electropolishing:

Electropolishing the ID of a SS filament guides might work if you can direct a stream into the orifice.

You might be able to do this at home with a battery charger, and water pump.

[web.eecs.umich.edu]

[en.wikipedia.org]

Graphite loaded PEEK is probably conducting heat into your filament.

This added heat I imagine would cause the filament to warm up and stick.

Graphite is an excellent conductor of heat, crucibles are made of it.

Teflon spray coating:

I've designed hotplate fusion welding tooling with a Teflon coating, works great.

I've conducted lots of experiments with different exotic coatings, and settled on Teflon, the same stuff on your pots and pans at home.

The Teflon coating eventually wears off, but it's cheap enough to sandblast off, and reapply. Coating the inside of a DIA 1.75 mm to 3 mm hole is not a realistic option for the hacker or for production (pita). I'm fairly confident the mfg would reject the work. It's a spray process, and the Teflon spray can't reach very far down a DIA 1/4” hole. In addition, the edge of the filament would chew up the Teflon quickly, this would necessitate recoating.

Electropolishing:

Electropolishing the ID of a SS filament guides might work if you can direct a stream into the orifice.

You might be able to do this at home with a battery charger, and water pump.

[web.eecs.umich.edu]

[en.wikipedia.org]

|

Re: Is there any alternative to Teflon? October 18, 2013 09:06AM |

Registered: 12 years ago Posts: 1,450 |

Hi A2,

The datasheet for Tecapeek graphite loaded PEEK does not give a number for thermal conductivity, but the choice of range indicates that it is in the same ballpark as PTFE - consistant with a graphite content of 10%.

I may try your idea of electropolishing the inside of the melt chamber -I keep phosphoric acid here as a flux for soldeing stainless steel and I am sure I can find sulphuric acid.

Mike.

The datasheet for Tecapeek graphite loaded PEEK does not give a number for thermal conductivity, but the choice of range indicates that it is in the same ballpark as PTFE - consistant with a graphite content of 10%.

I may try your idea of electropolishing the inside of the melt chamber -I keep phosphoric acid here as a flux for soldeing stainless steel and I am sure I can find sulphuric acid.

Mike.

|

Re: Is there any alternative to Teflon? October 18, 2013 09:06AM |

Registered: 11 years ago Posts: 246 |

Quote

A2

Electropolishing:

Electropolishing the ID of a SS filament guides might work if you can direct a stream into the orifice.

You might be able to do this at home with a battery charger, and water pump.

I am currently prototyping an all-metal hot end design that features an electropolished 1-piece Stainless Steel nozzle/heat break, so I can tell you that this is definitely possible. This is probably the most advanced polishing method available for these Stainless Steel heat breaks as it is far superior to any kind of mechanical polishing method (reaming, burnishing, lapping, etc...). However, this electropolishing is done on EDM machines in a professional CNC factory so I am not sure if you would be able to reconstruct this in a DIY setting. Also, it is quite expensive to have parts manufactured in this way.

I will receive my final sample of these SS electropolished heat breaks next week so I'll see how they perform

Eric

|

Re: Is there any alternative to Teflon? October 18, 2013 10:01AM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

The sleeve is there just for lower friction than a drilled hole and also to allow a thin wall on the stainless steel tube, so cutting down heat loss.

But above the taper you should be above the transition zone so you want as much heat loss as possible to keep it cool. I attached my heatsink where your PEEK is, as close as possible to the top of the taper.

There should not be significant friction in cold, unexpanded filament against the inside of the tube because it moves at such an oblique angle to it.

[www.hydraraptor.blogspot.com]

|

Re: Is there any alternative to Teflon? October 18, 2013 11:50AM |

Registered: 12 years ago Posts: 1,450 |

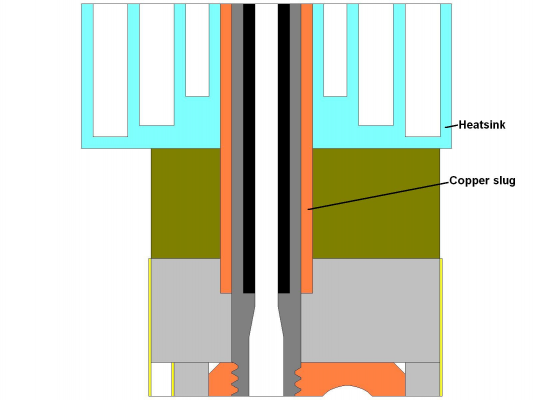

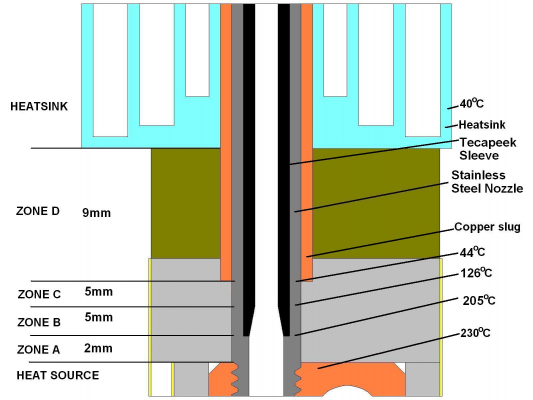

O.K., I see the point now. Feed the heat into the wide end of the tapered section, suck it out of the narrow end and maintain a gradient in the plastic from hot and fluid in the melt chamber to not-quite-molten at the entry. Something like a low thermal impedance connection at either end so that the temperatures don't waggle about with small changes in output.

To use bits that I have already made, do you think that this sort of arrangement would work.

I have a copper slug the length of which can be adjusted to get the profile right and have also shown the heatsink. This will only require shortening of the stainless nozzle and making a longer copper slug. There is an ulterior motive for keeping the PTFE or Tecapeek sleeve: Long thin drills snag and judder on stainless steel as the helix tries to unwrap itself. A short drill silver soldered to a bit of silver steel cuts cleanly. The same applies if I am to make up something th do the reverse taper in the chamber - I will need all of the rigidity that I can get.

Mike

To use bits that I have already made, do you think that this sort of arrangement would work.

I have a copper slug the length of which can be adjusted to get the profile right and have also shown the heatsink. This will only require shortening of the stainless nozzle and making a longer copper slug. There is an ulterior motive for keeping the PTFE or Tecapeek sleeve: Long thin drills snag and judder on stainless steel as the helix tries to unwrap itself. A short drill silver soldered to a bit of silver steel cuts cleanly. The same applies if I am to make up something th do the reverse taper in the chamber - I will need all of the rigidity that I can get.

Mike

|

Re: Is there any alternative to Teflon? October 18, 2013 12:37PM |

Registered: 10 years ago Posts: 1,381 |

@RP Iron Man

EDM = Electro Discharge Machining.

[en.wikipedia.org]

You can get a mirro finish with an EDM machine.

But I'm not sure if it's possible in a deep small ID pocket. I've only seen it done in shallow pockets.

Can you post a cross section of your extruder?

What did the machine shop quote you for the surface finish in RMS? 4 RMS is a mirror surface.

What SS are you using, did the machine shop make any recommendations, did you ask?

For some plastics an EDM surface works great as a mold release for injection molding.

This has got me thinking, I wonder if the stippled surface that the EDM typically leaves behind (32-64 RMS) would be beneficial?

The tiny pockets could act as an air cushion. To further this idea, electropolish the ID.

@leadinglights

Take pictures, and make notes of your electropolishing so we all can learn!

A2

EDM = Electro Discharge Machining.

[en.wikipedia.org]

You can get a mirro finish with an EDM machine.

But I'm not sure if it's possible in a deep small ID pocket. I've only seen it done in shallow pockets.

Can you post a cross section of your extruder?

What did the machine shop quote you for the surface finish in RMS? 4 RMS is a mirror surface.

What SS are you using, did the machine shop make any recommendations, did you ask?

For some plastics an EDM surface works great as a mold release for injection molding.

This has got me thinking, I wonder if the stippled surface that the EDM typically leaves behind (32-64 RMS) would be beneficial?

The tiny pockets could act as an air cushion. To further this idea, electropolish the ID.

@leadinglights

Take pictures, and make notes of your electropolishing so we all can learn!

A2

|

Re: Is there any alternative to Teflon? October 18, 2013 12:59PM |

Admin Registered: 17 years ago Posts: 7,879 |

@leadinglights,

Yes a copper sleeve should work. I used a thicker aluminium one in this design.

[www.hydraraptor.blogspot.com]

Yes a copper sleeve should work. I used a thicker aluminium one in this design.

[www.hydraraptor.blogspot.com]

|

Re: Is there any alternative to Teflon? October 18, 2013 01:26PM |

Registered: 11 years ago Posts: 246 |

Quote

A2

EDM = Electro Discharge Machining.

[en.wikipedia.org]

You can get a mirro finish with an EDM machine.

But I'm not sure if it's possible in a deep small ID pocket. I've only seen it done in shallow pockets.

Can you post a cross section of your extruder?

What did the machine shop quote you for the surface finish in RMS? 4 RMS is a mirror surface.

What SS are you using, did the machine shop make any recommendations, did you ask?

For some plastics an EDM surface works great as a mold release for injection molding.

This has got me thinking, I wonder if the stippled surface that the EDM typically leaves behind (32-64 RMS) would be beneficial?

The tiny pockets could act as an air cushion. To further this idea, electropolish the ID.

My manufacturer specifically uses Wire Cut EDM Machines.

I attached a drawing of the 1.75mm version of the Stainless Steel Nozzle used in my hot end for your reference. It has a 2mm bore and is 34mm long. so this kind of machining is definitely applicable to our needs

They recommended using SS304 grade for a better internal surface finish. I am not sure about the RMS rating because I never asked. I have a previous sample from them which I am looking at right now and I don't think it is quite a perfect mirror finish, but it is pretty darn close! It is difficult to see inside the nozzle as it has a small ID and has a small orifice on one end, but from what I can see, the surface finish is near perfectly smooth as I cannot detect any imperfections with my eyes

They recommended using SS304 grade for a better internal surface finish. I am not sure about the RMS rating because I never asked. I have a previous sample from them which I am looking at right now and I don't think it is quite a perfect mirror finish, but it is pretty darn close! It is difficult to see inside the nozzle as it has a small ID and has a small orifice on one end, but from what I can see, the surface finish is near perfectly smooth as I cannot detect any imperfections with my eyes  If I look through the Nozzle lengthwise, I can see the light passing through the small 0.4mm orifice reflected inside the nozzle without any significant distortion. When I shine a flashlight into the top opening (where the filament enters) at an angle, I can see the bottom geometry reflected in the curved walls of the internal pathway.

If I look through the Nozzle lengthwise, I can see the light passing through the small 0.4mm orifice reflected inside the nozzle without any significant distortion. When I shine a flashlight into the top opening (where the filament enters) at an angle, I can see the bottom geometry reflected in the curved walls of the internal pathway. In addition to the beautiful surface finish that is possible with Wire Cut EDM machines, the accuracy is also flawless. All of the dimensions on my previous sample from them are perfect as measured by my digital calipers.

I am really excited to see how my hot end performs with this electropolished interior! I'll let you know how the testing goes once I receive the samples

Eric

|

Re: Is there any alternative to Teflon? October 18, 2013 02:13PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Is there any alternative to Teflon? October 18, 2013 03:30PM |

Registered: 10 years ago Posts: 1,381 |

@RP Iron Man

Another note:

I see you have an "internal" 60 degree included angle leading up to the orifice, and a land of 1 mm. Is there a precedent for this angle and land? For contrast, on some 3D metal printers there is an internal radius (due to pressure feed back), and some maths to determine the length of the land. I've not given this much thought of what the common internal profile should be to accommodate most of the plastics being used today for 3D printers.

When you consider the design requirements of a plastic extrusion screw, plastic likes to be sheared.

For injection molding each type of plastics requires a different gate design, size, and land length.

It would be helpful to test different internal profiles to find the one that produces the best consistency, or has this been done already?

A2

Edited 1 time(s). Last edit at 10/20/2013 09:07AM by A2.

Another note:

I see you have an "internal" 60 degree included angle leading up to the orifice, and a land of 1 mm. Is there a precedent for this angle and land? For contrast, on some 3D metal printers there is an internal radius (due to pressure feed back), and some maths to determine the length of the land. I've not given this much thought of what the common internal profile should be to accommodate most of the plastics being used today for 3D printers.

When you consider the design requirements of a plastic extrusion screw, plastic likes to be sheared.

For injection molding each type of plastics requires a different gate design, size, and land length.

It would be helpful to test different internal profiles to find the one that produces the best consistency, or has this been done already?

A2

Edited 1 time(s). Last edit at 10/20/2013 09:07AM by A2.

|

Re: Is there any alternative to Teflon? October 18, 2013 09:52PM |

Registered: 11 years ago Posts: 246 |

@A2

The 60 degree angle leading up to the orifice is to minimize the amount of heat that is radiated to the part (which causes the plastic to curl up). In addition, this 60 degree angle decreases the chance of the nozzle catching on any plastic that has curled up. The J-Head nozzle has a 30 degree angle and it has problems with edges curling, getting stuck to the nozzle, and being dragged around during the print. The 60 degree angle is a design feature aimed at solving that problem.

The 1.2mm land serves to protect the nozzle for damage if it accidentally crashes into the bed, and helps flatten out the extruded filament to prevent curling on the edges of the part. It also increases the mass of the nozzle near the orifice which enables better heat conduction to the tip of the nozzle. This is essential for my Stainless Steel nozzle which has relatively low thermal conductivity when compared to conventional Brass or Aluminium nozzles. The effects of thermal hysteresis become more of a problem when printing at high speeds.

As for the 60 degree internal profile, once again, this is aimed at maximizing thermal conduction to the nozzle tip. Also, I assumed that a steeper internal exit angle would promote more laminar (streamlined) flow of melted plastic exiting the nozzle. However, this was a mere supposition, as I never really gave it much thought. I am glad that you mentioned this as it could be something that has a significant effect on the properties/behavior of extruded filament I am actually not aware of the various design requirements for the internal profiles used in these various plastic extrusion processes. This is something I must look into...

I am actually not aware of the various design requirements for the internal profiles used in these various plastic extrusion processes. This is something I must look into...

Yes, structured testing of various internal profiles would definitely be the way to go! I imagine that the properties of the thermoplastic being extruded would also be a significant factor in determining the optimal internal profile (ie. the optimal internal profile for PLA extrusion may be different than the optimal design for ABS extrusion).

I have never heard any significant discussion on this topic, so I assume that it has not yet been done. I don't have access to a machine shop so this kind of iterative testing is not something that I can easily do but I will put it on my to-do list.

but I will put it on my to-do list.

If anyone in RepRap has experimented with various internal profile designs, please share your knowledge with us!

Eric

The 60 degree angle leading up to the orifice is to minimize the amount of heat that is radiated to the part (which causes the plastic to curl up). In addition, this 60 degree angle decreases the chance of the nozzle catching on any plastic that has curled up. The J-Head nozzle has a 30 degree angle and it has problems with edges curling, getting stuck to the nozzle, and being dragged around during the print. The 60 degree angle is a design feature aimed at solving that problem.

The 1.2mm land serves to protect the nozzle for damage if it accidentally crashes into the bed, and helps flatten out the extruded filament to prevent curling on the edges of the part. It also increases the mass of the nozzle near the orifice which enables better heat conduction to the tip of the nozzle. This is essential for my Stainless Steel nozzle which has relatively low thermal conductivity when compared to conventional Brass or Aluminium nozzles. The effects of thermal hysteresis become more of a problem when printing at high speeds.

As for the 60 degree internal profile, once again, this is aimed at maximizing thermal conduction to the nozzle tip. Also, I assumed that a steeper internal exit angle would promote more laminar (streamlined) flow of melted plastic exiting the nozzle. However, this was a mere supposition, as I never really gave it much thought. I am glad that you mentioned this as it could be something that has a significant effect on the properties/behavior of extruded filament

I am actually not aware of the various design requirements for the internal profiles used in these various plastic extrusion processes. This is something I must look into...

I am actually not aware of the various design requirements for the internal profiles used in these various plastic extrusion processes. This is something I must look into... Yes, structured testing of various internal profiles would definitely be the way to go! I imagine that the properties of the thermoplastic being extruded would also be a significant factor in determining the optimal internal profile (ie. the optimal internal profile for PLA extrusion may be different than the optimal design for ABS extrusion).

I have never heard any significant discussion on this topic, so I assume that it has not yet been done. I don't have access to a machine shop so this kind of iterative testing is not something that I can easily do

but I will put it on my to-do list.

but I will put it on my to-do list.If anyone in RepRap has experimented with various internal profile designs, please share your knowledge with us!

Eric

|

Re: Is there any alternative to Teflon? October 19, 2013 11:27AM |

Registered: 11 years ago Posts: 374 |

Quote

Also, I assumed that a steeper internal exit angle would promote more laminar (streamlined) flow of melted plastic exiting the nozzle

The Reynolds number of the melted plastic flow is extremely low, so flow will be laminar regardless of your internal geometry. A steep internal chamfer may still be beneficial in reducing the force required to pump the molten plastic through the orifice.

Quote

The 1.2mm land serves to protect the nozzle for damage if it accidentally crashes into the bed, and helps flatten out the extruded filament to prevent curling on the edges of the part.

In my experience with jheads it's the land that catches on the already-printed filament, not the shallow cone.

Edited 1 time(s). Last edit at 10/19/2013 11:29AM by crispy1.

|

Re: Is there any alternative to Teflon? October 19, 2013 11:39AM |

Admin Registered: 17 years ago Posts: 7,879 |

You need a land to be able to get a flat surface when the filament width is wider than the nozzle aperture. It only catches if the flow rate is too high or the object curls upwards. To fix the later it needs a fan to cool the object.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Is there any alternative to Teflon? October 19, 2013 12:55PM |

Registered: 11 years ago Posts: 482 |

nophead Wrote:

-------------------------------------------------------

> You need a land to be able to get a flat surface

> when the filament width is wider than the nozzle

> aperture. It only catches if the flow rate is too

> high or the object curls upwards. To fix the later

> it needs a fan to cool the object.

Wait. .. fan cooling reduces warp?

-------------------------------------------------------

> You need a land to be able to get a flat surface

> when the filament width is wider than the nozzle

> aperture. It only catches if the flow rate is too

> high or the object curls upwards. To fix the later

> it needs a fan to cool the object.

Wait. .. fan cooling reduces warp?

|

Re: Is there any alternative to Teflon? October 19, 2013 02:33PM |

Admin Registered: 15 years ago Posts: 1,470 |

Simba Wrote:

-------------------------------------------------------

> Wait. .. fan cooling reduces warp?

No, it reduces curling on overhangs.

-------------------------------------------------------

> Wait. .. fan cooling reduces warp?

No, it reduces curling on overhangs.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Is there any alternative to Teflon? October 19, 2013 02:33PM |

Admin Registered: 17 years ago Posts: 7,879 |

It stops overhangs from curling up by hardening the layer below. That is the only reason I ever have problems with the nozzle catching things. Obviously if the part warps and lifts from the bed it will catch but I count that as scrap anyway.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Is there any alternative to Teflon? October 23, 2013 10:36AM |

Registered: 12 years ago Posts: 1,450 |

I have tried to machine an inverse taper in one of my nozzles as per nopheads recommendation, but so far have been spectacularly unsucessful - now unexpected as this would be 25mm down a blind hole. As I am quite intrigued by the idea that either feeding or retracting filament creates forces to pull the filament away from the wall, I decided to return to investigating the effect of an inverse taper in the graphite loaded PEEK that I have already tried. This also satisfies the OPs brief of - is there any alternative to PTFE.

I tried modeling the thermal behaviour of the system by treating it as a string of resistors, taking conductivities from [www.engineeringtoolbox.com] and the Tecapeek data sheet. Playing around with the lengths of the various zones I was able to get temperatures which look to be where we want to be, both by calculation and by pushing a thermocouple down the hole and measuring it.

So far, I have not drilled the hole in the nozzle as my little CNC machine is sett up with another job, but I can confirm that temperatures look good, ABS and PLA can be fed down and pulled out without sticking, HOT PLA and ABS don't seem too willing to stick to Tecapeek (but sticks like crazy to my polished stainless steel nozzle)

I hope to get back with cries of delight or sorrow by the end of the week.

Mike

I tried modeling the thermal behaviour of the system by treating it as a string of resistors, taking conductivities from [www.engineeringtoolbox.com] and the Tecapeek data sheet. Playing around with the lengths of the various zones I was able to get temperatures which look to be where we want to be, both by calculation and by pushing a thermocouple down the hole and measuring it.

So far, I have not drilled the hole in the nozzle as my little CNC machine is sett up with another job, but I can confirm that temperatures look good, ABS and PLA can be fed down and pulled out without sticking, HOT PLA and ABS don't seem too willing to stick to Tecapeek (but sticks like crazy to my polished stainless steel nozzle)

I hope to get back with cries of delight or sorrow by the end of the week.

Mike

|

Re: Is there any alternative to Teflon? October 23, 2013 10:54AM |

Admin Registered: 11 years ago Posts: 1,063 |

what are you doing the thermal modelling in?

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Is there any alternative to Teflon? October 23, 2013 11:18AM |

Registered: 12 years ago Posts: 1,450 |

Not having a thermal package (or not having learned one, I am sure that there are open source programs available), I modeled it as if it were a string of resistors: knowing the cross sectional area and length of each section and the thermal conductivity - which I treated by analogy to electrical conductivity. While I am not sure if the analogy holds up and there are many unknowns (and probably unknown unknowns), it does seem to be within 10 degrees at each point. With the fairly sharp gradient and pen marks on the thermocouple it is hard to get very accurate, but I know I am in the right general area.

Mike

Mike

|

Re: Is there any alternative to Teflon? October 26, 2013 07:32PM |

Registered: 13 years ago Posts: 1,918 |

leadinglights Wrote:

-------------------------------------------------------

> I hope to get back with cries of delight or sorrow

> by the end of the week.

>

Does it work?

Detlef

-------------------------------------------------------

> I hope to get back with cries of delight or sorrow

> by the end of the week.

>

Does it work?

Detlef

| Excalibur Hotend |

reprapzone.blogspot.de |

|

Re: Is there any alternative to Teflon? October 27, 2013 02:26AM |

Admin Registered: 11 years ago Posts: 1,063 |

leadinglights Wrote:

-------------------------------------------------------

> Not having a thermal package (or not having

> learned one, I am sure that there are open source

> programs available), I modeled it as if it were a

> string of resistors: knowing the cross sectional

> area and length of each section and the thermal

> conductivity - which I treated by analogy to

> electrical conductivity. While I am not sure if

> the analogy holds up and there are many unknowns

> (and probably unknown unknowns), it does seem to

> be within 10 degrees at each point. With the

> fairly sharp gradient and pen marks on the

> thermocouple it is hard to get very accurate, but

> I know I am in the right general area.

>

> Mike

i wouldn't rely on the thermal modelling to much even with the proper software it's only as accurate as the input data you give it, somthing to bear in mind as well that if you go get your hands on some thermal modelling software, a lot of designers who use it pretty much never actually do any modelling on the thermal bahaviour of the filament itself

-------------------------------------------------------

> Not having a thermal package (or not having

> learned one, I am sure that there are open source

> programs available), I modeled it as if it were a

> string of resistors: knowing the cross sectional

> area and length of each section and the thermal

> conductivity - which I treated by analogy to

> electrical conductivity. While I am not sure if

> the analogy holds up and there are many unknowns

> (and probably unknown unknowns), it does seem to

> be within 10 degrees at each point. With the

> fairly sharp gradient and pen marks on the

> thermocouple it is hard to get very accurate, but

> I know I am in the right general area.

>

> Mike

i wouldn't rely on the thermal modelling to much even with the proper software it's only as accurate as the input data you give it, somthing to bear in mind as well that if you go get your hands on some thermal modelling software, a lot of designers who use it pretty much never actually do any modelling on the thermal bahaviour of the filament itself

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Is there any alternative to Teflon? October 27, 2013 12:05PM |

Registered: 12 years ago Posts: 1,450 |

@theodleif

So far only sorrow, but not due to any failure of the theory, but because boring out a 2mm hole 50mm deep to 3mm dia is almost guaranteed to break through the 1mm wall. I used 2 of my 4 available nozzles before the full force of my stupidity struck me - bore the 3mm hole before turning the 4mm outside bit. Also, I want to get the 0.4mm (or 0.25, 0.35, 0.5 hole) precisely in line with the melt chamber as I think the inner edge of the hole will have more effect than the shoulder slope (just a guess) The 3mm drill will give a flat of about 0.8mm from the end of the bit, so I will need to modify a drill bit of say 1.5mm to give a nice taper and then drill from the inside. This last will need me to make up long and very concentric small drill bits silver soldered to silver steel rods.

The bleeding edge is so known because people slam their heads against it repeatedly.

@thejollygrimreaper

I have a well practiced hollow laugh which I reserve for when a newly qualified engineer wants to use modeling software and expects some high degree of accuracy. If they are only one order of magnitude out there may be some hope for them.

Part of the reason for keeping the modeling so simple is that not just the filament, but how it is being used - the feed speed, how much retract and many others are almost in the league of Rumplestiltskin's "unknown unknowns". I think I will keep mainly to the philosophy of "suck it and see"

Mike

So far only sorrow, but not due to any failure of the theory, but because boring out a 2mm hole 50mm deep to 3mm dia is almost guaranteed to break through the 1mm wall. I used 2 of my 4 available nozzles before the full force of my stupidity struck me - bore the 3mm hole before turning the 4mm outside bit. Also, I want to get the 0.4mm (or 0.25, 0.35, 0.5 hole) precisely in line with the melt chamber as I think the inner edge of the hole will have more effect than the shoulder slope (just a guess) The 3mm drill will give a flat of about 0.8mm from the end of the bit, so I will need to modify a drill bit of say 1.5mm to give a nice taper and then drill from the inside. This last will need me to make up long and very concentric small drill bits silver soldered to silver steel rods.

The bleeding edge is so known because people slam their heads against it repeatedly.

@thejollygrimreaper

I have a well practiced hollow laugh which I reserve for when a newly qualified engineer wants to use modeling software and expects some high degree of accuracy. If they are only one order of magnitude out there may be some hope for them.

Part of the reason for keeping the modeling so simple is that not just the filament, but how it is being used - the feed speed, how much retract and many others are almost in the league of Rumplestiltskin's "unknown unknowns". I think I will keep mainly to the philosophy of "suck it and see"

Mike

|

Re: Is there any alternative to Teflon? October 31, 2013 11:40PM |

Registered: 11 years ago Posts: 88 |

|

Re: Is there any alternative to Teflon? November 01, 2013 05:43AM |

Registered: 12 years ago Posts: 115 |

I have been always amazed at the number of all metal hot ends that are based on stainless steel. I don't know why there is such a fixation on stainless steel, other than it conducts heat kind of poorly and won't rust when left on a shelf in high humidity environments. Of course, it does sound cooler to say "stainless steel". In industrial plastic equipment, there are no stainless steel components used at all unless you count the wires to the high temp heater bands and cartridge heaters. A huge drawback of stainless steel, other than it's cost, is that it is harder to machine and much harder to polish and get super smooth finishes to it. It is also harder to get any coatings to stick and bond to it, but hot plastic will.

Instead of stainless steel, high temp tool steels are used in industrial plastic machinery, especially in the "hot end" of the machines. Typically, the "hot end" of these machines are far more complex and can heat up to far hotter temps for very wide ranges of plastics than 3d printers and absolutely no plastic components are used in industrial plastic machines.

That said, industrial machines do require water cooling only at the feed throat of the machine, to prevent bridging of the material pellets are it is dropped into the machine. Industrial extruders do have blowers mounted on the length of their barrels, generally to keep the barrel temps controllable, but only marginally so. Pinch wheel filament extruders, like we use in 3d printers mainly need to keep the filament below the glass trans temp at the pinch wheel, and keep force exerted to feed the molten/melting plastic below the force that the pinch wheel can deliver. This balancing trick is why we spend so much time toying with Teflon and trying to keep the filament from softening and binding to the sidewalls of the feed tube or the joints internal to the hot ends.

With industrial equipment hot ends, they are almost always made out of H-13 tool steel (or sometimes P-20). It is a great general purpose hot working tool steel that is also heat treatable. It has excellent machining characteristics and can be polished way beyond a typical mirror finish. here is a link to typical injection molding nozzles: [www.ppe.com] . Note, internal parts of nozzles are polished, not simply drilled. Drilling only leaves rifling that scores the hot end's internal surface. Rifle scoring will trip up the plastic as it heats up. I am unaware of anyone that even reams their hot end's internal bore, let alone polishes it. Reaming will drastically improve the internal surfaces smoothness, but requires more time and processing.

On top of that, H-13 tool steel could be coated with industrial coatings such as those that are typical in drills and metal working materials. Once the internal surfaces are as smooth as you can get them mechanically, they could be coated with a wide range of molecular scale industrial coatings used on metal cutting tools. Those coattings are always to improve lubricity and wear resistance which is why we currently use teflon.

On the flip side, increasing the amount of force on the filament being put into the hot end would also help. In agricultural equipment, large tractors have moved away from single wheel drive systems in favor of more wheels and finally to caterpillar drives for maximum force without slippage. I have played with a caterpillar drive extruder, mainly so that I could feed low durometer plastics like vinyl that can't be driven with a single pinch wheel.

Does anyone know of any existing hot ends that use tool steels in the hot end or any caterpillar drives in the cold end?

Instead of stainless steel, high temp tool steels are used in industrial plastic machinery, especially in the "hot end" of the machines. Typically, the "hot end" of these machines are far more complex and can heat up to far hotter temps for very wide ranges of plastics than 3d printers and absolutely no plastic components are used in industrial plastic machines.

That said, industrial machines do require water cooling only at the feed throat of the machine, to prevent bridging of the material pellets are it is dropped into the machine. Industrial extruders do have blowers mounted on the length of their barrels, generally to keep the barrel temps controllable, but only marginally so. Pinch wheel filament extruders, like we use in 3d printers mainly need to keep the filament below the glass trans temp at the pinch wheel, and keep force exerted to feed the molten/melting plastic below the force that the pinch wheel can deliver. This balancing trick is why we spend so much time toying with Teflon and trying to keep the filament from softening and binding to the sidewalls of the feed tube or the joints internal to the hot ends.

With industrial equipment hot ends, they are almost always made out of H-13 tool steel (or sometimes P-20). It is a great general purpose hot working tool steel that is also heat treatable. It has excellent machining characteristics and can be polished way beyond a typical mirror finish. here is a link to typical injection molding nozzles: [www.ppe.com] . Note, internal parts of nozzles are polished, not simply drilled. Drilling only leaves rifling that scores the hot end's internal surface. Rifle scoring will trip up the plastic as it heats up. I am unaware of anyone that even reams their hot end's internal bore, let alone polishes it. Reaming will drastically improve the internal surfaces smoothness, but requires more time and processing.

On top of that, H-13 tool steel could be coated with industrial coatings such as those that are typical in drills and metal working materials. Once the internal surfaces are as smooth as you can get them mechanically, they could be coated with a wide range of molecular scale industrial coatings used on metal cutting tools. Those coattings are always to improve lubricity and wear resistance which is why we currently use teflon.

On the flip side, increasing the amount of force on the filament being put into the hot end would also help. In agricultural equipment, large tractors have moved away from single wheel drive systems in favor of more wheels and finally to caterpillar drives for maximum force without slippage. I have played with a caterpillar drive extruder, mainly so that I could feed low durometer plastics like vinyl that can't be driven with a single pinch wheel.

Does anyone know of any existing hot ends that use tool steels in the hot end or any caterpillar drives in the cold end?

Sorry, only registered users may post in this forum.