Geeetech-Aluminum-Prusa-I3

Posted by Anonymous User

|

Re: Geeetech-Aluminum-Prusa-I3 March 14, 2016 08:07PM |

Registered: 8 years ago Posts: 34 |

Looking at the photo posted I had a good laugh. Such un-necessary complications.

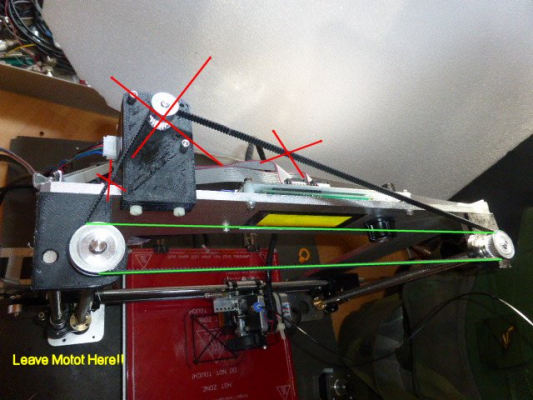

Why not leave the single Z motor in its mount below and connect the belt as shown?

After all this is a simple 3D printer, not a car.

http://forums.reprap.org/read.php?4,560469,560469

Edited 1 time(s). Last edit at 03/14/2016 08:15PM by bernbout.

Why not leave the single Z motor in its mount below and connect the belt as shown?

After all this is a simple 3D printer, not a car.

http://forums.reprap.org/read.php?4,560469,560469

Edited 1 time(s). Last edit at 03/14/2016 08:15PM by bernbout.

|

Anonymous User

Re: Geeetech-Aluminum-Prusa-I3 March 15, 2016 04:43AM |

Quote

bernbout

Looking at the photo posted I had a good laugh. Such un-necessary complications.

Why not leave the single Z motor in its mount below and connect the belt as shown?

After all this is a simple 3D printer, not a car.

http://forums.reprap.org/read.php?4,560469,560469

The answer is partially in the thread you refer to plus the basic error that you do not have any way to properly tension the belt and you need to be lucky to find the right belt length or build one which most can't even do !

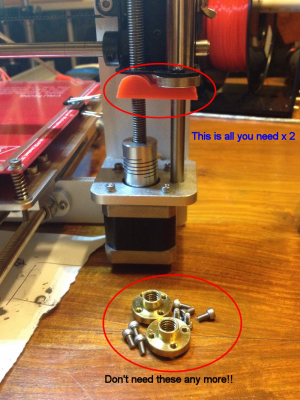

A proper design would call for a way to adjust the tension, usually an idler pulley. So what about having the driving pulley/motor perform this purpose ? It is what I did. And I got rid of the flexible coupler too ! Flexible couplers are often a way to alleviate a poor design / build BTW.

And what about wobbling with your motor plus nut plus ball bearing at the top ? Lucky there is a flexible coupler.

How is the weight applied via the lead screw ? Against the motor, the top bearing ???

In my approach, the two lead screws work the same way, just pull the X carriage and won't shake it !

BTW, everybody think at first as you did, it is obvious. The point is sometime you have to think past the obvious.

Edited 1 time(s). Last edit at 03/15/2016 06:19AM by MKSA.

|

Re: Geeetech-Aluminum-Prusa-I3 March 17, 2016 02:49AM |

Registered: 8 years ago Posts: 34 |

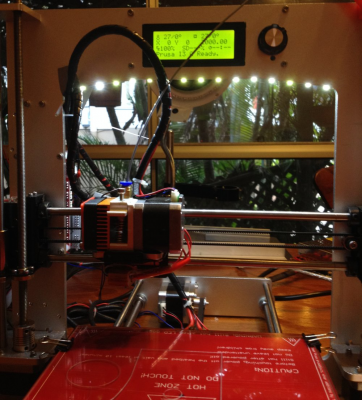

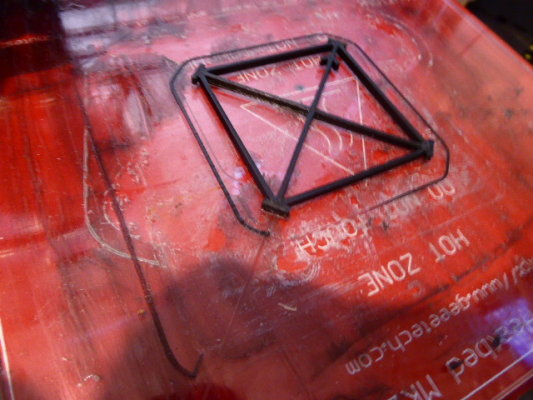

Just a simple mod. I got this strip of 12v LED's from China and stuck it to the edge of the printer frame. Wired it into the fan socket in parallel and Bob's your uncle. Now everything is well lit, including the print.

|

Anonymous User

Re: Geeetech-Aluminum-Prusa-I3 March 22, 2016 11:58AM |

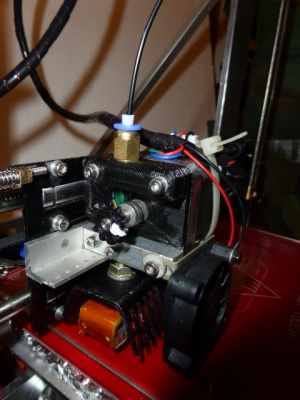

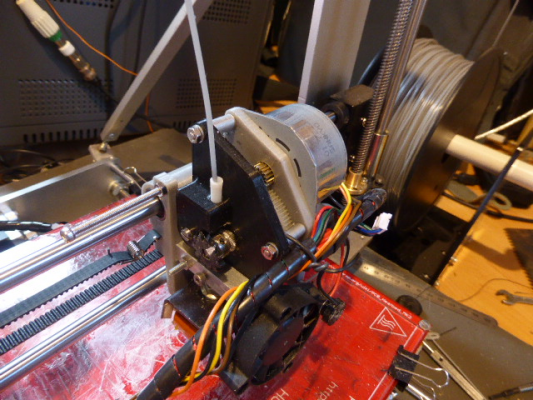

As said earlier, I didn't like much this MK8 extruder. Brass gear that didn't grip the filament, cumbersome to disassemble, no visibility of the filament, hotend you can't remove without dismounting everything, not rigid .... So I got rid of all these extra parts and only kept, for the time being, the fan and the hotend, which I modified to have a real thermal barrier.

To end up with this:

One screw to remove the hotend, two butterfly nuts to remove the whole assy.

To end up with this:

One screw to remove the hotend, two butterfly nuts to remove the whole assy.

|

Anonymous User

Re: Geeetech-Aluminum-Prusa-I3 March 24, 2016 05:12AM |

Just received and installed the new Y axis rods I mentioned earlier. These are quite good and pair well with the linear bearing SCS8UU. No more vibration due to excessive play.

I wonder why Geetech doesn't supply these. To save just a few bucks ? Or may be considering these require good alignment as they are more prone to bind and seize if not installed properly.

The majority of builders lacking the required skills, this could lead to more call to their helpline if not complains ?

Let's face it, a majority of these "imported" and even "western" printer kits are not superb in term of quality, workmanship, design, yet most of the issues are due to their users.

As we says: No matter how you design a product to be fool proof, a better fool will rise.

OK now let's print other parts than printer parts

Edited 1 time(s). Last edit at 03/24/2016 05:13AM by MKSA.

I wonder why Geetech doesn't supply these. To save just a few bucks ? Or may be considering these require good alignment as they are more prone to bind and seize if not installed properly.

The majority of builders lacking the required skills, this could lead to more call to their helpline if not complains ?

Let's face it, a majority of these "imported" and even "western" printer kits are not superb in term of quality, workmanship, design, yet most of the issues are due to their users.

As we says: No matter how you design a product to be fool proof, a better fool will rise.

OK now let's print other parts than printer parts

Edited 1 time(s). Last edit at 03/24/2016 05:13AM by MKSA.

|

Re: Geeetech-Aluminum-Prusa-I3 March 25, 2016 10:41AM |

Registered: 12 years ago Posts: 13 |

Few comments:

- talking about the ABL, don't forget that Repetier Firmware (at least) now supports also the Distortion Correction. It measures a grid and creates height map. Then it follows it for the first layers and slowly decreases the correction. Just FYI.

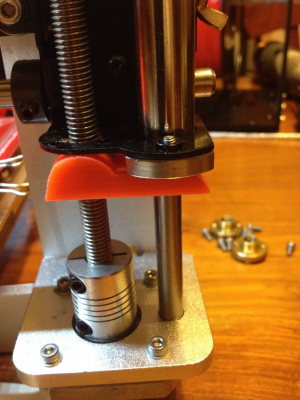

- using two Z motors in series I see no issue while they are on. As soon as they are released, the X carriage under own weight may go down on any side, and it depends on the X position it stays, and even on did you touch the head by hand or not. Just try and see that it is a real problem. To fight with that I put markers on couplers to make them oriented in the same direction. If I see them diverted, I had to move them by hand. Quite annoying.

- talking about the ABL, don't forget that Repetier Firmware (at least) now supports also the Distortion Correction. It measures a grid and creates height map. Then it follows it for the first layers and slowly decreases the correction. Just FYI.

- using two Z motors in series I see no issue while they are on. As soon as they are released, the X carriage under own weight may go down on any side, and it depends on the X position it stays, and even on did you touch the head by hand or not. Just try and see that it is a real problem. To fight with that I put markers on couplers to make them oriented in the same direction. If I see them diverted, I had to move them by hand. Quite annoying.

|

Re: Geeetech-Aluminum-Prusa-I3 March 25, 2016 03:26PM |

Registered: 8 years ago Posts: 15 |

So I printed out bernbout's Z axis anti-wobble brackets. This totally eliminated the small Z-wobble that I was getting in my prints. Thanks bernbout!

Z Axis brackets

I had read a lot about eliminating Z-wobble but hadn't yet determined how I wanted to address it. This bracket fixed it for me. I know, there are probably backlash issues, etc, but the walls of prints are now amazingly smooth.

Z Axis brackets

I had read a lot about eliminating Z-wobble but hadn't yet determined how I wanted to address it. This bracket fixed it for me. I know, there are probably backlash issues, etc, but the walls of prints are now amazingly smooth.

|

Anonymous User

Re: Geeetech-Aluminum-Prusa-I3 March 30, 2016 01:19AM |

Quote

stratosonic

So I printed out bernbout's Z axis anti-wobble brackets. This totally eliminated the small Z-wobble that I was getting in my prints. Thanks bernbout!

Z Axis brackets

I had read a lot about eliminating Z-wobble but hadn't yet determined how I wanted to address it. This bracket fixed it for me. I know, there are probably backlash issues, etc, but the walls of prints are now amazingly smooth.

An other example of what I mentioned, add something to hide a problem instead of simply getting rid of the problem by a proper design/build

The link you gave shows exactly how one can build things the wrong way.

Edited 2 time(s). Last edit at 03/30/2016 01:39AM by MKSA.

|

Anonymous User

Re: Geeetech-Aluminum-Prusa-I3 March 30, 2016 01:36AM |

Quote

osnwt

Few comments:

- talking about the ABL, don't forget that Repetier Firmware (at least) now supports also the Distortion Correction. It measures a grid and creates height map. Then it follows it for the first layers and slowly decreases the correction. Just FYI.

- using two Z motors in series I see no issue while they are on. As soon as they are released, the X carriage under own weight may go down on any side, and it depends on the X position it stays, and even on did you touch the head by hand or not. Just try and see that it is a real problem. To fight with that I put markers on couplers to make them oriented in the same direction. If I see them diverted, I had to move them by hand. Quite annoying.

-I maintain, no need for ABL on a proper built/designed cartesian machine. Fine if not a must for scalar machines due to their kinematic. Besides most of the system to probe the level are unsuitable if not crappy. I have yet to see any specs from their proponent, in term of REAL accuracy.

- there is NO issue in having the two steppers in series because IT IS THE WAY to wire two steppers in the case of Prusa 2 screw/ 2 motors. Yet the best is to have ONE stepper, so NO out of synch !

Thank for confirming that the two motors get out of synch as it seems there are still people questioning that fact. It is why I modified my Geetech as above.

|

Re: Geeetech-Aluminum-Prusa-I3 March 30, 2016 03:19PM |

Registered: 8 years ago Posts: 34 |

Quote

stratosonic

So I printed out bernbout's Z axis anti-wobble brackets. This totally eliminated the small Z-wobble that I was getting in my prints. Thanks bernbout!

Z Axis brackets

I had read a lot about eliminating Z-wobble but hadn't yet determined how I wanted to address it. This bracket fixed it for me. I know, there are probably backlash issues, etc, but the walls of prints are now amazingly smooth.

Yes. Despite what Know-it-all says this does work. Such a simple print and such BIG difference. Now I have no need to waste money buying T8 rods and conversion to one motor. All this is unnecessary for just 8 minutes of printing.

I want to state here that the original author of this mod, Jimmy Shaw has a video here, and you just need to watch the last 5 minutes of it to see why this is needed. I took his design and re-made it hi-res for a better print, as his was done on Tinkercad and the round part was not really round.

For those who want to and should do this mod, here are some photos of how it should be done.

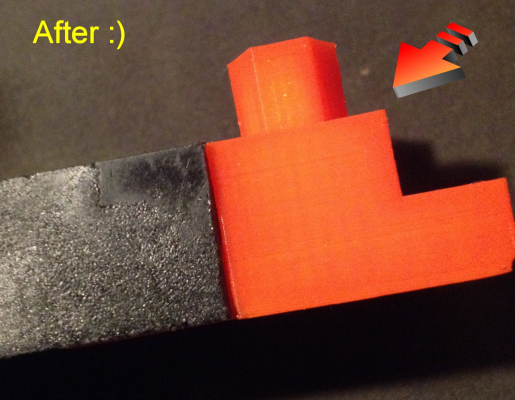

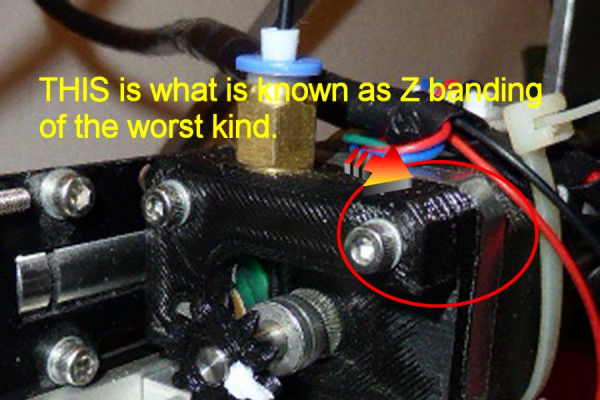

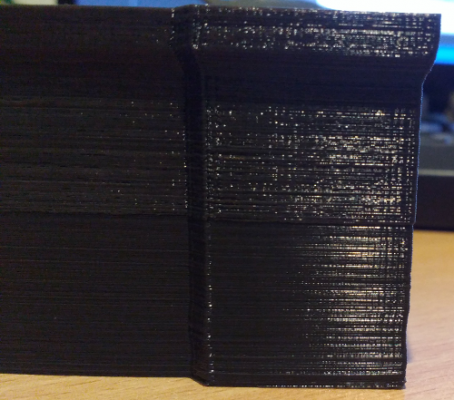

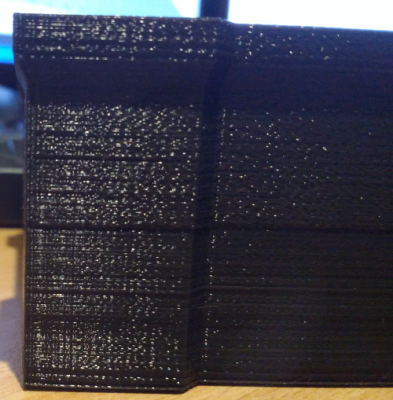

Before the mod. Notice the Z banding that is EXACTLY the threads of the M8 threaded rod?

After the mod.

No banding at all. The black bit is an injection moulded part of a tool for which I made an adapter. The RED is the part with no Z banding at all.

Zoom in to see the difference clearly.

Am I pleased? You bet. Best thing I ever printed.

|

Re: Geeetech-Aluminum-Prusa-I3 March 30, 2016 03:27PM |

Registered: 8 years ago Posts: 34 |

Quote

MKSA

Quote

stratosonic

So I printed out bernbout's Z axis anti-wobble brackets. This totally eliminated the small Z-wobble that I was getting in my prints. Thanks bernbout!

Z Axis brackets

I had read a lot about eliminating Z-wobble but hadn't yet determined how I wanted to address it. This bracket fixed it for me. I know, there are probably backlash issues, etc, but the walls of prints are now amazingly smooth.

An other example of what I mentioned, add something to hide a problem instead of simply getting rid of the problem by a proper design/build

The link you gave shows exactly how one can build things the wrong way.

Sorry your expensive and complicated mods did not produce the desired result.

I am happy that I have completely eliminated Z banding and am able to produce smoooooooth prints while yours still look terrible.

Anyway lets see some prints that you have done after your mods. After all the proof of the pudding is in the eating and so far there is nothing to see other than this example:

Edited 1 time(s). Last edit at 03/30/2016 03:46PM by bernbout.

|

Anonymous User

Re: Geeetech-Aluminum-Prusa-I3 March 31, 2016 11:25AM |

Quote

bernbout

Quote

MKSA

Quote

stratosonic

So I printed out bernbout's Z axis anti-wobble brackets. This totally eliminated the small Z-wobble that I was getting in my prints. Thanks bernbout!

Z Axis brackets

I had read a lot about eliminating Z-wobble but hadn't yet determined how I wanted to address it. This bracket fixed it for me. I know, there are probably backlash issues, etc, but the walls of prints are now amazingly smooth.

An other example of what I mentioned, add something to hide a problem instead of simply getting rid of the problem by a proper design/build

The link you gave shows exactly how one can build things the wrong way.

Sorry your expensive and complicated mods did not produce the desired result.

I am happy that I have completely eliminated Z banding and am able to produce smoooooooth prints while yours still look terrible.

Anyway lets see some prints that you have done after your mods. After all the proof of the pudding is in the eating and so far there is nothing to see other than this example:

[attachment 75641 Image1.jpg]

Don't worry, this part has been made before I modified the printer with a proper T8 leadscrew and unique Z motor. I made one since in ABS.

Thanks for teaching me a new expression " Z banding", I have been playing with these cheap 3D printer for only 6 weeks now.

For the rest, sorry but if I will pass on your "improvements", even the best one, the "Christmas decoration". You have a future there, not in engineering.

|

Re: Geeetech-Aluminum-Prusa-I3 March 31, 2016 12:01PM |

Registered: 8 years ago Posts: 15 |

For a great explanation of Z wobble (or z banding, there are many names for this), take a look at this link. Essentially it boils down to the lead screw is transferring movement to the guide rods. The lead screws should be allowed to float. In this printer, the flexible coupler is supposed to allow for this but it doesn't provide enough freedom. It might be possible to enlarge the hole that constrains the lead screw at the top but the brackets are a simpler fix.

Obviously there are differing opinions here as to the best solution and that is ok. Each design has trade offs. All I can go with is my experience and knowledge of how my print results have improved with minimal work.

Obviously there are differing opinions here as to the best solution and that is ok. Each design has trade offs. All I can go with is my experience and knowledge of how my print results have improved with minimal work.

|

Re: Geeetech-Aluminum-Prusa-I3 April 02, 2016 09:19PM |

Registered: 8 years ago Posts: 34 |

Seem like some people are ignorant about certain terms used. Here is an explanation.

|

Re: Geeetech-Aluminum-Prusa-I3 April 04, 2016 12:21AM |

Registered: 8 years ago Posts: 34 |

Quote

stratosonic

... I know, there are probably backlash issues, etc, but the walls of prints are now amazingly smooth.

Re: your comment on backlash.

As per the Reprap Wiki - Backlash

"Backlash is an effect caused by "slop" (too much freedom of movement, or too little constraint) in a mechanical drive system, leading to small discrepancies in positioning at points where axes reverse direction"

Now this can occur and does on the X and Y, especially for small parts when the head changes (reverses) direction abruptly, but for the Z axis, the only direction it is going is UP. During printing, the Z axis never goes down - there is no change of direction at all, unless you use ABL and we do not as yet use that.

However there is an abrupt stop every time it moves up per layer though this is extremely extremely minimal as you have seen with the vast improvement in the print surface with the Z axis mod.

So the only effect is "JERK" when the Z axis stops moving up which can be adjusted in Marlin if needed.

I am looking at installing a spring to "load" the top of the X axis bracket onto the printed mod. This will allow the X axis to "float", provided the spring is not too tight on the bracket and will eliminate any Z backlash, if any. Will let you know how I go with this.

.

Edited 1 time(s). Last edit at 04/04/2016 12:23AM by bernbout.

|

Anonymous User

Re: Geeetech-Aluminum-Prusa-I3 April 15, 2016 05:20AM |

While testing to print at 200% and more playing with the Fr, I noticed the extruder stepper was not able to keep up, missing steps.

My extruder is able to pull 5daN (PU idler plus tempered steel hobbed gear giving me more than 4 times the MK8 grip) before stripping the filament.

So let's have a look at the torque adj.

Fact is, the A4988 driver was set to deliver 0.5A and worse, Geetech supplies the 1A model, not the 1.5A ! See here: StepStick

Luckily, I had ordered and just received a few spare A4988 which are able to deliver 1.5A.

I replaced it, adjust for 1A and "voila". I tried to extrude with the print head squeezing a sheet of paper against the bed, and no problem, it extrudes.

Note, the only "original" part left is the hotend. OK for PLA and even with ABS on the few tests I made.

Will have to look at the cooling fan. Nopehead here has made an interesting study about it.

So far, no issue with X,Y,Z even set to 0.5A. My print head is light compared to most direct drive. I am more concerned about the Y as it has to move the bed. A weakness of the Prusa/Mendel design.

Even if not the best design and not the best parts supplied by Geetech, fact is that with a few properly done improvements, these Prusa machines are usable, the quality one can achieve is quite decent for an hard to beat price, and easy to setup.

I don't regret my purchase.

I wanted to post a short video of a test print done at 300% Fr but can't do it directly right now.

Quality is still OK. No step loss, the "clunks" I can hear sometimes are because the head hitting blobs as I notice a bit of overextrusion.

My extruder is able to pull 5daN (PU idler plus tempered steel hobbed gear giving me more than 4 times the MK8 grip) before stripping the filament.

So let's have a look at the torque adj.

Fact is, the A4988 driver was set to deliver 0.5A and worse, Geetech supplies the 1A model, not the 1.5A ! See here: StepStick

Luckily, I had ordered and just received a few spare A4988 which are able to deliver 1.5A.

I replaced it, adjust for 1A and "voila". I tried to extrude with the print head squeezing a sheet of paper against the bed, and no problem, it extrudes.

Note, the only "original" part left is the hotend. OK for PLA and even with ABS on the few tests I made.

Will have to look at the cooling fan. Nopehead here has made an interesting study about it.

So far, no issue with X,Y,Z even set to 0.5A. My print head is light compared to most direct drive. I am more concerned about the Y as it has to move the bed. A weakness of the Prusa/Mendel design.

Even if not the best design and not the best parts supplied by Geetech, fact is that with a few properly done improvements, these Prusa machines are usable, the quality one can achieve is quite decent for an hard to beat price, and easy to setup.

I don't regret my purchase.

I wanted to post a short video of a test print done at 300% Fr but can't do it directly right now.

Quality is still OK. No step loss, the "clunks" I can hear sometimes are because the head hitting blobs as I notice a bit of overextrusion.

|

Anonymous User

Re: Geeetech-Aluminum-Prusa-I3 April 17, 2016 09:39AM |

Here is the video shortened but not accelerated !

Square_cal Fr 300%

Funny but the sound got lost after a while.

Note it is PLA. 0.2mm layer

Edited 2 time(s). Last edit at 04/17/2016 09:48AM by MKSA.

Square_cal Fr 300%

Funny but the sound got lost after a while.

Note it is PLA. 0.2mm layer

Edited 2 time(s). Last edit at 04/17/2016 09:48AM by MKSA.

|

Anonymous User

Re: Geeetech-Aluminum-Prusa-I3 April 26, 2016 12:03PM |

The extrusion being now the limiting factor, I designed a new extruder, a lot lighter while keeping the same qualities in term of torque and filament grip.

Details in the discussion: 100gr extruder

Just rerun the test at 3 times the standard Prusa I3 speed.

Light Extruder. Fr 300%

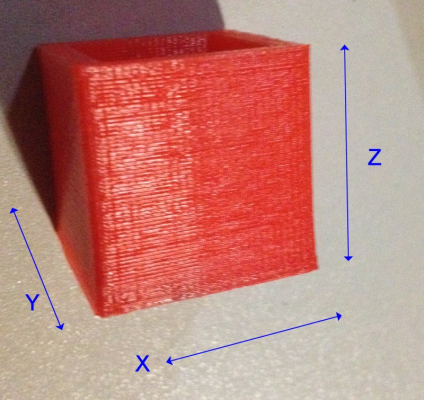

Result, Square Cal, Fr x 3

New extruder frame, (printed at 100mm/s) to move gravity center closer to guides with same holes spacing as NEMA17.

Details in the discussion: 100gr extruder

Just rerun the test at 3 times the standard Prusa I3 speed.

Light Extruder. Fr 300%

Result, Square Cal, Fr x 3

New extruder frame, (printed at 100mm/s) to move gravity center closer to guides with same holes spacing as NEMA17.

|

Anonymous User

Re: Geeetech-Aluminum-Prusa-I3 April 29, 2016 02:42AM |

To further gain weight, I designed a new carriage and moved the gravity center of the extruder closer to the guides and better centered. 100g less !

So from the original MK8 plus carriage 650g, I am now down to 280g.

To gain more requires a new kind of motor, an other time so.

The hotend, still the one supplied, needs some attention now. Moving speed is great but quality extrusion has to follow.

The Y axis should shed some weight too but so far, as I can print at 120mm/s (twice the speed the printer was set for) with good results, 180mm/s for prototyping, it will wait.

The Y moving bed is a major drawback of the Prusa design if we aim for speed. Not a blame as it is a trade off for simplicity.

Edited 2 time(s). Last edit at 04/30/2016 08:45AM by MKSA.

So from the original MK8 plus carriage 650g, I am now down to 280g.

To gain more requires a new kind of motor, an other time so.

The hotend, still the one supplied, needs some attention now. Moving speed is great but quality extrusion has to follow.

The Y axis should shed some weight too but so far, as I can print at 120mm/s (twice the speed the printer was set for) with good results, 180mm/s for prototyping, it will wait.

The Y moving bed is a major drawback of the Prusa design if we aim for speed. Not a blame as it is a trade off for simplicity.

Edited 2 time(s). Last edit at 04/30/2016 08:45AM by MKSA.

|

Re: Geeetech-Aluminum-Prusa-I3 May 03, 2016 12:23AM |

Registered: 8 years ago Posts: 5 |

I am having an issue where it seems my x-axis is curling as the z-axis goes up.

It is very slight but noticeable.

I am using bernbout mod for z banding so I am think my threaded rod is still hitting my x-axis carriage.

I'll upload a picture later of a print and my setup later as I am at work.

Does anyone have some steps I could go through to troubleshoot the issue?

It is very slight but noticeable.

I am using bernbout mod for z banding so I am think my threaded rod is still hitting my x-axis carriage.

I'll upload a picture later of a print and my setup later as I am at work.

Does anyone have some steps I could go through to troubleshoot the issue?

|

Anonymous User

Re: Geeetech-Aluminum-Prusa-I3 May 03, 2016 06:34AM |

Quote

F91W

I am having an issue where it seems my x-axis is curling as the z-axis goes up.

It is very slight but noticeable.

I am using bernbout mod for z banding so I am think my threaded rod is still hitting my x-axis carriage.

I'll upload a picture later of a print and my setup later as I am at work.

Does anyone have some steps I could go through to troubleshoot the issue?

If you don't use proper solution, don't be surprised to get mediocre results.

Edited 1 time(s). Last edit at 05/03/2016 06:36AM by MKSA.

|

Re: Geeetech-Aluminum-Prusa-I3 May 03, 2016 07:48AM |

Registered: 8 years ago Posts: 5 |

I just want some help with my printer.

I am getting better results with the mod but if there is a better way I will happily do it.

Look forward to your answer!

Edit:

Adding images of the issue.

Sorry if potato quality.

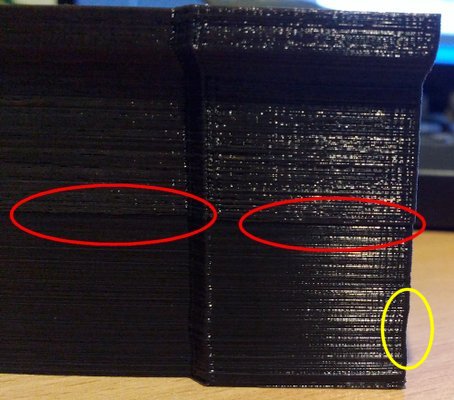

x-axis shifting

y-axis smooth

I am getting this fuzziness too as you can see

Edited 2 time(s). Last edit at 05/03/2016 08:13AM by F91W.

I am getting better results with the mod but if there is a better way I will happily do it.

Look forward to your answer!

Edit:

Adding images of the issue.

Sorry if potato quality.

x-axis shifting

y-axis smooth

I am getting this fuzziness too as you can see

Edited 2 time(s). Last edit at 05/03/2016 08:13AM by F91W.

|

Anonymous User

Re: Geeetech-Aluminum-Prusa-I3 May 03, 2016 09:16AM |

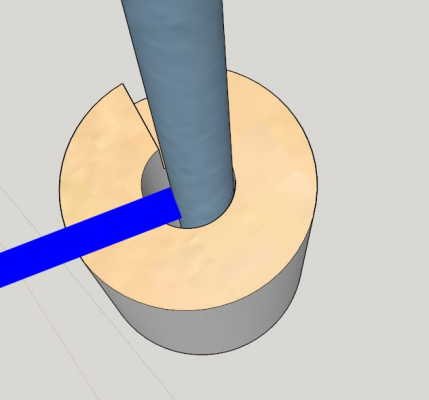

The "floating nut" you implemented is just a half way measure that doesn't address the basic problem, the use of a regular screw instead of a proper leadscrew. If you just replace these threaded rods (bent most of the time) by real lead screws (Tr8) and nut, and properly mount the flex, you will get far better results. These are straight and of the proper diam to fit the coupler, so minimal if at all wobble.

See what I did although you don't have to modify as much. Just that I wanted to get the most of my printer.

See what I did although you don't have to modify as much. Just that I wanted to get the most of my printer.

|

Re: Geeetech-Aluminum-Prusa-I3 May 03, 2016 12:27PM |

Registered: 8 years ago Posts: 34 |

Hi F91W

So your X axis is shifting.

At the outset let me make it clear that I am a hobbist 3D Printer and make no pretensions of being a SAMK (Split-Ass-Mechanik). I understand that you have come here because you have a problem and do not want to be treated like a child with a "I told you so" crappy attitude.

Ok so your prints have improved after the mod. Mine were great before and now the Z axis has totally smoothed out. Photos and light angles do not give the quality justice. But here goes.

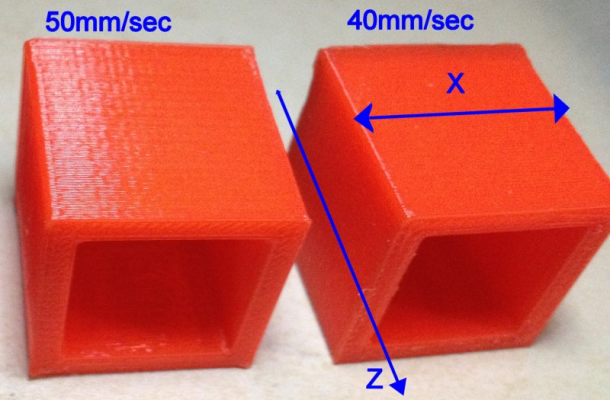

Here are a couple of prints of a 20mm cube I did as a test just yesterday. I did this because I had some feed problems with my extruder jamming and dismantled and cleaned up my extruder and nozzle and so did these prints. The results are self evident.

Both are @ 0.2mm layer resolution.

Remember this cube is only 20mm square. In real life you can hardly see any Z lines.

I see that there is some sort of edge movement in your print. You must realise that to get any proper solution, I must know exactly what you are seeing. It is difficult to express this in words but a picture = 1000 words I will try, with my limited experience, to assist you, but I need more info.

I will try, with my limited experience, to assist you, but I need more info.

Some Q.

1. How big is your model. In mm (X,Y,Z) please

2. Do you have the same printer (Geeetech Full Aluminium) or some other printer.

3. Can you post a photo of the X Axis where it joins the Y axis of your printer? Also post a photo of the corner of your object - The X/Y corner so it is easier to see the actual shift.

4. Is it this circled part in RED you are having the "shifting" problem with or is it the part in the Yellow highlihght?

Ok, it is well known that Threaded rods are not actually designed for this printing purpose and a Lead screw is better. In a lot of cases the T rod is slightly bent and being FIXED to the X axis the way it is, any wobble is transferred to the the X axis from the "wobble" of the Z axis. Secondly, the coupler, is not a proper fit and if that is not ABSOLUTELY vertical to the X axis, it will induce wobble into Z which gets transferred to the X.

To see this clearly, now that you have the mod in place, manually, using the software, raise the X axis in the Z direction by say 10mm and watch the plastic thingi you printed where it is screwed to the T rod. You will, in most cases, see it "dancing" around as the X axis rises. This is the Z wobble that gets transferred to the X axis and causes the lines in your print.

Given that you are usually printing @ 0.2 mm, even if your assembly is even slightly off, the result is Z wobble. My "fix" is just that - a fix to alleviate an otherwise severe design fault coupled with manufacturing faults.

From your photos you posted, it looks like you have a very SEVERE case of Z wobble, even with the mod in place, that has been alleviated some by the mod as even with the mod, your Z is not really smooth as it should be. This would be due to 1. bent rods 2. improper assembly (coupler)

Here's what I suggest you do:

1. Remove the Threaded rods and roll them on a glass surface slowly and lower your eye down to the glass level. You should be able to see if they are reasonably straight. If not, then try and straighten them out carefully without damaging the threads.

2. With the rods in place and straightened, take care that they are fixed vertically in the coupler. If you have the same printer as mine, then earlier in this thread I posted how and the sequence of tightening the coupler. If there is any play between the coupler and the rod, when you tighten the smaller screw to fix the coupler to the rod, it has a tendency, because of the flex design, to twist. It will tighten, but will not be perfectly vertical, having pushed the rod up against the other side of the coupler inner diameter. When at rest, the rod is now not vertical. Some of this the flex in the coupler takes care of and most the mod, but this is not good.

Of course do this on both sides.

So tighten the large screw first to reduce the inner dia. of the coupler. Then tighten the smaller screw just enough that it just about grips the rod without slipping. Now raise the X axis up and down a few times to "Settle" this and then tighten the screw fully, but TAKE CARE THAT THE coupler does not "flex" as it will as this will throw the T screw off the vertical when you stop tightening and the coupler "unflexes".

Now raise the X axis, and watch the joint. If there is a lot of wobble then the rods are not yet straight or not vertical or the coupler flexed etc. Loosen and try again. The X axis should ride up the T rod with the least amount of wobble noticeable for the mod to have any effect.

Now, as to the shifting, if your model prints up to a certain height correctly and then there is a "shift" and it continues to print in this shifted position, then this could be caused by some damage to the threads. One way to check is to print a vertical object like this one 20x50mmRect.stl

After printing, remove the object, move the STL object to a different area of the bed and reprint. Do this in about 3 or 4 places on your bed. Note the height where the "shift" in the model occurs on the X axis. If it happens to all the models at exactly the same height, then you know that there is something on either of the rods that is causing this shift. Measure how high up it happens and focus your attention on the Z rods at that height. Look for kinks or any thread damage.

See here the topic - Layer Shifting or Misalignment - [www.geeetech.com]

and also here - [support.3dverkstan.se]

Make getting new Lead screws your last resort. Provided they are actually absolutely straight, and provided you can recalculate and re-enter the new settings into your printer, you would still have to fix them VERTICALLY in your couplers. They will, if manufactured correctly, give a better performance that the current threaded rods but only if they are perfectly straight, and fixed vertically. You can start looking here:

[www.ebay.com.au] but get the best quality you can afford. For this printer you need 300mm x 2.

Just remember that just a difference of ONLY 0.5 degrees (1/2 degrees) off the vertical at the coupler end and the top of the 300mm Lead screw will be about 2.5mm off vertical that can adversely affect your prints, because this gives you a net wobble on the Z axis of about 5 mm. For a 0.2mm layer that is HUGE.

So will you get it absolutely vertical? Exactly @ 90 degrees to the X axis? Never. In your dreams. But you can get it as close as possible and then the Z wobble mod will do the rest.

Finally, if you are getting that same shift at exactly the same height on all models, then I suspect some imperfection in the threads of your Z rod. Check it. Fix it or replace it.

Come back here with your answers and any more questions. Happy to help and not criticize. If you succeed I would like to hear how you did that as well.

Cheers & Good luck.

Edited 1 time(s). Last edit at 05/03/2016 12:28PM by bernbout.

So your X axis is shifting.

At the outset let me make it clear that I am a hobbist 3D Printer and make no pretensions of being a SAMK (Split-Ass-Mechanik). I understand that you have come here because you have a problem and do not want to be treated like a child with a "I told you so" crappy attitude.

Ok so your prints have improved after the mod. Mine were great before and now the Z axis has totally smoothed out. Photos and light angles do not give the quality justice. But here goes.

Here are a couple of prints of a 20mm cube I did as a test just yesterday. I did this because I had some feed problems with my extruder jamming and dismantled and cleaned up my extruder and nozzle and so did these prints. The results are self evident.

Both are @ 0.2mm layer resolution.

Remember this cube is only 20mm square. In real life you can hardly see any Z lines.

I see that there is some sort of edge movement in your print. You must realise that to get any proper solution, I must know exactly what you are seeing. It is difficult to express this in words but a picture = 1000 words

I will try, with my limited experience, to assist you, but I need more info.

I will try, with my limited experience, to assist you, but I need more info.Some Q.

1. How big is your model. In mm (X,Y,Z) please

2. Do you have the same printer (Geeetech Full Aluminium) or some other printer.

3. Can you post a photo of the X Axis where it joins the Y axis of your printer? Also post a photo of the corner of your object - The X/Y corner so it is easier to see the actual shift.

4. Is it this circled part in RED you are having the "shifting" problem with or is it the part in the Yellow highlihght?

Ok, it is well known that Threaded rods are not actually designed for this printing purpose and a Lead screw is better. In a lot of cases the T rod is slightly bent and being FIXED to the X axis the way it is, any wobble is transferred to the the X axis from the "wobble" of the Z axis. Secondly, the coupler, is not a proper fit and if that is not ABSOLUTELY vertical to the X axis, it will induce wobble into Z which gets transferred to the X.

To see this clearly, now that you have the mod in place, manually, using the software, raise the X axis in the Z direction by say 10mm and watch the plastic thingi you printed where it is screwed to the T rod. You will, in most cases, see it "dancing" around as the X axis rises. This is the Z wobble that gets transferred to the X axis and causes the lines in your print.

Given that you are usually printing @ 0.2 mm, even if your assembly is even slightly off, the result is Z wobble. My "fix" is just that - a fix to alleviate an otherwise severe design fault coupled with manufacturing faults.

From your photos you posted, it looks like you have a very SEVERE case of Z wobble, even with the mod in place, that has been alleviated some by the mod as even with the mod, your Z is not really smooth as it should be. This would be due to 1. bent rods 2. improper assembly (coupler)

Here's what I suggest you do:

1. Remove the Threaded rods and roll them on a glass surface slowly and lower your eye down to the glass level. You should be able to see if they are reasonably straight. If not, then try and straighten them out carefully without damaging the threads.

2. With the rods in place and straightened, take care that they are fixed vertically in the coupler. If you have the same printer as mine, then earlier in this thread I posted how and the sequence of tightening the coupler. If there is any play between the coupler and the rod, when you tighten the smaller screw to fix the coupler to the rod, it has a tendency, because of the flex design, to twist. It will tighten, but will not be perfectly vertical, having pushed the rod up against the other side of the coupler inner diameter. When at rest, the rod is now not vertical. Some of this the flex in the coupler takes care of and most the mod, but this is not good.

Of course do this on both sides.

So tighten the large screw first to reduce the inner dia. of the coupler. Then tighten the smaller screw just enough that it just about grips the rod without slipping. Now raise the X axis up and down a few times to "Settle" this and then tighten the screw fully, but TAKE CARE THAT THE coupler does not "flex" as it will as this will throw the T screw off the vertical when you stop tightening and the coupler "unflexes".

Now raise the X axis, and watch the joint. If there is a lot of wobble then the rods are not yet straight or not vertical or the coupler flexed etc. Loosen and try again. The X axis should ride up the T rod with the least amount of wobble noticeable for the mod to have any effect.

Now, as to the shifting, if your model prints up to a certain height correctly and then there is a "shift" and it continues to print in this shifted position, then this could be caused by some damage to the threads. One way to check is to print a vertical object like this one 20x50mmRect.stl

After printing, remove the object, move the STL object to a different area of the bed and reprint. Do this in about 3 or 4 places on your bed. Note the height where the "shift" in the model occurs on the X axis. If it happens to all the models at exactly the same height, then you know that there is something on either of the rods that is causing this shift. Measure how high up it happens and focus your attention on the Z rods at that height. Look for kinks or any thread damage.

See here the topic - Layer Shifting or Misalignment - [www.geeetech.com]

and also here - [support.3dverkstan.se]

Make getting new Lead screws your last resort. Provided they are actually absolutely straight, and provided you can recalculate and re-enter the new settings into your printer, you would still have to fix them VERTICALLY in your couplers. They will, if manufactured correctly, give a better performance that the current threaded rods but only if they are perfectly straight, and fixed vertically. You can start looking here:

[www.ebay.com.au] but get the best quality you can afford. For this printer you need 300mm x 2.

Just remember that just a difference of ONLY 0.5 degrees (1/2 degrees) off the vertical at the coupler end and the top of the 300mm Lead screw will be about 2.5mm off vertical that can adversely affect your prints, because this gives you a net wobble on the Z axis of about 5 mm. For a 0.2mm layer that is HUGE.

So will you get it absolutely vertical? Exactly @ 90 degrees to the X axis? Never. In your dreams. But you can get it as close as possible and then the Z wobble mod will do the rest.

Finally, if you are getting that same shift at exactly the same height on all models, then I suspect some imperfection in the threads of your Z rod. Check it. Fix it or replace it.

Come back here with your answers and any more questions. Happy to help and not criticize. If you succeed I would like to hear how you did that as well.

Cheers & Good luck.

Edited 1 time(s). Last edit at 05/03/2016 12:28PM by bernbout.

|

Re: Geeetech-Aluminum-Prusa-I3 May 03, 2016 08:22PM |

Registered: 8 years ago Posts: 5 |

Thank you for your replies MKSA and bernbout.

Just as an FYI this is my first RepRap printer and I am fairly new to the community.

To answer your questions bernbout:

1. This is what I have printed - [www.thingiverse.com]

2. I have the Geeetech Full Aluminum - v2 I think as there is only one printed part.

3. I'll do this once I am home.

4. Well both. The yellow was what I was concerned with first as the red I think is caused by vibrations from the threaded rod clipping the holder.

I did purchase a new threaded rod set from the local hardware store as the ones that came with the printer where bent. Now that I know about the lead screws that is looking like a good option. Is it safe to buy them from china or is it worth the extra money to buy them local?

From what you have said bernbout, I have not followed the correct procedure on coupler. I tightened the large screw first but I did not alternate with the small screw as I got tighter to prevent bending of the coupler. I did lift the rod about 2mm before tightening though.

Edited 1 time(s). Last edit at 05/03/2016 11:09PM by F91W.

Just as an FYI this is my first RepRap printer and I am fairly new to the community.

To answer your questions bernbout:

1. This is what I have printed - [www.thingiverse.com]

2. I have the Geeetech Full Aluminum - v2 I think as there is only one printed part.

3. I'll do this once I am home.

4. Well both. The yellow was what I was concerned with first as the red I think is caused by vibrations from the threaded rod clipping the holder.

I did purchase a new threaded rod set from the local hardware store as the ones that came with the printer where bent. Now that I know about the lead screws that is looking like a good option. Is it safe to buy them from china or is it worth the extra money to buy them local?

From what you have said bernbout, I have not followed the correct procedure on coupler. I tightened the large screw first but I did not alternate with the small screw as I got tighter to prevent bending of the coupler. I did lift the rod about 2mm before tightening though.

Edited 1 time(s). Last edit at 05/03/2016 11:09PM by F91W.

|

Anonymous User

Re: Geeetech-Aluminum-Prusa-I3 May 04, 2016 03:46AM |

Quote

F91W

Thank you for your replies MKSA and bernbout.

Just as an FYI this is my first RepRap printer and I am fairly new to the community.

To answer your questions bernbout:

1. This is what I have printed - [www.thingiverse.com]

2. I have the Geeetech Full Aluminum - v2 I think as there is only one printed part.

3. I'll do this once I am home.

4. Well both. The yellow was what I was concerned with first as the red I think is caused by vibrations from the threaded rod clipping the holder.

I did purchase a new threaded rod set from the local hardware store as the ones that came with the printer where bent. Now that I know about the lead screws that is looking like a good option. Is it safe to buy them from china or is it worth the extra money to buy them local?

From what you have said bernbout, I have not followed the correct procedure on coupler. I tightened the large screw first but I did not alternate with the small screw as I got tighter to prevent bending of the coupler. I did lift the rod about 2mm before tightening though.

Get real Tr8 lead screws, they are really 8mm diam. You will never get perfect alignment with the coupler and M8 threaded rod (7.8mm diam) which are to hold things together, NOT move them. You can buy them locally or from China, but in this case, you never know. I did it and got the right stuff.

As for the coupler, you have to thighten the big screw that will squeeze the rod and align it somewhat (these couplers are OK here though), the grub screw is not even necessary on the Tr8 side. A grub screw will always misalign the parts, so tolerances have to be tight in order to prevent this. You DON'T alternate the big screw and the grub screw !!!

Slight misalignment will be taken care of by the flexible couplers (it is why they are flexible) and the vertical linear guides which are there to prevent all movement but the vertical one. Make sure there is no play there.

Note that the lateral play of the lead screw nut allows small misalignment too (in fact the part you printed does just that !) and because the nature of the Z movement doesn't require antibacklash, don't install one !

Sad to say, but the majority of people giving advices on forum don't know much, often devise irrelevant if not complex solutions to alleviate problems without first trying to reduce if not eliminate them !

Have a look at how real machines are made by professionals, from a CD Rom drive, printer to a lathe, CNC ....

|

Re: Geeetech-Aluminum-Prusa-I3 May 04, 2016 08:12AM |

Registered: 8 years ago Posts: 5 |

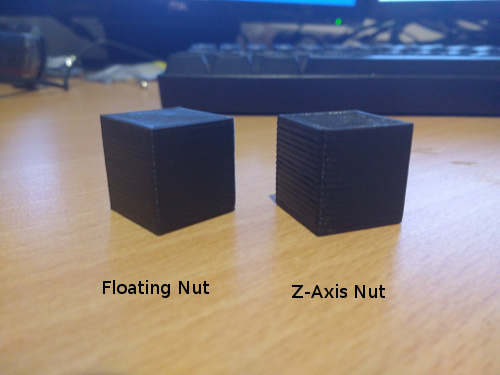

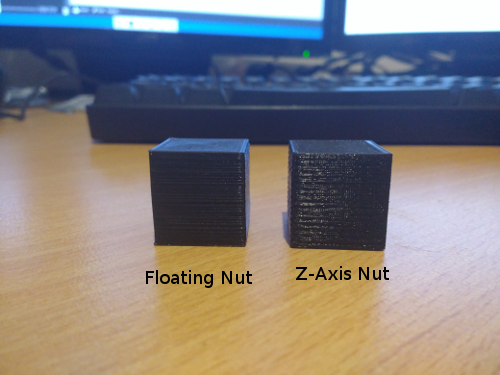

Ok so what I have done so far is I reseated the thread rod once with the 'Floating Nut' and once with the 'Z-Axis Nut'. When resetting I made sure not to tighten the small screw and I made sure that the coupler was working as a spring.

Printing a 20mm Hollow cube for each reseat (I just had it already downloaded).

It is hard to tell with the image but the 'Z-Axis Nut' is more square but has the 'Z Banding'.

The 'Floating Nut' is smoother but X-Axis is swayed and shifted (Worse on the first few Z-Levels).

If getting a 'Lead Screw' would remove the banding I would rather go for that approach as the 'Z-Axis Nut' is more square.

I am sorry if I have missed any instructions in your replies.

Printing a 20mm Hollow cube for each reseat (I just had it already downloaded).

It is hard to tell with the image but the 'Z-Axis Nut' is more square but has the 'Z Banding'.

The 'Floating Nut' is smoother but X-Axis is swayed and shifted (Worse on the first few Z-Levels).

If getting a 'Lead Screw' would remove the banding I would rather go for that approach as the 'Z-Axis Nut' is more square.

I am sorry if I have missed any instructions in your replies.

|

Re: Geeetech-Aluminum-Prusa-I3 May 21, 2016 06:55PM |

Registered: 8 years ago Posts: 5 |

I just wanted to give an update.

I have yet to get my lead screws but I was able to resolve my wobble issue. My problem was twofold 1) The X belt was rubbing inside the X carriage 2) The X Belt was way to tight.

Once I fixed these two things I am printing without shifts. I still have the Z-Wobble though but now I can print parts that are strait.

EDIT

Until my lead screws come I thought I would try bernbout Z-Wobble mod again. I am getting very good prints now. No banding!

Thanks for the help.

Edited 1 time(s). Last edit at 05/22/2016 06:42AM by F91W.

I have yet to get my lead screws but I was able to resolve my wobble issue. My problem was twofold 1) The X belt was rubbing inside the X carriage 2) The X Belt was way to tight.

Once I fixed these two things I am printing without shifts. I still have the Z-Wobble though but now I can print parts that are strait.

EDIT

Until my lead screws come I thought I would try bernbout Z-Wobble mod again. I am getting very good prints now. No banding!

Thanks for the help.

Edited 1 time(s). Last edit at 05/22/2016 06:42AM by F91W.

|

Re: Geeetech-Aluminum-Prusa-I3 May 09, 2017 10:00PM |

Registered: 6 years ago Posts: 11 |

|

Re: Geeetech-Aluminum-Prusa-I3 May 10, 2017 12:13AM |

Registered: 8 years ago Posts: 34 |

Sorry, only registered users may post in this forum.