Cast tooling plate print bed flatness

Posted by the_digital_dentist

|

Re: Cast tooling plate print bed flatness December 01, 2016 04:02AM |

Registered: 10 years ago Posts: 169 |

Quote

etfrench

You can calculate how much expansion the bed will have using tools on this site: [www.engineeringtoolbox.com]

I'd also recommend using socket head machine screws with a counterbore instead of countersunk flathead machine screws. The later won't allow expansion.

Thanks etfrench....I have a quantity of stainless steel, socket head 5 mm / .08 pitch countersunk screws I plan to use for the plate to 2020 connections. I will however need to counter bore the plate for the 3 longer socket head bolts used on the thumbscrew mounts. I think slotting those 3 bolt holes in the table top will allow for linear expansion on the long side. What is there about the perimeter stainless counter sunk screws that won't allow expansion?

|

Re: Cast tooling plate print bed flatness December 01, 2016 07:46AM |

Registered: 8 years ago Posts: 622 |

Thicker plate might be an option. I guess somewhere there will be a chart or formula that will allow you to calculate the deflection of the plate if it were unsupported. Bear in mind that 0.1mm will be too much. Also be aware though that the thicker the plate is, the longer it will take to warm up - insulation will help although that will add to the time it takes to cool down. That's not an issue if you use a removable print surface such as glass.

You also need to consider where to put the temperature sensor, whether it be a thermistor or thermocouple or PRT or whatever. I guess in your case you may have more than one? I initially made the mistake of using the thermistor that was supplied with the silicone heater and which was in the centre of the heater touching the plate. The trouble with that is that you are measuring the temperature at the underside of the plate close to the heating element and to start with, this will rise very quickly. The sensor will see that and the electronics will turn the heater off but the top of the plate will still be cold. Then the underside cools down a bit, the heater kicks back in etc, etc. Eventually the heat will find it's way through to the top surface but because you are controlling the heat at the underside and therefore switching this on and off as the heater kicks in and out, it will take even longer to warm through to the top surface. What I did with mine was drill hole in the edge of the bed, about 30mm deep, and as close to the top surface as I could get it without it breaking through, and fitted the temperature sensor in this hole. That cured the problem. I recently ran a check with a thermocouple taped to the top of my removable 6mm thick glass with Kapton tape whilst heating the bed. The two temperatures (inside the aluminium and on top of the glass) track each other very closely, although the top of the glass is about 1.5 deg C lower than the aluminium as would be expected. HTH

You also need to consider where to put the temperature sensor, whether it be a thermistor or thermocouple or PRT or whatever. I guess in your case you may have more than one? I initially made the mistake of using the thermistor that was supplied with the silicone heater and which was in the centre of the heater touching the plate. The trouble with that is that you are measuring the temperature at the underside of the plate close to the heating element and to start with, this will rise very quickly. The sensor will see that and the electronics will turn the heater off but the top of the plate will still be cold. Then the underside cools down a bit, the heater kicks back in etc, etc. Eventually the heat will find it's way through to the top surface but because you are controlling the heat at the underside and therefore switching this on and off as the heater kicks in and out, it will take even longer to warm through to the top surface. What I did with mine was drill hole in the edge of the bed, about 30mm deep, and as close to the top surface as I could get it without it breaking through, and fitted the temperature sensor in this hole. That cured the problem. I recently ran a check with a thermocouple taped to the top of my removable 6mm thick glass with Kapton tape whilst heating the bed. The two temperatures (inside the aluminium and on top of the glass) track each other very closely, although the top of the glass is about 1.5 deg C lower than the aluminium as would be expected. HTH

|

Re: Cast tooling plate print bed flatness December 01, 2016 01:10PM |

Registered: 9 years ago Posts: 483 |

|

Re: Cast tooling plate print bed flatness December 01, 2016 03:21PM |

Registered: 10 years ago Posts: 169 |

Thanks Deckingman and etfrench.....I think I'll stay with the 1/4" plate and put a center point adjuster fixed to the stainless table top. I should be able to limit the heat plate deflection by point loading the center of the plate to the same elevation as the long ends where the thumb wheel adjusters are mounted. I'll have to be careful the screw post center point isn't touching any of the heater elements inside the silicone pad at the contact point. So the idea is the plate itself will be leveled by the three thumb wheel adjusters with the 4th center point adjuster used to limit deflection in the otherwise unsupported center of the tooling plate. Any reasons you can think of this won't work? Thanks...TP.

|

Re: Cast tooling plate print bed flatness December 01, 2016 03:37PM |

Registered: 10 years ago Posts: 14,672 |

With a bed of that size, I think you may need to support all four corners. I know that it would be theoretically over-constained, but it's hard to make a very large bed rigid enough for 3 point support.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cast tooling plate print bed flatness December 01, 2016 04:01PM |

Registered: 10 years ago Posts: 169 |

Hmm....well let's look at this design from another standpoint. The SS table top is basis of the V-slot frame structure where all the perimeter extrusions are first screwed to the table top, then all the super structure is screwed, squared, and leveled off of that. The XY gantry moves as a unit along the Z axis of the 4 vertical corner extrusions. Once the heat bed plate is set level to the table top and hard mounted, its seems unlikely it will ever need to be leveled again relative to the frame structure itself. Heat cycling the bed plate may contribute to some lateral movement along the XY but Z or level should stay relatively constant wouldn't you think? Hot end Z movement along the XY plot would vary as an adjustment in programming based on the initial mapping wouldn't it? I've never setup to auto level using a probe but I understand that's what Z mapping does....is that correct? Therefore, if I do away with the 2020 below the heat plate and simply hard mount the plate to the SS table top where the plate is level with the base frame of the extrusion structure, wouldn't the Z mapping complete the necessary pre-print synchronizing of the hot end and the bed? Thanks for all the help...TP.

|

Re: Cast tooling plate print bed flatness December 04, 2016 04:02PM |

Registered: 8 years ago Posts: 622 |

Just my twopence worth but my first printer was built from a kit and had a thin aluminium plate that was basically just a means to spread the heat. Also, the Z axis used 2 motors which could become unsynchronised every time the machine was turned on or off. I had to rely completely on bed compensation which meant heating the hot end and bed, then homing all the axes and the doing the bed compensation every single time that I wanted to print anything. Even then, things would move and I'd be constantly having to adjust the Z probe trigger height.

My new printer has a bed that is flat and level. It is supported (driven) by 3 screws connected by a single closed loop belt and driven by a single stepper motor. It is prevented from any lateral movement by linear guides. I initially levelled it by slackening the grub screws holding the pulleys to the screws and rotating each screw. I made one further adjustment after a few tens of hours of printing when everything settled in. Since then I have never had to adjust anything. I do periodically do a 3 point Z probe check (probe the bed close to each of the 3 screws) just to be sure that nothing has moved but it's been months since I had to make any adjustment. My start gcode has commands to heat the bed and hot end, and home the axes. So now, instead of all the pre-print messing around with bed compensation etc, I simply turn on the machine, select the gcode file I want to print and sit back or walk away. Everything else just happens and I come back to a finished print.

So, you could go the potential "less robust" route and rely on the electronics to compensate but be prepared for a lot of pre-print messing around. Also, constantly adjusting the Z height during the print to compensate for defects in bed level or flatness will accelerate the wear on the Z rods and screws. On the other hand, you could build a bed that is flat and level and will stay level and you won't have to rely on any sort of software compensation. But of course this route may be more expensive and there may be difficulties to overcome. Personally, having gone down both routes, I'd go for the latter (again) but it's your choice.

Edit. Sorry, just re-read your post and from that I gather that the bed will be static. Having said that, most or what I wrote above still remains valid. I guess your next big challenge will be to build the X and Y axes so that they don't sag or flex.

Edited 1 time(s). Last edit at 12/04/2016 04:07PM by deckingman.

My new printer has a bed that is flat and level. It is supported (driven) by 3 screws connected by a single closed loop belt and driven by a single stepper motor. It is prevented from any lateral movement by linear guides. I initially levelled it by slackening the grub screws holding the pulleys to the screws and rotating each screw. I made one further adjustment after a few tens of hours of printing when everything settled in. Since then I have never had to adjust anything. I do periodically do a 3 point Z probe check (probe the bed close to each of the 3 screws) just to be sure that nothing has moved but it's been months since I had to make any adjustment. My start gcode has commands to heat the bed and hot end, and home the axes. So now, instead of all the pre-print messing around with bed compensation etc, I simply turn on the machine, select the gcode file I want to print and sit back or walk away. Everything else just happens and I come back to a finished print.

So, you could go the potential "less robust" route and rely on the electronics to compensate but be prepared for a lot of pre-print messing around. Also, constantly adjusting the Z height during the print to compensate for defects in bed level or flatness will accelerate the wear on the Z rods and screws. On the other hand, you could build a bed that is flat and level and will stay level and you won't have to rely on any sort of software compensation. But of course this route may be more expensive and there may be difficulties to overcome. Personally, having gone down both routes, I'd go for the latter (again) but it's your choice.

Edit. Sorry, just re-read your post and from that I gather that the bed will be static. Having said that, most or what I wrote above still remains valid. I guess your next big challenge will be to build the X and Y axes so that they don't sag or flex.

Edited 1 time(s). Last edit at 12/04/2016 04:07PM by deckingman.

|

Re: Cast tooling plate print bed flatness December 04, 2016 04:43PM |

Registered: 10 years ago Posts: 14,672 |

I agree. As your bed is static and large, in your position I would try a 5 point mounting arrangement without an additional frame. You can remove the centre point if it turns out not to be needed. The hard part will be avoiding sag in the gantry as the print head moves - although grid compensation can do a reasonable job of correcting for that if it is repeatable.

I don't have any direct experience of large print beds, so I will defer to anyone who has and offers different advice.

Edited 2 time(s). Last edit at 12/05/2016 03:12AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I don't have any direct experience of large print beds, so I will defer to anyone who has and offers different advice.

Edited 2 time(s). Last edit at 12/05/2016 03:12AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cast tooling plate print bed flatness December 04, 2016 05:16PM |

Registered: 10 years ago Posts: 169 |

Thanks to both deckingman and dc42 for your advice. I like the idea of the 5 point bed mount with the center point being the 5th for removing any weight deflection. The 4 perimeter mounts would be hard fixed to the bed allowing movement against the SS table top which can be secured tight once the bed XY level is achieved. The 5th center point adjustment collar will be hard fixed to the table top and allow a threaded shaft to point press against the bottom of the bed to remove deflection. That should also give me a few more MM of Z movement which will put the total print height over 800mm.

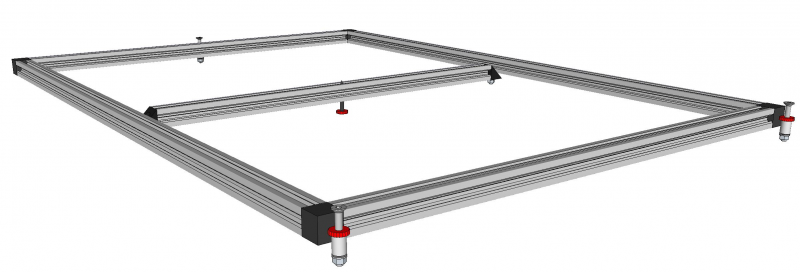

The XY gantry is made of 1000mm C-Beams on the long Y axis with 4040 and 2040 extrusions for the ends. I first mounted a 2020 extrusion for the X axis but I'm in the process of swapping that out for a 2040 to keep all the drive cables and pulleys enclosed within the structure. The 1000mm C-Beam Z axis towers uses 8mm threaded shafts tied together with belts below the table top to synchronize two NEMA 23s mounted on opposing corners. I build the structure for maximum bolt-together rigidity using mutiple screw connections at every corner. I plan to wire the NEMA 23 Z motors together using a common control feed to dual outboard stepper drivers. I'll just have to test and see if that setup works as planned. Thanks again to everyone for all the great advice....TP.

Edited 1 time(s). Last edit at 12/04/2016 05:17PM by simspeed.

The XY gantry is made of 1000mm C-Beams on the long Y axis with 4040 and 2040 extrusions for the ends. I first mounted a 2020 extrusion for the X axis but I'm in the process of swapping that out for a 2040 to keep all the drive cables and pulleys enclosed within the structure. The 1000mm C-Beam Z axis towers uses 8mm threaded shafts tied together with belts below the table top to synchronize two NEMA 23s mounted on opposing corners. I build the structure for maximum bolt-together rigidity using mutiple screw connections at every corner. I plan to wire the NEMA 23 Z motors together using a common control feed to dual outboard stepper drivers. I'll just have to test and see if that setup works as planned. Thanks again to everyone for all the great advice....TP.

Edited 1 time(s). Last edit at 12/04/2016 05:17PM by simspeed.

|

Re: Cast tooling plate print bed flatness December 04, 2016 11:57PM |

Registered: 14 years ago Posts: 19 |

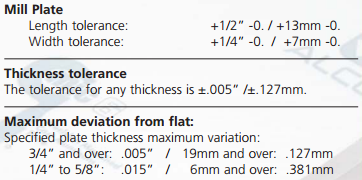

I have to add to this by saying that I picked up a 24x24" sheet of MIC-6, but reading their specs, they only specify flatness to 0.35mm at 1/4", and mine has a complex dip of about 0.25mm in it. In order to get .005" tolerance for flatness, you need to step up to 3/4" thick plate, which I don't think my machine could handle moving around.

I'm wondering if anyone else has run into this and modified/lapped/ground their plate flat afterwards. Mine is already covered in adhesive and heaters, so I'd probably need to do some work to pull all that off to grind it flat, but I'm wondering if i should spend another $150 on a piece of MIC6 or find somewhere where they can grind the whole thing flat.

Edited 1 time(s). Last edit at 12/04/2016 11:58PM by Chorca.

I'm wondering if anyone else has run into this and modified/lapped/ground their plate flat afterwards. Mine is already covered in adhesive and heaters, so I'd probably need to do some work to pull all that off to grind it flat, but I'm wondering if i should spend another $150 on a piece of MIC6 or find somewhere where they can grind the whole thing flat.

Edited 1 time(s). Last edit at 12/04/2016 11:58PM by Chorca.

|

Re: Cast tooling plate print bed flatness December 05, 2016 01:40AM |

Registered: 10 years ago Posts: 169 |

Hmmm....I'd hate to go with a 3/4" plate just for the weight and time to heat/cool. Thankfully my bed is fixed so the weight isn't relative except for handling the thing. I may compromise and do a 3/8" for the extra stiffness given the length of my bed. Thanks for the info on you bed Chorca. Hopefully mine will come without a complex dip.

|

Re: Cast tooling plate print bed flatness December 05, 2016 10:42AM |

Registered: 8 years ago Posts: 622 |

I think that if you buy machined tooling plate, it'll be guaranteed flat to the type of tolerance we need but check with the supplier. Here in the UK we can buy ECOCast aluminium tooling plate which is precision machined both sides.

Have you considered using a removable print surface on top of your plate? It needs to be flat and float glass fulfils that criteria. There are some on these forums who are dead against it but others like myself swear by it. The advantages are that it is flat (as long as you don't get it toughened), and of course you don't have to wait for the entire mass of aluminium to cool down before you can remove the print - simply slide the glass off the plate and if you have a spare, fit that and you are ready to print again. It will be less expansive to replace than the aluminium so it will act as a protector. You can of course have several pieces of glass with different print surfaces attached (blue tape, 3DLAC, Print bite or whatever) and swap between them. There are people who will state that the glass acts as an insulator and will therefore take longer to heat up but they have clearly never done any tests as I have. The warm up time for the top of the glass is within a few seconds of the top of the aluminium and the temperature difference that I have measured between the aluminium plate and the glass is less than 2 degrees C using 6mm thick glass.

Have you considered using a removable print surface on top of your plate? It needs to be flat and float glass fulfils that criteria. There are some on these forums who are dead against it but others like myself swear by it. The advantages are that it is flat (as long as you don't get it toughened), and of course you don't have to wait for the entire mass of aluminium to cool down before you can remove the print - simply slide the glass off the plate and if you have a spare, fit that and you are ready to print again. It will be less expansive to replace than the aluminium so it will act as a protector. You can of course have several pieces of glass with different print surfaces attached (blue tape, 3DLAC, Print bite or whatever) and swap between them. There are people who will state that the glass acts as an insulator and will therefore take longer to heat up but they have clearly never done any tests as I have. The warm up time for the top of the glass is within a few seconds of the top of the aluminium and the temperature difference that I have measured between the aluminium plate and the glass is less than 2 degrees C using 6mm thick glass.

|

Re: Cast tooling plate print bed flatness December 05, 2016 11:53AM |

Registered: 10 years ago Posts: 169 |

There are a couple of issues using glass in my scenario. First the size of the glass to cover my bed is larger than I'd like to handle on a regular basis. The machine will be fully enclosed in Lexan where the end panels are fixed and the front and back are sliding doors framed in 2020. The doors only slide open to roughly 80% so it won't be easy to remove a large plate of glass with the print attached. I can use smaller pieces of glass for smaller prints when necessary which will work considering that the silicone heater I ordered is zoned for smaller prints . I plan to cover the full plate with a sheet of PEI for the print surface. I probably won't be printing many single large prints but do plan to print a number of smaller ones at the same time. Based on accounts, the PEI is the best medium to use for the print bed surface. I do have a couple of large pieces of oven door glass that I want to run a dial indicator across once I get the bed locked down. It will be interesting to see how flat they actually are. Thanks for the feedback...TP.

|

Re: Cast tooling plate print bed flatness December 05, 2016 04:17PM |

Registered: 14 years ago Posts: 19 |

Quote

deckingman

I think that if you buy machined tooling plate, it'll be guaranteed flat to the type of tolerance we need but check with the supplier. Here in the UK we can buy ECOCast aluminium tooling plate which is precision machined both sides.

There are a few different dimensions specified for this type of plate. A quick glance will show you the thickness tolerance, which is the thickness of the actual material across the surface. The other parameter is flatness tolerance, which is how much it is bowed or bent before/after cutting. The thickness tolerance for MIC-6 (and every other cast alu tooling plate i've seen) is +- 0.127mm, which is fairly good and would be fine for most purposes.

However, the flatness tolerance is specified as 0.381mm, for 6-18mm thick (1/4" standard) material. This is the common stuff you can get from most suppliers, and what I purchased. So, while my bed has a very tight tolerance for thickness, flatness is further out than is usable.

I attempted to use the weight of the bed to prevent sagging by adding a middle support, however, it simply lifts the bed off the other supports, so it appears the bed is actually bent by around 0.25-0.30mm.

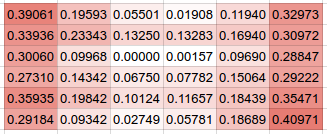

Using a BLTouch and doing a verbose grid bed level routine, I can get the values that Marlin sees whlie performing the grid leveling. By entering them into a spreadsheet and doing a conditional coloration, it shows my bed has a bit of a curve to the sides:

So, I need to try and straighten the bed out manually (bending it over something) or by fixing the height of the sides and using pressure in the center to attempt to force the bed back into shape while attached to the printer.

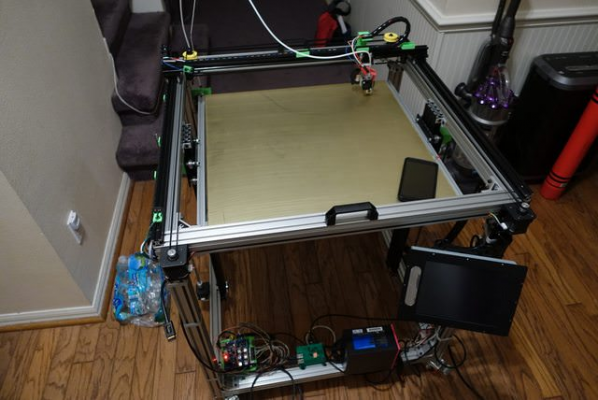

For reference, here's the machine:

|

Re: Cast tooling plate print bed flatness December 05, 2016 04:37PM |

Registered: 10 years ago Posts: 14,672 |

Quote

simspeed

There are a couple of issues using glass in my scenario. First the size of the glass to cover my bed is larger than I'd like to handle on a regular basis. The machine will be fully enclosed in Lexan where the end panels are fixed and the front and back are sliding doors framed in 2020. The doors only slide open to roughly 80% so it won't be easy to remove a large plate of glass with the print attached. I can use smaller pieces of glass for smaller prints when necessary which will work considering that the silicone heater I ordered is zoned for smaller prints . I plan to cover the full plate with a sheet of PEI for the print surface. I probably won't be printing many single large prints but do plan to print a number of smaller ones at the same time. Based on accounts, the PEI is the best medium to use for the print bed surface. I do have a couple of large pieces of oven door glass that I want to run a dial indicator across once I get the bed locked down. It will be interesting to see how flat they actually are. Thanks for the feedback...TP.

If you print PLA on PEI then you may find that it sticks too well. I sometimes have to put the bed + print in the freezer to separate them. PrintBite may be a better option for printing PLA on if your print bed will be non-removable.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cast tooling plate print bed flatness December 05, 2016 05:12PM |

Registered: 10 years ago Posts: 169 |

Quote

Chorca

Using a BLTouch and doing a verbose grid bed level routine, I can get the values that Marlin sees whlie performing the grid leveling. By entering them into a spreadsheet and doing a conditional coloration, it shows my bed has a bit of a curve to the sides:

So, I need to try and straighten the bed out manually (bending it over something) or by fixing the height of the sides and using pressure in the center to attempt to force the bed back into shape while attached to the printer.

Thanks for the spreadsheet reading Chorca....interesting to see such a wavy variation in your bed dimensions. I intend to do a similar surface check using a plain dial indicator and log the measurements manually. My XYZ gantry will zero out on the lower frame rails. so I'll level the bed there and then jog the XY head with the mounted dial indicator to some grid dimensions and take readings at the grid lines. Your point about straightening the bed makes sense if you lock down the corners and then apply upward pressure in the middle with the bow facing down. My table top is rather thin SS sheetmetal formed along the rails so there would be a lot of deflection in the middle without some cross-bracing underneath to help distribute the point load. It will be interesting to see how the load gets distributed throughout the frame. Certainly there's going to be limits of practicality using that technique.

|

Re: Cast tooling plate print bed flatness December 05, 2016 05:24PM |

Registered: 10 years ago Posts: 169 |

Quote

dc42

If you print PLA on PEI then you may find that it sticks too well. I sometimes have to put the bed + print in the freezer to separate them. PrintBite may be a better option for printing PLA on if your print bed will be non-removable.

Thanks for the info dc42.....do you heat the bed when using PLA? I've read accounts that some do and some don't. MY printer will be fully enclosed so I could heat the inside separately from the bed heater using heat strips down either side of the Z gantry rails. I'm just planning to experiment to see what works best but certainly I could use smaller sheets of glass for PLA prints if necessary. I'm hoping to be able to print almost everything on the big plate with the PEI sheet coating. Has anyone tried using a thick sheet of PEI rather than the thin film sheets? I was at Colorado Plastics today getting some 6mm PVC sheet for my frame skirt and noticed they have Ulterm/PEI in large sheets and thicknesses. Damn pricey of course so there'd have to be some serious advantages to go that route.

|

Re: Cast tooling plate print bed flatness December 05, 2016 07:37PM |

Registered: 11 years ago Posts: 5,780 |

You could skip the whole bed flatness/leveling thing and print on PIR foam...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Cast tooling plate print bed flatness December 05, 2016 08:09PM |

Registered: 10 years ago Posts: 169 |

|

Re: Cast tooling plate print bed flatness December 06, 2016 01:58AM |

Registered: 10 years ago Posts: 14,672 |

Quote

simspeed

Quote

dc42

If you print PLA on PEI then you may find that it sticks too well. I sometimes have to put the bed + print in the freezer to separate them. PrintBite may be a better option for printing PLA on if your print bed will be non-removable.

Thanks for the info dc42.....do you heat the bed when using PLA? I've read accounts that some do and some don't. MY printer will be fully enclosed so I could heat the inside separately from the bed heater using heat strips down either side of the Z gantry rails. I'm just planning to experiment to see what works best but certainly I could use smaller sheets of glass for PLA prints if necessary. I'm hoping to be able to print almost everything on the big plate with the PEI sheet coating. Has anyone tried using a thick sheet of PEI rather than the thin film sheets? I was at Colorado Plastics today getting some 6mm PVC sheet for my frame skirt and noticed they have Ulterm/PEI in large sheets and thicknesses. Damn pricey of course so there'd have to be some serious advantages to go that route.

Yes I heat the bed to about 50-55C. I tried printing PLA on cold PEI once and the print fell off part way through printing. I guess I should try heating the bed to lower temperatures.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.