|

DIY PCB Questions December 04, 2009 11:36AM |

Registered: 15 years ago Posts: 42 |

I have been looking into making PCBs at home with a CNC mill/drill. However, I have a couple issues/ideas I would like to run by everyone.

1) I have not been able to come up with an easy and cheap way of plating through holes. I have found the rivet solution such as, [www.megauk.com] and the paste solution such as, [www.lpkf.com]. But both seem expensive for as few boards as I see myself making. Has anyone come up with an easy and cheap method for plating through holes or used either of the above methods?

2) I don't like the idea of having the bare copper exposed on the PCBs. I would much rather have a protective layer of paint like professional made boards. My thought was to use acrylic paint and airbrush the entire board. For the pads, I would first put a drop of candle wax. Has anyone tried this? Is there something better the candle wax?

Thanks in advance,

Jeremy

1) I have not been able to come up with an easy and cheap way of plating through holes. I have found the rivet solution such as, [www.megauk.com] and the paste solution such as, [www.lpkf.com]. But both seem expensive for as few boards as I see myself making. Has anyone come up with an easy and cheap method for plating through holes or used either of the above methods?

2) I don't like the idea of having the bare copper exposed on the PCBs. I would much rather have a protective layer of paint like professional made boards. My thought was to use acrylic paint and airbrush the entire board. For the pads, I would first put a drop of candle wax. Has anyone tried this? Is there something better the candle wax?

Thanks in advance,

Jeremy

|

Re: DIY PCB Questions December 04, 2009 01:26PM |

Registered: 15 years ago Posts: 478 |

1) Vero pins or tin copper wire soldered both sides was the method used before PTH PCB Technology. clever positioning of resistors and axial capacitors was the normal way of make the through hole connections.

The leads being soldered on both sides of the board.

Home plating will be expensive, time consuming with possibly a high failure rate where the plating cracks around one of the hole edges.

2a) Just tin all the tracks with solder one of the old methods.

2b) Make your board test the board paint the board wih varnish.

2c) A Silkscreen is the usual method to apply the protective layer this is possible to do at home.

Edited 1 time(s). Last edit at 12/04/2009 01:27PM by BodgeIt.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

The leads being soldered on both sides of the board.

Home plating will be expensive, time consuming with possibly a high failure rate where the plating cracks around one of the hole edges.

2a) Just tin all the tracks with solder one of the old methods.

2b) Make your board test the board paint the board wih varnish.

2c) A Silkscreen is the usual method to apply the protective layer this is possible to do at home.

Edited 1 time(s). Last edit at 12/04/2009 01:27PM by BodgeIt.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

|

Re: DIY PCB Questions December 04, 2009 04:25PM |

Admin Registered: 16 years ago Posts: 13,891 |

Hi Jeremy,

... when making DS-boards, i used silvercoated copper-rivets similar to that in your first link but without press or crimping pen.

Simply insert the rivets from top side and solder only the collars with the top pad.

Then populate your board as usually and then solder the pins and rivet-bottoms with the bottom-pads.

I prototyped some doublesided series (until ten PCB's per serie) usually with 300 to 400 pins per PCB and 10% to 20% of the pads were doublesided, and some of them were hidden under IC-sockets too ...

Viktor

... when making DS-boards, i used silvercoated copper-rivets similar to that in your first link but without press or crimping pen.

Simply insert the rivets from top side and solder only the collars with the top pad.

Then populate your board as usually and then solder the pins and rivet-bottoms with the bottom-pads.

I prototyped some doublesided series (until ten PCB's per serie) usually with 300 to 400 pins per PCB and 10% to 20% of the pads were doublesided, and some of them were hidden under IC-sockets too ...

Viktor

|

Re: DIY PCB Questions January 04, 2010 10:06AM |

|

Re: DIY PCB Questions January 04, 2010 10:15AM |

Admin Registered: 16 years ago Posts: 13,891 |

|

Re: DIY PCB Questions January 04, 2010 10:49AM |

Registered: 15 years ago Posts: 300 |

Hi Steve

There are always a number of people looking for a european source of the semi standard PCB's for generation II and III boards.

It's all open source so maybe you could be a supplier, run our boards in odd left over spaces of other runs.

Have your "Challange Dave" contibute a re-design of the layouts?

There are always a number of people looking for a european source of the semi standard PCB's for generation II and III boards.

It's all open source so maybe you could be a supplier, run our boards in odd left over spaces of other runs.

Have your "Challange Dave" contibute a re-design of the layouts?

|

Re: DIY PCB Questions February 21, 2010 08:23PM |

useing my mig welder other day when i pressed trigger to start welding i heard pop and see smoke coming out of welder.checked pcb and find 2 capacistors gone.the solenoid for the gas was hanging loose and i think it stuck itself to the rectifier when i hit the trigger. stupid question but do you think this is why my caps popped.

|

Re: DIY PCB Questions March 06, 2010 07:04PM |

Registered: 16 years ago Posts: 900 |

Bodgeit pretty much has connecting both layers covered.

For protecting your baords and components try any of the usual PCB chemicals suppliers for conformal coating. (spray on coating ina an aerosol can) it works fine.

If you want something a little faster and more local try any of the hobby craft type stores and but the clear acrylic spray laquer. It also works fine.

Don;t spray your baords though until you have built and tested them.

Mask off any connectors and parts that get hot or you will later bolt to a heatsink.

The spray coats the boards and stops them oxidising, it also helps in higher humidity environments.

If you need to rework the board scrub the coating off the pads you want to re-do with a brass or fibreglass track cleaning pencil/brush. Most electronic stores have them even Maplin here in the UK.

Necessity hopefully becomes the absentee parent of successfully invented children.

For protecting your baords and components try any of the usual PCB chemicals suppliers for conformal coating. (spray on coating ina an aerosol can) it works fine.

If you want something a little faster and more local try any of the hobby craft type stores and but the clear acrylic spray laquer. It also works fine.

Don;t spray your baords though until you have built and tested them.

Mask off any connectors and parts that get hot or you will later bolt to a heatsink.

The spray coats the boards and stops them oxidising, it also helps in higher humidity environments.

If you need to rework the board scrub the coating off the pads you want to re-do with a brass or fibreglass track cleaning pencil/brush. Most electronic stores have them even Maplin here in the UK.

Necessity hopefully becomes the absentee parent of successfully invented children.

|

Re: DIY PCB Questions March 09, 2010 08:41AM |

Registered: 15 years ago Posts: 248 |

aka47 Wrote:

-------------------------------------------------------

> Bodgeit pretty much has connecting both layers

> covered.

>

> For protecting your baords and components try any

> of the usual PCB chemicals suppliers for conformal

> coating. (spray on coating ina an aerosol can) it

> works fine.

>

> If you want something a little faster and more

> local try any of the hobby craft type stores and

> but the clear acrylic spray laquer. It also works

> fine.

>

> Don;t spray your baords though until you have

> built and tested them.

>

> Mask off any connectors and parts that get hot or

> you will later bolt to a heatsink.

>

> The spray coats the boards and stops them

> oxidising, it also helps in higher humidity

> environments.

>

> If you need to rework the board scrub the coating

> off the pads you want to re-do with a brass or

> fibreglass track cleaning pencil/brush. Most

> electronic stores have them even Maplin here in

> the UK.

Although don't cover any parts requiring a heat sink or a heat sink itself

-------------------------------------------------------

> Bodgeit pretty much has connecting both layers

> covered.

>

> For protecting your baords and components try any

> of the usual PCB chemicals suppliers for conformal

> coating. (spray on coating ina an aerosol can) it

> works fine.

>

> If you want something a little faster and more

> local try any of the hobby craft type stores and

> but the clear acrylic spray laquer. It also works

> fine.

>

> Don;t spray your baords though until you have

> built and tested them.

>

> Mask off any connectors and parts that get hot or

> you will later bolt to a heatsink.

>

> The spray coats the boards and stops them

> oxidising, it also helps in higher humidity

> environments.

>

> If you need to rework the board scrub the coating

> off the pads you want to re-do with a brass or

> fibreglass track cleaning pencil/brush. Most

> electronic stores have them even Maplin here in

> the UK.

Although don't cover any parts requiring a heat sink or a heat sink itself

|

Re: DIY PCB Questions March 11, 2010 08:54PM |

Registered: 15 years ago Posts: 132 |

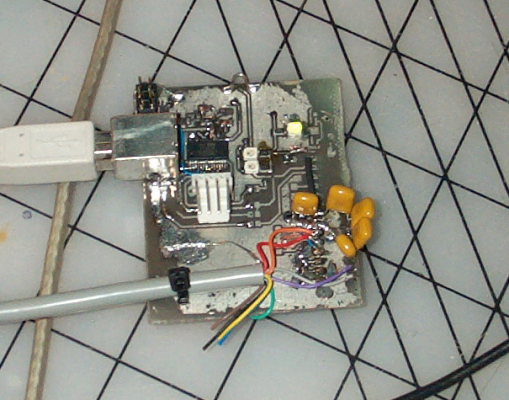

It has been many years since I made a PCB. Needing a USB converter and having a lot of FTDI chips, I found a scrap of some old PCB board and the toner transfer paper.

The scrap was pretty well oxidized from the years. I scrubbed it clean. My laser printer is getting long in the tooth, I cranked up the darkness to max. Even so the resulting image was a bit weak.

This time I set to use the laminator and top foil. I still had problems with the edges washing out, even though I did everything I could not to touch them. The top foil did not want to stick to the toner. I attempted several passes, which may not have been the best idea. The important thing was the pads for the FTDI chip were clean.

While building the board, I realized that a Max232 was needed as I wanted to use this to drive the Atmel ICE200 emulator. Since I used an arduino eagle layout for the FTDI footprint, I had half an arduino in the remaining section. The pads for the mega88 made a good place to barnicle on the max232 and bung on the caps.

Looks messy, but it works, and was completely made from stuff I had about. (Well the tin plating solution was new.)

I have more scrap PCB, but need to work out the weak toner issue.

Attached is the photograph of the halfduino.

-julie

The scrap was pretty well oxidized from the years. I scrubbed it clean. My laser printer is getting long in the tooth, I cranked up the darkness to max. Even so the resulting image was a bit weak.

This time I set to use the laminator and top foil. I still had problems with the edges washing out, even though I did everything I could not to touch them. The top foil did not want to stick to the toner. I attempted several passes, which may not have been the best idea. The important thing was the pads for the FTDI chip were clean.

While building the board, I realized that a Max232 was needed as I wanted to use this to drive the Atmel ICE200 emulator. Since I used an arduino eagle layout for the FTDI footprint, I had half an arduino in the remaining section. The pads for the mega88 made a good place to barnicle on the max232 and bung on the caps.

Looks messy, but it works, and was completely made from stuff I had about. (Well the tin plating solution was new.)

I have more scrap PCB, but need to work out the weak toner issue.

Attached is the photograph of the halfduino.

-julie

|

Re: DIY PCB Questions April 02, 2010 12:46AM |

I make all my own boards because I hate ordering multiples of the same board if I only need one. Secondly they are expensive for what I get. I make mine double sided boards using rivets on the vias. I also use these same rivets in connectors that have small pin diameters. The power is best with rivets because they can handle large currents. Outside of that it is mainly surface mount, it is all covered.

I have had great success with simply coating the board with solder flux and going at it with low heat and solder. I get covered surfaces that I can later clean with alcohol. I run a silk screen process for the solder mask and making my own cream masks. The lettering and so forth I use a toner transfer method form Pulsar that works okay for what I want. The board's solder mask is critical to soldering up the board with fine pitch devises. I use acrylic for that and it stands up to the heat okay. I have heard you can use lacquer I just do not like the smell nor the solvents. If I have a heavily populated board I will use an epoxy.

I have had great success with simply coating the board with solder flux and going at it with low heat and solder. I get covered surfaces that I can later clean with alcohol. I run a silk screen process for the solder mask and making my own cream masks. The lettering and so forth I use a toner transfer method form Pulsar that works okay for what I want. The board's solder mask is critical to soldering up the board with fine pitch devises. I use acrylic for that and it stands up to the heat okay. I have heard you can use lacquer I just do not like the smell nor the solvents. If I have a heavily populated board I will use an epoxy.

|

Re: DIY PCB Questions - Via Rivets March 16, 2012 03:25AM |

|

Re: DIY PCB Questions March 16, 2012 04:10AM |

Admin Registered: 16 years ago Posts: 13,891 |

... the problems are mostly vias with pins going through - like IC-pins's, that have to be soldered on both sides and the body of the part/socket is hiding the upper side of the pin.

Here my previously posted methode with pre-soldering hollow rivets can be used ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Here my previously posted methode with pre-soldering hollow rivets can be used ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.