Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures]

[Lots of pictures]

Posted by SanjayM

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 16, 2014 08:54AM |

Registered: 12 years ago Posts: 1,236 |

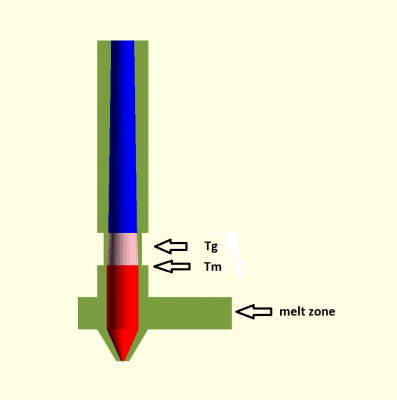

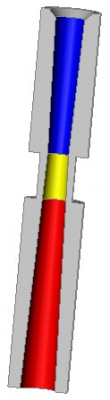

So this is my interpretation based on [hydraraptor.blogspot.co.uk]

Tg is achieved somewhere in the heatbreak region. Below Tm is the filament is fluid in the melt chamber. There is a taper from the inlet down to the top of the melt chamber.

Does that look right?

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

Tg is achieved somewhere in the heatbreak region. Below Tm is the filament is fluid in the melt chamber. There is a taper from the inlet down to the top of the melt chamber.

Does that look right?

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 16, 2014 03:44PM |

Registered: 10 years ago Posts: 1,381 |

@bobc:

One long taper looks good, and I'm sold on the idea of using one long taper. So what taper will be the ideal? I think it should be calculated based on the rate of expansion, as I stated in my earlier post.

@ nophead:

OK does this state the situation?

Plastic at the Tg is much harder to move than ridged or molten plastic.

The plug (i.e. plastic at Tg) is forming in the thermal break zone because: one, the machine sits idle, and there is time for the heat to conduct into the filament at, and above the thermal break, and two, there is enough heat input at the thermal break to raise the temperature of the filament to it's Tg. A taper will perform as it does in an injection mold as a mold release. A taper should make it easier to resume printing after the machine sits idle. The length of plastic at the Tg temperature should be as short as possible to help reduce the chance of jamming, and the force to move it.

Ideally you don't want heat input in the blue zone.

You only need enough support to guide, and prevent buckling of the filament in the blue zone. I think that a taper in the blue zone reduces the contact surface area.

Keeping the filament cool and out of the Tg stage aids in reducing jams in the blue zone.

But I think I'm splitting hairs here, and it is possible that it's not going to be an easily quantifiable, easily recognizable contribution.

That said, I have moved the blue zone above the top of the thermal break, you locate the blue zone where the plastic is not at it's Tg.

Above the Tg zone a taper reduces the contact, and the nearness of the warm side walls to the filament.

The taper in the red section is to optimize the heat input into the filament, which is based on the expansion rate of the filament. I believe that my earlier notes on how to calculate a taper still holds for the red zone.

I believe that the filament should enter the "red zone" cold, i.e. it's not at Tg.

As the filament warms up in the red zone it expands and forms the plug i.e. it's at the Tg, (I'm referring to the top portion, not the bottom portion of the red zone), the expansion follows the increasing diameter i.e. taper of the melt chamber. The increasing diameter of the melted surface area increases as the filament expands into the red zone, which I think is more efficient at transferring the heat into the filament. In addition the taper performs as a pressure reduction for when the machine is idle, possibly reducing drool.

Some distance away from the Tg zone the form of the side walls is less important, as the plastic has been liquidized.

Irregardless of my ideas, one continuous tapered barrel helps reduce the plug from binding, and I think that one long taper is a good idea.

The expansion is ~0.5% to ~2.5%, see my earlier notes about how I propose to calculate the taper.

2 mm is probably too short for the thermal break zone. I've drawn it at 6 mm.

Now that I understand the problem a little bit more, I would be focusing the majority of my efforts at actively cooling the thermal break, and coming up with a design that passively helps maintain a temperature below the Tg of the filament at the thermal break, and taper the bore of the barrel.

So is there a hot end being sold with a tapered barrel?

nophead tks for taking the time to explain this!

I'm looking forward to following thejollygrimreaper tests.

Edited 2 time(s). Last edit at 02/16/2014 03:46PM by A2.

One long taper looks good, and I'm sold on the idea of using one long taper. So what taper will be the ideal? I think it should be calculated based on the rate of expansion, as I stated in my earlier post.

@ nophead:

OK does this state the situation?

Plastic at the Tg is much harder to move than ridged or molten plastic.

The plug (i.e. plastic at Tg) is forming in the thermal break zone because: one, the machine sits idle, and there is time for the heat to conduct into the filament at, and above the thermal break, and two, there is enough heat input at the thermal break to raise the temperature of the filament to it's Tg. A taper will perform as it does in an injection mold as a mold release. A taper should make it easier to resume printing after the machine sits idle. The length of plastic at the Tg temperature should be as short as possible to help reduce the chance of jamming, and the force to move it.

Quote

nophead

You have the taper in the blue section the wrong way round

Ideally you don't want heat input in the blue zone.

You only need enough support to guide, and prevent buckling of the filament in the blue zone. I think that a taper in the blue zone reduces the contact surface area.

Keeping the filament cool and out of the Tg stage aids in reducing jams in the blue zone.

But I think I'm splitting hairs here, and it is possible that it's not going to be an easily quantifiable, easily recognizable contribution.

That said, I have moved the blue zone above the top of the thermal break, you locate the blue zone where the plastic is not at it's Tg.

Above the Tg zone a taper reduces the contact, and the nearness of the warm side walls to the filament.

Quote

nophead

and the one {taper} in the red section will have little effect because the plastic is a liquid at that point.

The taper in the red section is to optimize the heat input into the filament, which is based on the expansion rate of the filament. I believe that my earlier notes on how to calculate a taper still holds for the red zone.

I believe that the filament should enter the "red zone" cold, i.e. it's not at Tg.

Quote

nophead

I still don't see how thermal expansion is relevant.

As the filament warms up in the red zone it expands and forms the plug i.e. it's at the Tg, (I'm referring to the top portion, not the bottom portion of the red zone), the expansion follows the increasing diameter i.e. taper of the melt chamber. The increasing diameter of the melted surface area increases as the filament expands into the red zone, which I think is more efficient at transferring the heat into the filament. In addition the taper performs as a pressure reduction for when the machine is idle, possibly reducing drool.

Some distance away from the Tg zone the form of the side walls is less important, as the plastic has been liquidized.

Irregardless of my ideas, one continuous tapered barrel helps reduce the plug from binding, and I think that one long taper is a good idea.

Quote

nophead

and is only about 0.5%, less than the tolerance of the filament.

The expansion is ~0.5% to ~2.5%, see my earlier notes about how I propose to calculate the taper.

Quote

nophead

If you consider the thermal break on the E3D is only about 2mm, that is less that the filament diameter so heat is bound to spread upwards in the middle of a short fat cylinder that is heated at the bottom but only cooled at the edges.

2 mm is probably too short for the thermal break zone. I've drawn it at 6 mm.

Now that I understand the problem a little bit more, I would be focusing the majority of my efforts at actively cooling the thermal break, and coming up with a design that passively helps maintain a temperature below the Tg of the filament at the thermal break, and taper the bore of the barrel.

So is there a hot end being sold with a tapered barrel?

nophead tks for taking the time to explain this!

I'm looking forward to following thejollygrimreaper tests.

Edited 2 time(s). Last edit at 02/16/2014 03:46PM by A2.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 16, 2014 06:41PM |

Registered: 10 years ago Posts: 1,381 |

I'm trying to understand the reason for the varied designs of the hot end.

Will they always be different, is there one ideal hot end design, probably not.

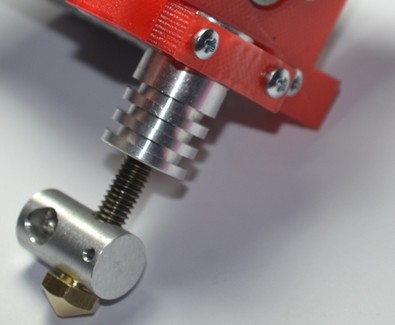

E3D

I see that most of the E3D barrel is encased within the heated block, the heat sink has more mass to dissipate heat that has migrated up through the thermal break than the Aluhotend, and the mass distribution is nonlinear, i.e. more near the thermal break. The E3D does not utilize a PTFE liner.

E3D

[e3d-online.com]

Documentation

[e3d-online.com]

Aluhotend

The Aluhotend hot end has more surface area exposed above the heated block for cooling, the heat sink has less mass than the E3D hot end, and the mass is uniformly distributed. The Aluhotend utilizes a PTFE liner. I couldn't find the length of the PTFE liner. What will happen to the Aluhotend PTFE liner when the barrel is tapered?

Aluhotend

[3d-industries.myshopify.com]

Documentation

[reprap.org]

I think both hot ends would benefit from an internal taper to make it easier to move the plug, i.e. the Tg zone.

They both look good, but what one has the shorter Tg plug?, and how would you verify it?

“idle hot ends are the devil's workshop”:

I think Ideally a steady state of constant extrusion is desired to achieve predictable thermal mapping, and to mitigate the length of the Tg of the plug.

Maybe all that is required is a script to constantly extrude while the machine is paused.

Edited 1 time(s). Last edit at 02/16/2014 06:42PM by A2.

Will they always be different, is there one ideal hot end design, probably not.

E3D

I see that most of the E3D barrel is encased within the heated block, the heat sink has more mass to dissipate heat that has migrated up through the thermal break than the Aluhotend, and the mass distribution is nonlinear, i.e. more near the thermal break. The E3D does not utilize a PTFE liner.

E3D

[e3d-online.com]

Documentation

[e3d-online.com]

Aluhotend

The Aluhotend hot end has more surface area exposed above the heated block for cooling, the heat sink has less mass than the E3D hot end, and the mass is uniformly distributed. The Aluhotend utilizes a PTFE liner. I couldn't find the length of the PTFE liner. What will happen to the Aluhotend PTFE liner when the barrel is tapered?

Aluhotend

[3d-industries.myshopify.com]

Documentation

[reprap.org]

I think both hot ends would benefit from an internal taper to make it easier to move the plug, i.e. the Tg zone.

They both look good, but what one has the shorter Tg plug?, and how would you verify it?

“idle hot ends are the devil's workshop”:

I think Ideally a steady state of constant extrusion is desired to achieve predictable thermal mapping, and to mitigate the length of the Tg of the plug.

Maybe all that is required is a script to constantly extrude while the machine is paused.

Edited 1 time(s). Last edit at 02/16/2014 06:42PM by A2.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 16, 2014 08:26PM |

Admin Registered: 12 years ago Posts: 1,063 |

Quote

A2

I think both hot ends would benefit from an internal taper to make it easier to move the plug, i.e. the Tg zone.

They both look good, but what one has the shorter Tg plug?, and how would you verify it?

“idle hot ends are the devil's workshop”:

I think Ideally a steady state of constant extrusion is desired to achieve predictable thermal mapping, and to mitigate the length of the Tg of the plug.

Maybe all that is required is a script to constantly extrude while the machine is paused.

actually, the plug on mine (Aluhotend) doesn't tend to go above the heater block too far because i use a thermal barrier and not a thermal break my cooling requirements aren't anywhere near as aggressive as a hotend that has a thermal break, eg this is what i do for cooling:

The fans in that photo are a pair of 12v very very crappy 40mm fans that barely blow any air and both are missing at least 3 blades, ( i think the movement of the carriage generates more airflow). so far i'm happy with the results i get from this hotend using the ptfe liner and a thermal barrier, jamming isn't an issue on idle, one of the first tests i normally do is let it sit idle for up to 6 hours and then hit extrude,

the taper inside a ptfe liner would just make things better but i don't think it's overly nessessary not when the coeffecient of friction is around 0.1, stainless steel is another kettle of fish, where as Nopheads example is done for 3mm, but this doesnt solve the 245c limit, thankfully these days there are higher temp fluropolymers available which can allow operation up to 300c and some are being tested atm , eg duponts ECA 3000 (try getting the stuff ) is rather promising especially under long term use.

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 17, 2014 02:00AM |

Registered: 12 years ago Posts: 1,236 |

Quote

A2

@bobc:

One long taper looks good, and I'm sold on the idea of using one long taper. So what taper will be the ideal? I think it should be calculated based on the rate of expansion, as I stated in my earlier post.

I am with nophead on this one. The purpose of the taper is purely mechanical, I think thermal expansion is a red herring. Expansion will occur because the filament is under pressure, as well as thermal expansion. The mechanical advantage is that if you have a solid plug formed in the hotend, a push will release the plug.

Quote

Quote

nophead

You have the taper in the blue section the wrong way round

Ideally you don't want heat input in the blue zone.

You only need enough support to guide, and prevent buckling of the filament in the blue zone. I think that a taper in the blue zone reduces the contact surface area.

I would disagree. In practice, the heat can and does get into the blue zone, so the taper is designed to deal with that. The walls in the blue zone are supposed to be cold, so contact there should not be a problem. The problem is that heat conducts up through the filament, so avoiding contact with the walls is not relevant to that. I think you want to contact the walls more in the blue zone, not less.

Your reverse taper in the blue zone will make things worse, as you will get a plug formed at the constriction where it cannot be pushed in or pulled out.

For the taper to work, it has to follow nopheads suggestion.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 18, 2014 05:36AM |

Registered: 10 years ago Posts: 19 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 19, 2014 07:40PM |

Registered: 12 years ago Posts: 177 |

Hi All,

It's been way too long since I've appeared and commented here - for that I apologise. It's been a crazy time here at E3D, we've constantly been in a state of scaling up to meet demand. I can't complain from a business perspective, but it's really hampered my ability to be present in these forums and elsewhere provide support and guidance where needed. I feel in some ways I haven't been able to keep the same level of engagement with the community that shaped E3D from where we started in these forums.

If you are having issues with your hotend please please get in touch via the contact page on our site and we will do all we can to support you. We reply to every email, it might take us a day or two, but we stand behind our product. Your hotend absolutely should print PLA without issues, and if it isn't something is wrong, we'll work with you to sort it out. We have thousands of these things in the wild, and our failure rate is really low - less than 0.2% at last count. Problems happen, sometimes it's a problem with a particular machine or setup, occasionally it's a problem due to manufacture on our end. Whatever happens, if you paid for a hotend you should get something that works.

Recently I've been doing some statistical analysis of how problems occur and it has become clear that almost all issues surrounding jamming happen in 1.75mm versions, with most (80%+) of those problems being in 1.75mm Bowden systems.

The most common cause of problems is lack of constraint on the filament. Where tubing in a bowden system isn't pushed right down into the hotend is a common cause of issues, also where the tubing has been pushed into the couplings, but not "locked" into place causes problems. (If you push the tubing into the coupler while pulling up on the collet it will lock into place with no backlash or wobble in the couplers.)

We also see issues where Bowden hotends are used as direct hotends by removing the coupler and simply mounting it as though it were a direct hotend. This is fine in principle, but there is an area of dead-space where the top of the hotend has been drilled out and tapped to accept the fitting. This dead space gives the filament and area to bow or buckle and this causes jams. It's an easy fix to use a short length of the supplied PTFE tubing to constrain and guide the filament down the into the hotend.

Onto more interesting matters!

We've been testing out the Kraken hotend a fair bit recently, and have had some really cool results with support material that breaks away cleanly and easily. This allows you to print objects with overhanging geometry without issues and without messy solvent/support dissolving steps which is really cool. We did a write up here:[e3d-online.com] which was done on a Kraken but should apply to any multi-extruder machine.

Our colour mixing hotend is developing quickly and we are optimising to try and get colour changes to happen as rapidly as possible. Responsiveness to colour change is our main priority. This project is a long term goal, and we are collaborating with other companies out there to make this work. I hope to have more to show off soon!

The E3Dv6 is shaping up well and we are concentrating on removing as much bulk and mass as possible for the next version. Our other priority is ease of use for the user. We hate having to use things like Kapton to secure thermistors but at the moment it's a needed evil.

I'm going to try and spend more of my day here on the forums chatting and responding to you guys, but forgive me if it takes a little more time than I should like!

Cheers,

Sanjay

It's been way too long since I've appeared and commented here - for that I apologise. It's been a crazy time here at E3D, we've constantly been in a state of scaling up to meet demand. I can't complain from a business perspective, but it's really hampered my ability to be present in these forums and elsewhere provide support and guidance where needed. I feel in some ways I haven't been able to keep the same level of engagement with the community that shaped E3D from where we started in these forums.

If you are having issues with your hotend please please get in touch via the contact page on our site and we will do all we can to support you. We reply to every email, it might take us a day or two, but we stand behind our product. Your hotend absolutely should print PLA without issues, and if it isn't something is wrong, we'll work with you to sort it out. We have thousands of these things in the wild, and our failure rate is really low - less than 0.2% at last count. Problems happen, sometimes it's a problem with a particular machine or setup, occasionally it's a problem due to manufacture on our end. Whatever happens, if you paid for a hotend you should get something that works.

Recently I've been doing some statistical analysis of how problems occur and it has become clear that almost all issues surrounding jamming happen in 1.75mm versions, with most (80%+) of those problems being in 1.75mm Bowden systems.

The most common cause of problems is lack of constraint on the filament. Where tubing in a bowden system isn't pushed right down into the hotend is a common cause of issues, also where the tubing has been pushed into the couplings, but not "locked" into place causes problems. (If you push the tubing into the coupler while pulling up on the collet it will lock into place with no backlash or wobble in the couplers.)

We also see issues where Bowden hotends are used as direct hotends by removing the coupler and simply mounting it as though it were a direct hotend. This is fine in principle, but there is an area of dead-space where the top of the hotend has been drilled out and tapped to accept the fitting. This dead space gives the filament and area to bow or buckle and this causes jams. It's an easy fix to use a short length of the supplied PTFE tubing to constrain and guide the filament down the into the hotend.

Onto more interesting matters!

We've been testing out the Kraken hotend a fair bit recently, and have had some really cool results with support material that breaks away cleanly and easily. This allows you to print objects with overhanging geometry without issues and without messy solvent/support dissolving steps which is really cool. We did a write up here:[e3d-online.com] which was done on a Kraken but should apply to any multi-extruder machine.

Our colour mixing hotend is developing quickly and we are optimising to try and get colour changes to happen as rapidly as possible. Responsiveness to colour change is our main priority. This project is a long term goal, and we are collaborating with other companies out there to make this work. I hope to have more to show off soon!

The E3Dv6 is shaping up well and we are concentrating on removing as much bulk and mass as possible for the next version. Our other priority is ease of use for the user. We hate having to use things like Kapton to secure thermistors but at the moment it's a needed evil.

I'm going to try and spend more of my day here on the forums chatting and responding to you guys, but forgive me if it takes a little more time than I should like!

Cheers,

Sanjay

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 19, 2014 08:17PM |

Registered: 11 years ago Posts: 210 |

Quote

biszkopt80

Any news when i will be able to buy your hotend Sanjay? On your shop from long time is pre-order,but i can get all parts separate.

They're out of fans at the moment, which is why you can do that (but you can't get the fan). Filastruder has the full hotends in stock though.

Edited 1 time(s). Last edit at 02/19/2014 08:17PM by greenman100.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 19, 2014 11:39PM |

Registered: 11 years ago Posts: 334 |

"We also see issues where Bowden hotends are used as direct hotends by removing the coupler and simply mounting it as though it were a direct hotend. This is fine in principle, but there is an area of dead-space where the top of the hotend has been drilled out and tapped to accept the fitting. This dead space gives the filament and area to bow or buckle and this causes jams. It's an easy fix to use a short length of the supplied PTFE tubing to constrain and guide the filament down the into the hotend."

I bought my e3d setup for 1.75 bowden because I was told it could be used direct or bowden. When I got mine I thought that that gap may be a problem. Is there any chance you have a screw in guide that would fill the gap?

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

I bought my e3d setup for 1.75 bowden because I was told it could be used direct or bowden. When I got mine I thought that that gap may be a problem. Is there any chance you have a screw in guide that would fill the gap?

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 20, 2014 08:03AM |

Registered: 12 years ago Posts: 177 |

Jzatopa

We don't have anything in the way of a threaded plug, however a small printed part is probably going to work just fine, especially if you're using some of the supplied PTFE tube inside to line it. I'll look at getting something CAD'd up for that and stick it on thingiverse when I get a chance.

biszkopt80

Greenman100 is right, in that we are out of fans at present. Chinese new year bit us, despite having made preparations to try and avoid it causes a supply chain headache. Best laid plans and all that! We should have them in from manufacture very soon, you can order in the meantime and your order will ship once the parts are in stock. Alternatively we have just added a "Metal Only Parts" options for those of you here that are a bit more experienced and probably have much of the electronics etc on hand already. It's also only £34. Obviously this doesn't come with a fan, so they are shipping same or next day. http://e3d-online.com/E3D-HotEnds

On tapers

Tapers are something I really want to experiment with, getting tiny reamers for 2mm holes (1.75mm filament) is a pain though. I'm going to look into getting some made up custom to get exactly the right geometry inside the break perhaps. There's definitely some gain to be had if stiction can be reduced or eliminated. It may also allow for a longer heat break, with less conduction, and therefore a smaller heatsink.

In General

Are people interested in teeny-tiny nozzles? We go down to 0.25mm at present, but I see people doing cool things on itty-bitty nozzles. The use case is limited, but I suppose in a setup with a Kraken you could have an array of nozzle sizes for different purposes, so you can do fast thick infill, with detailed perimeters. Maybe small different coloured details on objects? If people want it then I'll get some made up and sell them as "experimental".

Edited 1 time(s). Last edit at 02/20/2014 09:30AM by SanjayM.

I Design/Sell all-metal hotends. My company is called e3d-online - you can buy at [www.e3d-online.com]

We don't have anything in the way of a threaded plug, however a small printed part is probably going to work just fine, especially if you're using some of the supplied PTFE tube inside to line it. I'll look at getting something CAD'd up for that and stick it on thingiverse when I get a chance.

biszkopt80

Greenman100 is right, in that we are out of fans at present. Chinese new year bit us, despite having made preparations to try and avoid it causes a supply chain headache. Best laid plans and all that! We should have them in from manufacture very soon, you can order in the meantime and your order will ship once the parts are in stock. Alternatively we have just added a "Metal Only Parts" options for those of you here that are a bit more experienced and probably have much of the electronics etc on hand already. It's also only £34. Obviously this doesn't come with a fan, so they are shipping same or next day. http://e3d-online.com/E3D-HotEnds

On tapers

Tapers are something I really want to experiment with, getting tiny reamers for 2mm holes (1.75mm filament) is a pain though. I'm going to look into getting some made up custom to get exactly the right geometry inside the break perhaps. There's definitely some gain to be had if stiction can be reduced or eliminated. It may also allow for a longer heat break, with less conduction, and therefore a smaller heatsink.

In General

Are people interested in teeny-tiny nozzles? We go down to 0.25mm at present, but I see people doing cool things on itty-bitty nozzles. The use case is limited, but I suppose in a setup with a Kraken you could have an array of nozzle sizes for different purposes, so you can do fast thick infill, with detailed perimeters. Maybe small different coloured details on objects? If people want it then I'll get some made up and sell them as "experimental".

Edited 1 time(s). Last edit at 02/20/2014 09:30AM by SanjayM.

I Design/Sell all-metal hotends. My company is called e3d-online - you can buy at [www.e3d-online.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 20, 2014 12:38PM |

Registered: 10 years ago Posts: 1,381 |

@SanjayM:

I was hoping you would test a tapered bore.

I have designed custom cutters, and the cost is not much more than the off the shelf ones,

if you work with an outfit that is accustomed to grinding bespoke cutters.

Shop around, or it can be massively expensive with the wrong shop.

If you run into chatter (SS is tough) ask the machine shop their opinion of a left hand helix reamer,

5 deg radial rake angle, with a right hand cut, or for an alternative method, and tool (HSS, Cobalt, carbide).

Edited 1 time(s). Last edit at 02/20/2014 12:39PM by A2.

Quote

SanjayM

On tapers

Tapers are something I really want to experiment with, getting tiny reamers for 2mm holes (1.75mm filament) is a pain though. I'm going to look into getting some made up custom to get exactly the right geometry inside the break perhaps. There's definitely some gain to be had if stiction can be reduced or eliminated. It may also allow for a longer heat break, with less conduction, and therefore a smaller heatsink.

I was hoping you would test a tapered bore.

I have designed custom cutters, and the cost is not much more than the off the shelf ones,

if you work with an outfit that is accustomed to grinding bespoke cutters.

Shop around, or it can be massively expensive with the wrong shop.

If you run into chatter (SS is tough) ask the machine shop their opinion of a left hand helix reamer,

5 deg radial rake angle, with a right hand cut, or for an alternative method, and tool (HSS, Cobalt, carbide).

Quote

Bryan Enander

Left hand spiral reamers should be selected for through holes. A through hole has an opening on the other end. If you put your eye up to the hole, you would be able to see out of the other side of a through hole. A left hand spiral pushes the chips ahead of the reamer and out the other side of the hole. This reduces the chances of scarring the work-piece and reduces the chance of damaging the reamer by previously cut chips. Additionally a left hand spiral helps bridge interruptions such as cross-holes or keyways. Left hand spirals are excellent for reaming hard materials and typically provide the best size and finish as compared to right hand spiral or straight flutes.

A left hand spiral fluted reamer that is right hand cut is better for cutting harder materials because the opposing forces of the left hand spiral and the right hand cut balance each other out resulting in rounder and straighter holes.

[blog.supertoolinc.com]

Edited 1 time(s). Last edit at 02/20/2014 12:39PM by A2.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 07:24AM |

Registered: 12 years ago Posts: 64 |

Hi,

I am thinking about using the famous E3D hotend in a new printer design that I am working on. The reviews are amazing - I am convinced that it is truly the best hot-end out there - good job! Nevertheless, in light of the recent patent infringement case in the US, I am worried whether the E3D design potentially infringes on the thin-tube liquifier patent:

Patent US6004124

I am aware that it is often impossible to give a definite answer, and most of us are no lawyers here. However, some indication/thoughts/opinions would help a lot. I am sure that there are many other printer developers asking themselves the same question.

@Sanjay: Particularly your thoughts on this would be very helpful!

Thanks

I am thinking about using the famous E3D hotend in a new printer design that I am working on. The reviews are amazing - I am convinced that it is truly the best hot-end out there - good job! Nevertheless, in light of the recent patent infringement case in the US, I am worried whether the E3D design potentially infringes on the thin-tube liquifier patent:

Patent US6004124

I am aware that it is often impossible to give a definite answer, and most of us are no lawyers here. However, some indication/thoughts/opinions would help a lot. I am sure that there are many other printer developers asking themselves the same question.

@Sanjay: Particularly your thoughts on this would be very helpful!

Thanks

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 07:47AM |

Registered: 10 years ago Posts: 19 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 08:39AM |

Registered: 12 years ago Posts: 64 |

Quote

biszkopt80

This Stratasys ainc lookslike some patent troll,look how many patents they have, they shold ban companys like this to sell and buy in EU

The patent is not from a patent troll, but from Stratasys. This patent is being used in the legal case against Afinia.

Talking about banning companies, etc doesn't really help. Instead we should act smarter and work our way around these patents

Edited 1 time(s). Last edit at 02/21/2014 08:42AM by andin.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 08:47AM |

Registered: 10 years ago Posts: 553 |

Quote

andin

Hi,

I am thinking about using the famous E3D hotend in a new printer design that I am working on. The reviews are amazing - I am convinced that it is truly the best hot-end out there - good job! Nevertheless, in light of the recent patent infringement case in the US, I am worried whether the E3D design potentially infringes on the thin-tube liquifier patent:

Patent US6004124

I am aware that it is often impossible to give a definite answer, and most of us are no lawyers here. However, some indication/thoughts/opinions would help a lot. I am sure that there are many other printer developers asking themselves the same question.

@Sanjay: Particularly your thoughts on this would be very helpful!

Thanks

It helps if you read the patent...

"the first thin-wall tube has a wall thickness in the range of 0.008-0.015 inches, and an interior diameter of about 0.07 inches."

"the first section of the first tube is in the range of 0.02-0.04 inches long, and the second section of the first tube is about 2.5 inches long."

"the first and second metal tubes each have a wall thickness in the range of 0.008-0.015 inches, and an interior diameter of about 0.07 inches."

"the first section of the first and second thin-wall tubes are each in the range of 0.02-0.04 inches long, and the second section of the first and second thin-wall tubes are about 2.5 inches long."

Edited 1 time(s). Last edit at 02/21/2014 08:48AM by tjb1.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 08:54AM |

Registered: 12 years ago Posts: 64 |

I did notice these claims. However, they represent narrow claims. In Patents, I believe that the general claims are more important,

... at least to my knowledge of reading patents. I.e. Claim (1) in this case would fit well into what the E3D design achieves with a thermal break between the hot-end and the cold-end (heatsink):

1. An extrusion head for depositing layers of solidifying material in a desired pattern to form three-dimensional physical objects, the extrusion head comprising:

a heating block made of heat conductive material;

a heating element to heat the heating block;

a first thin-wall tube having an inlet end for receiving a flament of a first material, an outlet end for delivering the first material in a molten state, and having a first section adjacent the inlet end and exterior to the heating block and a second section which passes through the heating block;

a material advancee mechanism positioned to advance the filament of first material into the inlet end of the first thin-wall tube; and

a nozzle at the outlet end of the first thin-wall tube for dispensing the first material in a molten state.

Edited 1 time(s). Last edit at 02/21/2014 08:55AM by andin.

... at least to my knowledge of reading patents. I.e. Claim (1) in this case would fit well into what the E3D design achieves with a thermal break between the hot-end and the cold-end (heatsink):

1. An extrusion head for depositing layers of solidifying material in a desired pattern to form three-dimensional physical objects, the extrusion head comprising:

a heating block made of heat conductive material;

a heating element to heat the heating block;

a first thin-wall tube having an inlet end for receiving a flament of a first material, an outlet end for delivering the first material in a molten state, and having a first section adjacent the inlet end and exterior to the heating block and a second section which passes through the heating block;

a material advancee mechanism positioned to advance the filament of first material into the inlet end of the first thin-wall tube; and

a nozzle at the outlet end of the first thin-wall tube for dispensing the first material in a molten state.

Edited 1 time(s). Last edit at 02/21/2014 08:55AM by andin.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 10:09AM |

Registered: 10 years ago Posts: 553 |

Quote

andin

I did notice these claims. However, they represent narrow claims. In Patents, I believe that the general claims are more important,

... at least to my knowledge of reading patents. I.e. Claim (1) in this case would fit well into what the E3D design achieves with a thermal break between the hot-end and the cold-end (heatsink):

1. An extrusion head for depositing layers of solidifying material in a desired pattern to form three-dimensional physical objects, the extrusion head comprising:

a heating block made of heat conductive material;

a heating element to heat the heating block;

a first thin-wall tube having an inlet end for receiving a flament of a first material, an outlet end for delivering the first material in a molten state, and having a first section adjacent the inlet end and exterior to the heating block and a second section which passes through the heating block;

a material advancee mechanism positioned to advance the filament of first material into the inlet end of the first thin-wall tube; and

a nozzle at the outlet end of the first thin-wall tube for dispensing the first material in a molten state.

Thin-wall tube liquifier

US 6004124 A

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 10:15AM |

Registered: 12 years ago Posts: 64 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 10:24AM |

Registered: 12 years ago Posts: 1,236 |

Basically, Stratasys have patented heated tubes. (The "thin-wall" qualifier is meaningless, all tubes have thin walls).

It is a totally bogus patent, and I expect it to be ruled invalid in the Afinia case.

Instead of working around bogus patents, we should be getting rid of this stupid patent system.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

It is a totally bogus patent, and I expect it to be ruled invalid in the Afinia case.

Instead of working around bogus patents, we should be getting rid of this stupid patent system.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 10:30AM |

Registered: 10 years ago Posts: 553 |

Quote

bobc

Basically, Stratasys have patented heated tubes. (The "thin-wall" qualifier is meaningless, all tubes have thin walls).

It is a totally bogus patent, and I expect it to be ruled invalid in the Afinia case.

Instead of working around bogus patents, we should be getting rid of this stupid patent system.

"the first thin-wall tube has a wall thickness in the range of 0.008-0.015 inches, and an interior diameter of about 0.07 inches."

"the first section of the first tube is in the range of 0.02-0.04 inches long, and the second section of the first tube is about 2.5 inches long."

"the first and second metal tubes each have a wall thickness in the range of 0.008-0.015 inches, and an interior diameter of about 0.07 inches."

"the first section of the first and second thin-wall tubes are each in the range of 0.02-0.04 inches long, and the second section of the first and second thin-wall tubes are about 2.5 inches long."

They already define thin wall as .008-.015, the E3D wall is .4mm or .0157" which is outside the definition. E3D is also located in the UK, not sure if Stratasys has any power there.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 11:58AM |

Registered: 12 years ago Posts: 1,236 |

Quote

tjb1

Quote

bobc

Basically, Stratasys have patented heated tubes. (The "thin-wall" qualifier is meaningless, all tubes have thin walls).

It is a totally bogus patent, and I expect it to be ruled invalid in the Afinia case.

Instead of working around bogus patents, we should be getting rid of this stupid patent system.

"the first thin-wall tube has a wall thickness in the range of 0.008-0.015 inches, and an interior diameter of about 0.07 inches."

"the first section of the first tube is in the range of 0.02-0.04 inches long, and the second section of the first tube is about 2.5 inches long."

"the first and second metal tubes each have a wall thickness in the range of 0.008-0.015 inches, and an interior diameter of about 0.07 inches."

"the first section of the first and second thin-wall tubes are each in the range of 0.02-0.04 inches long, and the second section of the first and second thin-wall tubes are about 2.5 inches long.".

Repeating stuff doesn't contribute anything useful, and it's still a bogus patent.

Quote

They already define thin wall as .008-.015, the E3D wall is .4mm or .0157" which is outside the definition. E3D is also located in the UK, not sure if Stratasys has any power there.

You are looking at the claims too narrowly, being outside the definition didn't stop them suing Afinia.

E3D is sold in the USA, so any sellers (or indeed users) in the US could be sued.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 12:03PM |

Registered: 10 years ago Posts: 553 |

Quote

bobc

You are looking at the claims too narrowly, being outside the definition didn't stop them suing Afinia.

E3D is sold in the USA, so any sellers (or indeed users) in the US could be sued.

Did Stratsys win their case? I thought it was still on going. You can always file a suit against someone/company, but that doesn't mean you're going to win.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 01:05PM |

Registered: 10 years ago Posts: 553 |

Quote

bobc

Quote

tjb1

Quote

bobc

Basically, Stratasys have patented heated tubes. (The "thin-wall" qualifier is meaningless, all tubes have thin walls).

It is a totally bogus patent, and I expect it to be ruled invalid in the Afinia case.

Instead of working around bogus patents, we should be getting rid of this stupid patent system.

"the first thin-wall tube has a wall thickness in the range of 0.008-0.015 inches, and an interior diameter of about 0.07 inches."

"the first section of the first tube is in the range of 0.02-0.04 inches long, and the second section of the first tube is about 2.5 inches long."

"the first and second metal tubes each have a wall thickness in the range of 0.008-0.015 inches, and an interior diameter of about 0.07 inches."

"the first section of the first and second thin-wall tubes are each in the range of 0.02-0.04 inches long, and the second section of the first and second thin-wall tubes are about 2.5 inches long.".

Repeating stuff doesn't contribute anything useful, and it's still a bogus patent.

Quote

They already define thin wall as .008-.015, the E3D wall is .4mm or .0157" which is outside the definition. E3D is also located in the UK, not sure if Stratasys has any power there.

You are looking at the claims too narrowly, being outside the definition didn't stop them suing Afinia.

E3D is sold in the USA, so any sellers (or indeed users) in the US could be sued.

Look at the definition, just because they sue for something doesn't make it right or mean they will win but they have patented .008-.015 thinwall tubing.

"the first thin-wall tube has a wall thickness in the range of 0.008-0.015 inches, and an interior diameter of about 0.07 inches."

"the first section of the first tube is in the range of 0.02-0.04 inches long, and the second section of the first tube is about 2.5 inches long."

"the first and second metal tubes each have a wall thickness in the range of 0.008-0.015 inches, and an interior diameter of about 0.07 inches."

"the first section of the first and second thin-wall tubes are each in the range of 0.02-0.04 inches long, and the second section of the first and second thin-wall tubes are about 2.5 inches long."

Edited 1 time(s). Last edit at 02/21/2014 01:05PM by tjb1.

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 08:02PM |

Registered: 11 years ago Posts: 374 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 08:29PM |

Registered: 12 years ago Posts: 177 |

Patents

I'm completely unphased by the whole patent debacle here - we are lucky enough that we know some of the best patent solicitors here in the UK purely by personal connection. I did see the afinia case, particularly the "Thin wall tube" patent. They pretty much laughed at the patent as being incredibly narrow in it's scope - in particular regarding specific dimensions and materials. These dimensions and materials are not congruent with what we sell, and our product is quite different concept to the stratsys product described in patent.

The most key point here is that the "thin wall" is mandated in the stratasys patent as an area to increase conduction of heat in the melt zone. The thin walled tube is used in the heater block, so that heat can penetrate the thin walls effectively.

Trying to retroactively pin the use of a heatbreak with this patent is entirely erroneous when stratasys' patent applies to the "melt zone" in the design, not the "transition zone" that in an E3D nozzle has a thin wall.

TL R = Patent is crap, I'm not fussed.

R = Patent is crap, I'm not fussed.

crispy1

0.5mm is a pretty obvious and lacking nozzle size, I see no reason we shouldn't have these up for sale. We'll get those in stock - thanks for your input.

Edited 1 time(s). Last edit at 02/21/2014 08:29PM by SanjayM.

I Design/Sell all-metal hotends. My company is called e3d-online - you can buy at [www.e3d-online.com]

I'm completely unphased by the whole patent debacle here - we are lucky enough that we know some of the best patent solicitors here in the UK purely by personal connection. I did see the afinia case, particularly the "Thin wall tube" patent. They pretty much laughed at the patent as being incredibly narrow in it's scope - in particular regarding specific dimensions and materials. These dimensions and materials are not congruent with what we sell, and our product is quite different concept to the stratsys product described in patent.

The most key point here is that the "thin wall" is mandated in the stratasys patent as an area to increase conduction of heat in the melt zone. The thin walled tube is used in the heater block, so that heat can penetrate the thin walls effectively.

Trying to retroactively pin the use of a heatbreak with this patent is entirely erroneous when stratasys' patent applies to the "melt zone" in the design, not the "transition zone" that in an E3D nozzle has a thin wall.

TL

R = Patent is crap, I'm not fussed.

R = Patent is crap, I'm not fussed.crispy1

0.5mm is a pretty obvious and lacking nozzle size, I see no reason we shouldn't have these up for sale. We'll get those in stock - thanks for your input.

Edited 1 time(s). Last edit at 02/21/2014 08:29PM by SanjayM.

I Design/Sell all-metal hotends. My company is called e3d-online - you can buy at [www.e3d-online.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 21, 2014 08:58PM |

Registered: 11 years ago Posts: 46 |

Quote

SanjayM

[snip...]

Recently I've been doing some statistical analysis of how problems occur and it has become clear that almost all issues surrounding jamming happen in 1.75mm versions, with most (80%+) of those problems being in 1.75mm Bowden systems. [snip...]

Just don't drop support for 3mm like so many other companies. 3mm is far superior to 1.75 and its not surprising to see your stats on this. I wish more people would request shops carry 3mm supplies because 3mm should be more prevalent when you consider its superior parameters for 3D FFF printing. I suppose if you are running direct drive multiple extruders you might be forced to go with 1.75 but in most other use cases 3mm is better. E3D's support of 3mm is why I decided on the hot end and its been working great!

[www.printrbottalk.com] Printrbot Forum and Wiki

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 22, 2014 01:07AM |

Registered: 10 years ago Posts: 239 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 22, 2014 08:13AM |

Registered: 12 years ago Posts: 177 |

Plexus

We've no intention of dropping 3mm whatsoever - especially with flexible filaments becoming more popular which are much more easily printed in 3mm.

Bill Clark

I can't find an order that corresponds with your name - but if you shoot me an email with more details then I'll be able to look you up.

In short:

v4 =First version, one batch made/sold only - thick fins, shallow nozzle point.

v4.1 = Sold between v4 and v5, lots of changes made in here, 3 batches made/sold, design was in flux at this point. Fins made thinner, then nozzle point made steeper, lots of tweaks made to internal chamfers, some versions sold in v4.1 have a slightly shorter heatbreak than all other batches. In retrospect I regret v4.1 altogether - not because there was anything wrong with them, but just because it meant I had a huge amount of disparate product in the wild, with too many variables when it came to problem solving and customer support.

v5 - Design locked down - incorporates all positive changes from v4.1, new manufacturer for certain parts to increase consistency in manufacture. Throughout v5 we've made small changes to the heater block thermistor holes due to EPCOS ceasing manufacture of their 100k thermistor. Moved to smaller Semitec thermistors. See here for details: [e3d-online.com]

Newest lot of blocks has just a single small hole for Semitec Thermistors, and all current hotend kits are sold with Semitec. (Thermistor #5 in Marlin etc)

I Design/Sell all-metal hotends. My company is called e3d-online - you can buy at [www.e3d-online.com]

We've no intention of dropping 3mm whatsoever - especially with flexible filaments becoming more popular which are much more easily printed in 3mm.

Bill Clark

I can't find an order that corresponds with your name - but if you shoot me an email with more details then I'll be able to look you up.

In short:

v4 =First version, one batch made/sold only - thick fins, shallow nozzle point.

v4.1 = Sold between v4 and v5, lots of changes made in here, 3 batches made/sold, design was in flux at this point. Fins made thinner, then nozzle point made steeper, lots of tweaks made to internal chamfers, some versions sold in v4.1 have a slightly shorter heatbreak than all other batches. In retrospect I regret v4.1 altogether - not because there was anything wrong with them, but just because it meant I had a huge amount of disparate product in the wild, with too many variables when it came to problem solving and customer support.

v5 - Design locked down - incorporates all positive changes from v4.1, new manufacturer for certain parts to increase consistency in manufacture. Throughout v5 we've made small changes to the heater block thermistor holes due to EPCOS ceasing manufacture of their 100k thermistor. Moved to smaller Semitec thermistors. See here for details: [e3d-online.com]

Newest lot of blocks has just a single small hole for Semitec Thermistors, and all current hotend kits are sold with Semitec. (Thermistor #5 in Marlin etc)

I Design/Sell all-metal hotends. My company is called e3d-online - you can buy at [www.e3d-online.com]

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 22, 2014 08:22AM |

Registered: 10 years ago Posts: 239 |

Re: Update on the E3D All Metal Hotend (Now finally shipping!)  [Lots of pictures] [Lots of pictures] February 22, 2014 10:01PM |

Registered: 10 years ago Posts: 553 |

Quote

plexus

Quote

SanjayM

[snip...]

Recently I've been doing some statistical analysis of how problems occur and it has become clear that almost all issues surrounding jamming happen in 1.75mm versions, with most (80%+) of those problems being in 1.75mm Bowden systems. [snip...]

Just don't drop support for 3mm like so many other companies. 3mm is far superior to 1.75 and its not surprising to see your stats on this. I wish more people would request shops carry 3mm supplies because 3mm should be more prevalent when you consider its superior parameters for 3D FFF printing. I suppose if you are running direct drive multiple extruders you might be forced to go with 1.75 but in most other use cases 3mm is better. E3D's support of 3mm is why I decided on the hot end and its been working great!

Far superior huh? In what way?

Sorry, only registered users may post in this forum.