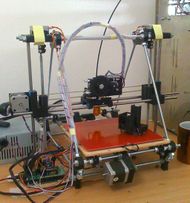

Prusa Mendel (iteration 2)

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Release status: working

Contents

Introduction

The Prusa Mendel Iteration 2 is an improvement of the Prusa Mendel (iteration 1), and was released in November 2011. This version precedes a third iteration (i3) which can be found here: Prusa i3

Dimensions

The external dimensions of the Prusa Mendel Iteration 2 are approximately 44x47x37 cm.

Main improvements

The following is a list of the main improvements made on the original Prusa

- More parts are made to be push-fit

- The carriages accommodate bushings and linear bearings

- Nut traps were added to parts that were attached with M3 screws (e.g. endstop holders etc.)

- The second bed plate was removed (The PCB heatbed is the second plate)

- The belts were changed to GT2 belts - it is recommended to buy machined belt pulleys

- Most M4 screws were changed to M3s

- A printed plastic belt guide was designed to replace the large M8x30 fender washers

- The belt clamp was redesigned

Development

The development of the Prusa Mendel is hosted on github: http://github.com/prusajr/PrusaMendel.

History

- Iteration 2 announcement

- This page by Gary Hodgson shows the differences between the original Prusa and Iteration 2

Printed Parts

Printing Prusa Mendel Iteration 2

Download the parts using the github link below, then print the parts you require. Note that the "metric-prusa" folder contains parts for a brass-bushing printer, whereas metric-prusa-lm8uu contains a parts for the LM8UU version. Don't make the mistake of printing the wrong idlers/carriages only to have to print them again.

The Greg Frost Accessible Extruder contained within the repository will not fit your bolts and nuts correctly! Download and print from [Thingiverse Greg's Hinged Accesible Extruder]

Parts

The [Github repository] for the iteration 2 has all the STL files you need in order to make the printer. Run "generate-metric.bat" (or one of the batch files for the linear bearings) and it'll generate all the STLs needed. You will need OpenSCAD installed and it will need to be in your path.

The following is a list of what needs to be printed:

Parts for Wade's extruder are also included with the iteration 2 STLs:

Parts included in Github repository have the wrong dimensions for the nut traps! Download the correct version from [Thingiverse Greg's Hinged Accesible Extruder]

| Quantity | STL file | Picture |

|---|---|---|

| 1 | wade.stl | |

| 1 | wade-big.stl | |

| 1 | wade-small.stl | |

Non-printed parts

Derived from parts list by Kliment

| Quantity | Description | Comments |

|---|---|---|

| Fasteners | ||

| 100 | M8 nut | Easier to buy a box of 100, spares are handy. Enough for Wade's extruder too |

| 100 | M8 washer | Easier to buy a box of 100, spares are handy. Enough for Wade's extruder too |

| 50 | M3×20 bolt | Enough for Wade's extruder too |

| 50 | M3 nut - 5.5mm wide to fit nut traps | Enough for Wade's extruder too |

| 50 | M3 washer | Enough for Wade's extruder too |

| 6 | M3x10 bolt | |

| 2 | M3x8 grub (a.k.a. set) screw | |

| 1 | M8x50 grub (a.k.a. set) screw OR 50 mm length of threaded M8 rod | x end idler to hold belt bearing |

| 6 | M8x30mm fender washer | Used during assembly instructions, but not necessary if bearing-guide.stl is used instead - make sure your bearings can fit into bearing-guide.stl, some printers are not precise enough for printing bearing guides, can also use 5/16 x 1-1/4in fender washers |

| Bearings | ||

| 10 | LM8UU (Asia) or LME8UU (US, Europe) linear bearings OR 8mmx25mm brass bushings |

If using linear bearings, don't cut costs here. Cheap ones can damage the smooth rods. (check plastic parts, in some cases could be required 11 pieces, (for example, if your X carriage has a spot for 4 bearings). When in doubt, just purchase 11 and you'll have an extra if you don't need it |

| 3 | 608 "roller skate" bearings | "6082RS" for sealed, "608ZZ" for shielded. Again, don't skimp. |

| Threaded Rods - threaded lengths can all be cut from 6x1m lengths of M8 threaded rod ( 370 + 370 +210 ) * 2, ( 294 + 294 + 370 ) * 2, 440 + 440 , 440 | ||

| 6 | 370mm M8 threaded rod | Three per side |

| 4 | 294mm M8 threaded rod | Front/rear. Can use 300mm too |

| 3 | 440mm M8 threaded rod | Top/Bottom. Can use 450m too |

| 2 | 210mm M8 threaded rod | z-axis lead screws. Can use 300mm too |

| Smooth Rods - smooth lengths can all be cut from 3x1m lengths of O1 tool steel (350 + 350), (405 + 405), (420 + 420) | ||

| 2 | 350mm 8mm smooth rod | |

| 2 | 405mm 8mm smooth rod | |

| 2 | 420mm 8mm smooth rod | |

| Belts | ||

| 1 | 840mm GT2 toothed belt | T2.5 can be used as well. Be sure to match the pulleys. If you really want you can use T5 but it's not advised. |

| 1 | 900mm GT2 toothed belt | T2.5 can be used as well. Be sure to match the pulleys. If you really want you can use T5 but it's not advised. |

| 2 | 16-tooth pulleys to fit GT2 belts | Can be 12-tooth, but 16 is advised for less backlash. Bore diameter should be 5mm. |

| Other | ||

| 2 | 1.5cm vinyl tubing, 6.35mm OD 4.32mm ID (3cm total) | Used to attach motors to the Z axis threaded rods. Can be found at most hardware stores, typically used in toilets to connect refill tube to outlet. |

| 1 | 140x225x6mm OR 225x225x6mm thick MDF/flat wood | Used as the bottom print bed, 225x225 can be used to directly mount a MK1/MK2 heat bed |

| 1 | Glass surface or mirror | Used as the top print bed. Small, cheap Ikea mirrors work well cut to 200x200mm if using a MK2 |

If using Wade's extruder as included in the STLs:

| Quantity | Description | Comments |

|---|---|---|

| Fasteners | ||

| 4 | M8 washers | Included in count above |

| 2 | M8 nuts | Included in count above |

| 6 | M3 nuts | Included in count above |

| 3 | M3x10 bolts | |

| 3 | M3x40 bolts | |

| 1 | M3x8 grub screw | |

| 1 | M8x20 grub screw OR 20 mm length of M8 threaded rod | Use this in the idler to hold bearing, a cut piece of threaded rod is much more cost effective |

| 1 | M8x50 hobbed bolt | |

| Bearings | ||

| 3 | 608 "roller skate" bearings | "6082RS" for sealed, "608ZZ" for shielded. |

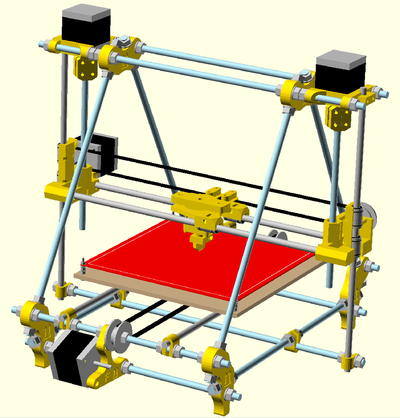

Assembled Model

Here is an "assembled" model of the Prusa Mendel IT2 made in OpenSCAD (using a variation with slightly longer X axis smooth rods (412mm) and an extra 4 nuts and 4 washers on the top (allowing the z-motor-mounts to be adjustable)):

http://www.thingiverse.com/thing:356386

Electronics

Stepper Motors

The Prusa iteration 2 uses 5 NEMA17 stepper motors, including the extruder. Two of these motors, the Z axis motors, are connected to the same stepper driver of the electronics, which are typically wired in parallel but some builders wire them in series so that each motor gets the same amps (in case the resistances are not exactly the same). If using Wade's Extruder, its stepper motor needs a minimum holding torque of 40Ncm (0.4Nm or 57 Oz-in). More information can be found on the Stepper Motor page.

Controller Electronics

About any RepRap controller works for the Prusa iteration 2. Required features: 4 stepper drivers, 1 thermistor input and 1 heater output for the extruder and optionally another thermistor/heater pair for the heated bed. Choosing the best one for your printer is mostly a matter of taste. For comparisons, see List of electronics, Comparison of Electronics and Alternative Electronics. Remember you will need a power supply unit (PSU), as this is not included with most assembled boards. Also remember that some electronics (RAMPS first and foremost) need an Arduino as well.

Extruder

The extruder included in the Prusa Mendel i2 STL files is [Thingiverse Greg's Hinged Accesible Extruder]. If planning on using a different extruder, ensure that it is compatible with the X-carriage that you have printed.

In terms of hot end, many recommend a J-head hot end as they are very common and easy to work with. It is HIGHLY RECOMMENDED that you purchase an official j-head, as the Chinese manufactured j-heads have issues with tolerances and reliability.

Remember that a J-head will require some sort of aluminum/printed assembly to attach to the extruder.

More information can be found here: Extruder

Heated Bed

If you are planning on using a heated bed, plan your support bed for the bed you plan on using. For example, if you are planning on using a MK2 series heated bed for your printer, your bottom plate should be cut to approximately 225x225 mm, but not much larger than that to clear the frame of the printer.

Another thing to note: try not to use acrylic to support your heat bed, it will warp from the heat. 3mm thick Aluminum/6mm thick MDF/very very flat plywood are recommended - if you can't find 3mm thick aluminum or 6 mm thick MDF, look for the flattest plywood they have. Birch plywood can work in a pinch.

More information can be found here: Heated Bed