Mendel

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

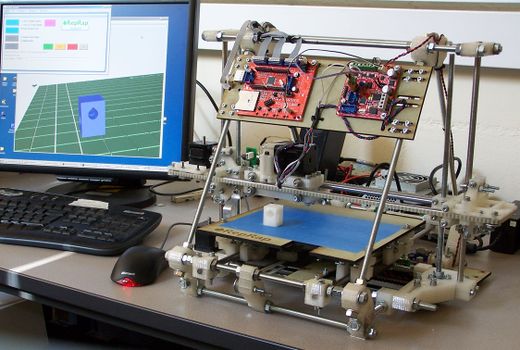

| The machine on the right is the RepRap printer, which we call "Mendel" after the father of genetics. It's the second, improved version of RepRap: small enough to fit on your desk, but with a print volume large enough for you to make big things (see specifications below). The machine is made up of bits bought in from local suppliers or online, and parts which it can make for itself - all the translucent structural components you can see.

In the picture, behind the machine, you can see the RepRap software which you can use to print your thing. We give this, and the designs for the machine away, free - it's all open source (GPL 2). Though you do have to buy in some standard components from... well, whoever you want... which cost about €400. The idea of getting all the materials and building a machine yourself may seem daunting, but this area of the wiki is dedicated to making the whole process as easy as possible. Click a "How To ...." link above for building and using tips and more.... There are a number of instructional videos distributed through the Mendel documentation. These are also all gathered together in one place here. You can see examples of people's Mendels, and where they got their parts at Mendel Source Logs. |

Mendel Specifications

The table below outlines the specifications of the machine.

| Metric | US imperial | |

|---|---|---|

| Manufacturer | RepRap (or anyone who wants...) | |

| Model | Mendel | |

| Technology | FFF (Fused Filament Fabrication)/Thermoplastic extrusion | |

| Price of all materials | €400 | $520 |

| Annual Service Cost | Occasional oiling = €5. It can print its own replacement printed parts at material cost. | Occasional oiling = $8. It can print its own replacement printed parts at material cost. |

| Size | 500 mm (W) x 400 mm (D) x 360 mm (H) | 20” (W) x 16” (D) x 14” (H) |

| Weight | 7.0 kg | 15.5 pounds |

| Build Envelope | 200 mm (W) x 200 mm (D) x 140 mm (H) | 8” (W) x 8” (D) x 5.5” (H) |

| Materials | PLA, HDPE, ABS & more. Uses ø 3 mm filament. | PLA, HDPE, ABS & more. Uses ø 1/8” filament. |

| Material Cost | PLA: €22/kg, HDPE: €11/kg, ABS: €17/kg | PLA: $14/lb, HDPE: $7/lb, ABS: $10/lb |

| Speed | 15.0 cm3 per hour solid (test done for PLA, similar for others). Maximum X and Y axis speed of 725mm/s. | 0.92 inch3 per hour solid (test done for PLA, similar for others) |

| Accuracy | Diameter of nozzle 0.5 mm, 2 mm min. feature size, 0.1 mm positioning accuracy, layer thickness 0.3 mm | Diameter of nozzle 0.020”, 0.080” min. feature size, 0.004" positioning accuracy, layer thickness 0.012” |

| Finish | Fair | |

| Volume of printed parts to replicate | 1110 cm3 | 67.7 inches3 |

(With the standard infill settings the 15.0 cm3 per hour solid extrusion rate is equivalent to a built volume rate of 19.0 cm3 per hour.)

Mendel vs. Darwin

Mendel is the second RepRap machine. Mendel supersedes the first version, which we call Darwin. RepRap Version I "Darwin" instructions

Ed Sells, a student of Dr. Adrian Bowyer, designed and built the first Mendel printer, sometimes called a "Sells Mendel" to distinguish the original design from later tweaks.

It has the following key improvements over Darwin:

- Bigger print area, smaller machine footprint

- Improved constraint on the z-axis to eliminate jamming

- Better axis efficiency

- Simpler assembly

- Capacity for tool changing (to follow very shortly)

- Lighter and more portable

This video illustrates these improvements:

For a numerical comparison see this blog post.