Request for Simplify3D gcode test

Posted by Firefox3D

|

Re: Request for Simplify3D gcode test July 16, 2015 04:07PM |

Registered: 9 years ago Posts: 638 |

|

Re: Request for Simplify3D gcode test July 16, 2015 04:08PM |

Registered: 9 years ago Posts: 1,699 |

My code:

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

G91 G1 Z5 ;End (for object height detection) G90 G1 X0 Y200 F6000 ;M107 ;M0 M104 S0 ; turn off extruder M140 S0 ; turn off bed ;M84 ; disable motors

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 16, 2015 04:24PM |

Registered: 9 years ago Posts: 638 |

|

Re: Request for Simplify3D gcode test July 16, 2015 04:31PM |

Registered: 9 years ago Posts: 1,699 |

Congratulations.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 16, 2015 06:52PM |

Registered: 8 years ago Posts: 443 |

The settings that are giving the most grief are the speeds, it appears the S3D pritnts a LOT slower than Slic3r, but the speeds I see in the program don't make a great deal of sense when I compare them to the settings and the settings in Slic3r... of course this could just be pointing out that my actual problem with slic3r was it was printing too fast

|

Re: Request for Simplify3D gcode test July 16, 2015 07:35PM |

Registered: 9 years ago Posts: 1,699 |

The speed settings are much easier compared to other programs - in my eyes and you can easily speed up things. For beginners it is much easier to print slower as you will get stick problems and more if you print too fast.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 17, 2015 07:55AM |

Registered: 10 years ago Posts: 2,472 |

Quote

bgkdavis

The settings that are giving the most grief are the speeds, it appears the S3D pritnts a LOT slower than Slic3r, but the speeds I see in the program don't make a great deal of sense when I compare them to the settings and the settings in Slic3r... of course this could just be pointing out that my actual problem with slic3r was it was printing too fast

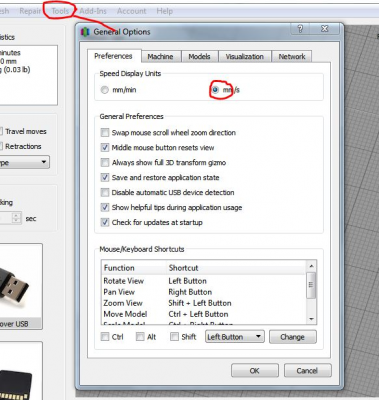

S3D speed settings are in mm per minute rather than mm per second, so you need to multiply your Slic3r settings by 60.

Dave

|

Re: Request for Simplify3D gcode test July 17, 2015 08:07AM |

Registered: 10 years ago Posts: 1,230 |

Quote

dmould

Quote

bgkdavis

The settings that are giving the most grief are the speeds, it appears the S3D pritnts a LOT slower than Slic3r, but the speeds I see in the program don't make a great deal of sense when I compare them to the settings and the settings in Slic3r... of course this could just be pointing out that my actual problem with slic3r was it was printing too fast

S3D speed settings are in mm per minute rather than mm per second, so you need to multiply your Slic3r settings by 60.

Dave

or change it here:

Erik

|

Re: Request for Simplify3D gcode test July 17, 2015 08:19AM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Request for Simplify3D gcode test July 17, 2015 09:13AM |

Registered: 9 years ago Posts: 1,699 |

Quote

ormerod168

Quote

Firefox3D

G1 X0 Y200 F6000

I like to park the machine at G1 X205 Y205 after the print, to clean the nozzle (you retract 10mm and suppose its clean but its not, its snot) before it cools down and clear the bed area for cleaning before the next print

Erik

I think everyone has its own settings which he/ she prefers. For example I do not like direct homing as I still use the stock proximity sensor and it may happen that the height differs after a print after homing again.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 17, 2015 09:17AM |

Registered: 8 years ago Posts: 443 |

|

Re: Request for Simplify3D gcode test July 17, 2015 09:44AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Treito

Quote

ormerod168

Quote

Firefox3D

...being extremely picky - tiny bit of stringing between the really small V cuts at the top, but that's ok as it's a very quick needle file removal...

..reducing the minimal travel distance before retraction might make a difference

[attachment 58181 SF3D_retraction.JPG]

Erik

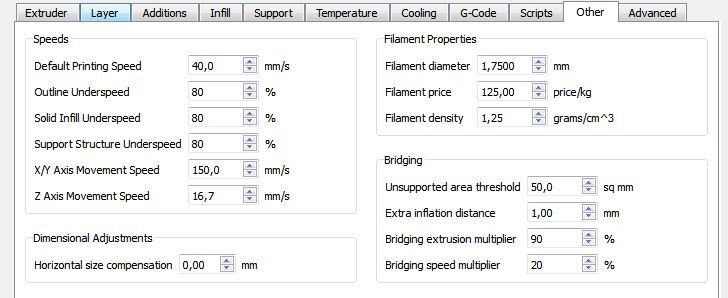

Thanks for this advice. I just changed this in my settings. What about your speed settings? (Others tab)

yes forgot to note that moment speed (and retraction speed, 45 to 60mm/sec) is also a way to reduce stringing

and bridging, new in latest version, "extra inflation distance", adjust for larger overlap of layers below if bridging fails

oh how I waited for that one, don't you just hate it when the nozzle seems to play tag and miss the post and return with a loop dragging?, what's the point in that? - "come to papa my little spider, do you thing, yesss there a good boy!....just a liiittle bit closer....oh no you don't!, come back here!, you missed it you bastard you! :-)

..ahem, back to boring seriousness..

but please notice my setting is never static, I do save factory files (oh how I love that feature, factory files save everything support, scaling included, so you can make fine adjustment and re-slice the model later) for most models sliced when I think I got the settings just right, but generally, I like to go through every setting before slicing to keep me sharp

Erik

|

Re: Request for Simplify3D gcode test July 17, 2015 09:52AM |

Registered: 9 years ago Posts: 1,699 |

To be honest I was only interested in the underspeed settings. For me these are the hardest parameters to configure. That is why I wanted to compare them.

And yes the factory files are not bad. I got them from ZPL so the beginning was easier for me. And now there is no limit on installations (only usage at the same time). and that is great as I have a dektop PC with Linux and Windows as also a notebook with nearly the same configuration. So in theory I would need have needed 4 licenses but I did not use the notebook for slicing yet.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

And yes the factory files are not bad. I got them from ZPL so the beginning was easier for me. And now there is no limit on installations (only usage at the same time). and that is great as I have a dektop PC with Linux and Windows as also a notebook with nearly the same configuration. So in theory I would need have needed 4 licenses but I did not use the notebook for slicing yet.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 17, 2015 02:49PM |

Registered: 9 years ago Posts: 638 |

how do you force a T0 command before the temperature is set? in slic3r i could just put T0 attop to custom start code and it would put it at the start of the file ,but Simplify puts it like

G90

M83

M106 S0

M140 S65

M190 S65

M104 S190 T0

M109 S190 T0

T0

slic3r:

M107

M190 S60 ; set bed temperature

M104 S190 ; set temperature

T0

G28 Z0 f3000

M83

M109 S190 ; wait for temperature to be reached

How do i make S3D to put T0 before M109 command??

G90

M83

M106 S0

M140 S65

M190 S65

M104 S190 T0

M109 S190 T0

T0

slic3r:

M107

M190 S60 ; set bed temperature

M104 S190 ; set temperature

T0

G28 Z0 f3000

M83

M109 S190 ; wait for temperature to be reached

How do i make S3D to put T0 before M109 command??

|

Re: Request for Simplify3D gcode test July 17, 2015 05:55PM |

Registered: 9 years ago Posts: 1,699 |

You can add the T0 in your start code, but depending on your firmware you may need other firmware settings.

If this does not work for you, you may try the attached file. You can import and use this in your firmware settings.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

If this does not work for you, you may try the attached file. You can import and use this in your firmware settings.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 18, 2015 02:50AM |

Registered: 9 years ago Posts: 1,159 |

Quote

Darathy

how do you force a T0 command before the temperature is set? in slic3r i could just put T0 attop to custom start code and it would put it at the start of the file ,but Simplify puts it like

G90

M83

M106 S0

M140 S65

M190 S65

M104 S190 T0

M109 S190 T0

T0

slic3r:

M107

M190 S60 ; set bed temperature

M104 S190 ; set temperature

T0

G28 Z0 f3000

M83

M109 S190 ; wait for temperature to be reached

How do i make S3D to put T0 before M109 command??

Looks to me like it has implied T0 on the M104/M109 lines in Simplify3D which I guess is absolutely fine you could also put the T0 in your Config.g file.

I to have taken the plunge and purchased S3D And boy is it a lot quicker than Slic3r will generate some test prints with it later and see how much difference it makes to the Quality of the Prints.

Doug

|

Re: Request for Simplify3D gcode test July 18, 2015 03:00AM |

Registered: 9 years ago Posts: 1,699 |

Hello Doug,

quicker? do you think so? Quicker as Slic3r 1.1.x but compared to Slic3r 1.2.x Slic3r wins as ot slices in the background. But if your settings do not fit you may have bad quality compared to Slic3r, normally the quality is better even if you print faster.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

quicker? do you think so? Quicker as Slic3r 1.1.x but compared to Slic3r 1.2.x Slic3r wins as ot slices in the background. But if your settings do not fit you may have bad quality compared to Slic3r, normally the quality is better even if you print faster.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Request for Simplify3D gcode test July 18, 2015 03:06AM |

Registered: 8 years ago Posts: 443 |

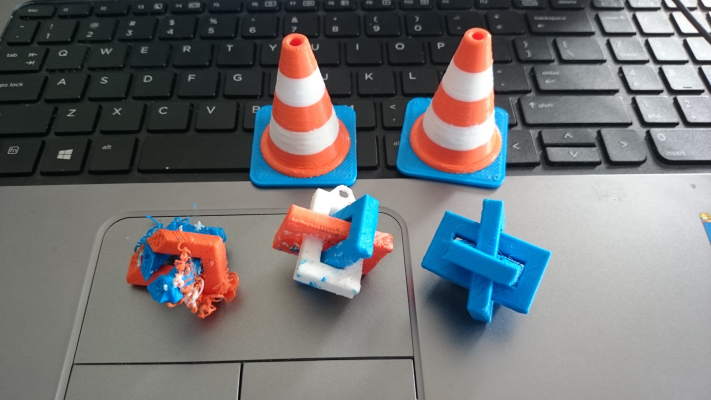

I spent some more time with S3Ds settings for my MEndel 3 tri colour and have some success'

When using Slic3er I was having some serious ooze problems, that was leading me to doubt the wisdom of a tri extruder printer

the problem I was getting can be seen on the failed print on the left, a lot of ooze artifacts which can still be seen after fettling.

The cones at the back you can see look great but the key difference is these don't change colour every level. where the cube changes 3x per level.

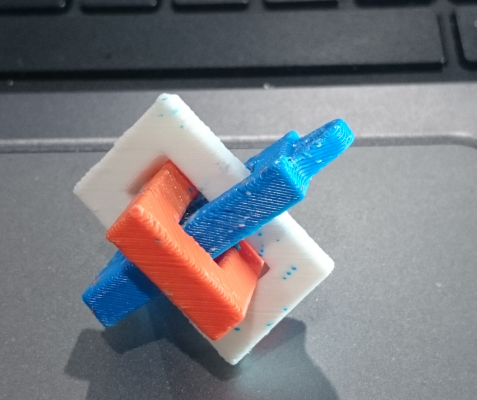

On a recommendation I tried Simplify3D and this is what the print looks like with the ooze shield function active

you can see here that S3D has added a shell and it has all the ooze artifacts attached..... but when you peel off the shell, you get.....

A massive improvement,in conclusion, whilst Slic3r may be suitable for 99% of single extruder prints, S3D is definitely to be recommended for 99% of multi extruder prints.

When using Slic3er I was having some serious ooze problems, that was leading me to doubt the wisdom of a tri extruder printer

the problem I was getting can be seen on the failed print on the left, a lot of ooze artifacts which can still be seen after fettling.

The cones at the back you can see look great but the key difference is these don't change colour every level. where the cube changes 3x per level.

On a recommendation I tried Simplify3D and this is what the print looks like with the ooze shield function active

you can see here that S3D has added a shell and it has all the ooze artifacts attached..... but when you peel off the shell, you get.....

A massive improvement,in conclusion, whilst Slic3r may be suitable for 99% of single extruder prints, S3D is definitely to be recommended for 99% of multi extruder prints.

|

Re: Request for Simplify3D gcode test July 18, 2015 03:15AM |

Registered: 10 years ago Posts: 14,672 |

Quote

bgkdavis

I spent some more time with S3Ds settings for my MEndel 3 tri colour and have some success'

When using Slic3er I was having some serious ooze problems, that was leading me to doubt the wisdom of a tri extruder printer

What retraction do you have set in slic3r (or in your tool change files) on a tool change, and what standby temperature are you using? I have a dual extrusion Ormerod, and I have never had ooze problems on 2-colour prints.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Request for Simplify3D gcode test July 18, 2015 03:24AM |

Registered: 8 years ago Posts: 443 |

I tried reducing the Standby temperature to 150C and had a print temp of 195, but was finding that the heat up/cool down times were huge, this print took 45min with a standby and extruder temp of 195C, setting a low standly temp can triple this time!

Retraction in Z didn't help at all, you still got ooze that would deposit once the printer returned to level, and even with a 15mm retraction on E I was still getting ooze.

I maybe should have tried the 0.3mm nozzles I've got instead of the standard 0.5mm, but on building the printer I came to the conclusion that I probably should make of bought a set of hot end kits instead of just the nozzles, so plan on leaving this test until later when I maybe order some more stuff from RRP

With your dual Ormerod do you have just the one hot end assembly or two? Ive got two complete hot end heads, one with one Bowden and the other with two.

Edited 1 time(s). Last edit at 07/18/2015 03:26AM by bgkdavis.

Retraction in Z didn't help at all, you still got ooze that would deposit once the printer returned to level, and even with a 15mm retraction on E I was still getting ooze.

I maybe should have tried the 0.3mm nozzles I've got instead of the standard 0.5mm, but on building the printer I came to the conclusion that I probably should make of bought a set of hot end kits instead of just the nozzles, so plan on leaving this test until later when I maybe order some more stuff from RRP

With your dual Ormerod do you have just the one hot end assembly or two? Ive got two complete hot end heads, one with one Bowden and the other with two.

Edited 1 time(s). Last edit at 07/18/2015 03:26AM by bgkdavis.

|

Re: Request for Simplify3D gcode test July 18, 2015 04:46AM |

Registered: 10 years ago Posts: 14,672 |

I converted my Ormerod to dual nozzle before RRP brought the kit out. I described it here [miscsolutions.wordpress.com]. I use 150C standby temperature and the default (10mm) tool change retraction in slic3r. To speed up tool changes, in the tool change files I wait for the new tool to heat up, but not for the old one to cool down (that's why I added the P parameter to the M116 command in my fork). I use 0.5mm nozzles.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Request for Simplify3D gcode test July 18, 2015 06:57AM |

Registered: 9 years ago Posts: 638 |

Quote

dougal1957

Looks to me like it has implied T0 on the M104/M109 lines in Simplify3D which I guess is absolutely fine you could also put the T0 in your Config.g file.

I to have taken the plunge and purchased S3D And boy is it a lot quicker than Slic3r will generate some test prints with it later and see how much difference it makes to the Quality of the Prints.

Doug

No The printer starts as if its in simulation mode with T0 in M104/109 command , it has to come before these 2 commands and my G28 before M109 so i can check if nozzle is zeroed correctly. In cura i could just put M104{} in costume gcode and it would fill the set temperature at {} but in S3D it does not ,i was wondering if i can somehow do something simular in S3D.

|

Re: Request for Simplify3D gcode test July 18, 2015 07:49AM |

Registered: 10 years ago Posts: 14,672 |

It occurs to me that when the firmware sees M109 T0, it probably makes sense for the firmware to execute T0 implicitly. You wouldn't ask to "set temperature of tool 0 and wait till it is reached" unless you intended the tool to be selected.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Request for Simplify3D gcode test July 18, 2015 12:43PM |

Registered: 9 years ago Posts: 638 |

Quote

dc42

It occurs to me that when the firmware sees M109 T0, it probably makes sense for the firmware to execute T0 implicitly. You wouldn't ask to "set temperature of tool 0 and wait till it is reached" unless you intended the tool to be selected.

If i understand you correctly. you mean firmware should see M109 T0 and turn on the hot end. But it does not see it and starts printing withought actualy extruding). It has to be seporate from the M109 command and has to come 1st in Gcode line.

|

Re: Request for Simplify3D gcode test July 19, 2015 08:49AM |

Registered: 9 years ago Posts: 1,159 |

Quote

Darathy

Quote

dc42

It occurs to me that when the firmware sees M109 T0, it probably makes sense for the firmware to execute T0 implicitly. You wouldn't ask to "set temperature of tool 0 and wait till it is reached" unless you intended the tool to be selected.

If i understand you correctly. you mean firmware should see M109 T0 and turn on the hot end. But it does not see it and starts printing withought actualy extruding). It has to be seporate from the M109 command and has to come 1st in Gcode line.

I can now confirm this action I have got arround it by putting a T0 command at the end of the Config.g File this however won't let you put the G28 in the Start code either

|

Re: Request for Simplify3D gcode test July 19, 2015 09:07AM |

Registered: 9 years ago Posts: 638 |

Quote

dougal1957

Quote

Darathy

Quote

dc42

It occurs to me that when the firmware sees M109 T0, it probably makes sense for the firmware to execute T0 implicitly. You wouldn't ask to "set temperature of tool 0 and wait till it is reached" unless you intended the tool to be selected.

If i understand you correctly. you mean firmware should see M109 T0 and turn on the hot end. But it does not see it and starts printing withought actualy extruding). It has to be seporate from the M109 command and has to come 1st in Gcode line.

I can now confirm this action I have got arround it by putting a T0 command at the end of the Config.g File this however won't let you put the G28 in the Start code either

Guess i'll have to home Z before i start a Print then. Thanks

|

Re: Request for Simplify3D gcode test July 19, 2015 09:14AM |

Registered: 10 years ago Posts: 14,672 |

Quote

dougal1957

Quote

Darathy

Quote

dc42

It occurs to me that when the firmware sees M109 T0, it probably makes sense for the firmware to execute T0 implicitly. You wouldn't ask to "set temperature of tool 0 and wait till it is reached" unless you intended the tool to be selected.

If i understand you correctly. you mean firmware should see M109 T0 and turn on the hot end. But it does not see it and starts printing withought actualy extruding). It has to be seporate from the M109 command and has to come 1st in Gcode line.

I can now confirm this action I have got arround it by putting a T0 command at the end of the Config.g File this however won't let you put the G28 in the Start code either

Why can't you put a G28 in the start gcode? Not that I want to, I'm just curious.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Request for Simplify3D gcode test July 19, 2015 09:28AM |

Registered: 9 years ago Posts: 1,159 |

Quote

dc42

Quote

dougal1957

Quote

Darathy

Quote

dc42

It occurs to me that when the firmware sees M109 T0, it probably makes sense for the firmware to execute T0 implicitly. You wouldn't ask to "set temperature of tool 0 and wait till it is reached" unless you intended the tool to be selected.

If i understand you correctly. you mean firmware should see M109 T0 and turn on the hot end. But it does not see it and starts printing withought actualy extruding). It has to be seporate from the M109 command and has to come 1st in Gcode line.

I can now confirm this action I have got arround it by putting a T0 command at the end of the Config.g File this however won't let you put the G28 in the Start code either

Why can't you put a G28 in the start gcode? Not that I want to, I'm just curious.

You can but S3D puts it after the extruder heater steps then the Start Gcode then the rest of it.

Another thing I have just found with it is that it seems to deselect the tool after the print so next one your back to square one with it. Not a big issue I have just generated a macro to home ans select T0.

One big thing tho Dave is that it has totally cured my Blobing with the E3D just need to tweek the retraction/temps to stop some very fine stringing.

another problem has just reared it's ugly head tho and not sure what is causing it?

When i heat the hotend to 230+ the temp's error out until I reset the DUET if I keep it to 225 or less then it is fine just wondering if I have an Iffy Thermistor?

Any suggestion's re this would be gratefully received

Doug

|

Re: Request for Simplify3D gcode test July 19, 2015 09:33AM |

Registered: 10 years ago Posts: 14,672 |

Quote

dougal1957

another problem has just reared it's ugly head tho and not sure what is causing it?

When i heat the hotend to 230+ the temp's error out until I reset the DUET if I keep it to 225 or less then it is fine just wondering if I have an Iffy Thermistor?

Any suggestion's re this would be gratefully received

Probably the time-to-hot timer is timing out. See [reprap.org]. I think the default is 120 seconds.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Request for Simplify3D gcode test July 19, 2015 09:34AM |

Registered: 9 years ago Posts: 638 |

Sorry, only registered users may post in this forum.