New E3D-V6 hotend - with10% off.....

Posted by Traveltrousers

|

New E3D-V6 hotend - with10% off..... May 25, 2014 01:15PM |

Registered: 10 years ago Posts: 94 |

I pulled the trigger on a new hot end yesterday that might tempt a few of you, I was waiting for their 0.8mm nozzles to come back in for the V5 and then discovered the V6 has been released for the same price as the V5 and it's 10% off this weekend...

Picked up some bridge nylon to try too....

So.... can I just follow the instructions for the V5??

The V6 uses the ATC Semitec 104GT-2 thermistor like the V5 which is good....

The bad is that it looks like the heater block is bigger, 20x16mm....

Anyone else designed a fan so I don't have to??

Picked up some bridge nylon to try too....

So.... can I just follow the instructions for the V5??

The V6 uses the ATC Semitec 104GT-2 thermistor like the V5 which is good....

The bad is that it looks like the heater block is bigger, 20x16mm....

Anyone else designed a fan so I don't have to??

|

Re: New E3D-V6 hotend - with10% off..... May 26, 2014 07:43PM |

Registered: 11 years ago Posts: 195 |

|

Re: New E3D-V6 hotend - with10% off..... May 27, 2014 09:16AM |

Registered: 11 years ago Posts: 71 |

|

Re: New E3D-V6 hotend - with10% off..... May 27, 2014 09:49AM |

Registered: 10 years ago Posts: 439 |

This is my fan for a v5:

[www.thingiverse.com]

I don't have a v6 yet to check it on. It may need modification. The scad files are included.

[www.thingiverse.com]

I don't have a v6 yet to check it on. It may need modification. The scad files are included.

|

Re: New E3D-V6 hotend - with10% off..... May 27, 2014 11:39AM |

Registered: 10 years ago Posts: 94 |

|

Re: New E3D-V6 hotend - with10% off..... May 27, 2014 07:37PM |

Registered: 10 years ago Posts: 439 |

|

Re: New E3D-V6 hotend - with10% off..... May 29, 2014 07:50AM |

Registered: 10 years ago Posts: 94 |

Excellent Ralph, thanks.

My V6 arrived this morning and I'm printing the fan now.... I knew there was something I should have started off last night before I went to bed....

Anyway, it looks good and was pretty easy to put together following Thomas Sanladerers video guide, which was really useful because the E3D documentation on their site is slightly lacking, mentioning photos that don't exsist and not mentioning the thermistor extension cable at all. Not really a major problem for people that put printers together but all those thousands of people scratching their collective heads for 5 minutes add up... I'll drop them a note...

I'll post a pic when I'm done...

Have to run PID auto tune too which should be interesting, never did that before....

My V6 arrived this morning and I'm printing the fan now.... I knew there was something I should have started off last night before I went to bed....

Anyway, it looks good and was pretty easy to put together following Thomas Sanladerers video guide, which was really useful because the E3D documentation on their site is slightly lacking, mentioning photos that don't exsist and not mentioning the thermistor extension cable at all. Not really a major problem for people that put printers together but all those thousands of people scratching their collective heads for 5 minutes add up... I'll drop them a note...

I'll post a pic when I'm done...

Have to run PID auto tune too which should be interesting, never did that before....

|

Re: New E3D-V6 hotend - with10% off..... May 29, 2014 03:58PM |

Registered: 10 years ago Posts: 94 |

Seems like putting the head together was the easiest part.... everything else.... well...

As Mendel90 reported in another thread the metal lip where you lock it down with the three bolts is about a millimeter less than the regular jhead... I tried bending the washers which didn't really work before drilling off a larger hole where the bolts go into the x carriage. Time to reprint that part anyway I think...

The instructions warn you not to use any force on the heat break since it is 'fragile' which makes it tricky to get the mini fan off once it's on, especially when its on the machine! I found I could fit a 1.5mm hex spanner between the fins of the heat sink and lever it off without using much force.

There is also *no* room under the x-carriage! I had to remove the right wing nut and the bolt now come up below into a regular locking nut which plan on making into a plastic finger locking version for easier access. It's also a tight squeeze through the carriage hole... and don't mount the fan too early or you'll only have to take it off...

Ralph's fan mount was good with plenty of room but it touches the frame when you home the x axis, I'm going to reprint it but mirror the stl so it points the other way.

The fan adapter wasn't so good, it doesn't have any support like the regular adapter so it's not very strong. It's also too high so I ended up breaking it when I was making it shorter... The V6 head is also smaller so the belt rubs slightly as it moves across. I made a new version but now the heat block is too close to the fan shroud that it will not last very long, another version is coming off as I speak with slots instead of holes for better positioning...

So, my view of the head? Pretty good, the metal looks so much better than the plastic and the new plastic fan shroud is nicer than the normal ABS one, not that you'll be looking at it much... :p

I picked up a 0.25 and 0.8mm nozzle too so I'm looking forward to having speedier rough prints in a quarter of the time...

It is noisier though, the fan isn't 'loud' but it adds another sound that is always on...

Overall I like it and it's future proofed me for further filament development, however if you're only printing ABS and PLA and are satisfied with 0.4mm then there isn't a pressing need to change up... especially if you haven't got five hours to waste getting it to work

I'll post some pictures later...

As Mendel90 reported in another thread the metal lip where you lock it down with the three bolts is about a millimeter less than the regular jhead... I tried bending the washers which didn't really work before drilling off a larger hole where the bolts go into the x carriage. Time to reprint that part anyway I think...

The instructions warn you not to use any force on the heat break since it is 'fragile' which makes it tricky to get the mini fan off once it's on, especially when its on the machine! I found I could fit a 1.5mm hex spanner between the fins of the heat sink and lever it off without using much force.

There is also *no* room under the x-carriage! I had to remove the right wing nut and the bolt now come up below into a regular locking nut which plan on making into a plastic finger locking version for easier access. It's also a tight squeeze through the carriage hole... and don't mount the fan too early or you'll only have to take it off...

Ralph's fan mount was good with plenty of room but it touches the frame when you home the x axis, I'm going to reprint it but mirror the stl so it points the other way.

The fan adapter wasn't so good, it doesn't have any support like the regular adapter so it's not very strong. It's also too high so I ended up breaking it when I was making it shorter... The V6 head is also smaller so the belt rubs slightly as it moves across. I made a new version but now the heat block is too close to the fan shroud that it will not last very long, another version is coming off as I speak with slots instead of holes for better positioning...

So, my view of the head? Pretty good, the metal looks so much better than the plastic and the new plastic fan shroud is nicer than the normal ABS one, not that you'll be looking at it much... :p

I picked up a 0.25 and 0.8mm nozzle too so I'm looking forward to having speedier rough prints in a quarter of the time...

It is noisier though, the fan isn't 'loud' but it adds another sound that is always on...

Overall I like it and it's future proofed me for further filament development, however if you're only printing ABS and PLA and are satisfied with 0.4mm then there isn't a pressing need to change up... especially if you haven't got five hours to waste getting it to work

I'll post some pictures later...

|

Re: New E3D-V6 hotend - with10% off..... May 30, 2014 04:32AM |

Registered: 10 years ago Posts: 541 |

@Traveltrousers: Would a re-engineered Wades block address most of these issues? I have a feeling it might be a better solution.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

Regards,

Neil Darlow

I try to write with consideration for all nationalities. Please let me know if something is unclear.

Printing with Mendel90 from fedora 25 using Cura, FreeCAD, MeshLab, OpenSCAD, Skeinforge and Slic3r tools.

|

Re: New E3D-V6 hotend - with10% off..... May 30, 2014 05:04AM |

Registered: 10 years ago Posts: 439 |

I was redesigning the setup for my Mendel90 when I saw that the v6 had come out. I made a new wade block with a fitting for the v5 clamped from the side rather than the bottom. Now the fan and adaptor need redesigning so I'll do that when I get the v6 which I should be able to order today with plenty of bowden tube for experiments.

|

Re: New E3D-V6 hotend - with10% off..... May 30, 2014 08:09AM |

Registered: 10 years ago Posts: 94 |

@Neil:

I'm not so sure, the problem of the height difference on the lip is solved easier with a 16mm washer. The fan would still need to be changed since the heater block is so large.

@Ralph:

I uploaded my adapter to thingiverse for your fan. A new fan would probably be quite popular as I predict E3d getting lots of sales, they're already out of stock....

I might have a go at making my own version, someone uploaded a version with a quarter of the fan missing so you can see what you're printing which is pretty useful..

I'm not so sure, the problem of the height difference on the lip is solved easier with a 16mm washer. The fan would still need to be changed since the heater block is so large.

@Ralph:

I uploaded my adapter to thingiverse for your fan. A new fan would probably be quite popular as I predict E3d getting lots of sales, they're already out of stock....

I might have a go at making my own version, someone uploaded a version with a quarter of the fan missing so you can see what you're printing which is pretty useful..

|

Re: New E3D-V6 hotend - with10% off..... May 30, 2014 09:21AM |

Registered: 10 years ago Posts: 439 |

|

Re: New E3D-V6 hotend - with10% off..... May 30, 2014 09:33AM |

Admin Registered: 17 years ago Posts: 7,879 |

Hi Guys, I am interested to hear what benefits you find the E3D has over the J-Head? For me the loss of build height, problems providing cooling to the part and persistent reports of jams with PLA put me off.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: New E3D-V6 hotend - with10% off..... May 30, 2014 11:03AM |

Registered: 10 years ago Posts: 439 |

I've been printing with 3mm PLA and only had jamming problems with bad filament. I had problems with 3 J-heads. If there are problems with the E3D then it is easy to take apart.

I don't personally need the build height but it is fairly easy to solve by mounting the E3D higher. I made a new fan housing so don't have problems with part cooling.

I don't personally need the build height but it is fairly easy to solve by mounting the E3D higher. I made a new fan housing so don't have problems with part cooling.

|

Re: New E3D-V6 hotend - with10% off..... May 30, 2014 02:03PM |

Registered: 10 years ago Posts: 94 |

@nophead

Well according to sanjay at E3D the v6 fixes any jamming problems and it's mainly a 1.75mm + bowden issue anyway, hardly something that affects the M90... I lost about 11m of build height over the jhead and since I'm unlikely to print anything that high it's not a major issue, in any case it might be better and stronger to print parts like that at a 45 degree angle across the bed (assuming they fit). If you offered the v6 as an optional upgrade you might be surprised by how many people would opt for it, however I'll reserve my final judgement for when I've had a good play with it... better support for flexible filaments and swappable nozzle sizes makes it a nice option

Well according to sanjay at E3D the v6 fixes any jamming problems and it's mainly a 1.75mm + bowden issue anyway, hardly something that affects the M90... I lost about 11m of build height over the jhead and since I'm unlikely to print anything that high it's not a major issue, in any case it might be better and stronger to print parts like that at a 45 degree angle across the bed (assuming they fit). If you offered the v6 as an optional upgrade you might be surprised by how many people would opt for it, however I'll reserve my final judgement for when I've had a good play with it... better support for flexible filaments and swappable nozzle sizes makes it a nice option

|

Re: New E3D-V6 hotend - with10% off..... May 30, 2014 03:54PM |

Admin Registered: 17 years ago Posts: 7,879 |

|

Re: New E3D-V6 hotend - with10% off..... May 30, 2014 08:26PM |

Registered: 10 years ago Posts: 94 |

From their site:

"Improving Performance for Flexible Filaments.

Flexible filaments are amazing and open up a huge range of possibilities for new practical applications in 3D printing, and they're also just plain fun. However printing them can be really hard work, especially in 1.75mm where the lower diameter of the filament results in a filament that has mechanical properties similar to that of a wet noodle. To make matters worse many of these filaments also have a certain amount of surface tack, that rubber like grippyness - great for printing things like tyres and grips, terrible when you're trying to make it slide down an extruder neatly.

To solve this issue we have added the (optional) ability to run PTFE tubing all the way from your hobbed bolt/drive gear to deep down into the hotend."

[e3d-online.com]

I'll see when I get around to trying my ninjaflex samples....

"Improving Performance for Flexible Filaments.

Flexible filaments are amazing and open up a huge range of possibilities for new practical applications in 3D printing, and they're also just plain fun. However printing them can be really hard work, especially in 1.75mm where the lower diameter of the filament results in a filament that has mechanical properties similar to that of a wet noodle. To make matters worse many of these filaments also have a certain amount of surface tack, that rubber like grippyness - great for printing things like tyres and grips, terrible when you're trying to make it slide down an extruder neatly.

To solve this issue we have added the (optional) ability to run PTFE tubing all the way from your hobbed bolt/drive gear to deep down into the hotend."

[e3d-online.com]

I'll see when I get around to trying my ninjaflex samples....

|

Re: New E3D-V6 hotend - with10% off..... May 30, 2014 08:33PM |

Admin Registered: 17 years ago Posts: 7,879 |

I meant why is it better than a J-head not the previous E3D. J-head already has a PTFE liner and can print ninjaflex.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: New E3D-V6 hotend - with10% off..... May 30, 2014 08:58PM |

Registered: 10 years ago Posts: 94 |

|

Re: New E3D-V6 hotend - with10% off..... May 31, 2014 08:15AM |

Registered: 11 years ago Posts: 3 |

The e3d is not better than the J-head, I would say they are pretty much equal in performance. The e3d (v6) is a very well designed hotend, maybe more technologically advanced than the J-head, but both work well so there is really no big need to switch if you have an J-head working. At least if you stay inside the temperature range the J-head is comfortable in. The e3d excells where the J-head melts. I won't be changing out the J-head on my Mendel 90 anytime soon, since it just works rock solid. But my next bot will be equipped with a e3d, cause I'd like to print stuff like PC, which needs temperatures only a all metal Hot-end is able to achive (Nylon at 245°C is right at the end of what a J-head can do, too). The possibility to change out nozzle sizes is also a big plus. Simple setup process of the v6 using screws only is nice, too.

I could not find the exact length of a J-head for comparison, but at least the new v6 is a lot shorter than the v5, 62.3mm total.

In my view a part of the e3d hype is that it is perceived as "sexier", it certainly looks nice, that combined with its outstanding performance seems to be it.

I could not find the exact length of a J-head for comparison, but at least the new v6 is a lot shorter than the v5, 62.3mm total.

In my view a part of the e3d hype is that it is perceived as "sexier", it certainly looks nice, that combined with its outstanding performance seems to be it.

|

Re: New E3D-V6 hotend - with10% off..... May 31, 2014 09:01AM |

Admin Registered: 17 years ago Posts: 7,879 |

I wouldn't say 245C was right at the end of what a J-Head can do. I print all the parts of the kit at 250C and on some of my machines I do the first layer at 255C. I wouldn't go higher than that though.

Interesting what E3D say about PC. That was the only plastic I perceived I would need an all metal hot end for but I had read it doesn't print well so never bothered trying it.

[www.hydraraptor.blogspot.com]

Interesting what E3D say about PC. That was the only plastic I perceived I would need an all metal hot end for but I had read it doesn't print well so never bothered trying it.

[www.hydraraptor.blogspot.com]

|

Re: New E3D-V6 hotend - with10% off..... May 31, 2014 09:29AM |

Admin Registered: 17 years ago Posts: 7,879 |

The actually length of a J-head Mk5 is 51.2mm, although the Mendel90 was designed assuming it was 54mm. So 8.3mm would need to go into the Wades.

That is doable I think but not with the three screw mounting I use. I have tried various clamping from the side schemes before but they didn't hold it firm enough, so it waggled. That means going back to two screws all the way through the extruder, which I never liked.

[www.hydraraptor.blogspot.com]

That is doable I think but not with the three screw mounting I use. I have tried various clamping from the side schemes before but they didn't hold it firm enough, so it waggled. That means going back to two screws all the way through the extruder, which I never liked.

[www.hydraraptor.blogspot.com]

|

Re: New E3D-V6 hotend - with10% off..... May 31, 2014 10:06AM |

Registered: 11 years ago Posts: 3 |

Quote

nophead

I wouldn't say 245C was right at the end of what a J-Head can do. I print all the parts of the kit at 250C and on some of my machines I do the first layer at 255C. I wouldn't go higher than that though.

Ah, that's interesting to know. hotends.com states 247°C is the max. one should use.

And yes, mounting the e3d to a Mendel 90 is no fun. Main reason (besides the J-head working fine) I never considered switching.

|

Re: New E3D-V6 hotend - with10% off..... May 31, 2014 12:29PM |

Registered: 10 years ago Posts: 439 |

I have 2 40mm M3 bolts from the side going through the extruder holding in my E3D now and that seems to hold it firmly. It goes 12mm into the block. The 3 mounting screws work abysmally with the E3D as the heatsink is wide so I really couldn't see another way to go for a firm mounting.Quote

nophead

The actually length of a J-head Mk5 is 51.2mm, although the Mendel90 was designed assuming it was 54mm. So 8.3mm would need to go into the Wades.

That is doable I think but not with the three screw mounting I use. I have tried various clamping from the side schemes before but they didn't hold it firm enough, so it waggled. That means going back to two screws all the way through the extruder, which I never liked.

|

Re: New E3D-V6 hotend - with10% off..... May 31, 2014 02:57PM |

Admin Registered: 17 years ago Posts: 7,879 |

How do you get it tight? I have only used the two screw method on soft hot ends, where the screws dig into the plastic. With aluminium it seems like the screws would need to be in just the right place or you would get some vertical movement?

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: New E3D-V6 hotend - with10% off..... May 31, 2014 04:06PM |

Registered: 10 years ago Posts: 439 |

obwadclp.stl

obwadblk.stl

These are the files for the block and clip I am using at the moment.

If I tighten the 40mm bolts (which need washers to pad them out to avoid hitting the gears) then the E3D is held firmly. Vertical movement is constrained by the clamp which has a section that fits in the v5 E3D.

***The files are not final versions and using these versions means that fan parts will not fit unless chopped up and epoxied as mine currently are.***

The v6 appeared just after I finished putting these parts in - I was about to modify the fan parts to fit with my new v5 setup.

Configuring 2 fans on the Xcarriage with the new v6 is brain strain. I'm probably shifting to a bowden setup but trying to do it in a way that makes it not too difficult to change back if it gives inferior prints.

Edited 2 time(s). Last edit at 05/31/2014 04:28PM by Ralph.Hilton.

obwadblk.stl

These are the files for the block and clip I am using at the moment.

If I tighten the 40mm bolts (which need washers to pad them out to avoid hitting the gears) then the E3D is held firmly. Vertical movement is constrained by the clamp which has a section that fits in the v5 E3D.

***The files are not final versions and using these versions means that fan parts will not fit unless chopped up and epoxied as mine currently are.***

The v6 appeared just after I finished putting these parts in - I was about to modify the fan parts to fit with my new v5 setup.

Configuring 2 fans on the Xcarriage with the new v6 is brain strain. I'm probably shifting to a bowden setup but trying to do it in a way that makes it not too difficult to change back if it gives inferior prints.

Edited 2 time(s). Last edit at 05/31/2014 04:28PM by Ralph.Hilton.

|

Re: New E3D-V6 hotend - with10% off..... May 31, 2014 05:28PM |

Admin Registered: 17 years ago Posts: 7,879 |

I tried a clamp very much like that for a J-head but because it was only held vertically by one side of the wades it would deflect in the Y direction. The slightest amount of flex in the plastic gets magnified by the length of the hot end.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: New E3D-V6 hotend - with10% off..... June 01, 2014 07:15AM |

Registered: 10 years ago Posts: 439 |

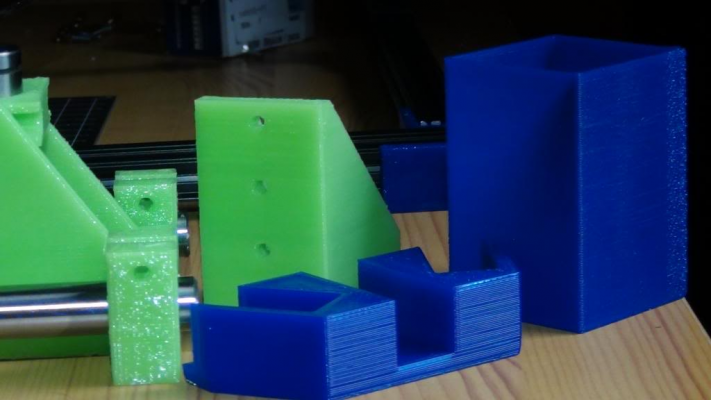

Theses are a few recent prints with the side clamped E3D. Maybe the E3D is worth trying :-) The rightmost print has a banding at the point where Z level is changed. I haven't figured that one out yet.

Edited 1 time(s). Last edit at 06/01/2014 07:16AM by Ralph.Hilton.

|

Re: New E3D-V6 hotend - with10% off..... June 01, 2014 12:05PM |

Registered: 10 years ago Posts: 94 |

After following the instructions, namely mount the head, run PID auto-tune and then mount the fan I can't print at 250 degrees... it seems the mini fan being on permanently keeps lowing the temperature and resetting the M109 command...

should the fan be on all the time? Also, shouldn't I run PID with filament in the nozzle, surely this will effect the result...

I'm running PID again now with the fan and ABS inside, will report back...

should the fan be on all the time? Also, shouldn't I run PID with filament in the nozzle, surely this will effect the result...

I'm running PID again now with the fan and ABS inside, will report back...

|

Re: New E3D-V6 hotend - with10% off..... June 01, 2014 12:08PM |

Registered: 10 years ago Posts: 94 |

Sorry, only registered users may post in this forum.