Precision Piezo Z-probe Now available.

Posted by DjDemonD

|

Re: Precision Piezo Z-probe Now available. July 05, 2020 05:26PM |

Registered: 3 years ago Posts: 5 |

I Have a question about using this kit with CR10/Ender3 printers.

I have a CR10S with a E3D Titan Aero. So far I have only found one mount that supports the Titan Aero, and Piezo ABL. The problem is you lose about 10mm of bed space over the position of the head. Sadly the Titan Aero is hard to use on the CR10 and not lose some space just from the size of everything.

Have you (or anyone on this thread) had any luck with this combination?

I have an Ender3 Pro that I would like to upgrade at some point, I'm still using a BLTouch with the default hot end, but want to go DD with it at some point, Titan, or hack job to modify the default hot end into a DD, I'm still trying to make my mind up.

From what I can tell the only implementations for Piezo on the hot end is to drill the center and mount inline with the bowden tube.

Does anyone have alternative mounts to use complete disks without needing to drill?

Thanks, I've had a few hiccups here and there, it seems that the system is extremely sensitive, and took me some time to dial in, I still have to re calibrate and spend some time turning the trim pots to get it dialed back in every time I remove the hotend and reattach it (had to replace belts once, and had to take it apart for jams a few times)

I definitely get that the other method with the drilled hole makes for an assembly that is independent from the hot end thus no need to reconfigure each time, I just cannot use that method with the hot end I have. I've somewhat fixed this by making my own piezo (soldering my own 22awg wires to the disk directly) and zip tying the holy crap out of it. But any ideas for other mounts would be most appreciated! (I'm starting to play with Fusion 360 so I may try my hand at modeling one of my own) but I'd rather not recreate the wheel if there were a mount that already exists.

Cheers! and thanks for making this PCB I definitely like this ABL above any other I have tried!.

Side question, if the trim pots do eventually die on me, can you tell me the ratings, so I can try to replace them should this become a problem?

Thanks again!

I have a CR10S with a E3D Titan Aero. So far I have only found one mount that supports the Titan Aero, and Piezo ABL. The problem is you lose about 10mm of bed space over the position of the head. Sadly the Titan Aero is hard to use on the CR10 and not lose some space just from the size of everything.

Have you (or anyone on this thread) had any luck with this combination?

I have an Ender3 Pro that I would like to upgrade at some point, I'm still using a BLTouch with the default hot end, but want to go DD with it at some point, Titan, or hack job to modify the default hot end into a DD, I'm still trying to make my mind up.

From what I can tell the only implementations for Piezo on the hot end is to drill the center and mount inline with the bowden tube.

Does anyone have alternative mounts to use complete disks without needing to drill?

Thanks, I've had a few hiccups here and there, it seems that the system is extremely sensitive, and took me some time to dial in, I still have to re calibrate and spend some time turning the trim pots to get it dialed back in every time I remove the hotend and reattach it (had to replace belts once, and had to take it apart for jams a few times)

I definitely get that the other method with the drilled hole makes for an assembly that is independent from the hot end thus no need to reconfigure each time, I just cannot use that method with the hot end I have. I've somewhat fixed this by making my own piezo (soldering my own 22awg wires to the disk directly) and zip tying the holy crap out of it. But any ideas for other mounts would be most appreciated! (I'm starting to play with Fusion 360 so I may try my hand at modeling one of my own) but I'd rather not recreate the wheel if there were a mount that already exists.

Cheers! and thanks for making this PCB I definitely like this ABL above any other I have tried!.

Side question, if the trim pots do eventually die on me, can you tell me the ratings, so I can try to replace them should this become a problem?

Thanks again!

|

Re: Precision Piezo Z-probe Now available. July 15, 2020 09:14AM |

Registered: 3 years ago Posts: 15 |

|

Re: Precision Piezo Z-probe Now available. July 15, 2020 11:12AM |

Registered: 3 years ago Posts: 15 |

Thinking about it... i was wondering why these 2 extra empty holes? And then... would the diagonal arrangement possibly translate in tilting off side where there is less resistance?

Anyhow... 3 might be the magic number. I'd call her trinity.

Anyhow... 3 might be the magic number. I'd call her trinity.

|

Re: Precision Piezo Z-probe Now available. July 16, 2020 10:49AM |

Registered: 9 years ago Posts: 487 |

If it were simply a matter of fitting the parts as close together as possible then yes, it could be made smaller, but there are other factors at play here.

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. July 16, 2020 11:46AM |

Registered: 3 years ago Posts: 15 |

|

Re: Precision Piezo Z-probe Now available. July 18, 2020 05:00PM |

Admin Registered: 11 years ago Posts: 3,096 |

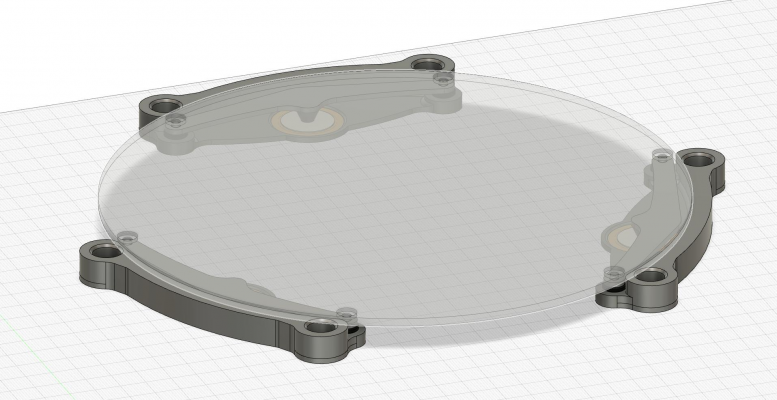

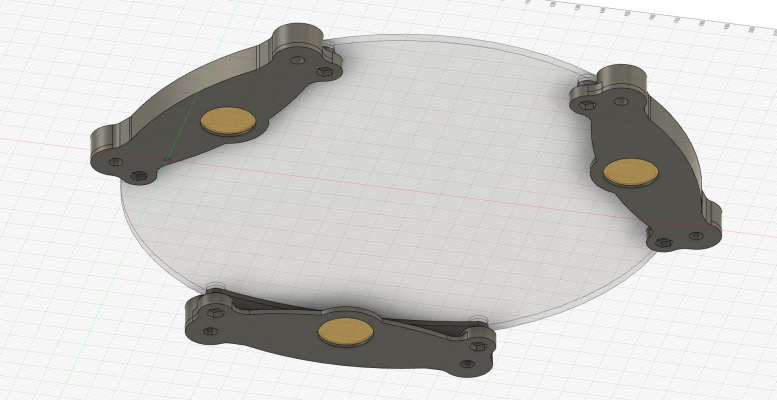

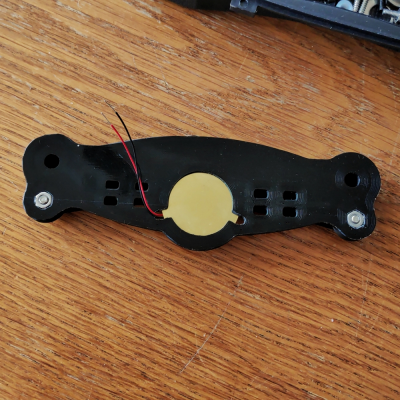

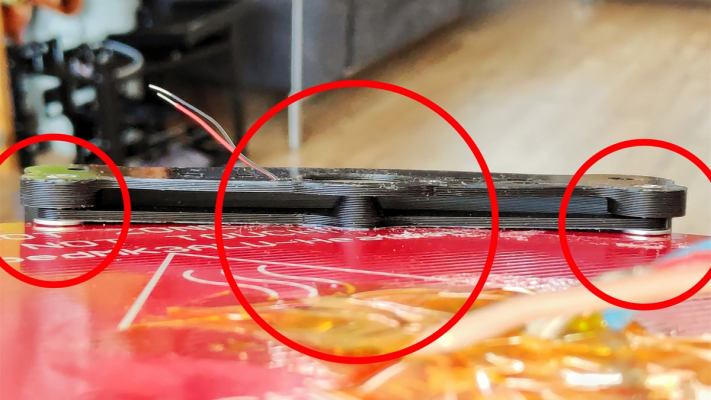

So maybe I'm just thinking way too complicated here, but I'm sketching a Delta mount for my heated bed:

The 'depressor' is held up on two little black pieces of rubber that go around each screw. This is supposed to 'preload' the piezo discs to a certain extent.

On the bottom there is a hole so the piezo disc rests only around it's edge:

Am I making it too complicated? The depressor is a floating part that sits flush against the heated bed underside. The tapered point is 5mm wide in diameter and compressed with a preload onto the piezo disc. I will add a layer of cork to insulate the bottom of the heated bed to try and minimize the piezo heating up.

Edited 1 time(s). Last edit at 07/18/2020 05:01PM by Ohmarinus.

http://www.marinusdebeer.nl/

The 'depressor' is held up on two little black pieces of rubber that go around each screw. This is supposed to 'preload' the piezo discs to a certain extent.

On the bottom there is a hole so the piezo disc rests only around it's edge:

Am I making it too complicated? The depressor is a floating part that sits flush against the heated bed underside. The tapered point is 5mm wide in diameter and compressed with a preload onto the piezo disc. I will add a layer of cork to insulate the bottom of the heated bed to try and minimize the piezo heating up.

Edited 1 time(s). Last edit at 07/18/2020 05:01PM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Precision Piezo Z-probe Now available. July 18, 2020 07:03PM |

Registered: 9 years ago Posts: 487 |

I don't see any issues with that design, should work well.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. July 19, 2020 06:31AM |

Admin Registered: 11 years ago Posts: 3,096 |

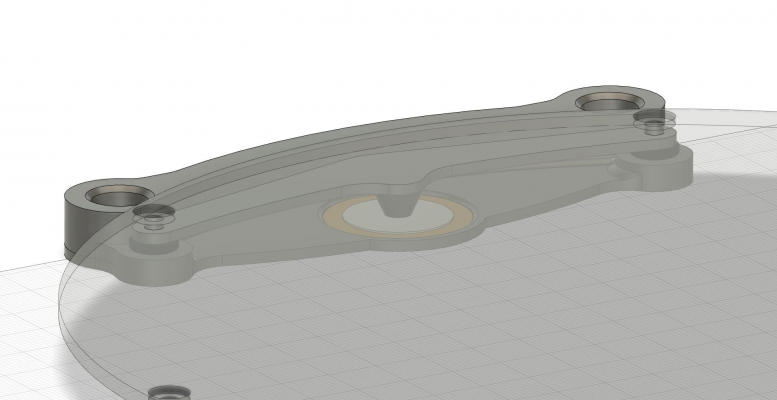

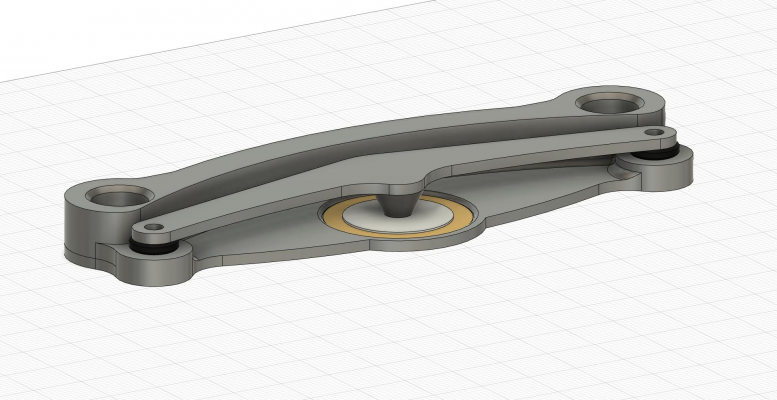

Printed one example, and it looks like it could actually work. I don't even think that the rubber is needed between the left and right bolts. If I 'bend' the compression arm by using a spacer between the bed and the arm at the bolt points, this will cause the sides of the compression bar to curve down and logically the center of the bar will be the highest point, logically causing it to be the only point the bed then rests on. The bolts will only keep the bed in place and apply a bit of downforce.

Finished module; the top bar is pushing on the piezo disc with a 5mm round point:

Top view, notice the hole for the wires:

Here you see the bottom of the disc and how it is supported around it's rim:

I wonder if anyone has ever made something similar.

When I print the other three parts, I will show it mounted to the heated bed.

Meanwhile, concerning the electronics... Does anyone have an idea how to best connect the wires? And is it critical all piezo's have the same total wire length? I have bad experiences with crimping such thin wires and the wires are only 40mm long so they need to be extended because in this setup the three discs cannot be connected to the PCB with such short wires.

Furthermore, is a 5mm surface point enough to depress the piezo? Do I have to visually deform the piezo under stress to generate a signal, or is simply pushing on it already enough? I can re-design the pressure bar to have a smaller point, resulting in a lower surface area of contact, and a higher pressure in the center of the piezo.

Edit;

One more example showing how the bed is mainly touching the piezo:

(in this configuration the bolts are not tied down completely so the bed is really only resting purely on the piezo)

Edited 3 time(s). Last edit at 07/19/2020 06:47AM by Ohmarinus.

http://www.marinusdebeer.nl/

Finished module; the top bar is pushing on the piezo disc with a 5mm round point:

Top view, notice the hole for the wires:

Here you see the bottom of the disc and how it is supported around it's rim:

I wonder if anyone has ever made something similar.

When I print the other three parts, I will show it mounted to the heated bed.

Meanwhile, concerning the electronics... Does anyone have an idea how to best connect the wires? And is it critical all piezo's have the same total wire length? I have bad experiences with crimping such thin wires and the wires are only 40mm long so they need to be extended because in this setup the three discs cannot be connected to the PCB with such short wires.

Furthermore, is a 5mm surface point enough to depress the piezo? Do I have to visually deform the piezo under stress to generate a signal, or is simply pushing on it already enough? I can re-design the pressure bar to have a smaller point, resulting in a lower surface area of contact, and a higher pressure in the center of the piezo.

Edit;

One more example showing how the bed is mainly touching the piezo:

(in this configuration the bolts are not tied down completely so the bed is really only resting purely on the piezo)

Edited 3 time(s). Last edit at 07/19/2020 06:47AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Precision Piezo Z-probe Now available. July 19, 2020 10:32AM |

Registered: 12 years ago Posts: 1,450 |

5mm should be fine. If the contact point is too small then there is a risk of damaging the PZT ceramic while if it is too large much of the bending would be in theo uoter part where there is no piezoelectric material.

Your design should work well but try not to let the perimeter of the bed snag on the body part of your supports - as long as there is a little clearance around the edge then a quick tap with your knuckles or the blunt end of a screwdriver will stop it snagging.

Mike

Your design should work well but try not to let the perimeter of the bed snag on the body part of your supports - as long as there is a little clearance around the edge then a quick tap with your knuckles or the blunt end of a screwdriver will stop it snagging.

Mike

|

Re: Precision Piezo Z-probe Now available. July 19, 2020 12:19PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

leadinglights

5mm should be fine. If the contact point is too small then there is a risk of damaging the PZT ceramic while if it is too large much of the bending would be in theo uoter part where there is no piezoelectric material.

Your design should work well but try not to let the perimeter of the bed snag on the body part of your supports - as long as there is a little clearance around the edge then a quick tap with your knuckles or the blunt end of a screwdriver will stop it snagging.

Mike

Thanks for the feedback! The edges won't snag, I'll keep an eye on it. Printing the second module now and the third in an hour or so. Today is the day! I'll update if it worked.

http://www.marinusdebeer.nl/

|

Re: Precision Piezo Z-probe Now available. July 20, 2020 03:30AM |

Admin Registered: 11 years ago Posts: 3,096 |

Something confused me a bit, the guide: Guide still talks about the 2.75 version. Some pinouts are different and I noticed a 'D' and an 'A' on the v2.85

But the guide doesn't explain the difference, I have searched for both digital and analog in the guide but to no avail. From what I understand is that with the Analog connection you can set the sensitivity, and with the Digital, you cannot? Which mode is best for me? I'm using the v2.85 on an SKR 1.3 as the z-min endstop (on a Delta).

Also, I have read the wires to the piezo's should be as short as possible. But at the same time, I need to be able to tune the sensitivity. I'm about to add around 5~10cm of wire to the piezo's. Does that matter much, and is it okay if the wire length is different for each piezo? I can imagine the wire length might influence the signal timing a little bit? I'm no expert on this, but won't it cause a small shift in reading and therefor the signal can be seen as noise?

Going to go ahead, but would like to know the theory so that I can at least change the wiring if it turns out to not be working and I don't know why.

PS first results are in:

[www.youtube.com]

Edited 3 time(s). Last edit at 07/20/2020 10:36AM by Ohmarinus.

http://www.marinusdebeer.nl/

But the guide doesn't explain the difference, I have searched for both digital and analog in the guide but to no avail. From what I understand is that with the Analog connection you can set the sensitivity, and with the Digital, you cannot? Which mode is best for me? I'm using the v2.85 on an SKR 1.3 as the z-min endstop (on a Delta).

Also, I have read the wires to the piezo's should be as short as possible. But at the same time, I need to be able to tune the sensitivity. I'm about to add around 5~10cm of wire to the piezo's. Does that matter much, and is it okay if the wire length is different for each piezo? I can imagine the wire length might influence the signal timing a little bit? I'm no expert on this, but won't it cause a small shift in reading and therefor the signal can be seen as noise?

Going to go ahead, but would like to know the theory so that I can at least change the wiring if it turns out to not be working and I don't know why.

PS first results are in:

[www.youtube.com]

Edited 3 time(s). Last edit at 07/20/2020 10:36AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Precision Piezo Z-probe Now available. July 20, 2020 02:22PM |

Registered: 9 years ago Posts: 487 |

You can solder extension wires to the piezo disks cables, try to keep the total length short but you shouldn't have issues with lengths up to 300mm. I strongly suggest you secure the wires close to the piezo disk and ensure that there is no stress on the solder joints of the disk itself, they are quite delicate. The lengths do not need to be the same.

You do not need to see any deflection of the disk, movement of the disk will probably be well under 0.1mm.

The guide has not been updated since the release of the v2.85 board, for your application use the D pins and everything will behave identically to the v2.75 described in the guide.

The A pins output an analog signal that can be used with a Duet to set the trigger threshold through the web interface, as far as I know this cannot be done with any other controller.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

You do not need to see any deflection of the disk, movement of the disk will probably be well under 0.1mm.

The guide has not been updated since the release of the v2.85 board, for your application use the D pins and everything will behave identically to the v2.75 described in the guide.

The A pins output an analog signal that can be used with a Duet to set the trigger threshold through the web interface, as far as I know this cannot be done with any other controller.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. July 21, 2020 01:45PM |

Admin Registered: 11 years ago Posts: 3,096 |

Okay, so far the system runs fine (by the way, I'm using the analog signal without having it even tuned and it runs perfectly!), I have made a correct mesh, but all of a sudden after stopping one print and starting it again, the heated bed is suddenly not even anymore according to the machine. I do not understand what's happening since I've been printing fine for about a whole day without this issue. The system is fixed and everything is in place. The hotend is straight, didn't move and the bed is also still exactly in the same place. I checked the flatness with a ruler and the heated bed doesn't seem to bend after some time of being hot.

Is there a way so I can do a bed-level check before each and every print instead of relying on:

G29 L0

G29 A

at the beginning of every print?

Because somehow the printer seems to vary in first layer height. This is giving me too much of a headache. On my MendelMax 1.8 printer I use an inductive sensor and before each print it measures 9 points on the bed and it always has perfect prints. Is there a way to get my Delta run the same type of calibration before each print with the piezo setup? I don't want to use mesh bed leveling anymore because due to some unknown reason the printer seems to lose it's calibration even though everything is fixed. Must be heat creep or something.

Update;

It seems the machine is more bipolar than its motors.. Now all of a sudden it wants to lay down perfect layers.

[youtu.be]

Do I have a machine with a mental disorder? Btw Digital output is extremely sensitive and not usable. It already triggers when the motors think of moving.

Edited 3 time(s). Last edit at 07/21/2020 03:47PM by Ohmarinus.

http://www.marinusdebeer.nl/

Is there a way so I can do a bed-level check before each and every print instead of relying on:

G29 L0

G29 A

at the beginning of every print?

Because somehow the printer seems to vary in first layer height. This is giving me too much of a headache. On my MendelMax 1.8 printer I use an inductive sensor and before each print it measures 9 points on the bed and it always has perfect prints. Is there a way to get my Delta run the same type of calibration before each print with the piezo setup? I don't want to use mesh bed leveling anymore because due to some unknown reason the printer seems to lose it's calibration even though everything is fixed. Must be heat creep or something.

Update;

It seems the machine is more bipolar than its motors.. Now all of a sudden it wants to lay down perfect layers.

[youtu.be]

Do I have a machine with a mental disorder? Btw Digital output is extremely sensitive and not usable. It already triggers when the motors think of moving.

Edited 3 time(s). Last edit at 07/21/2020 03:47PM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Precision Piezo Z-probe Now available. July 22, 2020 10:51AM |

Registered: 9 years ago Posts: 487 |

The digital output probably needs tuning using VR2.

Unfortunately I don't have much current experience of Marlin so I can't help you with that.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Unfortunately I don't have much current experience of Marlin so I can't help you with that.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. July 23, 2020 06:02AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

Moriquendi

The digital output probably needs tuning using VR2.

Unfortunately I don't have much current experience of Marlin so I can't help you with that.

Idris

Thanks, I'll try the digital way the next time I open the machine.

For now I discovered that with this startup script it works perfectly:

G28 ;Home

G29 A ; Activate the UBL System.

G29 L0 ; Load the mesh stored in slot 0 (from G29 S0)

G29 J ; No size specified on the J option tells G29 to probe the specified 3 points and tilt the mesh according to what it finds.

http://www.marinusdebeer.nl/

|

Re: Precision Piezo Z-probe Now available. September 24, 2020 09:25PM |

Registered: 6 years ago Posts: 30 |

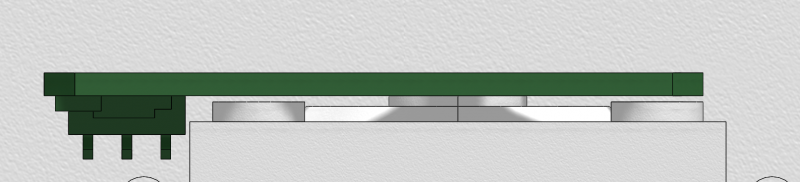

Hello! I have a Orion here that I am assembling on my new hotend, and I have a question: The mount has a 0.4mm difference between the mid hole and the four holes around it, if I am not mistaken, something like this

Am I supposed to squeeze the screws as much as possible, or just enough, or what is the torque for that? My worry is getting those screws uneven and throwing the hotend out of tram.

Thanks!

Am I supposed to squeeze the screws as much as possible, or just enough, or what is the torque for that? My worry is getting those screws uneven and throwing the hotend out of tram.

Thanks!

|

Re: Precision Piezo Z-probe Now available. September 25, 2020 04:47AM |

Registered: 9 years ago Posts: 487 |

You should tighten the screws so that there is no gap between the PCB and the mount, this preloads the PCB.

It's not easy to say exactly how tight the screws should be, too tight and the sensor will be unresponsive, too loose and you'll get false triggers. My advice is to tighten the screws so that there is no gap then probe the bed. If the probe doesn't trigger as soon as the nozzle touches the bed, loosen the screws half a turn each. Repeat until you get accurate triggering but no false triggers.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

It's not easy to say exactly how tight the screws should be, too tight and the sensor will be unresponsive, too loose and you'll get false triggers. My advice is to tighten the screws so that there is no gap then probe the bed. If the probe doesn't trigger as soon as the nozzle touches the bed, loosen the screws half a turn each. Repeat until you get accurate triggering but no false triggers.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. September 29, 2020 10:48AM |

Registered: 3 years ago Posts: 3 |

I have installed an Orion to my Ender 5 (Duet wifi with RRF3) with Gulfcoast hotend (same-same microswiss) using the top mount from here

[www.thingiverse.com]

and the bottom mount from here

[www.thingiverse.com]

I modified the top end a bit because I felt there was not enough "meat" to support the 3mm inserts I have - at least with my skill level .....

I also enlarged the holes for the tool fan and used 2mm nuts as "inserts" and made it a little more supportive. I did not make any changes to the "interior"

Same for the bottom end - except I filled in the hollow section between the screw holes - essentially, it is now one solid piece (see attached stl).

I've been having some issues getting reproducible mesh leveling / getting consistent triggering. I snugged up the mount screws and then relaxed them one full turn. I adjusted the potentiometer so that it occasionally triggers on a carriage move. My config.g has this setting. Note that with lower F values - it will sometimes just push the bed up without triggering. I checked that a manual push up (versus a tap) triggered the probe (on then off). Relaxing the push up did nothing.

M558 P8 C"^!zprobe.in" R0.6 H5 F600 T3000

Any advice? Specifically - how important is that hollow section in the bottom end ? Is there a way to actually measure the deviation across multiple probes (say at the same point ?)

Thanks in advance.

Edited 1 time(s). Last edit at 09/29/2020 10:49AM by stuartofmt.

[www.thingiverse.com]

and the bottom mount from here

[www.thingiverse.com]

I modified the top end a bit because I felt there was not enough "meat" to support the 3mm inserts I have - at least with my skill level .....

I also enlarged the holes for the tool fan and used 2mm nuts as "inserts" and made it a little more supportive. I did not make any changes to the "interior"

Same for the bottom end - except I filled in the hollow section between the screw holes - essentially, it is now one solid piece (see attached stl).

I've been having some issues getting reproducible mesh leveling / getting consistent triggering. I snugged up the mount screws and then relaxed them one full turn. I adjusted the potentiometer so that it occasionally triggers on a carriage move. My config.g has this setting. Note that with lower F values - it will sometimes just push the bed up without triggering. I checked that a manual push up (versus a tap) triggered the probe (on then off). Relaxing the push up did nothing.

M558 P8 C"^!zprobe.in" R0.6 H5 F600 T3000

Any advice? Specifically - how important is that hollow section in the bottom end ? Is there a way to actually measure the deviation across multiple probes (say at the same point ?)

Thanks in advance.

Edited 1 time(s). Last edit at 09/29/2020 10:49AM by stuartofmt.

|

Re: Precision Piezo Z-probe Now available. September 29, 2020 02:19PM |

Registered: 9 years ago Posts: 487 |

By filling in the hollow section you have made the bottom clamp too stiff. The compliance of the bottom part is vital to the correct functioning of the sensor.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. September 29, 2020 04:37PM |

Registered: 3 years ago Posts: 3 |

|

Re: Precision Piezo Z-probe Now available. October 20, 2020 04:31PM |

Registered: 11 years ago Posts: 65 |

My Orion V1 started to act up and since its always been a pita to adjust the pot I decided to get a new V2.

It's turned out not to be a simple swap and go. After installation and wiring it to the digital pins I adjusted the pot so it trips with very light pressure. When homed and its lowering to the bed I can bump the hot end and it immediately retracts. If I let it lower to the bed it hits the bed hard and pushes it down. I've adjusted and readjusted with no success. I've changed probing speeds with no improvement.

I've searched this thread but haven't found anything that helps.

Anyone have any ideas?

Thanks

Rambo controller

My Max (heavily modified MendelMax 1.5)

FWIW I see another post from inventabuild on 12/4/19 who had a similar issue that was never answered

Edited 1 time(s). Last edit at 10/21/2020 09:08AM by Flyer2.

It's turned out not to be a simple swap and go. After installation and wiring it to the digital pins I adjusted the pot so it trips with very light pressure. When homed and its lowering to the bed I can bump the hot end and it immediately retracts. If I let it lower to the bed it hits the bed hard and pushes it down. I've adjusted and readjusted with no success. I've changed probing speeds with no improvement.

I've searched this thread but haven't found anything that helps.

Anyone have any ideas?

Thanks

Rambo controller

My Max (heavily modified MendelMax 1.5)

FWIW I see another post from inventabuild on 12/4/19 who had a similar issue that was never answered

Edited 1 time(s). Last edit at 10/21/2020 09:08AM by Flyer2.

|

Re: Precision Piezo Z-probe Now available. October 21, 2020 03:15PM |

Registered: 9 years ago Posts: 487 |

You probably need to adjust the four assembly screws, if they're too tight they can show the behaviour you describe. Try loosening each screw by half a turn and re-tune, you may need to do this more than once.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Precision Piezo Z-probe Now available. October 21, 2020 07:40PM |

Registered: 11 years ago Posts: 65 |

|

Re: Precision Piezo Z-probe Now available. October 21, 2020 11:58PM |

Registered: 3 years ago Posts: 3 |

Sadly - these are the same sort of issues I had and caused me to go back (successfully) to BLTouch (that and thermal sensitivity). In retrospect - I had one situation (that may be of help / a clue) -- this was that I accidentally disconnected the hotend fan and caused the lower mount to warp - making it impossible to calibrate. However, even after reprinting a lower mount - I could not get repeatability to my satisfaction. Hope this helps. YMMV.

|

Re: Precision Piezo Z-probe Now available. October 22, 2020 12:54AM |

Registered: 5 years ago Posts: 60 |

|

Re: Precision Piezo Z-probe Now available. October 22, 2020 08:33AM |

Registered: 11 years ago Posts: 65 |

Thanks for the input. As much as I like 3D printing everything becomes a chore. What should be a simple swap out is another exercise in frustration. I gave up on the fan for my e3d a long time ago. Finally made a water cooling jacket for it and haven’t had filament issues since then but now the water pump needs to be replaced. Fixed one issue just to create another.

|

Re: Precision Piezo Z-probe Now available. October 22, 2020 11:52AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

Ohmarinus

Printed one example, and it looks like it could actually work. I don't even think that the rubber is needed between the left and right bolts. If I 'bend' the compression arm by using a spacer between the bed and the arm at the bolt points, this will cause the sides of the compression bar to curve down and logically the center of the bar will be the highest point, logically causing it to be the only point the bed then rests on. The bolts will only keep the bed in place and apply a bit of downforce.

Finished module; the top bar is pushing on the piezo disc with a 5mm round point:

[attachment 116225 IMG_POCO_F1_20200719_121733-01.jpeg]

Top view, notice the hole for the wires:

[attachment 116226 IMG_POCO_F1_20200719_121758-01.jpeg]

Here you see the bottom of the disc and how it is supported around it's rim:

[attachment 116227 IMG_POCO_F1_20200719_121744-01.jpeg]

I wonder if anyone has ever made something similar.

When I print the other three parts, I will show it mounted to the heated bed.

Meanwhile, concerning the electronics... Does anyone have an idea how to best connect the wires? And is it critical all piezo's have the same total wire length? I have bad experiences with crimping such thin wires and the wires are only 40mm long so they need to be extended because in this setup the three discs cannot be connected to the PCB with such short wires.

Furthermore, is a 5mm surface point enough to depress the piezo? Do I have to visually deform the piezo under stress to generate a signal, or is simply pushing on it already enough? I can re-design the pressure bar to have a smaller point, resulting in a lower surface area of contact, and a higher pressure in the center of the piezo.

Edit;

One more example showing how the bed is mainly touching the piezo:

(in this configuration the bolts are not tied down completely so the bed is really only resting purely on the piezo)

[attachment 116228 IMG_POCO_F1_20200719_124302-01_d.jpg]

Someone asked me to share the design files for this DIY underbed mount. I kinda forgot but here is the STEP file. I am not going to share an STL because I firmly believe that STEP files should be the norm and not STL files.

This is the design file:

Heated_bed_piezomountv14.step

http://www.marinusdebeer.nl/

|

Re: Precision Piezo Z-probe Now available. October 22, 2020 02:57PM |

Registered: 12 years ago Posts: 1,450 |

Piezos are inherently very sensitive and this means that they can pick up movement that is not what is being looked for. The most noticeable example of this is that the end of a X, Y or XY movement will result in shaking of the printer which can last for several hundred milliseconds - this movement will be picked up by the piezo and, if it is above the trip point, will result in a false signal. The best way of avoiding this is to have a delay between X and/or Y movements and the Z probe operation (Zpop). Most firmware has an option to introduce this delay and will be named something like DELAY_BEFORE_Z_PROBE or something similar.

If the acceleration of the print head at the beginning of a Zpop is too high then that can also result in a false signal - it is not necessary to use a high speed for probing and I routinely use 2mm/sec although I have even probed down at 0.5mm/sec.

A further problem is that during heating or cooling of a piezo disk there will be a quite high voltage developed by the piezo itself - this is called the pyroelectric effect. This voltage will result in the trip being either too sensitive or insufficiently sensitive. This can be avoided by allowing a warm-up period and also by some thermal insulation of isolation of the piezo disk.

Yet another problem can arise with underbed piezos is there is dynamic movement caused by having the piezo sensors too far in from the edges of the bed - of possibly from having a too flexible bed or poor mountings.

Having said the forgoing, I still find that these piezo disks are an all round better bed leveling probe than anything else available. I have used these on 5 printers and many more experimental setup since 2016 ( [reprap.org] ) I have tried in my experiments to make sensors not for high sensitivity, but to be insensitive to any signal I didn't want.

Mike

If the acceleration of the print head at the beginning of a Zpop is too high then that can also result in a false signal - it is not necessary to use a high speed for probing and I routinely use 2mm/sec although I have even probed down at 0.5mm/sec.

A further problem is that during heating or cooling of a piezo disk there will be a quite high voltage developed by the piezo itself - this is called the pyroelectric effect. This voltage will result in the trip being either too sensitive or insufficiently sensitive. This can be avoided by allowing a warm-up period and also by some thermal insulation of isolation of the piezo disk.

Yet another problem can arise with underbed piezos is there is dynamic movement caused by having the piezo sensors too far in from the edges of the bed - of possibly from having a too flexible bed or poor mountings.

Having said the forgoing, I still find that these piezo disks are an all round better bed leveling probe than anything else available. I have used these on 5 printers and many more experimental setup since 2016 ( [reprap.org] ) I have tried in my experiments to make sensors not for high sensitivity, but to be insensitive to any signal I didn't want.

Mike

|

Re: Precision Piezo Z-probe Now available. October 31, 2020 06:07PM |

Registered: 6 years ago Posts: 12 |

Hello,

Am interested in getting the Orion for my Anycubic Kossel Linear Plus and have a few questions :

1) Does the screw mount adapter fit my stock effector? I watched a YouTube video of someone running the Orion on a AKLP and it seems like the screw mount adaptor can be attached directly.

2) Does the Orion need me to order an additional PCB to make work? Or is everything included when I order the kit.

3) If i do install the Orion, I'll need another way to mount the hot end fan and the part cooling fans, is there a link to the 4010 blower fans that are on your demo videos?

Thanks in advance.

Am interested in getting the Orion for my Anycubic Kossel Linear Plus and have a few questions :

1) Does the screw mount adapter fit my stock effector? I watched a YouTube video of someone running the Orion on a AKLP and it seems like the screw mount adaptor can be attached directly.

2) Does the Orion need me to order an additional PCB to make work? Or is everything included when I order the kit.

3) If i do install the Orion, I'll need another way to mount the hot end fan and the part cooling fans, is there a link to the 4010 blower fans that are on your demo videos?

Thanks in advance.

|

Re: Precision Piezo Z-probe Now available. November 02, 2020 01:44PM |

Registered: 9 years ago Posts: 487 |

I haven't been able to find dimensions for the effector of that printer but the spacing of the holes on the screwmount top piece is 23mmx12.5mm.

If you're currently using a groovemount hot end you could get the groove mount kit and fit it as you would your normal hotend.

The Orion PCB is self contained, it does not require another PCB to operate. Everything you need is included if you order the kit.

You will need to find another way of mounting your hotend fan if you're not using one that clips to the heatsink. Same for the part fan. Unfortunately the 40x10mm fans that we used to sell are no longer available.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

If you're currently using a groovemount hot end you could get the groove mount kit and fit it as you would your normal hotend.

The Orion PCB is self contained, it does not require another PCB to operate. Everything you need is included if you order the kit.

You will need to find another way of mounting your hotend fan if you're not using one that clips to the heatsink. Same for the part fan. Unfortunately the 40x10mm fans that we used to sell are no longer available.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Sorry, only registered users may post in this forum.