Smartrap evolution, improvements...

Posted by smartfriendz

|

Smartrap evolution, improvements... April 30, 2014 10:56AM |

Registered: 10 years ago Posts: 992 |

Hi everyone.

This topic would be the place to post evolutions of the model, hacks and adaptation to other systems ( like the j-head version of no servo system ? ) . I will use it to show how we update and improve ( i hope?) the model for smartfriendz kits.

Other topics are in the same folder for builds , problems or any questions about this project

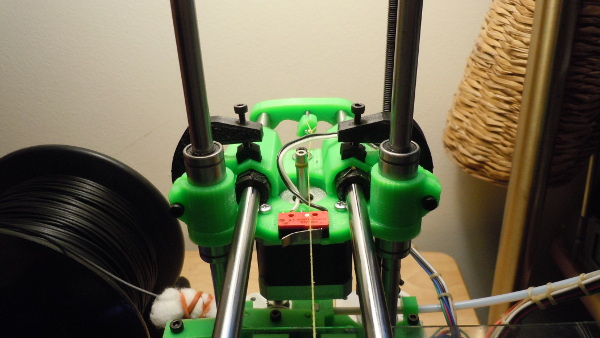

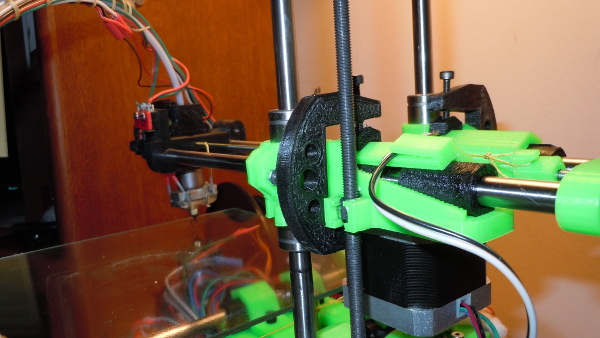

As i'm in this first post, i just add two pictures ( a little messy , sorry ) i've added in the french forum about integration of rack and pinion for X and Y axis.

Also, a new Zcoupler , made for motors with a flat part on he shaft. This one has no screw and is the first part of a no-wobble system ..to come soon i hope

The R&P system is not really better than fishing line or belt, but I find very good for the Smartrap public, which is mostly first time builders. It seems to be more easy to setup than fishing line . It is also more visually appealing ( my opinion only .

.

Thank you

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

This topic would be the place to post evolutions of the model, hacks and adaptation to other systems ( like the j-head version of no servo system ? ) . I will use it to show how we update and improve ( i hope?) the model for smartfriendz kits.

Other topics are in the same folder for builds , problems or any questions about this project

As i'm in this first post, i just add two pictures ( a little messy , sorry ) i've added in the french forum about integration of rack and pinion for X and Y axis.

Also, a new Zcoupler , made for motors with a flat part on he shaft. This one has no screw and is the first part of a no-wobble system ..to come soon i hope

The R&P system is not really better than fishing line or belt, but I find very good for the Smartrap public, which is mostly first time builders. It seems to be more easy to setup than fishing line . It is also more visually appealing ( my opinion only

.

.Thank you

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Smartrap evolution, improvements... April 30, 2014 04:18PM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap evolution, improvements... April 30, 2014 04:46PM |

Registered: 10 years ago Posts: 116 |

Cool Serge

Good idea with this topic.

As the new axis drive, interesting design. For me it looks bit heavy, but if I will be albe to, then I will probably try this There can't be simper solution

There can't be simper solution

Personally, I really want to get the files of Geared extruder made by Regpye. Or if not, then will use some desigh from thingiverse

Good idea with this topic.

As the new axis drive, interesting design. For me it looks bit heavy, but if I will be albe to, then I will probably try this

There can't be simper solution

There can't be simper solution

Personally, I really want to get the files of Geared extruder made by Regpye. Or if not, then will use some desigh from thingiverse

|

Re: Smartrap evolution, improvements... April 30, 2014 05:29PM |

Registered: 10 years ago Posts: 229 |

+1 on the good idea for this thread. Right now, from my perspective, about the only weak link - if there is one - is the X axis and the way the bearings are held in place. The way it is now, with the added pressure while doing the bed probing "No Servo" style, there is a little bit of flex. Enough to throw the bed level of 10 -20 microns.

What I'm currently thinking of doing is making what is now the lm8_holder_x and integrating the bushings into it, making the "holder" and bushings one solid unit. Once I have something printed and working, I'll post it here. Think this will end up being a decent mod.

Mark

What I'm currently thinking of doing is making what is now the lm8_holder_x and integrating the bushings into it, making the "holder" and bushings one solid unit. Once I have something printed and working, I'll post it here. Think this will end up being a decent mod.

Mark

|

Re: Smartrap evolution, improvements... April 30, 2014 06:30PM |

Registered: 10 years ago Posts: 116 |

|

Re: Smartrap evolution, improvements... April 30, 2014 06:31PM |

Registered: 10 years ago Posts: 349 |

Nice LEGO style! :-)

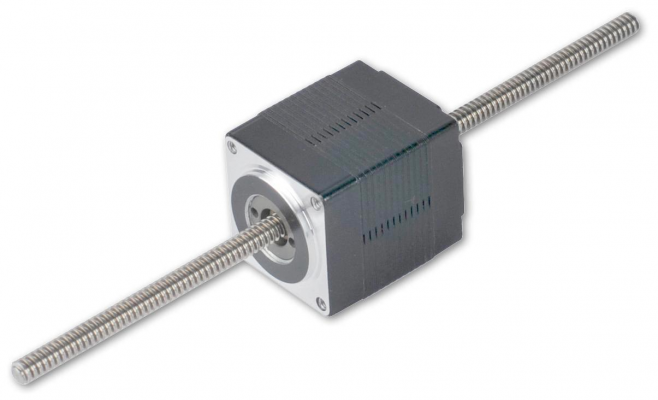

Makes me wonder if the threaded rod itself could be used as 'rack teeth' then that would perhaps save some plastic and printing time?

A slanted pineon gear on the stepper would then be enough.

OR

something like this:

but that could turn out to be expensive

Makes me wonder if the threaded rod itself could be used as 'rack teeth' then that would perhaps save some plastic and printing time?

A slanted pineon gear on the stepper would then be enough.

OR

something like this:

but that could turn out to be expensive

|

Re: Smartrap evolution, improvements... April 30, 2014 07:21PM |

Registered: 10 years ago Posts: 992 |

You're so right mark .

I've tried many ways to make those lm8 straight, but always failed

The thing is: I stopped working on it because i believe it would be better to have a fixed X axis with sliding head on it. We would loose the simplicity of one line of fishing line or belt or rack ( it would need a pulley and belt loop ) , but we could win so much from this :

- more straight because rods are strongly attached to the motor ( we can even think about a third line to make it more stable)

- Lighter because only the head and 4 lm8 would move

- we could put the smartrap on a wall ( no need space behind anymore)

Besides, it would be good to have an integrated lm8 holders there. It's just that there is very few space !

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

I've tried many ways to make those lm8 straight, but always failed

The thing is: I stopped working on it because i believe it would be better to have a fixed X axis with sliding head on it. We would loose the simplicity of one line of fishing line or belt or rack ( it would need a pulley and belt loop ) , but we could win so much from this :

- more straight because rods are strongly attached to the motor ( we can even think about a third line to make it more stable)

- Lighter because only the head and 4 lm8 would move

- we could put the smartrap on a wall ( no need space behind anymore)

Besides, it would be good to have an integrated lm8 holders there. It's just that there is very few space !

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Smartrap evolution, improvements... May 01, 2014 01:20AM |

Registered: 10 years ago Posts: 229 |

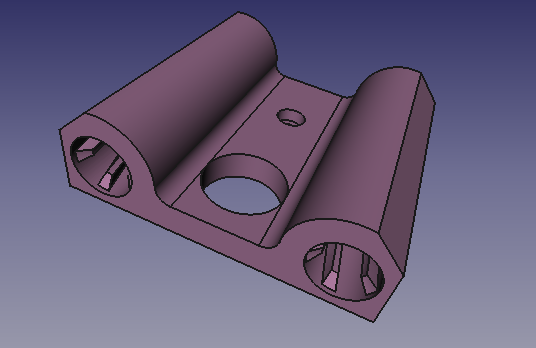

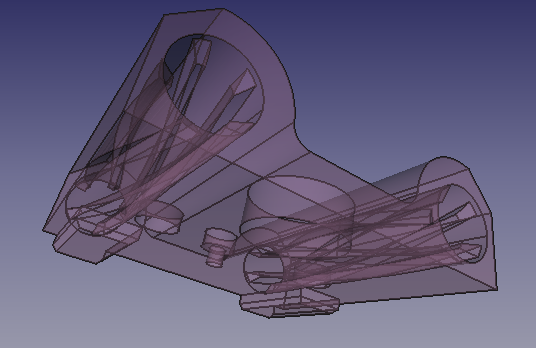

A sneak-peek at the bushing plate. Hope to be testing later on today / tomorrow. We'll see how it goes.

Mark

Mark

|

Re: Smartrap evolution, improvements... May 01, 2014 01:56AM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap evolution, improvements... May 01, 2014 02:29AM |

Registered: 10 years ago Posts: 229 |

Yes, made to fit on top of the plate. the 2 tabs in the back a suppose to fit into the 2 rear LM8 bearing slots to keep it square. Thicker center section to stop the twisting. Lands are 1:165 twist, or in other words, they make 1/3 turn for the length. ~1 mm width bearing surface per land which works out to around 1:5 contact:free surface area on the rods. keep in mind this is only a first run and more than likely, there will be changes.

Mark

Mark

|

Re: Smartrap evolution, improvements... May 01, 2014 08:26AM |

Registered: 10 years ago Posts: 992 |

haaa. yes mark. direct bushing

i dream having the all smartrap like this with integrated bushing we can reprint when it gets old All with the rack&pinions, we're on the good way to the all printed structure . Yes, i'm thinking about that too .. hehe.

All with the rack&pinions, we're on the good way to the all printed structure . Yes, i'm thinking about that too .. hehe.

I was experimenting printed linear guides ( replace rods) with felt and grease. Not so bad in fact .. need tests. My last canon printer is using that , on metal though.. but there's no bearing anymore ! just felt and grease. cheapy !

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

i dream having the all smartrap like this with integrated bushing we can reprint when it gets old

All with the rack&pinions, we're on the good way to the all printed structure . Yes, i'm thinking about that too .. hehe.

All with the rack&pinions, we're on the good way to the all printed structure . Yes, i'm thinking about that too .. hehe. I was experimenting printed linear guides ( replace rods) with felt and grease. Not so bad in fact .. need tests. My last canon printer is using that , on metal though.. but there's no bearing anymore ! just felt and grease. cheapy !

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Smartrap evolution, improvements... May 01, 2014 08:27AM |

Registered: 10 years ago Posts: 992 |

but why extra plate ? we could redo the all plate_x from this . More simple and less PLA ?

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Smartrap evolution, improvements... May 01, 2014 08:42AM |

Registered: 10 years ago Posts: 992 |

you're right backemf,

I've tested some rack using maritime insert for extruder ( the brass one). It fits perfectly with a M5 threaded rod. It needs only a bearing on the other side to press well the rod on the insert.It would work, definitely !

But... the challenge of the smartrap is ( and will stay for me) to have printed structure ans still a nice little cartesian printer.

I know it's challenging because printed parts are far less reliable than wood or metal , but it is indeed the main challenge of the project There's enough other reprap projects doing wonderful job with aluminium frame, metal frame, etc...

There's enough other reprap projects doing wonderful job with aluminium frame, metal frame, etc...

I believe in all printed structure because of easiness of sharing ( like we do now ) , just CAD files and printers at home. Its the only way i know to have a real shared project with everyone coming with solutions or new way of designing parts and other testing them in almost real time

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

I've tested some rack using maritime insert for extruder ( the brass one). It fits perfectly with a M5 threaded rod. It needs only a bearing on the other side to press well the rod on the insert.It would work, definitely !

But... the challenge of the smartrap is ( and will stay for me) to have printed structure ans still a nice little cartesian printer.

I know it's challenging because printed parts are far less reliable than wood or metal , but it is indeed the main challenge of the project

There's enough other reprap projects doing wonderful job with aluminium frame, metal frame, etc...

There's enough other reprap projects doing wonderful job with aluminium frame, metal frame, etc... I believe in all printed structure because of easiness of sharing ( like we do now ) , just CAD files and printers at home. Its the only way i know to have a real shared project with everyone coming with solutions or new way of designing parts and other testing them in almost real time

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Smartrap evolution, improvements... May 01, 2014 09:49AM |

Registered: 10 years ago Posts: 814 |

The benefit of printed bearings is they bring down the cost. It allows you to use cheaper and easier to get drill rods.

I think I kinda like the plate idea like Mark did, as it seems wasteful to throw away a large chunk of plastic when only a small part has worn out. The idea of the Whole plate with the bearings would be easier to assemble though, but I'm not sure how well it could be printed?

Serge, you definitely have something going here. You have the mostly plastic printer, Cliff is working on a mostly wood version and Skyrider is working on a mostly metal version. LOL.

I saw another alternate version pop up on Thingiverse. Wish that guy would join over here too.

I think I kinda like the plate idea like Mark did, as it seems wasteful to throw away a large chunk of plastic when only a small part has worn out. The idea of the Whole plate with the bearings would be easier to assemble though, but I'm not sure how well it could be printed?

Serge, you definitely have something going here. You have the mostly plastic printer, Cliff is working on a mostly wood version and Skyrider is working on a mostly metal version. LOL.

I saw another alternate version pop up on Thingiverse. Wish that guy would join over here too.

|

Re: Smartrap evolution, improvements... May 01, 2014 11:48AM |

Registered: 10 years ago Posts: 349 |

Serge,

True fully printed has many advanatges in the digital domain. :-)

Though i'm also happy to hear that the threaded rod R&P works!

Mike and Mark

Yes, there are many nice SmartRap idea's in the wild. If any of the builders are reading this then please join the conversation!

I like the simplicity of the low partcount, though replaceble bushings also have advantages.

would a lego style snap on (printed LM8UU with some kind of LEGO press fit) be an option?

Or a stretched and slimmed down version of this:

https://www.thingiverse.com/thing:239686

double the length and half the width..

The simplicity and low partcount are still a big advantage. Maybe it a matter of figuring out how long the printed bushings last?

True fully printed has many advanatges in the digital domain. :-)

Though i'm also happy to hear that the threaded rod R&P works!

Mike and Mark

Yes, there are many nice SmartRap idea's in the wild. If any of the builders are reading this then please join the conversation!

I like the simplicity of the low partcount, though replaceble bushings also have advantages.

would a lego style snap on (printed LM8UU with some kind of LEGO press fit) be an option?

Or a stretched and slimmed down version of this:

https://www.thingiverse.com/thing:239686

double the length and half the width..

The simplicity and low partcount are still a big advantage. Maybe it a matter of figuring out how long the printed bushings last?

|

Re: Smartrap evolution, improvements... May 01, 2014 12:01PM |

Registered: 10 years ago Posts: 229 |

The problem with printing the plate "all in one" is the issue of lamination. Sense this assembly couples the X and Z there are stresses on both those planes. I would believe that is why the bottom plate is currently printed laying flat and the current bearing clamps are printed up on their sides.

Now, after running the Gcode through a simulator, and not overly thrilled about the time involved in making the print for the bushing plate, or the amount of PLA extruded, all for a part that is intended to suffer wear, I'm rethinking the problem and I might have another solution. One that involves a lot less print time/material and can be readily added on with little hassle and only minor disassembly.

Mark

Now, after running the Gcode through a simulator, and not overly thrilled about the time involved in making the print for the bushing plate, or the amount of PLA extruded, all for a part that is intended to suffer wear, I'm rethinking the problem and I might have another solution. One that involves a lot less print time/material and can be readily added on with little hassle and only minor disassembly.

Mark

|

Re: Smartrap evolution, improvements... May 01, 2014 01:32PM |

Registered: 12 years ago Posts: 46 |

Quote

markstephen

A sneak-peek at the bushing plate. Hope to be testing later on today / tomorrow. We'll see how it goes.

Mark

[attachment 31964 Bushing_Plate1.png]

[attachment 31965 Bushing_Plate2.png]

You need the mount for the limit switch.

Woops, wasn't paying attention.

But it might be worth trying to incorporate the stepper mounting screws. If it could be done it would be 1l less screw (and nut) and wouls gaurantee the bearings didn't wobble about.

Edited 1 time(s). Last edit at 05/01/2014 01:45PM by TCase.

|

Re: Smartrap evolution, improvements... May 01, 2014 03:02PM |

Registered: 10 years ago Posts: 229 |

Quote

TCase

Quote

markstephen

A sneak-peek at the bushing plate. Hope to be testing later on today / tomorrow. We'll see how it goes.

Mark

[attachment 31964 Bushing_Plate1.png]

[attachment 31965 Bushing_Plate2.png]

You need the mount for the limit switch.

Woops, wasn't paying attention.

But it might be worth trying to incorporate the stepper mounting screws. If it could be done it would be 1l less screw (and nut) and wouls gaurantee the bearings didn't wobble about.

Thought about that, but the clearance is not there between the rods and screws. The Z rods would need 15 - 20 mm more width between them for that to work out.

|

Re: Smartrap evolution, improvements... May 01, 2014 08:22PM |

Registered: 10 years ago Posts: 229 |

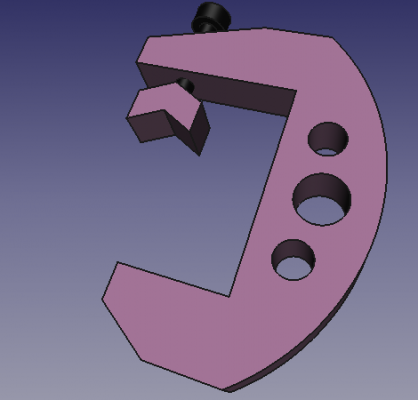

i came up with what I think is a reasonable stop gap solution to the flexing problem and seems to be working well. It should hold me over until a more permanent solution can be conjured up. All i did was knock out a couple of made to fit C Clamps and feet to hold down the front of the holder. Works a treat...

I need to make a little adjustment before I upload the files, that is, if anyone is interested in them.

Mark

I need to make a little adjustment before I upload the files, that is, if anyone is interested in them.

Mark

|

Re: Smartrap evolution, improvements... May 02, 2014 01:00AM |

Registered: 11 years ago Posts: 791 |

Quote

verteez

Personally, I really want to get the files of Geared extruder made by Regpye. Or if not, then will use some desigh from thingiverse

I have a left hand and a right hand version of the geared extruder, which would you like to use? Left hand has the exit on the left, right hand on the right.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... May 02, 2014 01:02AM |

Registered: 11 years ago Posts: 791 |

Quote

verteez

Mark is right. The X axis bearing mouting is a week spot. Mine, ewen with not changing to 'no servo' bed probing were loose, and just popping out.

Will wait for some progras with it. Anny change to this will be good one.

I have found that too, so I have re-designed the part to make it stronger and more stable. Not tested it out yet because I am re-designing a few other parts too.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... May 02, 2014 03:03AM |

Registered: 10 years ago Posts: 116 |

Quote

regpye

Quote

verteez

Personally, I really want to get the files of Geared extruder made by Regpye. Or if not, then will use some desigh from thingiverse

I have a left hand and a right hand version of the geared extruder, which would you like to use? Left hand has the exit on the left, right hand on the right.

I don't know, both will be good

It can be left, it can be also right. It's the direction told by facing printer prom front(hotend) or back?

It can be left, it can be also right. It's the direction told by facing printer prom front(hotend) or back?

|

Re: Smartrap evolution, improvements... May 02, 2014 07:16PM |

Registered: 10 years ago Posts: 12 |

I'm a big fan of this rack and pinion setup, this is a really neat solution, as is the great no servo auto leveling you're working on. [www.youtube.com]

When would a smartrap be available with these improvements to buy?

When would a smartrap be available with these improvements to buy?

|

Re: Smartrap evolution, improvements... May 02, 2014 07:24PM |

Registered: 10 years ago Posts: 229 |

|

Re: Smartrap evolution, improvements... May 02, 2014 07:31PM |

Registered: 10 years ago Posts: 349 |

|

Re: Smartrap evolution, improvements... May 02, 2014 07:44PM |

Registered: 10 years ago Posts: 12 |

Thanks

I think I'll wait till R&P has been incorporatated into the design, all the problems I have with my current printer (a Mendel) are to do with the belts. I'm hoping this system could remove a lot of headaches, it's really pretty too.

Edited 1 time(s). Last edit at 05/02/2014 07:49PM by JohnC.

I think I'll wait till R&P has been incorporatated into the design, all the problems I have with my current printer (a Mendel) are to do with the belts. I'm hoping this system could remove a lot of headaches, it's really pretty too.

Edited 1 time(s). Last edit at 05/02/2014 07:49PM by JohnC.

|

Re: Smartrap evolution, improvements... May 02, 2014 08:00PM |

Registered: 11 years ago Posts: 791 |

Quote

markstephen

i came up with what I think is a reasonable stop gap solution to the flexing problem and seems to be working well. It should hold me over until a more permanent solution can be conjured up. All i did was knock out a couple of made to fit C Clamps and feet to hold down the front of the holder. Works a treat...

I need to make a little adjustment before I upload the files, that is, if anyone is interested in them.

Mark

[attachment 32006 C_Clamp_Assembly.png]

[attachment 32008 C_Clamps_1.JPG]

[attachment 32009 C_Clamps_2.JPG]

I have re-designed the same part, in fact all the parts to be stronger and more stable.

Testing soon, so I wont put any files up until all has been fully tested.

For those that want to try out the extruder, download from this URL

[url=http://regpye.com.au/Smartrap/SmartRap geared extruder L.stl]Left hand version, filament exit on left.[/url]

[url=http://regpye.com.au/Smartrap/SmartRap geared extruder R.stl]Right hand version, filament exit on right.[/url]

[url]http://regpye.com.au[/url]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... May 02, 2014 08:19PM |

Registered: 11 years ago Posts: 791 |

Quote

verteez

Quote

regpye

Quote

verteez

Personally, I really want to get the files of Geared extruder made by Regpye. Or if not, then will use some desigh from thingiverse

I have a left hand and a right hand version of the geared extruder, which would you like to use? Left hand has the exit on the left, right hand on the right.

I don't know, both will be goodIt can be left, it can be also right. It's the direction told by facing printer prom front(hotend) or back?

Looking at the front of the printer.

If you need to change the way it is you can always mirror the STL file in Cura, however I have both available at the following URLs

[url=http://regpye.com.au/Smartrap/SmartRap geared extruder R.stl]Right hand version[/url]

[url=http://regpye.com.au/Smartrap/SmartRap geared extruder L.stl]Left hand version[/url]

[url]http://regpye.com.au[/url]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... May 02, 2014 10:56PM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap evolution, improvements... May 02, 2014 11:48PM |

Registered: 10 years ago Posts: 229 |

Quote

madmike8

Regpye, I can't wait till you have those tested and post them. Really Nice.

Mark, can you make bearings that just bolt down thru the stepper holes?

Mentioned that in this post.

I originally was thinking that there was not enough clearance in there for that, but looking at it again... Maybe, but it would be very close. Serge did a great job compacting the original design, which leaves some tight spaces to work within for modifying that section. It might work. Let me see how well I can get everything to fit together in CAD.

Sorry, only registered users may post in this forum.