First layer infill "ripples"

Posted by stuart576

|

First layer infill "ripples" March 15, 2015 11:31AM |

Registered: 9 years ago Posts: 18 |

So when printing large areas of infill, typically with long strokes, with my 0.3mm nozzle I tend to get a rippling effect where the line doesn't adhere to the bed properly. From experimenting I've found that this can be much reduced by dialling down the print speed, however my first layer infill speeds are 12.5mm/s and even at half that speed I still get some rippling. This effect doesn't occur with my 0.5mm nozzle, I guess because there is a larger surface area for adhesion.

Now so far I've stuck with plain old Kapton tape on a heated bed and I get fairly good results most the time, provided my first layer speed is pretty slow, as above. I've seen a few videos around where printers wizz around at high speeds, even for the first layer. What's the trick? What's the best method for bed adhesion out there at the moment? I'm not talking bed levelling as I think I've got that nailed excepting I think the middle of my glass is slightly bowed, can I do 5-point bed compensation manually (i.e. G30 P0 X60 Y20 Z0..P2...P5)?

Any ideas?

Thanks

Now so far I've stuck with plain old Kapton tape on a heated bed and I get fairly good results most the time, provided my first layer speed is pretty slow, as above. I've seen a few videos around where printers wizz around at high speeds, even for the first layer. What's the trick? What's the best method for bed adhesion out there at the moment? I'm not talking bed levelling as I think I've got that nailed excepting I think the middle of my glass is slightly bowed, can I do 5-point bed compensation manually (i.e. G30 P0 X60 Y20 Z0..P2...P5)?

Any ideas?

Thanks

|

Re: First layer infill "ripples" March 15, 2015 01:22PM |

Registered: 9 years ago Posts: 191 |

I have had this issue several times. The solution for me has been hotter and lower. More pressure to the bed and stickier plastic to get better adhesion. I am using BuildTak and cold bed but I think same solution applies. Try by increasing temp by 5 degrees and lower Z by 0.05. If it gets worse go higher.

Maybe a bit more extrusion to first layer may help too but my experience is that it just makes it worse.

/Tomas

Edited 1 time(s). Last edit at 03/15/2015 01:25PM by fotomas.

Maybe a bit more extrusion to first layer may help too but my experience is that it just makes it worse.

/Tomas

Edited 1 time(s). Last edit at 03/15/2015 01:25PM by fotomas.

|

Re: First layer infill "ripples" March 15, 2015 02:01PM |

Registered: 10 years ago Posts: 1,230 |

Quote

stuart576

..Now so far I've stuck with plain old Kapton tape on a heated bed and I get fairly good results most the time, provided my first layer speed is pretty slow, as above. I've seen a few videos around where printers wizz around at high speeds, even for the first layer. What's the trick? What's the best method for bed adhesion out there at the moment?

Printing on Kapton too and seldom have any problems getting prints to stick, the occasionally "bad kapton day" made me try sanding the surface with P400 wet and dry sandpaper and that solved the problem for me (up to now that is), another upside is that its much easier to apply the tape and get a perfect surface, no pinpoint accuracy needed to get the edges to match, I ad the tape with a small overlay and then sand those away, yet another upside is that the tape can be used much longer as you can sand away any protruding bit if the tape get scratched - wipe the tape with acetone after sanding to remove the dust

For me kapton tape is ok and I'll stick to that as long as the filament do :-)

Besides that, cant give better advice than the slic3r manual, higher first layer hight, fatter extrusion width

[manual.slic3r.org]

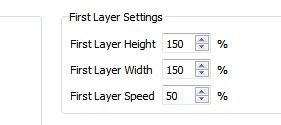

My normal temp. settings for PLA is 57/190 degrees, normal first layer settings as screenshot from simplify3d, I usually print at 40 to 60mm/sec so first layer at 20 to 30mm/sec

Quote

I'm not talking bed levelling as I think I've got that nailed excepting I think the middle of my glass is slightly bowed, can I do 5-point bed compensation manually (i.e. G30 P0 X60 Y20 Z0..P2...P5)?

Yes, You can write in your numbers, e.g. like this, save it as setbed.g in your sd-cards gcodes folder and "print" it before the real print

G30 P0 X0 Y0 Z0.0

G30 P1 X0 Y200 Z0.0

G30 P2 X200 Y200 Z0.0

G30 P3 X200 Y0 Z0.0

G30 P4 X100 Y100 Z0.08 S

Erik

|

Re: First layer infill "ripples" March 15, 2015 02:57PM |

Registered: 9 years ago Posts: 18 |

|

Re: First layer infill "ripples" March 15, 2015 03:34PM |

Registered: 10 years ago Posts: 1,230 |

Quote

stuart576

I'll give the sanding a go. I take it that the rougher surface increases adhesion?

It gives the filament more to cling to and the unevenness from sanding expands the area of the surface - pull test of layers of paint on sanded vs non-sanded shows a difference (so I'm told)

Quote

I found out about the extra P4 just a few minutes ago, out of curiousity can I add as many points as I want?

Only five points compensation possible for now afaik

Erik

|

Re: First layer infill "ripples" March 15, 2015 04:26PM |

Registered: 9 years ago Posts: 102 |

I also had the problem for large prints. covering nearly the complete printbed. As my bed is a little warped i also have this ripple effect where the bed is to far away from the bed. It starts with a small disturbance

which gets bigger and bigger if the bed is not getting closer to the head (due to the "warped" printbed). Sometimes it help turning the printed object as its really very little disturbances which get bigger which each go. So little changes might make a big change. I haven't had seen any differences of this problem with temperature.

dc42 has 9 point bed leveling on his TODO list, so one can hope as i think this will remedy this problem. I you have not fotomas y-axis compensation you might give these a try.

Tim

which gets bigger and bigger if the bed is not getting closer to the head (due to the "warped" printbed). Sometimes it help turning the printed object as its really very little disturbances which get bigger which each go. So little changes might make a big change. I haven't had seen any differences of this problem with temperature.

dc42 has 9 point bed leveling on his TODO list, so one can hope as i think this will remedy this problem. I you have not fotomas y-axis compensation you might give these a try.

Tim

|

Re: First layer infill "ripples" March 19, 2015 02:40PM |

Registered: 9 years ago Posts: 18 |

Sorry, only registered users may post in this forum.