Smartrap evolution, improvements...

Posted by smartfriendz

|

Re: Smartrap evolution, improvements... June 20, 2014 01:27PM |

Registered: 10 years ago Posts: 992 |

I saw this one. I'm interested because i'm going to try a double head ..the smartrap way  ( cheap cheap ). One head, two nozzles very near with one heat and one fan... it implies we must use two compatibles PLA, but hey.. it's two colors for super cheap , right ?

( cheap cheap ). One head, two nozzles very near with one heat and one fan... it implies we must use two compatibles PLA, but hey.. it's two colors for super cheap , right ?

let's try

two or mode heads are the logical next step ( a part the continuous debugging and improvement like regpye brings here everyday .

.

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

( cheap cheap ). One head, two nozzles very near with one heat and one fan... it implies we must use two compatibles PLA, but hey.. it's two colors for super cheap , right ?

( cheap cheap ). One head, two nozzles very near with one heat and one fan... it implies we must use two compatibles PLA, but hey.. it's two colors for super cheap , right ? let's try

two or mode heads are the logical next step ( a part the continuous debugging and improvement like regpye brings here everyday

.

.the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Smartrap evolution, improvements... June 20, 2014 02:47PM |

Registered: 10 years ago Posts: 229 |

Not just 2 colors, so we can print cool stuff like this frog, but being able to use that Water Soluble PVA filament for support.

|

Re: Smartrap evolution, improvements... June 20, 2014 02:54PM |

Registered: 10 years ago Posts: 229 |

Quote

madmike8

Looks cool... So when you going to try it?You probably have a dual holder for the Smartrap already designed up and your head and your fingers are twitching over your mouse waiting to put those ideas in to FreeCAD... I'll mail you a spare Jhead-Lite thanks to Regpye. Come on... You know you want too... I think I have some spare PTFE tube too...

Oh, I have the spare tube for the Bowden, and a spare driver board for the ramps.

Me thinks you are getting to know me too well Mike.

Yes, I do already have the design in my head, and requiring no mod of current parts, just a couple of new parts to attach.

Yes, I do already have the design in my head, and requiring no mod of current parts, just a couple of new parts to attach.

|

Re: Smartrap evolution, improvements... June 20, 2014 04:47PM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap evolution, improvements... June 21, 2014 05:20PM |

Registered: 10 years ago Posts: 229 |

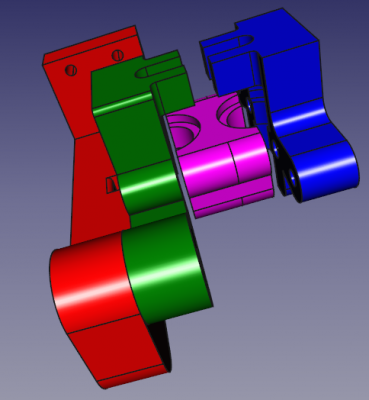

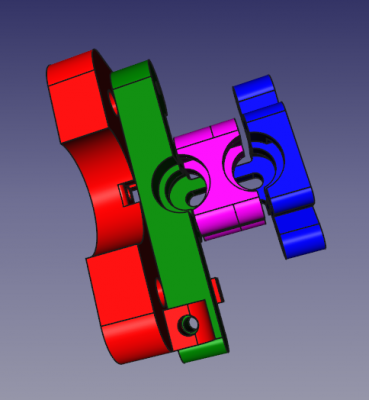

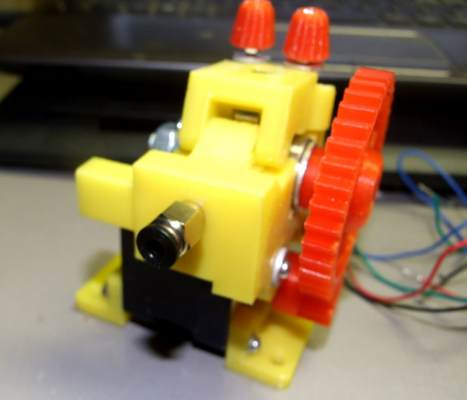

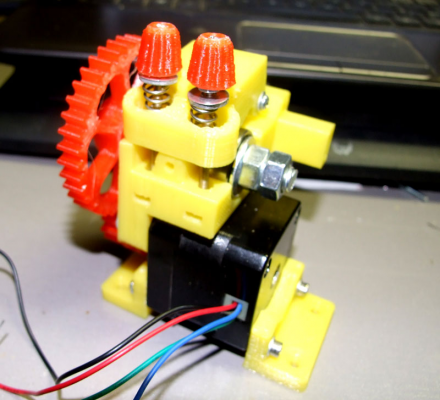

OK, here is my first run at the dual Hotend mount for the Smartrap. Simple, minimal offset between Hotends, (16 mm), and only one part discarded and 2 new parts added. Probably start a print later on today.

Mark

Mark

|

Re: Smartrap evolution, improvements... June 21, 2014 07:39PM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap evolution, improvements... June 21, 2014 08:06PM |

Registered: 11 years ago Posts: 791 |

Quote

madmike8

Don't think I've seen a front to back arrangement before. Is the weight going to effect the swing arm any?

We will see, wont we? That is what SmartRap is all about I think. New ideas to try out and push the limits.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... June 21, 2014 10:56PM |

Registered: 10 years ago Posts: 229 |

|

Re: Smartrap evolution, improvements... June 21, 2014 10:58PM |

Registered: 11 years ago Posts: 791 |

Quote

markstephen

I don't think the weight would make a difference one way or the other. There are two of them no matter which way you mount it. But like Reg says - "We will see, wont we"

I think it will work just fine.

Mark

Me too. When will you be testing it ha..ha..

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... June 21, 2014 11:06PM |

Registered: 10 years ago Posts: 229 |

The hold up will be waiting for the stepper motor to arrive I'm thinking. That and figuring out the settings for dual extrudes... Though I really want to print out that frog so I'v got some motivation there. I could "barrow" one of the motors from my CNC machine, but I'd have to leave it hanging over the edge as it's one of those 47mm high torque jobs with a shaft sticking out of both ends.

|

Re: Smartrap evolution, improvements... June 22, 2014 04:43AM |

Registered: 10 years ago Posts: 992 |

wonderful mark ! I'm so curious to see that in place

I'm thinking about where to put those 2 extruder steppers already

and what if we put 4 ? thinking hard here ..

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

I'm thinking about where to put those 2 extruder steppers already

and what if we put 4 ? thinking hard here ..

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Smartrap evolution, improvements... June 22, 2014 05:25AM |

Registered: 11 years ago Posts: 791 |

Quote

smartfriendz

wonderful mark ! I'm so curious to see that in place

I'm thinking about where to put those 2 extruder steppers already

and what if we put 4 ? thinking hard here ..

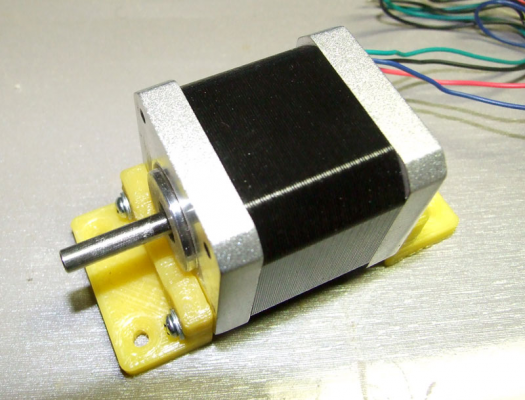

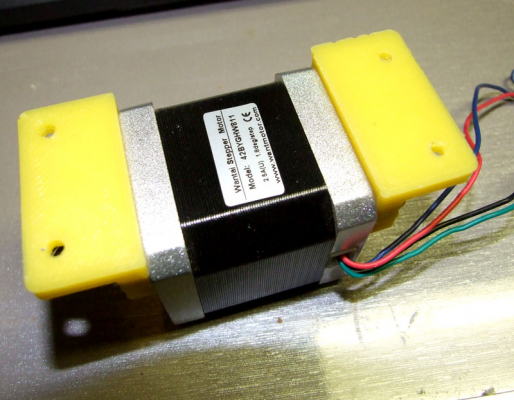

That is easy Serge, just use a couple or more of my extruders and do what MeIT did only using the new mounting brackets that I have in "Free Stuff" on my website, instead of a block of wood..

You could bank as many as you want that way.

EDIT:

Here are a couple of photos of the motor mount attached to a motor.

Top

Bottom

Back

Front

Edited 1 time(s). Last edit at 06/22/2014 06:39AM by regpye.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... June 22, 2014 07:51AM |

Registered: 9 years ago Posts: 80 |

|

Re: Smartrap evolution, improvements... June 22, 2014 10:50PM |

Registered: 10 years ago Posts: 349 |

|

Re: Smartrap evolution, improvements... June 23, 2014 10:22PM |

Registered: 10 years ago Posts: 229 |

Think I have about all the printed parts made. Center section and outer retainer for the second Hotend, the dual extruder extension and idler, and Bowden tube looms - 4 "dog bone" and 3 "C" type, for Bowden tube management.

Mark

Mark

|

Re: Smartrap evolution, improvements... June 23, 2014 10:59PM |

Registered: 11 years ago Posts: 791 |

Quote

markstephen

Think I have about all the printed parts made. Center section and outer retainer for the second Hotend, the dual extruder extension and idler, and Bowden tube looms - 4 "dog bone" and 3 "C" type, for Bowden tube management.

Mark

This should prove to be very interesting, can't wait to see the prints.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... June 23, 2014 11:24PM |

Registered: 10 years ago Posts: 229 |

|

Re: Smartrap evolution, improvements... July 16, 2014 07:12PM |

Registered: 10 years ago Posts: 99 |

Quote

BackEMF

Hmm, for some reason the Z axis is screeming especially during bedleveling. The small adjustments during a print are quiet.

could this be the stepper drivers need adjusting to control the current going to the motor?

Usually the noise from motors, except for vibration - i use dampeners, is from not having the sweet spot adjusted on the stepper drivers.

|

Re: Smartrap evolution, improvements... July 16, 2014 07:43PM |

Registered: 10 years ago Posts: 349 |

hehe nice coincidence that you writhe this at the same moment as I was starting a separate topic on this issue. :-)

And, yes I have fine tuned the stepper currents.

What kind of dampener do you use on the Z axis? I've tried it but that made the Z axis less stable.

I have the feeling there is something else going on on the Z-axis. I will try again to finetune.

I remember that the first days it seemed to make far less noise. Not sure if my memory is correct.

And, yes I have fine tuned the stepper currents.

What kind of dampener do you use on the Z axis? I've tried it but that made the Z axis less stable.

I have the feeling there is something else going on on the Z-axis. I will try again to finetune.

I remember that the first days it seemed to make far less noise. Not sure if my memory is correct.

|

Re: Smartrap evolution, improvements... July 16, 2014 09:55PM |

Registered: 11 years ago Posts: 791 |

Quote

BackEMF

Hmm, for some reason the Z axis is screeming especially during bedleveling. The small adjustments during a print are quiet.

Around about line 375 in configuration.h file there should be a line that is similar to this

v

#define DEFAULT_MAX_FEEDRATE {500, 500, 2.5, 25} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {1000,1000,50,500} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good

Make sure that you don't have the settings too high.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... August 07, 2014 05:47PM |

Registered: 10 years ago Posts: 99 |

Hi Smartrap users and developers,

I have been building and using 3D printers for about 9 months and have a connection to the local high school teacher who wants to include building and working with 3D printers in his technology class.

I have suggested he get Kits for the students to build, test, calibrate, print parts for another printer and then take the printer apart so that the next semester students can do the same thing all over again.

To test out my theory, I used hardware I already had from taking apart a printer, and I bought a set of Smartrap plastic parts (in USA) but they are based on version 0.4.x prior to the current version, and once I realized that, after I had started assembly, I going to start printing parts for version 0.4.9 and take this one apart to rebuild it. Don't want to use Spectra fishing line,,,,been there, done that,,,,,not interested in the cheapest option, but trying to keep costs low in anticipation of making a recommendation to the high school teacher.

Some of the students will never make it to actually printing something, unless we give them a kit that has all the parts and we know it will work once assembled.

Other students will be able to take on a more challenging project, like Smartrap, where the design is evolving, and they can make changes and upgrades as they go along.

So, I am thinking of getting a printing farm started at the local high school, get them printing Smartrap parts, get the teacher to buy several hardware kits - I am typing up a parts list and sourcing with prices this week.

I would like to stay in the loop on the evolving design of the Smartrap and so will frequent this forum reading, but maybe not commenting.

I have all the links to Smartrap on Github, thingiverse, other websites and forums, and Google: [sites.google.com]

I am most interested in the overall strategy for the evolving Smartrap.

Anyone in the USA putting together a complete kit for someone to assemble a Smartrap?

Thank you

I have been building and using 3D printers for about 9 months and have a connection to the local high school teacher who wants to include building and working with 3D printers in his technology class.

I have suggested he get Kits for the students to build, test, calibrate, print parts for another printer and then take the printer apart so that the next semester students can do the same thing all over again.

To test out my theory, I used hardware I already had from taking apart a printer, and I bought a set of Smartrap plastic parts (in USA) but they are based on version 0.4.x prior to the current version, and once I realized that, after I had started assembly, I going to start printing parts for version 0.4.9 and take this one apart to rebuild it. Don't want to use Spectra fishing line,,,,been there, done that,,,,,not interested in the cheapest option, but trying to keep costs low in anticipation of making a recommendation to the high school teacher.

Some of the students will never make it to actually printing something, unless we give them a kit that has all the parts and we know it will work once assembled.

Other students will be able to take on a more challenging project, like Smartrap, where the design is evolving, and they can make changes and upgrades as they go along.

So, I am thinking of getting a printing farm started at the local high school, get them printing Smartrap parts, get the teacher to buy several hardware kits - I am typing up a parts list and sourcing with prices this week.

I would like to stay in the loop on the evolving design of the Smartrap and so will frequent this forum reading, but maybe not commenting.

I have all the links to Smartrap on Github, thingiverse, other websites and forums, and Google: [sites.google.com]

I am most interested in the overall strategy for the evolving Smartrap.

Anyone in the USA putting together a complete kit for someone to assemble a Smartrap?

Thank you

|

Re: Smartrap evolution, improvements... August 07, 2014 05:50PM |

Registered: 10 years ago Posts: 99 |

SmartrapBOM.pdf

Here is my current list of parts and links for sourcing.

I would appreciate comments because I hope to share this with the local high school teacher and maybe buy enough to start a printer farm.

Here is my current list of parts and links for sourcing.

I would appreciate comments because I hope to share this with the local high school teacher and maybe buy enough to start a printer farm.

|

Re: Smartrap evolution, improvements... August 07, 2014 06:17PM |

Registered: 10 years ago Posts: 99 |

OK, I updated my list of parts, sources and pricing for Smartrap and posted it on Google Drive as a public PDF.

Any comments are welcome.

[drive.google.com]

Any comments are welcome.

[drive.google.com]

|

Re: Smartrap evolution, improvements... August 08, 2014 11:01PM |

Registered: 10 years ago Posts: 349 |

I have a few suggestions:

Why not let the kids keep the printer and also teach them to work with the printer and CAD stuff etc.

The printers keep evolving too, so just print new parts with the existing printers and this gives you a more recent model fort the next group.

To teach about tuning the printer Spectra line is actually great to teach about calculating to tune the printer. GT2 and R&P are simpler to set up, though in my opinion you would me missing an opportunity to teach a few valuable things.

You could also make a simple breadboard with RAMPS and a few motors just to teach about the firmware without doing harm to the hardware if there are adventurers who like to experiment a bit.

For the BOM.

You should be able to save some money on the PCB's

Also consider Regpyes Genie hotend and also his geared extruder.

I don't know if it is practical, but you can also build several types of extruders and again do some teaching on the tuning side of things.

you could also include a bit of bearing grease or use printed LM8UU bearing replacements

Edited 1 time(s). Last edit at 08/08/2014 11:28PM by BackEMF.

Quote

RTurnock

Kits for the students to build, test, calibrate, print parts for another printer and then take the printer apart so that the next semester students can do the same thing all over again.

Why not let the kids keep the printer and also teach them to work with the printer and CAD stuff etc.

The printers keep evolving too, so just print new parts with the existing printers and this gives you a more recent model fort the next group.

Quote

RTurnock

Don't want to use Spectra fishing line,

To teach about tuning the printer Spectra line is actually great to teach about calculating to tune the printer. GT2 and R&P are simpler to set up, though in my opinion you would me missing an opportunity to teach a few valuable things.

You could also make a simple breadboard with RAMPS and a few motors just to teach about the firmware without doing harm to the hardware if there are adventurers who like to experiment a bit.

For the BOM.

You should be able to save some money on the PCB's

Also consider Regpyes Genie hotend and also his geared extruder.

I don't know if it is practical, but you can also build several types of extruders and again do some teaching on the tuning side of things.

you could also include a bit of bearing grease or use printed LM8UU bearing replacements

Edited 1 time(s). Last edit at 08/08/2014 11:28PM by BackEMF.

|

Re: Smartrap evolution, improvements... August 08, 2014 11:54PM |

Registered: 10 years ago Posts: 99 |

Quote

BackEMF

I have a few suggestions:

Quote

RTurnock

Kits for the students to build, test, calibrate, print parts for another printer and then take the printer apart so that the next semester students can do the same thing all over again.

Why not let the kids keep the printer and also teach them to work with the printer and CAD stuff etc.

The printers keep evolving too, so just print new parts with the existing printers and this gives you a more recent model fort the next group.

Yes, my plan is evolving into me accumulating kits and printers and drawing robots before Sept when school starts. Then donating them to the school to seed the program.

Their printers keep evolving as the designs online improve and evolve. Just like you wrote.

Quote

BackEMF

Quote

RTurnock

Don't want to use Spectra fishing line,

To teach about tuning the printer Spectra line is actually great to teach about calculating to tune the printer. GT2 and R&P are simpler to set up, though in my opinion you would me missing an opportunity to teach a few valuable things.

You could also make a simple breadboard with RAMPS and a few motors just to teach about the firmware without doing harm to the hardware if there are adventurers who like to experiment a bit.

Excellent ideas....I will include them in my documentation of the teacher.

Quote

BackEMF

For the BOM.

You should be able to save some money on the PCB's

Also consider Regpyes Genie hotend and also his geared extruder.

I don't know if it is practical, but you can also build several types of extruders and again do some teaching on the tuning side of things.

you could also include a bit of bearing grease or use printed LM8UU bearing replacements

Yes, thank you...Just found on Aliexpress, for about $45 or less, I can get Mega2560+Ramps+A4988 steppers, and some sets include a 2004 LCD

You are right about exposing them to different extruders. Thanks

|

Re: Smartrap evolution, improvements... August 20, 2014 07:20PM |

Registered: 10 years ago Posts: 125 |

Hi Guys,

Maybe someone can help me with a few Smartrap issues.

1) Does anyone have any info about fitting the new J-head lite?

I just got my Smartrap through the post from Smartfrienz and there are no documents advising on how to put it together or adjust it. I assume the Ramps board included is pre-programmed to accept the new auto levelling setup but again I am unsure.

2) Do i need to put heat sinks on the pololus on the Ramps board? There were none attached to mine and none in the box that I got.

The reason I ask is because I can see heatsinks on the units that are shown on the Smartfrienz website but I would think that they would be part of the kit if I needed them.

3) What would you recommend to coat the glass bed to print PLA? I think blue tape ruins the finish of the printed parts and I know hairspray can clog up the nozzle.

Any help would be really appreciated.

Thanks

Mike

Edited 1 time(s). Last edit at 08/20/2014 07:23PM by mikefiatx19.

Maybe someone can help me with a few Smartrap issues.

1) Does anyone have any info about fitting the new J-head lite?

I just got my Smartrap through the post from Smartfrienz and there are no documents advising on how to put it together or adjust it. I assume the Ramps board included is pre-programmed to accept the new auto levelling setup but again I am unsure.

2) Do i need to put heat sinks on the pololus on the Ramps board? There were none attached to mine and none in the box that I got.

The reason I ask is because I can see heatsinks on the units that are shown on the Smartfrienz website but I would think that they would be part of the kit if I needed them.

3) What would you recommend to coat the glass bed to print PLA? I think blue tape ruins the finish of the printed parts and I know hairspray can clog up the nozzle.

Any help would be really appreciated.

Thanks

Mike

Edited 1 time(s). Last edit at 08/20/2014 07:23PM by mikefiatx19.

|

Re: Smartrap evolution, improvements... August 20, 2014 07:40PM |

Registered: 10 years ago Posts: 99 |

Quote

mikefiatx19

I assume the Ramps board included is pre-programmed to accept the new auto levelling setup but again I am unsure.

Specifically the Mega2560 board, that the Ramps board mounts on top of, is the one with the chip on it that accepts the firmware, called Marlin, that has the auto leveling code.

You know to use Arduino IDE to upload the firmware?

Quote

mikefiatx19

2) Do i need to put heat sinks on the pololus on the Ramps board? There were none attached to mine and none in the box that I got.

The reason I ask is because I can see heatsinks on the units that are shown on the Smartfrienz website but I would think that they would be part of the kit if I needed them.

Lots of confusion on the forums about heat sinks. My source is an electrical engineer friend and reading online.

The stepper drivers do NOT require heat sinks. Yes they get too hot to touch but they are made to operate that way.

The trick is to learn how to turn the little screw thing, to reduce the resistance, that reduces the current limit and therefore the voltage used by the motors.

Depends on which stepper drivers you have what to set them at so the motors don't make a lot of noise and so the motors don't get too hot.

I don't have the values right now. maybe someone else will list them.

Quote

mikefiatx19

3) What would you recommend to coat the glass bed to print PLA? I think blue tape ruins the finish of the printed parts and I know hairspray can clog up the nozzle.

Any help would be really appreciated.

Thanks

Mike

Elmer's washable school glue stick, disappearing purple OR something similar.

I use a razor blade in a metal holder, to scrap off excess dried glue after a print, but I don't push so hard all the glue comes off. the glue washes off the bottom of the plastic.

Then refresh by putting on thin layer, with no overlap, where the next print is going to hit the bed.

Depending on the object I will slice with a brim that is 5 wide.

|

Re: Smartrap evolution, improvements... August 20, 2014 07:58PM |

Registered: 11 years ago Posts: 791 |

Quote

mikefiatx19

Hi Guys,

Maybe someone can help me with a few Smartrap issues.

1) Does anyone have any info about fitting the new J-head lite?

I just got my Smartrap through the post from Smartfrienz and there are no documents advising on how to put it together or adjust it. I assume the Ramps board included is pre-programmed to accept the new auto levelling setup but again I am unsure.

2) Do i need to put heat sinks on the pololus on the Ramps board? There were none attached to mine and none in the box that I got.

The reason I ask is because I can see heatsinks on the units that are shown on the Smartfrienz website but I would think that they would be part of the kit if I needed them.

3) What would you recommend to coat the glass bed to print PLA? I think blue tape ruins the finish of the printed parts and I know hairspray can clog up the nozzle.

Any help would be really appreciated.

Thanks

Mike

HI Mike,

Are you using a heated bed or a cold bed?

If using a cold bed, coat the glass sheet with a heavy coating of PVA wood glue and a little water to thin it out so it is paintable. Let the glue dry very well before using. You will be able to lift the printed part off the bed with a sharp point of a knife, but be careful so you don't destroy the PVA coating.

If using a heated bed, clean the glass and add a small amount of sugar that has been mixed with a little water so it is now a thick syrup. Rub the sugar all over the glass very thinly (fingers) and then heat the bed as normal and print. Let the bed cool before removing the printed part (it will fall off easy) You can then print again straight away using the same sugar coating (many times)

To clean off the sugar at any time, just rinse under some water for a few minutes.

I would suggest several pieces of glass that are coated this way so you can do continual printings as the bed plates are cooling off.

It is best to have heatsinks where possible. With careful adjustment you can get away without them.

It is most likely that you will have to program your board because there will be some setting that need adjustment anyway. I most case (any kit) the boards are not pre-programmed. You should learn about the programming part as you will need to make several changes later as you get more experience with this machine or any other machine that you might want to build. We will help you, don't worry.

There are many heads available, the J-head lite is just one of them. My hotend has several mounting designs included and soon will also be a J-head lite direct replacement or a E3D replacement. Because of the printer design changing so much as it has been developing, new ideas for the head mount have been developing as well. Best to contact Serge about that part as he will know what this has been supplied for.

Edited 1 time(s). Last edit at 08/20/2014 08:09PM by regpye.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... August 20, 2014 11:26PM |

Registered: 10 years ago Posts: 349 |

Quote

mikefiatx19

Hi Guys,

Maybe someone can help me with a few Smartrap issues.

1) Does anyone have any info about fitting the new J-head lite?

I just got my Smartrap through the post from Smartfrienz and there are no documents advising on how to put it together or adjust it. I assume the Ramps board included is pre-programmed to accept the new auto levelling setup but again I am unsure.

2) Do i need to put heat sinks on the pololus on the Ramps board? There were none attached to mine and none in the box that I got.

The reason I ask is because I can see heatsinks on the units that are shown on the Smartfrienz website but I would think that they would be part of the kit if I needed them.

3) What would you recommend to coat the glass bed to print PLA? I think blue tape ruins the finish of the printed parts and I know hairspray can clog up the nozzle.

Any help would be really appreciated.

Thanks

Mike

1. I think you have to flash the firmware yourself. you need to install Arduino for this.

2. I'm not sure if the heatsinks are really needed. With the 40mm motors i think you can do without.

3. dilute some PVA glue (woodglue) 1 part PVA 3 parts water and brush it evenly on the glass with a paintbrush. (Initially i had a woodglue that didn't stick at all) Now i have Bison D2 and that works fine. I also tried sugar, and that worked reasonable too. Hairspray didn't work for me Though i see MarkStephen has very nice results with Aquanet hairspray. (Unfortunately that stuff is not available where i live)

|

Re: Smartrap evolution, improvements... August 20, 2014 11:37PM |

Registered: 11 years ago Posts: 791 |

Quote

BackEMF

Quote

mikefiatx19

Hi Guys,

Maybe someone can help me with a few Smartrap issues.

1) Does anyone have any info about fitting the new J-head lite?

I just got my Smartrap through the post from Smartfrienz and there are no documents advising on how to put it together or adjust it. I assume the Ramps board included is pre-programmed to accept the new auto levelling setup but again I am unsure.

2) Do i need to put heat sinks on the pololus on the Ramps board? There were none attached to mine and none in the box that I got.

The reason I ask is because I can see heatsinks on the units that are shown on the Smartfrienz website but I would think that they would be part of the kit if I needed them.

3) What would you recommend to coat the glass bed to print PLA? I think blue tape ruins the finish of the printed parts and I know hairspray can clog up the nozzle.

Any help would be really appreciated.

Thanks

Mike

1. I think you have to flash the firmware yourself. you need to install Arduino for this.

2. I'm not sure if the heatsinks are really needed. With the 40mm motors i think you can do without.

3. dilute some PVA glue (woodglue) 1 part PVA 3 parts water and brush it evenly on the glass with a paintbrush. (Initially i had a woodglue that didn't stick at all) Now i have Bison D2 and that works fine. I also tried sugar, and that worked reasonable too. Hairspray didn't work for me Though i see MarkStephen has very nice results with Aquanet hairspray. (Unfortunately that stuff is not available where i live)

The sugar method should only be used with a heated bed. PVA glue can be used with either heated or cold, but not as good as sugar, but really only method if you have a cold bed apart from using the paper glue sticks that also work pretty good. I have tried about 4 or 5 brands of the glue stick and they all work the same. Can't beat the sugar though if you have a heated bed.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

Sorry, only registered users may post in this forum.