Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 12:12PM |

Registered: 11 years ago Posts: 46 |

I know it might be a pain, but if you can measure the temp along the filament path from top to bottom, with the heatsink fan running etc as usual. use a thermocouple or thermistor based digital thermometer (not an IR thermometer as they are too inaccurate). what you are looking for is an sign that the path and heat break are getting to hot. if so this will soften and expand the filament prematurely and can cause a plug that can't be overcome with the extruder pressure. touch the sensor to the metal, away from air flow if possible so you are truly reading the temp of the metal. if you can, get the sensor as deep into the heat sink as possible (as close to the path of the filament). you will have to guestimate the temp the filament sees. if its not something very safe like <50C, then if it were me, i'd try getting the sensor down into the filament tube to measure the inside wall temp. just to rule this possibility out. i've had it happen to me E3D and Magma hot ends so I know... in the end I put a 50mm fan on the E3D to ensure it was cooled down enough to prevent the plug of death.

[www.printrbottalk.com] Printrbot Forum and Wiki

[www.printrbottalk.com] Printrbot Forum and Wiki

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 12:20PM |

Registered: 10 years ago Posts: 44 |

Quote

plexus

I know it might be a pain, but if you can measure the temp along the filament path from top to bottom, with the heatsink fan running etc as usual. use a thermocouple or thermistor based digital thermometer (not an IR thermometer as they are too inaccurate). what you are looking for is an sign that the path and heat break are getting to hot. if so this will soften and expand the filament prematurely and can cause a plug that can't be overcome with the extruder pressure. touch the sensor to the metal, away from air flow if possible so you are truly reading the temp of the metal. if you can, get the sensor as deep into the heat sink as possible (as close to the path of the filament). you will have to guestimate the temp the filament sees. if its not something very safe like <50C, then if it were me, i'd try getting the sensor down into the filament tube to measure the inside wall temp. just to rule this possibility out. i've had it happen to me E3D and Magma hot ends so I know... in the end I put a 50mm fan on the E3D to ensure it was cooled down enough to prevent the plug of death.

I'm not going to those lengths to trouble shoot... if the design is sound. This should not be needed. Any problems I have should be able to be resolved with a round of Q&A with E3D or here.

I've tried with only the E3D fan, Only the bulldog fan (which some have reported success with) and both Bulldog and E3D and have tried in a Bowden config... I've tried Long (3mm) retracts in bowden config and short (.5mm) retracts in direct drive. My extruder is strong and will drive filament worry free even at the lowest tension.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 12:50PM |

Registered: 10 years ago Posts: 553 |

Quote

3DogNate

No pics handy... I reduced the dia of the top fin to about half, and tapped the top for M5 for a bowden connection... that fin doesn't even fit into the fan housing before I turned it down. Plus the bulldog fan blows there anyway. and yes wired straight to 12V, not the heater

There is a fan shroud for the Bulldog that fits around the E3D that they released themselves.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 01:04PM |

Registered: 10 years ago Posts: 44 |

Yes, and I printed one Tuesday and am using it.Quote

tjb1

Quote

3DogNate

No pics handy... I reduced the dia of the top fin to about half, and tapped the top for M5 for a bowden connection... that fin doesn't even fit into the fan housing before I turned it down. Plus the bulldog fan blows there anyway. and yes wired straight to 12V, not the heater

There is a fan shroud for the Bulldog that fits around the E3D that they released themselves.

Wait... got a link? I want to make sure we are talking about the same thing..

I'm using the e3dholder.zip holder from this link... [forum.reprapdiscount.com]

Edited 2 time(s). Last edit at 03/06/2014 01:43PM by 3DogNate.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 02:31PM |

Registered: 10 years ago Posts: 553 |

Quote

3DogNate

Yes, and I printed one Tuesday and am using it.Quote

tjb1

Quote

3DogNate

No pics handy... I reduced the dia of the top fin to about half, and tapped the top for M5 for a bowden connection... that fin doesn't even fit into the fan housing before I turned it down. Plus the bulldog fan blows there anyway. and yes wired straight to 12V, not the heater

There is a fan shroud for the Bulldog that fits around the E3D that they released themselves.

Wait... got a link? I want to make sure we are talking about the same thing..

I'm using the e3dholder.zip holder from this link... [forum.reprapdiscount.com]

I can't open that right now but I know the one they released had a bigger opening to clear the heatsink so why would you need to modify one of the slats?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 02:40PM |

Registered: 10 years ago Posts: 44 |

Quote

tjb1

I can't open that right now but I know the one they released had a bigger opening to clear the heatsink so why would you need to modify one of the slats?

Yes I printed the correct part that fits the E3D in Because when I got the E3D I did not have a functional hot end to print a new one... I had to modify the original mount and make a mod to the E3D Heat Sink to get that to work with the original plastic part...

But regardless that end of the heat sink is colder than the ambient temp in the room thanks to two fans blowing on the heat sink.,.. so it's irrelevant to my filament jamming up.

Edited 1 time(s). Last edit at 03/06/2014 02:46PM by 3DogNate.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 03:03PM |

Registered: 11 years ago Posts: 210 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 03:08PM |

Registered: 10 years ago Posts: 44 |

Quote

greenman100

Quote

3DogNate

that end of the heat sink is colder than the ambient temp in the room thanks to two fans blowing on the heat sink.,.. so it's irrelevant to my filament jamming up.

This is exciting, you have broken the laws of thermodynamics!

Huh??? are you saying that if you blow a fan on a room temperature block of aluminum that it is impossible to cool it to below the ambient temperature in the room?

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 03:12PM |

Registered: 11 years ago Posts: 46 |

Quote

3DogNate

Quote

greenman100

Quote

3DogNate

that end of the heat sink is colder than the ambient temp in the room thanks to two fans blowing on the heat sink.,.. so it's irrelevant to my filament jamming up.

This is exciting, you have broken the laws of thermodynamics!

Huh??? are you saying that if you blow a fan on a room temperature block of aluminum that it is impossible to cool it to below the ambient temperature in the room?

*eats popcorn and watches*

[www.printrbottalk.com] Printrbot Forum and Wiki

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 03:22PM |

Registered: 10 years ago Posts: 44 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 04:07PM |

Registered: 11 years ago Posts: 210 |

Quote

3DogNate

Quote

greenman100

Quote

3DogNate

that end of the heat sink is colder than the ambient temp in the room thanks to two fans blowing on the heat sink.,.. so it's irrelevant to my filament jamming up.

This is exciting, you have broken the laws of thermodynamics!

Huh??? are you saying that if you blow a fan on a room temperature block of aluminum that it is impossible to cool it to below the ambient temperature in the room?

Yes. That's exactly what I'm saying. Well, myself and Isaac Newton. I guess we're both internet experts.

The one exception is if there's evaporation occurring, but I doubt you're spraying the heat sink with water.

Edited 1 time(s). Last edit at 03/06/2014 04:08PM by greenman100.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 04:09PM |

Admin Registered: 15 years ago Posts: 1,470 |

Quote

greenman100

Quote

3DogNate

Quote

greenman100

Quote

3DogNate

that end of the heat sink is colder than the ambient temp in the room thanks to two fans blowing on the heat sink.,.. so it's irrelevant to my filament jamming up.

This is exciting, you have broken the laws of thermodynamics!

Huh??? are you saying that if you blow a fan on a room temperature block of aluminum that it is impossible to cool it to below the ambient temperature in the room?

Yes. That's exactly what I'm saying. Well, myself and Isaac Newton. I guess we're both internet experts.

The one exception is if there's evaporation occurring, but I doubt you're spraying the heat sink with water.

If you get the aluminum wet first, then blow air over it, you could cool it down below ambient temperature

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 04:30PM |

Registered: 10 years ago Posts: 44 |

Geezz.... I'm ashamed to be referred to as a geek sometimes.

Back to my hot end... If you have something to contribute to having a successful E3D implementation I'm happy to hear it... otherwise... don't waste the thread space.

Edited 1 time(s). Last edit at 03/06/2014 04:31PM by 3DogNate.

Back to my hot end... If you have something to contribute to having a successful E3D implementation I'm happy to hear it... otherwise... don't waste the thread space.

Edited 1 time(s). Last edit at 03/06/2014 04:31PM by 3DogNate.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 04:38PM |

Admin Registered: 12 years ago Posts: 1,063 |

Quote

3DogNate

Geezz.... I'm ashamed to be referred to as a geek sometimes.

Back to my hot end... If you have something to contribute to having a successful E3D implementation I'm happy to hear it... otherwise... don't waste the thread space.

are you running the bulldog XL or the bulldog lite? and which size of the filament?

if you are running the buldog XL how much current are you giving it?

exactly what is happening when it jams, is the stepper skipping steps or stripping the filament?

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 04:53PM |

Registered: 10 years ago Posts: 44 |

Quote

thejollygrimreaper

Quote

3DogNate

Geezz.... I'm ashamed to be referred to as a geek sometimes.

Back to my hot end... If you have something to contribute to having a successful E3D implementation I'm happy to hear it... otherwise... don't waste the thread space.

are you running the bulldog XL or the bulldog lite? and which size of the filament?

if you are running the buldog XL how much current are you giving it?

exactly what is happening when it jams, is the stepper skipping steps or stripping the filament?

I'm running the Bulldog Lite... 1.75mm filament. I'm running the Stepper Drive at 1.2A... the Extruder will strip the filament before it skips steps... (If I apply enough tension it will grind the filament in half before skipping steps.) When it jams, it's really simple... it stops extruding... the filament gets jammed and the extruder keeps trying to work but just ends up grinding at the filament until it no longer has tension on it. If I catch it before it grinds too far... I can pretty easily pull the jammed filament out of the hot end barrel (Heat brake)... Several examples of just the same thing in this thread. I generally run the bulldog with the tension screws backed off as even then there is plenty of power to move the filament under normal circumstances.

Edited 1 time(s). Last edit at 03/06/2014 04:54PM by 3DogNate.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 05:18PM |

Admin Registered: 12 years ago Posts: 1,063 |

Quote

3DogNate

Quote

thejollygrimreaper

Quote

3DogNate

Geezz.... I'm ashamed to be referred to as a geek sometimes.

Back to my hot end... If you have something to contribute to having a successful E3D implementation I'm happy to hear it... otherwise... don't waste the thread space.

are you running the bulldog XL or the bulldog lite? and which size of the filament?

if you are running the buldog XL how much current are you giving it?

exactly what is happening when it jams, is the stepper skipping steps or stripping the filament?

I'm running the Bulldog Lite... 1.75mm filament. I'm running the Stepper Drive at 1.2A... the Extruder will strip the filament before it skips steps... (If I apply enough tension it will grind the filament in half before skipping steps.) When it jams, it's really simple... it stops extruding... the filament gets jammed and the extruder keeps trying to work but just ends up grinding at the filament until it no longer has tension on it. If I catch it before it grinds too far... I can pretty easily pull the jammed filament out of the hot end barrel (Heat brake)... Several examples of just the same thing in this thread. I generally run the bulldog with the tension screws backed off as even then there is plenty of power to move the filament under normal circumstances.

pla or abs? and what color?

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 05:31PM |

Admin Registered: 15 years ago Posts: 1,470 |

Quote

thejollygrimreaper

Quote

3DogNate

Quote

thejollygrimreaper

Quote

3DogNate

Geezz.... I'm ashamed to be referred to as a geek sometimes.

Back to my hot end... If you have something to contribute to having a successful E3D implementation I'm happy to hear it... otherwise... don't waste the thread space.

are you running the bulldog XL or the bulldog lite? and which size of the filament?

if you are running the buldog XL how much current are you giving it?

exactly what is happening when it jams, is the stepper skipping steps or stripping the filament?

I'm running the Bulldog Lite... 1.75mm filament. I'm running the Stepper Drive at 1.2A... the Extruder will strip the filament before it skips steps... (If I apply enough tension it will grind the filament in half before skipping steps.) When it jams, it's really simple... it stops extruding... the filament gets jammed and the extruder keeps trying to work but just ends up grinding at the filament until it no longer has tension on it. If I catch it before it grinds too far... I can pretty easily pull the jammed filament out of the hot end barrel (Heat brake)... Several examples of just the same thing in this thread. I generally run the bulldog with the tension screws backed off as even then there is plenty of power to move the filament under normal circumstances.

pla or abs? and what color?

And what supplier? Poor quality filament can jam up the best hot ends.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 05:37PM |

Registered: 11 years ago Posts: 46 |

Quote

NewPerfection

Quote

thejollygrimreaper

Quote

3DogNate

Quote

thejollygrimreaper

Quote

3DogNate

Geezz.... I'm ashamed to be referred to as a geek sometimes.

Back to my hot end... If you have something to contribute to having a successful E3D implementation I'm happy to hear it... otherwise... don't waste the thread space.

are you running the bulldog XL or the bulldog lite? and which size of the filament?

if you are running the buldog XL how much current are you giving it?

exactly what is happening when it jams, is the stepper skipping steps or stripping the filament?

I'm running the Bulldog Lite... 1.75mm filament. I'm running the Stepper Drive at 1.2A... the Extruder will strip the filament before it skips steps... (If I apply enough tension it will grind the filament in half before skipping steps.) When it jams, it's really simple... it stops extruding... the filament gets jammed and the extruder keeps trying to work but just ends up grinding at the filament until it no longer has tension on it. If I catch it before it grinds too far... I can pretty easily pull the jammed filament out of the hot end barrel (Heat brake)... Several examples of just the same thing in this thread. I generally run the bulldog with the tension screws backed off as even then there is plenty of power to move the filament under normal circumstances.

pla or abs? and what color?

And what supplier? Poor quality filament can jam up the best hot ends.

I use what is often considered the poor quality ABS and PLA from repraper in china without any issues with the E3D with both 3mm and 1.75. FYI

[www.printrbottalk.com] Printrbot Forum and Wiki

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 05:57PM |

Admin Registered: 12 years ago Posts: 1,063 |

Quote

plexus

Quote

NewPerfection

Quote

thejollygrimreaper

Quote

3DogNate

Quote

thejollygrimreaper

Quote

3DogNate

Geezz.... I'm ashamed to be referred to as a geek sometimes.

Back to my hot end... If you have something to contribute to having a successful E3D implementation I'm happy to hear it... otherwise... don't waste the thread space.

are you running the bulldog XL or the bulldog lite? and which size of the filament?

if you are running the buldog XL how much current are you giving it?

exactly what is happening when it jams, is the stepper skipping steps or stripping the filament?

I'm running the Bulldog Lite... 1.75mm filament. I'm running the Stepper Drive at 1.2A... the Extruder will strip the filament before it skips steps... (If I apply enough tension it will grind the filament in half before skipping steps.) When it jams, it's really simple... it stops extruding... the filament gets jammed and the extruder keeps trying to work but just ends up grinding at the filament until it no longer has tension on it. If I catch it before it grinds too far... I can pretty easily pull the jammed filament out of the hot end barrel (Heat brake)... Several examples of just the same thing in this thread. I generally run the bulldog with the tension screws backed off as even then there is plenty of power to move the filament under normal circumstances.

pla or abs? and what color?

And what supplier? Poor quality filament can jam up the best hot ends.

I use what is often considered the poor quality ABS and PLA from repraper in china without any issues with the E3D with both 3mm and 1.75. FYI

i'm suspecting the colorant to be more of the issue

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 07:24PM |

Registered: 10 years ago Posts: 1,381 |

Quote

3DogNate

I took it apart and the barrel bent...

Quote

3DogNate

I put in an order last week for some replacement parts from Filastruder.com to rebuild the hot end.

I rebuilt the hot end yesterday

Correct me if I have misinterpreted you, but you were the cause of the first hot end failure (bent heat break), and the bent heat break caused the filament to jam, is this correct.

If this is the case, lets assume that you are the cause of the second failure, and conduct a test to determine if the heat break was bent again.

There is an assumption that the bore of the barrel should be straight enough for a filament to pass through without jamming.

I don't see a straightness call out on the blueprint, nor do I see a (do not exceed assembly/disassemble torque specification), so you are not entirely to blame.

In view that there is not a call out on the blueprint for straightness,

I'll make up a straightness specification for you to test, based on the barrel, and GD&T concentricity tolerance.

Note: I think that datum -A- would be better served if it was applied to the axis of the barrel bore, and not to the O.D of one end of the part.

Barrel diameter 2.0 mm (±0.05 mm).

Concentricity tolerance: 0.05 mm.

2.0 mm - 0.05 mm = 1.95 mm. Smallest barrel diameter.

1.95 mm - (0.05 mm /2) = 1.925 mm. This value represent the maximum diameter that should pass through the length of the heat break.

Use a pin gauge to check for straightness with a tolerance of ±0.0002", (0.00508 mm).

I would test for straightness with a diameter 1.925 mm pin gauge with a minimum length of 25.5 mm.

You need to measure, and validate that you are conducting your test with a part that is within blueprint specifications.

After you have verified that the replacement part is to a specification (yet to be determined), you can begin ruling out other variables.

In addition conduct all trouble shooting tests with natural (uncolored) filament.

GD&T Concentricity Definition

[www.emachineshop.com]

Filament tolerance

[bootsindustries.com]

E3D Online Limited, (ISS B )

[files.e3d-online.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 08:03PM |

Registered: 10 years ago Posts: 44 |

Quote

A2

Correct me if I have misinterpreted you, but you were the cause of the first hot end failure (bent heat break), and the bent heat break caused the filament to jam, is this correct.

If this is the case, lets assume that you are the cause of the second failure, and conduct a test to determine if the heat break was bent again.

There is an assumption that the bore of the barrel should be straight enough for a filament to pass through without jamming.

I don't see a straightness call out on the blueprint, nor do I see a (do not exceed assembly/disassemble torque specification), so you are not entirely to blame.

In view that there is not a call out on the blueprint for straightness,

I'll make up a straightness specification for you to test, based on the barrel, and GD&T concentricity tolerance.

Note: I think that datum -A- would be better served if it was applied to the axis of the barrel bore, and not to the O.D of one end of the part.

Barrel diameter 2.0 mm (±0.05 mm).

Concentricity tolerance: 0.05 mm.

2.0 mm - 0.05 mm = 1.95 mm. Smallest barrel diameter.

1.95 mm - (0.05 mm /2) = 1.925 mm. This value represent the maximum diameter that should pass through the length of the heat break.

Use a pin gauge to check for straightness with a tolerance of ±0.0002", (0.00508 mm).

I would test for straightness with a diameter 1.925 mm pin gauge with a minimum length of 25.5 mm.

You need to measure, and validate that you are conducting your test with a part that is within blueprint specifications.

After you have verified that the replacement part is to a specification (yet to be determined), you can begin ruling out other variables.

In addition conduct all trouble shooting tests with natural (uncolored) filament.

GD&T Concentricity Definition

[www.emachineshop.com]

Filament tolerance

[bootsindustries.com]

E3D Online Limited, (ISS B )

[files.e3d-online.com]

I'm using Ultimaker PLA, 1.75mm, Black and Deltamaker PLA 1.75mm red (Good stuff, that all prints nicely with my other QU-BD extruder/Hot end)

You did misinterpret me... I could not get good results with my first attempt with the E3D... so I disassembled it to verify that I built it correctly, but when I went to remove the barrel it was REALLY stuck and bent when I removed it... That's why I had to re-order parts. (I'm a hobby machinist... I have a CNC mill retro-fit that I did, a lathe blah, blah... I'm actually a good fabricator. I'll get pics up when I get a chance..) I assembled it with no damage to the new parts. If I were to spin the heat break on the lathe it would spin true... I did inspect the new parts before assembling and with a caliper the new barrel was in spec and the interior was smooth.. (smoother than the first one I received)...

Lets assume that everything is in spec and assembled correctly... what should I start looking at? I've calibrated my extruder... ran PID autotune... My thermistor setting is correct in firmware, My retract is set at .5mm/60mm-sec...

Plexus.... what are your Slic3r setting for your PLA? I have some Zen ABS also to use... but If I can't do PLA then I'm not going to move on to other filament types... PLA is a good choice for so many things.

Edited 1 time(s). Last edit at 03/06/2014 08:04PM by 3DogNate.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 08:11PM |

Registered: 11 years ago Posts: 46 |

Quote

3DogNate

Quote

A2

Correct me if I have misinterpreted you, but you were the cause of the first hot end failure (bent heat break), and the bent heat break caused the filament to jam, is this correct.

If this is the case, lets assume that you are the cause of the second failure, and conduct a test to determine if the heat break was bent again.

There is an assumption that the bore of the barrel should be straight enough for a filament to pass through without jamming.

I don't see a straightness call out on the blueprint, nor do I see a (do not exceed assembly/disassemble torque specification), so you are not entirely to blame.

In view that there is not a call out on the blueprint for straightness,

I'll make up a straightness specification for you to test, based on the barrel, and GD&T concentricity tolerance.

Note: I think that datum -A- would be better served if it was applied to the axis of the barrel bore, and not to the O.D of one end of the part.

Barrel diameter 2.0 mm (±0.05 mm).

Concentricity tolerance: 0.05 mm.

2.0 mm - 0.05 mm = 1.95 mm. Smallest barrel diameter.

1.95 mm - (0.05 mm /2) = 1.925 mm. This value represent the maximum diameter that should pass through the length of the heat break.

Use a pin gauge to check for straightness with a tolerance of ±0.0002", (0.00508 mm).

I would test for straightness with a diameter 1.925 mm pin gauge with a minimum length of 25.5 mm.

You need to measure, and validate that you are conducting your test with a part that is within blueprint specifications.

After you have verified that the replacement part is to a specification (yet to be determined), you can begin ruling out other variables.

In addition conduct all trouble shooting tests with natural (uncolored) filament.

GD&T Concentricity Definition

[www.emachineshop.com]

Filament tolerance

[bootsindustries.com]

E3D Online Limited, (ISS B )

[files.e3d-online.com]

I'm using Ultimaker PLA, 1.75mm, Black and Deltamaker PLA 1.75mm red (Good stuff, that all prints nicely with my other QU-BD extruder/Hot end)

You did misinterpret me... I could not get good results with my first attempt with the E3D... so I disassembled it to verify that I built it correctly, but when I went to remove the barrel it was REALLY stuck and bent when I removed it... That's why I had to re-order parts. (I'm a hobby machinist... I have a CNC mill retro-fit that I did, a lathe blah, blah... I'm actually a good fabricator. I'll get pics up when I get a chance..) I assembled it with no damage to the new parts. If I were to spin the heat break on the lathe it would spin true... I did inspect the new parts before assembling and with a caliper the new barrel was in spec and the interior was smooth.. (smoother than the first one I received)...

Lets assume that everything is in spec and assembled correctly... what should I start looking at? I've calibrated my extruder... ran PID autotune... My thermistor setting is correct in firmware, My retract is set at .5mm/60mm-sec...

Plexus.... what are your Slic3r setting for your PLA? I have some Zen ABS also to use... but If I can't do PLA then I'm not going to move on to other filament types... PLA is a good choice for so many things.

I dont use Slic3r. I use KISSlicer (RIP). 210C for PLA. nothing fancy.

[www.printrbottalk.com] Printrbot Forum and Wiki

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 06, 2014 08:47PM |

Registered: 10 years ago Posts: 1,381 |

Quote

3DogNate

I'm a hobby machinist... I have a CNC mill retro-fit

Quote

3DogNate

I'm using Ultimaker PLA, 1.75mm, Black

The filament might not be the cause of your jamming, but for debugging purposes you need to rule out things that could potentially skew your test results.

Conduct all tests with natural (uncolored) filament.

Quote

3DogNate

when I went to remove the barrel it was REALLY stuck and bent when I removed it... That's why I had to re-order parts

Did you disassembled the hot end while it was cold.

I reviewed the E3D assembly instructions, and I didn't find guidance of how to disassemble it.

Query these forums for advice of how others have successfully disassembled their E3D hot end.

I'll venture a guess that the hot end is warmed up a little to help reduce the torque.

@bruce356:

Quote

3DogNate

I did inspect the new parts before assembling and with a caliper the new barrel was in spec and the interior was smooth.. (smoother than the first one I received)...

That's interesting because bruce356 believes his filament jamming might be due to the finish on the bore of the barrel.

If you're able, take a picture of the barrel finish of both heat breaks, or try to quantify the surface finish roughness.

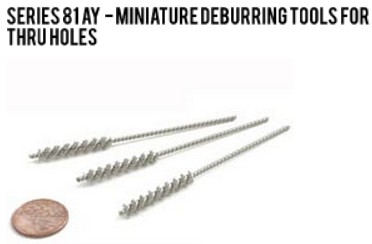

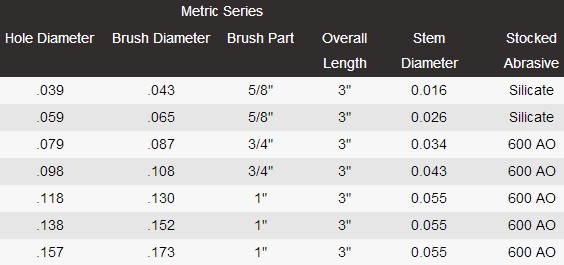

You could try to improve the finish of the barrel bore with a miniature flex hone, and some mineral oil.

Brush Research Manufacturing

[www.brushresearch.com]

Edited 1 time(s). Last edit at 03/06/2014 08:49PM by A2.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 07, 2014 10:10AM |

Registered: 10 years ago Posts: 44 |

Quote

A2

Did you disassembled the hot end while it was cold.

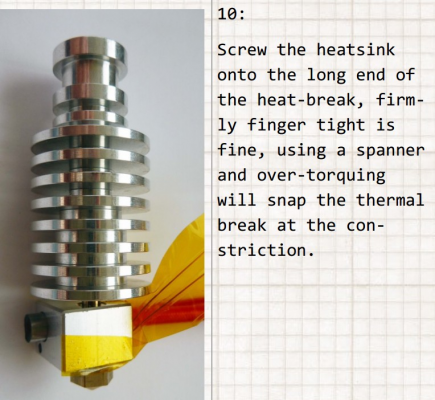

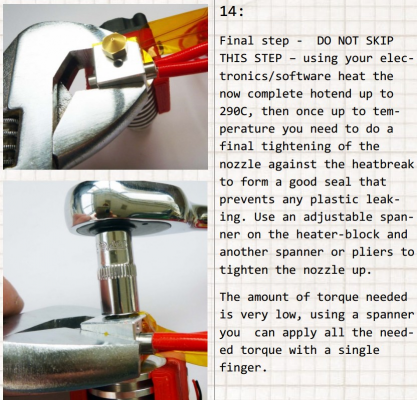

Assembled cold then heated up and torqued the nozzle down tight... Just as the E3D instructions stated

Quote

A2

That's interesting because bruce356 believes his filament jamming might be due to the finish on the bore of the barrel.

If you're able, take a picture of the barrel finish of both heat breaks, or try to quantify the surface finish roughness.

You could try to improve the finish of the barrel bore with a miniature flex hone, and some mineral oil.

No, I'll not go to that length... I need to be able to trust the people I buy from to handle any quality control issues... They should not be conducting business if they can't control a thing like that.

Here are some photos of my setup..My iPhone 5 doesn't take the best low light pics... Apologies

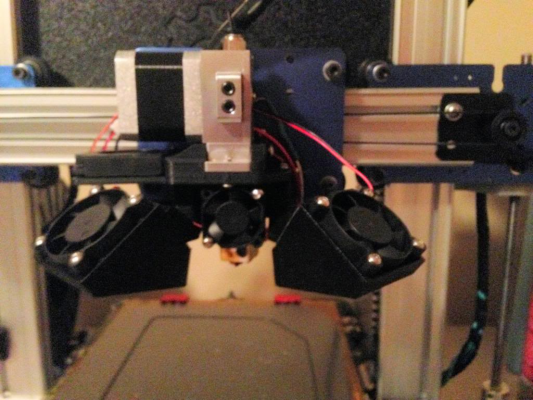

E3D with both Fans Mounted (Note the Dual PLA cooling fans... yes, I've tried no PLA cooling, Fan on full time and Auto cooling)

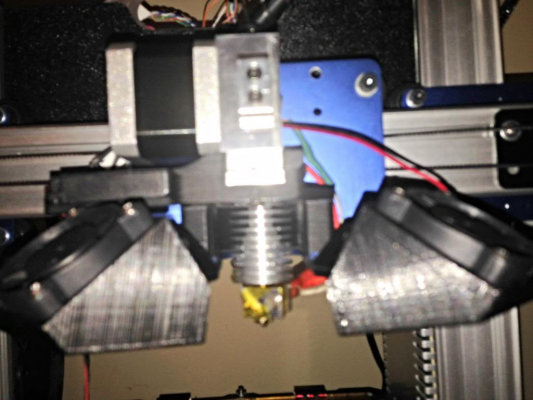

Here's the setup with the E3D fan removed so that you can see the E3D Heat Sink

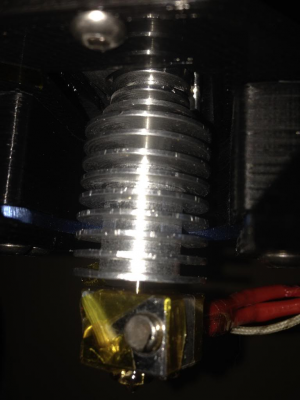

Closeup of the E3D Heat Sink

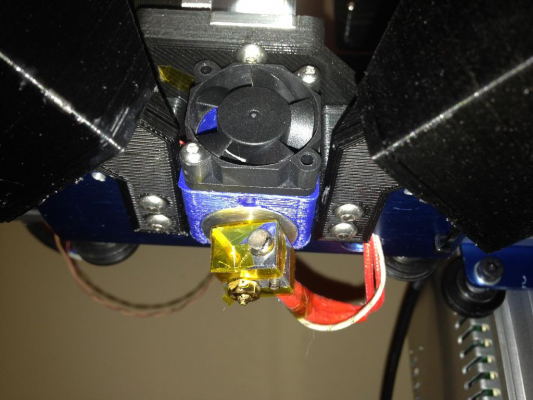

Here you can see that the fan duct indeed covers the bottom fin...

The fan parts, Bull dog mount and extruder riser were all printed with a different hot end and extruder... The only deviation I've done from the E3D instructions is to use PTFE tubes to insulate the THermistor leads... I did the kapton tape as per instructions first time and found it to be a smidge kludgy to fuss with...

Edited 1 time(s). Last edit at 03/07/2014 10:13AM by 3DogNate.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 07, 2014 12:09PM |

Registered: 11 years ago Posts: 46 |

Quote

3DogNate

No, I'll not go to that length... I need to be able to trust the people I buy from to handle any quality control issues... They should not be conducting business if they can't control a thing like that.

My personal feeling is that you should correspond with E3D exclusively and stop wasting our time on this forum since you are unwilling to try anything we suggest and ultimately are just not aligned to the spirit of this whole 3D printing escapade. Most of these "companies", like E3D, are producing these things for us because they feel they have a good idea that they can mass produce to some small degree and share the fruits of their labour and passion with the larger 3D printing community. Very few of these companies are big, usually just a few people trying to push the envelope. more often than not there is something we, the end user, needs to do in order to get these things to work. it's supposed to be part of the fun - its fun for a lot of people and for some its just something tolerated in order to get back to printing. regardless there is a spirit and a sense of co-operation and collaboration that appears to be lost with you. so if you dont mind, could you take your issues up with E3D. thanks.

Edited 1 time(s). Last edit at 03/07/2014 12:10PM by plexus.

[www.printrbottalk.com] Printrbot Forum and Wiki

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 07, 2014 12:38PM |

Registered: 10 years ago Posts: 44 |

Quote

plexus

Quote

3DogNate

No, I'll not go to that length... I need to be able to trust the people I buy from to handle any quality control issues... They should not be conducting business if they can't control a thing like that.

My personal feeling is that you should correspond with E3D exclusively and stop wasting our time on this forum since you are unwilling to try anything we suggest and ultimately are just not aligned to the spirit of this whole 3D printing escapade. Most of these "companies", like E3D, are producing these things for us because they feel they have a good idea that they can mass produce to some small degree and share the fruits of their labour and passion with the larger 3D printing community. Very few of these companies are big, usually just a few people trying to push the envelope. more often than not there is something we, the end user, needs to do in order to get these things to work. it's supposed to be part of the fun - its fun for a lot of people and for some its just something tolerated in order to get back to printing. regardless there is a spirit and a sense of co-operation and collaboration that appears to be lost with you. so if you dont mind, could you take your issues up with E3D. thanks.

I just expressed that I wasn't going to the lengths of buying a micro-hone to clean up my barrel... I am sorry if my experiences with someone's favorite thing isn't a good one... I'm being patient, I think I'm just now getting it across that I have a clean build and installation and that I haven't done any thing moronic... So I'll leave the personal opinions out if you will...

I did get a response from E3D they asked about the filament path. Which with the bulldog there is no more than a mm or so anywhere that the filament is unsupported to allow for a flex or bind in the path...

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 07, 2014 12:44PM |

Registered: 11 years ago Posts: 334 |

3DogNate I am in the middle of building a printer and plan on using the same combination of extruder and E3D except I will be using the bulldogXL. How did you account for the size mismatch between the e3D and bulldog mount? Did you use a metal shim or something else? I skimmed your posts and didn't see if you explained that yet.

I see you have quite a lot of fans on your print head. Have you tried pointing them all at the barrel while printing? This isn't a fix but it might help narrow down your problem to thermal or mechanical.

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

I see you have quite a lot of fans on your print head. Have you tried pointing them all at the barrel while printing? This isn't a fix but it might help narrow down your problem to thermal or mechanical.

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 07, 2014 01:08PM |

Registered: 10 years ago Posts: 44 |

Quote

jzatopa

3DogNate I am in the middle of building a printer and plan on using the same combination of extruder and E3D except I will be using the bulldogXL. How did you account for the size mismatch between the e3D and bulldog mount? Did you use a metal shim or something else? I skimmed your posts and didn't see if you explained that yet.

I see you have quite a lot of fans on your print head. Have you tried pointing them all at the barrel while printing? This isn't a fix but it might help narrow down your problem to thermal or mechanical.

I turned a press fit bushing for the top ring of the heat sink on the lathe to fit the bulldog with no slop. The heater cartridge has no problems keeping a constant temp even with the PLA cooling fans blowing.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 07, 2014 04:27PM |

Registered: 11 years ago Posts: 210 |

Quote

3DogNate

I did get a response from E3D they asked about the filament path. Which with the bulldog there is no more than a mm or so anywhere that the filament is unsupported to allow for a flex or bind in the path...

Didn't you bore/tap the heatsink for a bowden connector? That would leave many millimeters unsupported.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] March 07, 2014 06:00PM |

Registered: 10 years ago Posts: 44 |

Quote

greenman100

Quote

3DogNate

I did get a response from E3D they asked about the filament path. Which with the bulldog there is no more than a mm or so anywhere that the filament is unsupported to allow for a flex or bind in the path...

Didn't you bore/tap the heatsink for a bowden connector? That would leave many millimeters unsupported.

No, the tapped portion has a length of Teflon tube to ensure that doesn't happen. ;-) I already thought of that... Oh and you can see the press fit bushing that I added to better fit the bulldog Extruder in this photo...

Sorry, only registered users may post in this forum.