Smartrap evolution, improvements...

Posted by smartfriendz

|

Re: Smartrap evolution, improvements... May 03, 2014 04:36AM |

Registered: 10 years ago Posts: 116 |

|

Re: Smartrap evolution, improvements... May 03, 2014 05:49AM |

Registered: 10 years ago Posts: 992 |

Hi Johnc,

Yes, the R&P will be integrated soon.. In fact, I'm planning to have kits with this system starting from 2 weeks from now . After some tests , i find it very great, more easy to install and it makes the both axis more strong ( M5 screwed on top !) . I can't see any difference from the fishing line in term of print quality . I find also quiet cute , more like i would imagine for the Smartrap from the beginning

Regpye, HEAVY design work there. It's impressive I like your work on the plateX . It's also my next work : we really ned to find a more simple system and still strong enough . From the last dev with R&P, I believe the very simple supports we have for Y would work now on X too. It's not as strong as your system, but there's no screws, just put the lm8 in

I like your work on the plateX . It's also my next work : we really ned to find a more simple system and still strong enough . From the last dev with R&P, I believe the very simple supports we have for Y would work now on X too. It's not as strong as your system, but there's no screws, just put the lm8 in

You can follow the dev in blender files on github in blender/dev/0.4.7 and 0.4,8.

I did some changes about endstopZ attach ( now one screw only) , huxley attach ( one screw no nut) , 2 endstops X Y ( one M2.5 only direct in plastic) ... new Z-coupler without screws ( direct in shaft with plate part) .

Thank you for all your debs guys, it really helps the all model to be more pro .. that's really cool

I'm sorry i don't have time enough to test all .. with the prod, support,maintenance and evolution .. hu. why days are only 24 hours ???

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

Yes, the R&P will be integrated soon.. In fact, I'm planning to have kits with this system starting from 2 weeks from now . After some tests , i find it very great, more easy to install and it makes the both axis more strong ( M5 screwed on top !) . I can't see any difference from the fishing line in term of print quality . I find also quiet cute , more like i would imagine for the Smartrap from the beginning

Regpye, HEAVY design work there. It's impressive

I like your work on the plateX . It's also my next work : we really ned to find a more simple system and still strong enough . From the last dev with R&P, I believe the very simple supports we have for Y would work now on X too. It's not as strong as your system, but there's no screws, just put the lm8 in

I like your work on the plateX . It's also my next work : we really ned to find a more simple system and still strong enough . From the last dev with R&P, I believe the very simple supports we have for Y would work now on X too. It's not as strong as your system, but there's no screws, just put the lm8 in

You can follow the dev in blender files on github in blender/dev/0.4.7 and 0.4,8.

I did some changes about endstopZ attach ( now one screw only) , huxley attach ( one screw no nut) , 2 endstops X Y ( one M2.5 only direct in plastic) ... new Z-coupler without screws ( direct in shaft with plate part) .

Thank you for all your debs guys, it really helps the all model to be more pro .. that's really cool

I'm sorry i don't have time enough to test all .. with the prod, support,maintenance and evolution .. hu. why days are only 24 hours ???

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Smartrap evolution, improvements... May 11, 2014 10:37AM |

Registered: 10 years ago Posts: 229 |

Here's a question - How thick is the glass you all are using for your plate? I am using 3/32" (~2.4 mm) and the Glass Support parts, (the new ones) are way too tall to hold that thickness of glass. It's easy enough to make these fit, just wondering if there is a standard or preferred thickness for the plate?

Mark

Mark

|

Re: Smartrap evolution, improvements... May 11, 2014 10:43AM |

Registered: 10 years ago Posts: 116 |

|

Re: Smartrap evolution, improvements... May 11, 2014 06:09PM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap evolution, improvements... May 11, 2014 06:25PM |

Registered: 11 years ago Posts: 791 |

Quote

markstephen

Here's a question - How thick is the glass you all are using for your plate? I am using 3/32" (~2.4 mm) and the Glass Support parts, (the new ones) are way too tall to hold that thickness of glass. It's easy enough to make these fit, just wondering if there is a standard or preferred thickness for the plate?

Mark

I am using 3mm window glass, but when I measure it the actual thickness is only 2.8mm. Easy to make a glass clip that is far shorter than you need and just slip a washer or two underneath.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... May 21, 2014 05:33PM |

Registered: 10 years ago Posts: 229 |

Another bushing for you all to play around with. This time it's a SC8 type. I'v printed a prototype and it works like a champ. Very light and sturdy. You can check it out here on Thingiverse. This made in the same fashion as the LMF8 type bushing. Please let me know how they work if you try one. I have seen several mods that have used this type of bearing (SC8) and Blackfrog's build is using the LMF8 type of bearing.

Mark

SC8 Bushing

LMF Bushing

Edited 1 time(s). Last edit at 05/21/2014 05:35PM by markstephen.

Mark

SC8 Bushing

LMF Bushing

Edited 1 time(s). Last edit at 05/21/2014 05:35PM by markstephen.

|

Re: Smartrap evolution, improvements... June 03, 2014 04:32AM |

Registered: 10 years ago Posts: 992 |

Hi,

I've just updated a sketchfab model for assembly. It is updated regular, so everyone can see quickly the evolution ( it goes fast lately) .

[skfb.ly]

last development are :

- anti wobble on z

- gt2 for X and Y integrated

- 300 mm rods fro 180x180 real printable space.

to follow :

- separate extruder to have option to use krisdaniels direct or regpye geared.

- new auto level system no touch.

then, we reach V1.0 without big updates to be able to do a nice doc, assembly guide, and support.

V2 to follow in some months... quiet different

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

I've just updated a sketchfab model for assembly. It is updated regular, so everyone can see quickly the evolution ( it goes fast lately) .

[skfb.ly]

last development are :

- anti wobble on z

- gt2 for X and Y integrated

- 300 mm rods fro 180x180 real printable space.

to follow :

- separate extruder to have option to use krisdaniels direct or regpye geared.

- new auto level system no touch.

then, we reach V1.0 without big updates to be able to do a nice doc, assembly guide, and support.

V2 to follow in some months... quiet different

the Smartrap project

[smartfriendz.com]

[www.thingiverse.com]

[reprap.org]

[github.com]

doc assemblage: [reprap.org]

NEW: Forum smartfriendz: [smartraptalk.smartfriendz.com]

|

Re: Smartrap evolution, improvements... June 03, 2014 04:55AM |

Registered: 9 years ago Posts: 80 |

No touch auto level? That's a dream!

I have the no servo x end but I find that unlike the servo version, my j-head nozzle wiggles a bit as the bowden cable moves around. It will really help with the print quality if the hot end will be fixed more rigidly on the X end.

Any chance I can try it out now?

I have the no servo x end but I find that unlike the servo version, my j-head nozzle wiggles a bit as the bowden cable moves around. It will really help with the print quality if the hot end will be fixed more rigidly on the X end.

Any chance I can try it out now?

|

Re: Smartrap evolution, improvements... June 03, 2014 07:40AM |

Registered: 10 years ago Posts: 116 |

|

Re: Smartrap evolution, improvements... June 03, 2014 10:12AM |

Registered: 10 years ago Posts: 37 |

|

Re: Smartrap evolution, improvements... June 03, 2014 11:07AM |

Registered: 9 years ago Posts: 80 |

Of course there's no harm in trying especially if you already have a working 3D printer, but if I had a working servo motor, I would probably stick with it compared to the servo-less version. The reason being that my j-head is more sturdy when it is mounted directly on the X end that connects to the rods. I'm currently using the servo-less version and if I move the ptfe tube, the nozzle tip wiggles considerably. This could explain why my walls are not completely flat and ridges are visible. Maybe my tube is too short or I don't know what else. Just sharing before you try it.

Again, no harm in trying. Hope it works well for you.

Again, no harm in trying. Hope it works well for you.

|

Re: Smartrap evolution, improvements... June 03, 2014 12:33PM |

Registered: 10 years ago Posts: 37 |

Good point, MeIT.

The endstop arm connected to my servo motor is somewhat fragile and wobbles a lot. I often unwittingly knock it slightly out of alignment while pulling parts off the bed. The wobble/misalignment affects the set z-offset between nozzle and z-endstop position with the servo down. This results in problems with first-layer thickness. The wobble problem was why I was contemplating going to the servo-less X-end attachment for my hot-end during the upgrade.

Your comment about hot-end movement during a print in the servo-less version makes me reconsider my decision to move to the servo-less bed leveling x-end with moveable arm right now. Hot-end movement in the middle of a print would be harder to catch and would affect the entire print. Whereas servo/endstop wobble only affects the initial z-offset and can be detected early by keeping an eye on the thickness of the first layer.

With that said, I am still looking forward to upgrading to GT2 belts and the anti-z-wobble threaded rod mount in the new 0.4.8 version! I have the first plate from yesterday's GitHub update printed out already.

I was planning on switching from a RAMPS 1.4 board to a Sanguinololu board I have been soldering together while my SmartRap (my wife named her "Strudy") is down for the upgrade. Now I just have to figure out how to control a servo with the Sanguinololu board.

The endstop arm connected to my servo motor is somewhat fragile and wobbles a lot. I often unwittingly knock it slightly out of alignment while pulling parts off the bed. The wobble/misalignment affects the set z-offset between nozzle and z-endstop position with the servo down. This results in problems with first-layer thickness. The wobble problem was why I was contemplating going to the servo-less X-end attachment for my hot-end during the upgrade.

Your comment about hot-end movement during a print in the servo-less version makes me reconsider my decision to move to the servo-less bed leveling x-end with moveable arm right now. Hot-end movement in the middle of a print would be harder to catch and would affect the entire print. Whereas servo/endstop wobble only affects the initial z-offset and can be detected early by keeping an eye on the thickness of the first layer.

With that said, I am still looking forward to upgrading to GT2 belts and the anti-z-wobble threaded rod mount in the new 0.4.8 version! I have the first plate from yesterday's GitHub update printed out already.

I was planning on switching from a RAMPS 1.4 board to a Sanguinololu board I have been soldering together while my SmartRap (my wife named her "Strudy") is down for the upgrade. Now I just have to figure out how to control a servo with the Sanguinololu board.

|

Re: Smartrap evolution, improvements... June 03, 2014 04:38PM |

Registered: 11 years ago Posts: 791 |

Quote

MelT

Of course there's no harm in trying especially if you already have a working 3D printer, but if I had a working servo motor, I would probably stick with it compared to the servo-less version. The reason being that my j-head is more sturdy when it is mounted directly on the X end that connects to the rods. I'm currently using the servo-less version and if I move the ptfe tube, the nozzle tip wiggles considerably. This could explain why my walls are not completely flat and ridges are visible. Maybe my tube is too short or I don't know what else. Just sharing before you try it.

Again, no harm in trying. Hope it works well for you.

On my version of servo less, there is no wiggle because I put a PTFE guide tube to stop any movement. It is very firm and yet can trigger the limit switch easily.

Also allows the machine to print faster too, because it is more sturdy.

See how I did it here;

SmartRap build

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... June 03, 2014 07:08PM |

Registered: 9 years ago Posts: 80 |

Oh yeah, that looks like it can resist wiggle better since the arm has a wider contact with the x end.

It looks a little advanced though and but I should be able to modify it to keep my current Z plate. Then I can probably use a spring from a pen so I can try it out.

Is your design open and posted somewhere?

It looks a little advanced though and but I should be able to modify it to keep my current Z plate. Then I can probably use a spring from a pen so I can try it out.

Is your design open and posted somewhere?

|

Re: Smartrap evolution, improvements... June 03, 2014 10:15PM |

Registered: 11 years ago Posts: 791 |

Quote

MelT

Oh yeah, that looks like it can resist wiggle better since the arm has a wider contact with the x end.

It looks a little advanced though and but I should be able to modify it to keep my current Z plate. Then I can probably use a spring from a pen so I can try it out.

Is your design open and posted somewhere?

I will post a URL for you.

Edited 2 time(s). Last edit at 06/03/2014 10:18PM by regpye.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... June 03, 2014 10:27PM |

Registered: 11 years ago Posts: 791 |

Quote

regpye

Quote

MelT

Oh yeah, that looks like it can resist wiggle better since the arm has a wider contact with the x end.

It looks a little advanced though and but I should be able to modify it to keep my current Z plate. Then I can probably use a spring from a pen so I can try it out.

Is your design open and posted somewhere?

I will post a URL for you.

No servo head found here No servo head

Edited 1 time(s). Last edit at 06/03/2014 10:28PM by regpye.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... June 03, 2014 10:56PM |

Registered: 11 years ago Posts: 791 |

Quote

MelT

Oh yeah, that looks like it can resist wiggle better since the arm has a wider contact with the x end.

It looks a little advanced though and but I should be able to modify it to keep my current Z plate. Then I can probably use a spring from a pen so I can try it out.

Is your design open and posted somewhere?

The extra contact does do something to stop it, but the PTFE tube takes all of the wiggle movement out.I can't move it sideways even if I push or pull hard with my fingers., it only has up and down movement. The reason for the wide arm is to increase the lever action so that less pressure is required to operate the micro switch. The spring needs to be very light, in fact I stopped using the spring, it isn't really needed.

This is probably a better image of the PTFE tube that I mentioned

This photo is before cutting off the excess length after screwing the PTFE into the threaded hole.

The other part slides on this PTFE tube and can;t move sideways.

Edited 2 time(s). Last edit at 06/03/2014 11:18PM by regpye.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... June 04, 2014 05:44AM |

Registered: 9 years ago Posts: 80 |

In my case, it's not really the lateral movement but the axial wiggle. I noticed you there was a reinforcement on your arm so I hope this fixes it for me.  Thanks a lot for sharing it!

Thanks a lot for sharing it!

I will surely try it after I replace my extruder with yours. I just printed the small gear and the base but it was pointing to the other side Anyway, I have a spare motor so I will probably mount it separately like when I was trying the airtripper version and will print a mirror image once tested.

Anyway, I have a spare motor so I will probably mount it separately like when I was trying the airtripper version and will print a mirror image once tested.

Thanks a lot for sharing it!

Thanks a lot for sharing it!

I will surely try it after I replace my extruder with yours. I just printed the small gear and the base but it was pointing to the other side

Anyway, I have a spare motor so I will probably mount it separately like when I was trying the airtripper version and will print a mirror image once tested.

Anyway, I have a spare motor so I will probably mount it separately like when I was trying the airtripper version and will print a mirror image once tested.

|

Re: Smartrap evolution, improvements... June 04, 2014 01:03PM |

Registered: 10 years ago Posts: 37 |

|

Re: Smartrap evolution, improvements... June 04, 2014 05:58PM |

Registered: 10 years ago Posts: 349 |

|

Re: Smartrap evolution, improvements... June 08, 2014 01:34AM |

Registered: 10 years ago Posts: 37 |

I gave a shot at designing a J-head mount for the newest servoless x-ends from Smartfriendz. I also used Regpye's idea of the PTFE tube near the switch and a longer radius between the pivot and the PTFE tube so that the PTFE tube does not shift much perpendicular to its axis. I'm going to give the whole thing a try this week during a teardown/rebuild switch to 0.4.8.

|

Re: Smartrap evolution, improvements... June 08, 2014 02:04AM |

Registered: 11 years ago Posts: 791 |

Quote

CellJeffe

I gave a shot at designing a J-head mount for the newest servoless x-ends from Smartfriendz. I also used Regpye's idea of the PTFE tube near the switch and a longer radius between the pivot and the PTFE tube so that the PTFE tube does not shift much perpendicular to its axis. I'm going to give the whole thing a try this week during a teardown/rebuild switch to 0.4.8.

Hey! Looks good.

If anyone wants to design their own to suit my hotend, here are the measurements of the groove nut.

The M5 thread takes a pneumatic hose quick connector for very easy Bowden fitting. Just plug the hose in.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Smartrap evolution, improvements... June 08, 2014 09:42AM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap evolution, improvements... June 08, 2014 11:44AM |

Registered: 10 years ago Posts: 229 |

|

Re: Smartrap evolution, improvements... June 08, 2014 12:34PM |

Registered: 10 years ago Posts: 814 |

|

Re: Smartrap evolution, improvements... June 08, 2014 02:09PM |

Registered: 10 years ago Posts: 229 |

|

Re: Smartrap evolution, improvements... June 08, 2014 02:30PM |

Registered: 10 years ago Posts: 814 |

Yup, with the quick connect.

Save a bit of time is the least I could do...

Thanks Mark!

Quote

regpye

No, mine is 2.75" or 65mm from tip of nozzle to the end of the cold end, so it is not too different from the standard J-head.

Mine also has a few more parts than the J-head, those are to stop the heat travel.

Source files will be available when I get time to put them up on my website.

Save a bit of time is the least I could do...

Thanks Mark!

|

Re: Smartrap evolution, improvements... June 08, 2014 02:59PM |

Registered: 10 years ago Posts: 229 |

|

Re: Smartrap evolution, improvements... June 08, 2014 06:02PM |

Registered: 10 years ago Posts: 229 |

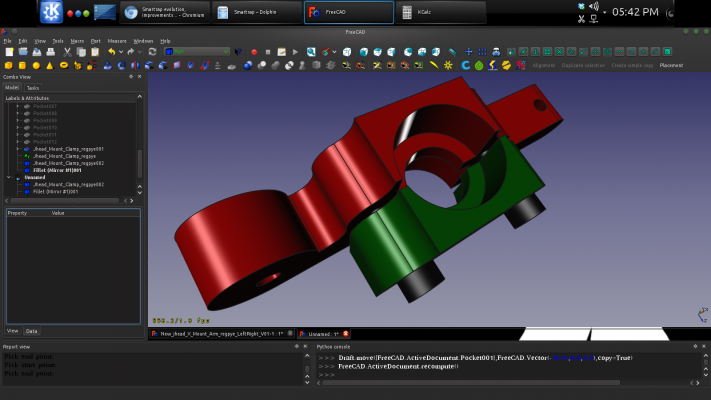

Alright, after about a half dozen distractions these should be good enough to give a try. The meshes are all good, no errors.You should note however, I have not printed one of these out, and even if I did, I don't have one of those nice hotends to test it out on. So your on your own for that part. Let me know if anything needs adjusting. I think you were using the left hand version? That's why the screenshot is of a lefty. I have included both left and right arms, just in case.

Mark

Jhead_Mount_Arm_regpye_Left.stl

Jhead_Mount_Arm_regpye_Right.stl

Jhead_Mount_Clamp_regpye.stl

Edited 2 time(s). Last edit at 06/08/2014 06:06PM by markstephen.

Mark

Jhead_Mount_Arm_regpye_Left.stl

Jhead_Mount_Arm_regpye_Right.stl

Jhead_Mount_Clamp_regpye.stl

Edited 2 time(s). Last edit at 06/08/2014 06:06PM by markstephen.

Sorry, only registered users may post in this forum.