Open Build Pursa Concept

Posted by geekbox32

|

Open Build Pursa Concept March 27, 2014 02:21PM |

Registered: 10 years ago Posts: 3 |

I've been thinking about building my own Prusa for sometime now. Lacking the funds i have been thinking about ways to cheapen the system.

So i have come up with some ways to reduce the part count in the X/Z Gantry

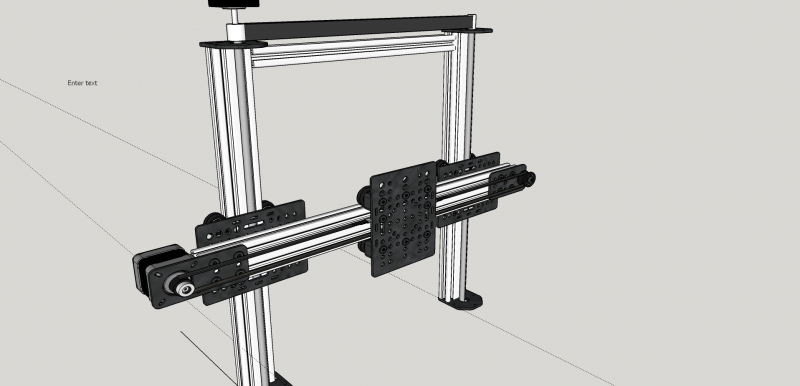

I made a very quick and crude sketchup of my ideas using open build v-slot rails.

First we can eliminate the need to have two Z motors if we link both of the lead screws with a timing belt across the top.

Doing this also reduces the chance of the screws from coming out of sync and creating an unlevel X Axis.

Secondly we can get rid of the need to have a separate frame and smooth rail guide if we use Open Build's V-slot frame.

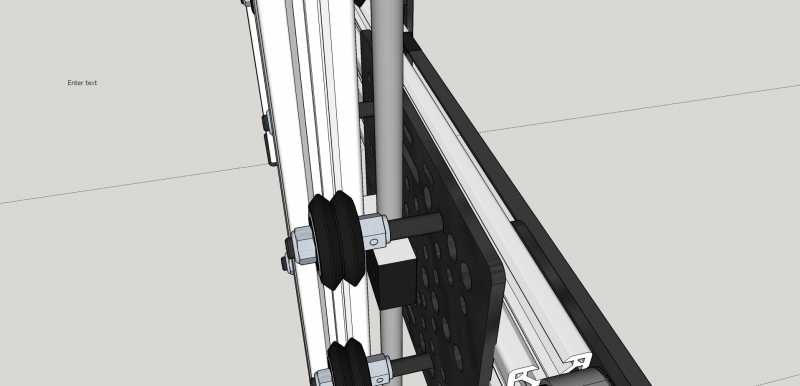

Below is the details of such a setup. The V wheels would needed extended spaces but that should be relative simple to make/buy.

This concept will be a cheaper and much more rigid setup.

Although the concept still needs refining i believe this system won't rely on any printed parts excluding the extruder.

I also think the v-slot frames can also be used to make a simpler y-axis bed.

Let me know what you think!!

geekbox32

So i have come up with some ways to reduce the part count in the X/Z Gantry

I made a very quick and crude sketchup of my ideas using open build v-slot rails.

First we can eliminate the need to have two Z motors if we link both of the lead screws with a timing belt across the top.

Doing this also reduces the chance of the screws from coming out of sync and creating an unlevel X Axis.

Secondly we can get rid of the need to have a separate frame and smooth rail guide if we use Open Build's V-slot frame.

Below is the details of such a setup. The V wheels would needed extended spaces but that should be relative simple to make/buy.

This concept will be a cheaper and much more rigid setup.

Although the concept still needs refining i believe this system won't rely on any printed parts excluding the extruder.

I also think the v-slot frames can also be used to make a simpler y-axis bed.

Let me know what you think!!

geekbox32

|

Re: Open Build Pursa Concept March 28, 2014 03:56AM |

Registered: 10 years ago Posts: 148 |

Looks nice and I use a single motor z drive on my prusa.

Have you checked that its easy to find the type and length of the closed belt ?

I simply used a kossel closed belt for my mod.

How do you attach the motor?

You should also think of something to hide all wires as there is a s*** load of wires

If you have little funds have you checked the smartrap that is a extremely lowcost complete printer and probably good to learn from?

[smartfriendz.com]

Have you checked that its easy to find the type and length of the closed belt ?

I simply used a kossel closed belt for my mod.

How do you attach the motor?

You should also think of something to hide all wires as there is a s*** load of wires

If you have little funds have you checked the smartrap that is a extremely lowcost complete printer and probably good to learn from?

[smartfriendz.com]

|

Re: Open Build Pursa Concept March 28, 2014 05:24AM |

Registered: 13 years ago Posts: 7,616 |

Cheaper with custom aluminium profiles and custom rollers? Never ever. Even the two motor setup was choosen because a stepper is cheaper as a belt.

Please don't confuse kit prices with raw material prices. With a kit you get a lot more than just a frame and also pay quite a margin for the kit producer.

Please don't confuse kit prices with raw material prices. With a kit you get a lot more than just a frame and also pay quite a margin for the kit producer.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Open Build Pursa Concept March 28, 2014 08:21AM |

Registered: 10 years ago Posts: 20 |

|

Re: Open Build Pursa Concept March 28, 2014 09:44AM |

Registered: 10 years ago Posts: 3 |

I guess I'm not really looking at the the cost perspective but more of a simplification reducing part count and relying more on COTS parts.

Most of the simplification will be from not relying on smooth rods which can get pricey ($15 for 300mm) compared to openbuilds vslot rail ($10 for 1000mm) and not requiring a separate frame.

The machine parts used so far are all readily available from the openbuild store for relatively low prices but you are right they can be made cheaper out of plastic if you have access to a printer.

I mainly went with one Z-axis motor not for the cost but to lessen the chance of any timing issues between the two actuators. I would still have to add a belt tensioner and clamp most likely making it more expensive compared to just a extra nema17.

I'm not acutally planning to build my own reprap soon. I apologize if my first post was misleading. I have my wedding coming up in a few months with most of my funds going into that. I'm sure after my wedding cost will not longer be an issue and more importantly i'll have approval from the other half. I just wanted to toss this idea I had in my head out there for now.

Thanks for the feedback and I'll keep posting my ideas as i keep refining them more.

geekbox32

Most of the simplification will be from not relying on smooth rods which can get pricey ($15 for 300mm) compared to openbuilds vslot rail ($10 for 1000mm) and not requiring a separate frame.

The machine parts used so far are all readily available from the openbuild store for relatively low prices but you are right they can be made cheaper out of plastic if you have access to a printer.

I mainly went with one Z-axis motor not for the cost but to lessen the chance of any timing issues between the two actuators. I would still have to add a belt tensioner and clamp most likely making it more expensive compared to just a extra nema17.

I'm not acutally planning to build my own reprap soon. I apologize if my first post was misleading. I have my wedding coming up in a few months with most of my funds going into that. I'm sure after my wedding cost will not longer be an issue and more importantly i'll have approval from the other half. I just wanted to toss this idea I had in my head out there for now.

Thanks for the feedback and I'll keep posting my ideas as i keep refining them more.

geekbox32

|

Re: Open Build Pursa Concept April 01, 2014 02:03AM |

Registered: 10 years ago Posts: 3 |

I am using vslot to build me current printer but it is FAR from cheaper. I thought it was and went with it but the alignment of the wheels doesn't work out well and you need their shim to get it perfect (2.00ea). And the sketchup models of their stuff is deceiving you can't just mount the wheels to the plate and have perfect alignment or the wheels in the slot. I ended up bailing on the wheels all together and using UHMW as my linear guides in the slots. After doing this extruded aluminum would have worked just as we'll and been cheaper. Also the parts tend to be pretty bulky.

Don't get me wrong it's a good product if you throw the money at it. I bought 4 of the shims for the wheels and after aligned the carriage moves like butter.

I will say uhmw in extruded aluminum is awesome little to no play and it's pretty cheap and low profile.

Don't get me wrong it's a good product if you throw the money at it. I bought 4 of the shims for the wheels and after aligned the carriage moves like butter.

I will say uhmw in extruded aluminum is awesome little to no play and it's pretty cheap and low profile.

Sorry, only registered users may post in this forum.