Rugged CoreXY

Posted by hobbymods

|

Re: Rugged CoreXY May 30, 2016 09:23AM |

Registered: 11 years ago Posts: 5,780 |

My printer uses NEMA-23 motors in all three axes (only really necessary in the Y axis, but I had the other motors so I used them). While they can be driven directly by the smoothieboard, I used external DSP based drivers for the X and Y axes because the Y axis motor required more current than the smoothieboard drivers could deliver and I wanted to experiment with microstepping in X and Y to make the machine quieter (it didn't help the Y axis, but the X axis just hisses quietly as it moves). As long as the motors need 2A or less you can drive them with the smoothieboard. NEMA-23 motors tend to vibrate more than NEMA-17 motors, so if you can use the smaller motors, do it, unless you don't mind a noisy printer.

It is very easy to connect external drivers to the smoothieboard, if you need to.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It is very easy to connect external drivers to the smoothieboard, if you need to.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Rugged CoreXY May 30, 2016 09:25AM |

Registered: 8 years ago Posts: 776 |

Quote

hobbymods

Yeah....I'm getting all the emotion.

and now for something completely different [www.youtube.com]

and now for something completely different [www.youtube.com]Quote

Back on track....did a little research and my contacts assure me that 15mm EG/HG rails not only have better features than the miniature rails, but he can do them cheaper.

got any photos / specs / links to datasheets?

Quote

Yes I will have a 3 point spring loaded manual bed leveling system, and yes I agree that springs on the build plate are a necessary insurance policy against busting something really expensive. I just plan to do something better than chinese spec wing nuts and soggy mismatched springs.

[/quote}

haha yeah. do consider that 2-extra-fixed-rods-not-dissimilar-to-tiny-3mm-ID-linear-bearings idea. in fact if you _can_ find tiny linear bearings...

Quote

I think I've been misunderstood about my Z axis plans....I'm hoping to do something like this monstrosity (check the PRICE!!):

[3dprintersuperstore.com.au]

yeaaaoowwwww check out the length of those linear bearings, one at each corner. my guess is that those are so over-spec'd that they would prevent exactly the kind of rotation i was talking about if you had only 2 ball / lead screws.

Quote

Only with rails instead of rods, and the 2 ball screws driven by the same motor/belt/pulley system.

even with rails you have an axis of rotation about the 2 ball screw mount-points onto the print-bed any rotation about that axis will be transferred into rotation of the rails, but with a lever-effect that dramatically increases the amount of force being applied. so if the rail carriages are say 50mm long, and the distance to the edge of the printbed is 150mm (a 300mm bed, 1/2 the distance), you have a THREE to one increase in any rotation (see-sawing) around the 2 ball screws.

so when you get the datasheet on those rails, you'll need to check the carriage length, check the expected amount of weight deflection that you're happy to tolerate, check the amount of rotation that they'll withstand, check the amount of force that they can tolerate before they'll go out of specs (BUT remember to multiply it by the calculated lever effect!), check that the anticipated wear and tear due to potential rotational side-loading is acceptable during their projected lifetime....

... beginning to sound like a f****g pain in the ass, isn't it?in my mind, all that checking i just to be absolutely honest i could not be bothered when by simply adding one extra ball screw the need for all that checking... simply disappears.

the rest i don't have the experience or expertise to comment so i'll leave it there, hth hobbymods.

l.

Edited 1 time(s). Last edit at 05/30/2016 09:26AM by lkcl.

|

Re: Rugged CoreXY May 30, 2016 09:35AM |

Registered: 9 years ago Posts: 1,873 |

I suspect you may be overthinking it a little Ikcl. While you're right that some degree of turning moment around the line joining the two lead screw nuts will exist, it's likely to be very small. The two screw design with the screws in the mid-points of opposing edges is relatively well balanced, and remember that there are plenty of printers with fully cantilevered beds supported from a single edge. It seems the bigger problem people have with 4 guide systems is getting them well enough aligned to avoid binding.

|

Re: Rugged CoreXY May 30, 2016 09:43AM |

Registered: 7 years ago Posts: 168 |

Quote

lkcl

Quote

hobbymods

Yeah....I'm getting all the emotion.

and now for something completely different [www.youtube.com]

Quote

Back on track....did a little research and my contacts assure me that 15mm EG/HG rails not only have better features than the miniature rails, but he can do them cheaper.

got any photos / specs / links to datasheets?

Quote

Yes I will have a 3 point spring loaded manual bed leveling system, and yes I agree that springs on the build plate are a necessary insurance policy against busting something really expensive. I just plan to do something better than chinese spec wing nuts and soggy mismatched springs.

[/quote}

haha yeah. do consider that 2-extra-fixed-rods-not-dissimilar-to-tiny-3mm-ID-linear-bearings idea. in fact if you _can_ find tiny linear bearings...

Quote

I think I've been misunderstood about my Z axis plans....I'm hoping to do something like this monstrosity (check the PRICE!!):

[3dprintersuperstore.com.au]

yeaaaoowwwww check out the length of those linear bearings, one at each corner. my guess is that those are so over-spec'd that they would prevent exactly the kind of rotation i was talking about if you had only 2 ball / lead screws.

Quote

Only with rails instead of rods, and the 2 ball screws driven by the same motor/belt/pulley system.

even with rails you have an axis of rotation about the 2 ball screw mount-points onto the print-bed any rotation about that axis will be transferred into rotation of the rails, but with a lever-effect that dramatically increases the amount of force being applied. so if the rail carriages are say 50mm long, and the distance to the edge of the printbed is 150mm (a 300mm bed, 1/2 the distance), you have a THREE to one increase in any rotation (see-sawing) around the 2 ball screws.

so when you get the datasheet on those rails, you'll need to check the carriage length, check the expected amount of weight deflection that you're happy to tolerate, check the amount of rotation that they'll withstand, check the amount of force that they can tolerate before they'll go out of specs (BUT remember to multiply it by the calculated lever effect!), check that the anticipated wear and tear due to potential rotational side-loading is acceptable during their projected lifetime....

... beginning to sound like a f****g pain in the ass, isn't it?in my mind, all that checking i just to be absolutely honest i could not be bothered when by simply adding one extra ball screw the need for all that checking... simply disappears.

the rest i don't have the experience or expertise to comment so i'll leave it there, hth hobbymods.

l.

Clearly I'm missing something here....

It seems that you've said that the linear bearing rods on the printer I've linked to are good enough to work with the 2 ball screws configured as shown, but go on to say that supported rails in their place won't work with the same 2 ball screws. Unless of course I've misunderstood you.

And then there's the fact that I've never seen a printer sold with 3 ball screws on the Z axis, including the one I've linked to, can you please link me to an actual picture of the setup you're describing?

I'm certainly not saying you're wrong, but I've never seen it done that way.

The bed size I'm going for is 300x300mm, half the size of the printer shown.

|

Re: Rugged CoreXY May 30, 2016 09:47AM |

Registered: 7 years ago Posts: 168 |

Quote

JamesK

I suspect you may be overthinking it a little Ikcl. While you're right that some degree of turning moment around the line joining the two lead screw nuts will exist, it's likely to be very small. The two screw design with the screws in the mid-points of opposing edges is relatively well balanced, and remember that there are plenty of printers with fully cantilevered beds supported from a single edge. It seems the bigger problem people have with 4 guide systems is getting them well enough aligned to avoid binding.

That's kind of what I was thinking.

Plus I am not talking about those brass nuts straight on the thread lead screws (if that's what you are talking about), I'm talking about a pair of recirculating ball screws:

[www.hiwin.tw]

I don't think I'll need anti backlash in this case, as the load of the plate sitting down on it should be all that is needed.

And yes, the possibility of binding would be very real, if not difficult to avoid. There would need to be some careful jiggery there for sure.

Edited 2 time(s). Last edit at 05/30/2016 09:50AM by hobbymods.

|

Re: Rugged CoreXY May 30, 2016 09:58AM |

Registered: 7 years ago Posts: 168 |

Quote

the_digital_dentist

My printer uses NEMA-23 motors in all three axes (only really necessary in the Y axis, but I had the other motors so I used them). While they can be driven directly by the smoothieboard, I used external DSP based drivers for the X and Y axes because the Y axis motor required more current than the smoothieboard drivers could deliver and I wanted to experiment with microstepping in X and Y to make the machine quieter (it didn't help the Y axis, but the X axis just hisses quietly as it moves). As long as the motors need 2A or less you can drive them with the smoothieboard. NEMA-23 motors tend to vibrate more than NEMA-17 motors, so if you can use the smaller motors, do it, unless you don't mind a noisy printer.

It is very easy to connect external drivers to the smoothieboard, if you need to.

Yep, saw those drivers that pretty much piggybacked straight onto the board.

I've never really looked at what kind of current the Nema 17's on my various printers draw other than to wind up the extruder motor from 400mA to 600mA on my Zortrax's. My understanding is that they're rated to 1.2A?

This one case where I'd rather go smaller, not due to the cost/noise/etc, but due to the 17 being so common.

Is it true that the Smoothie uses a software setting to set the stepper driver power, not a potentiometer?

|

Re: Rugged CoreXY May 30, 2016 10:08AM |

Registered: 8 years ago Posts: 776 |

Quote

JamesK

I suspect you may be overthinking it a little Ikcl. While you're right that some degree of turning moment around the line joining the two lead screw nuts will exist, it's likely to be very small.

"likely" is a subjective assessment, where we vary greatly on our ability to "assess". .basically i'm leaving it open to you, hobbymod, as to whether you believe it is worth doing the *calculations* in advance, or whether you trust a subjective judgement - take a calculated risk in other words.

when i'm looking at this, my subjective assessment says "don't do it". your subjective assessment may say "yeahhh it seems fine". but there is only one way to be absolutely sure: build it and see

Quote

The two screw design with the screws in the mid-points of opposing edges is relatively well balanced,

... which creates a perfect see-saw, as opposed to something closer to a cantilevered bed, so you only halve the amount of leverage effect on the rails. i.e. you have to deal with 150mm of lever-effect (as opposed and compared to say a full 300mm in a cantilevered bed)

Quote

and remember that there are plenty of printers with fully cantilevered beds supported from a single edge.

indeed... and look at how much engineering goes into them, and how beefy the parts have to be. relying on brute strength... i mean yes sure you can do it, but to me it says "design mistake". that's from having made a cantilevered bed (using beefy parts), and realised that yes, it was a design mistake.

Edited 1 time(s). Last edit at 05/30/2016 10:08AM by lkcl.

|

Re: Rugged CoreXY May 30, 2016 10:17AM |

Registered: 7 years ago Posts: 168 |

To be honest it'll be forever until I get to that.

I'm sure the gantry will keep me busy for a while.

I actually don't have a subjective assessment at this stage, just asking for clarification, but I do see the Makerbot Z18 uses the same configuration as well.

Mind you, I've heard they are shit.......

I'm sure the gantry will keep me busy for a while.

I actually don't have a subjective assessment at this stage, just asking for clarification, but I do see the Makerbot Z18 uses the same configuration as well.

Mind you, I've heard they are shit.......

|

Re: Rugged CoreXY May 30, 2016 10:18AM |

Registered: 8 years ago Posts: 776 |

Quote

hobbymods

That's kind of what I was thinking.

it's subjective. in essence i'm suggesting that you *consider* doing the side-load calculations in advance, so that you can be absolutely sure that you will not end up with binding or worse tiny but significant variations in height as the print progresses, due to the weight of an object pushing down on one side.

this obviously won't be noticeable with smaller prints or with dead-symmetrically-printed parts that are *exactly* on the axis between the two [planned] ball screws. but an asymmetric weighted large print? that's where i was inviting you to consider doing the calculations to make absolutely sure...

... and to remove that "subjective" aspect out of the assessment.equation.

Quote

And yes, the possibility of binding would be very real, if not difficult to avoid. There would need to be some careful jiggery there for sure.

well, that would be another reason in favour of using triple lead/ball screws and only dual rails, wouldn't it? if quad rails would possibly bind, dual rails i believe you can see would definitely not.

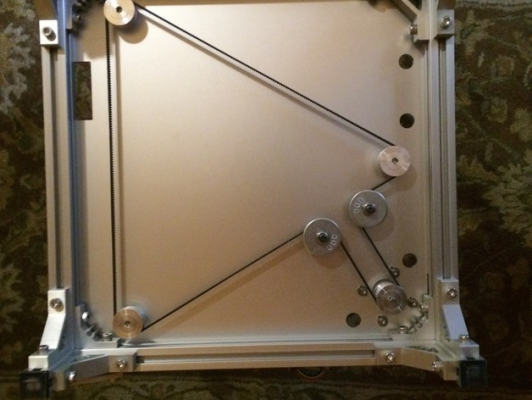

ok so apologies for breaking the reply chain i'm running out of time. i did a quick google search for "triple lead screw 3d printer" and came up with this:

[www.thingiverse.com]

an underside photo is here:

the ones i've seen on this forum, i apologise, i can't remember who they were, otherwise i'd give some links.

|

Re: Rugged CoreXY May 30, 2016 10:34AM |

Registered: 8 years ago Posts: 776 |

Quote

hobbymods

To be honest it'll be forever until I get to that.

... exactly

which is why i went for the much-easier-to-assess design.

which is why i went for the much-easier-to-assess design.Quote

I'm sure the gantry will keep me busy for a while.

I actually don't have a subjective assessment at this stage, just asking for clarification, but I do see the Makerbot Z18 uses the same configuration as well.

Mind you, I've heard they are shit.......

yyyeah, you heard the story about makerbot, how they secretly patented publicly-discussed prior art in community forums, because in the U.S. patents are considered to be "tangible assets" that go onto the balance sheet. thus they not only SERIOUSLY f****d off the ENTIRE 3d printing community but actively deceived their investors, possibly going as far as committing investor fraud for knowingly patenting pre-existing prior art.

so now imagine that you're an engineer working for such a company. you *know* that something's really wrong, but you either don't want to admit it or you just keep quiet... but - and this is actually a well-known phenomenon - as a whole the *entire* company's employees *subconsciously* sabotage the products and the sales. it's not deliberate, but it's like... "self-punishment".

anyway, bottom line i would not use makerbot products for comparison. of anything.

|

Re: Rugged CoreXY May 30, 2016 10:50AM |

Registered: 11 years ago Posts: 5,780 |

Yes, smoothieboard and AFAIK, most other 32 bit controllers, set motor current with a line of text in the config file. No little pots to break!

For me the best thing about the smoothieboard is that configuration changes and firmware updates don't involve compiling the firmware. There's a single config.txt file located on a uSD card that contains all the variables including motor currents. You edit it with any text editor then reboot the board and you're done. Firmware updates are just as easy- copy the new firmware to the uSD card and reboot. Done.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

For me the best thing about the smoothieboard is that configuration changes and firmware updates don't involve compiling the firmware. There's a single config.txt file located on a uSD card that contains all the variables including motor currents. You edit it with any text editor then reboot the board and you're done. Firmware updates are just as easy- copy the new firmware to the uSD card and reboot. Done.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Rugged CoreXY May 30, 2016 11:25AM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

Yes, smoothieboard and AFAIK, most other 32 bit controllers, set motor current with a line of text in the config file. No little pots to break!

For me the best thing about the smoothieboard is that configuration changes and firmware updates don't involve compiling the firmware. There's a single config.txt file located on a uSD card that contains all the variables including motor currents. You edit it with any text editor then reboot the board and you're done. Firmware updates are just as easy- copy the new firmware to the uSD card and reboot. Done.

duets are the same arrangement, with RepRapFirmware. i don't normally consider c++ to be "safe" to use in embedded code but in this case it's a good match. RepRapFirmware is extremely well-designed, everything is again customisable via text files, including what you want to do with "home" on both x, y, z *and* the homeall command - there's many more but that's just a start.

then the duet itself has had design input from i think it's like six of the top most renowned community 3d printing engineers, as well as community input and feedback and they're onto the third generation, now, called the Duet NG. like the smoothieboard, the duet has always had an ethernet port, and thanks to RepRapFirmware it also has a web interface. so there's a web server. running on a 120mhz board with a tiny amount of RAM. i'm just amazed by that.

so i don't know about the smoothieboard but there's actually an editor built-in to the web interface, so you can edit the configuration directly over the internet, hit "save", the new configuration will be saved to the microsd card and it will restart and reload the new configuration. you *don't* have to remove the micro-sd card, although you can do so if you really want to.

but... my advice is, wait for the duet NG - it's coming out very soon, it's just on final review and testing of the newly-selected stepper ICs, which, knowing dc42, are going to be extremely good ones capable of supplying much higher current. the reason for the delay is to make absolutely sure that the heat dissipation is okay. otherwise they have to redesign and go back to the same ones used on the 0.8.5 or something.

but, yeah - do evaluate the duet as well, side-by-side i think you'll find it's comparable and may even come out on top.

|

Re: Rugged CoreXY May 30, 2016 11:37AM |

Registered: 11 years ago Posts: 5,780 |

Smoothie has a web server too. I don't know about editing the config file and rebooting via the web interface- I've never tried it (I'm not sure why you'd want to do it remotely, but then I don't get the point of trying to remote control a printer at all- too old, I guess). You can edit the config file via the USB port or pull the uSD card and sneakernet it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Rugged CoreXY May 30, 2016 11:52AM |

Registered: 10 years ago Posts: 14,672 |

Quote

the_digital_dentist

Smoothie has a web server too. I don't know about editing the config file and rebooting via the web interface- I've never tried it (I'm not sure why you'd want to do it remotely, but then I don't get the point of trying to remote control a printer at all- too old, I guess). You can edit the config file via the USB port or pull the uSD card and sneakernet it.

The web interface on the Duet is useful in several different ways:

- It replaces the USB connection to whatever PC you use for slicing your STL files, and for controlling the printer if normally you do that from a PC. The web interface has a direct link into the firmware, so it provides a lot more real-time status information than you can get from Pronterface, Repetier host and the like.

- Using Ethernet instead of USB avoids the problems with ground loops that USB connections are prone to.

- If it's not convenient to have the printer and the PC in the same room, that's not a problem, just hook them both into your home network.

- The web interface provides fast uploading of the gcode files that you slice on the PC to the SD card on the Duet.

- If you leave the printer unattended during long prints, you can monitor the status of the print on a tablet or smartphone, and take action if necessary e.g. to pause the print while you return to the printer.

Most Duet users don't use the USB port any more, so they also find it convenient that you can make configuration changes in the web interface, and install new firmware from the web interface.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Rugged CoreXY May 30, 2016 11:53AM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

Smoothie has a web server too. I don't know about editing the config file and rebooting via the web interface- I've never tried it (I'm not sure why you'd want to do it remotely, but then I don't get the point of trying to remote control a printer at all- too old, I guess). You can edit the config file via the USB port or pull the uSD card and sneakernet it.

it's not about "remote control" - i wouldn't call it "remote" if i am sitting 1 metre away from the printer! i'm used to mendel90s and i bought a rumba v1.2g (which turned out to have a component flaw on it, hopefully corrected by now). so i too was used to the USB thing... and having those awful USB-related ESD-spikes. and having to position the laptop right next to the 3d printer, and not being able to touch it. or the mendel90. or breathe on it. i touched the dibond once deliberately and once by mistake... *both times* that was enough to terminate a two-hour print which had to be chucked out and start again.

argh

to solve the ESD problems of course you upload to micro-sd then physically transfer the card over. but that is a lot of hassle all by itself. fiddle about. unplug the card. put the card in the printer's slot. drop it. try to find it. bend over backwards. put the card reader in the laptop and bash it, breaking the laptop's USB port.

now i have a duet. it's connected by ethernet. i power up the laptop. it's connected by WIFI. i sit comfortably on my sofa (or in some cases uncomfortably on the floor). i don't have to have a power cord or a usb cable or a micro-sd card reader slotted in the side which could get bashed off the laptop by mistake. i upload GCODE files over the web interface. i then sit back and watch a film on the laptop whilst the printer's chundering away, safe and secure in the knowledge that my laptop's ESD problems when it's plugged back into the mains will *NOT* destroy 2 to 3 hours of 3d printing.

it's a massive, massive difference dd, that yes, can only really truly be appreciated once you've experienced both.

so i can say with a resounding "yes" that being able to upload via a web interface and change configs is most definitely a hell of a lot less hassle than micro-sd or usb-tethered 3d printing.

Edited 1 time(s). Last edit at 05/30/2016 11:54AM by lkcl.

|

Re: Rugged CoreXY May 30, 2016 12:04PM |

Registered: 11 years ago Posts: 5,780 |

Maybe the new printer will get a Duet...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Rugged CoreXY May 30, 2016 04:17PM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

Maybe the new printer will get a Duet...

please do ask other people first, get a few more opinions, there's a sub-forum for it... where is it.... [forums.reprap.org] although the duet wiki page itself i believe says a lot of discussion actually occurs on the ormerod forum page as well. setting up corexy on RepRapFirmware is a bit... odd, took me several hours to work it out (and a couple of head-crashes.... waark don't want to be reminded about the sound it made...), here's a config you can use which will get you started [hands.com] that's a 3 "NC" endstops arrangement (no z-probe) and the X-axis endstop is at *MAX* (Y-axis is at MIN) you actually have to code that up (in homeall.g and homex.g) yourself, so please do check it and study it carefully - it's all in g-code and it's commented so should be easy to follow.

|

Re: Rugged CoreXY May 30, 2016 08:51PM |

Registered: 11 years ago Posts: 1,049 |

You forgot:

that the outside of the hotend (the place that just melted the plastic)

is very cold and the blob is not very soft, and hotend does not just plow thru the blob

and the blob is so well adhered to the bed it can't be knocked off.

AND the sensors and actuators for:

glass crack,heated bed PCB (which is fibreglass) bending / cracking,

carriage damage, belts broken, NEMA17s stall, severe juddering,

huge movement spikes, smashing the hotend repeatedly down against the glass

and hotend nozzle damage .

are not working or adjusted properly to recover to a pristine print.

AND you lost your white cane and are printing anyway?

and mercury is not in retrograde?

When are you going to Oslo, Norway to accept the award?

that the outside of the hotend (the place that just melted the plastic)

is very cold and the blob is not very soft, and hotend does not just plow thru the blob

and the blob is so well adhered to the bed it can't be knocked off.

AND the sensors and actuators for:

glass crack,heated bed PCB (which is fibreglass) bending / cracking,

carriage damage, belts broken, NEMA17s stall, severe juddering,

huge movement spikes, smashing the hotend repeatedly down against the glass

and hotend nozzle damage .

are not working or adjusted properly to recover to a pristine print.

AND you lost your white cane and are printing anyway?

and mercury is not in retrograde?

When are you going to Oslo, Norway to accept the award?

Quote

ikcl

so let's imagine that someone has done that, but they are experimenting, so they have some firmware where the hotend hasn't quite been set up properly, or the slicing software hasn't been set up properly yet, and it heats up the hotend and a lot of plastic oozes out. let's imagine then that there is a huge blob of plastic on the hotend which they don't notice is there (or don't realise what's coming next). during the print, that blob then goes onto the printbed (they don't notice it because it's at the back of the hotend, out of their line of sight). that blob ends up on the printbed, and the hotend runs over it.

|

Re: Rugged CoreXY May 30, 2016 09:26PM |

Registered: 7 years ago Posts: 168 |

Seriously, does it take the new guy to say "C'mon kids, play nice with each other. Don't make me come back there"?

Back on topic (which was about a rugged corexy printer)....

A valid point that was raised was the issue of thermal expansion binding up the rails in the XY axis'.

Speaking to the linear motion guys, they seemed to think that over 3-500mm it would be negligible, but weren't sure. As no one had raised the issue with them before they seemed to think it wasn't a big issue.

They did however strongly recommend the machining of a single reference edge for one of the parallel rails, and said that while the manual shows the use of a dial gauge to align the second rail, everyone just bolts up the second rail and slides it back and forth while tightening the bolts.

They also surmised that this would reduce the chances of binding due to thermal expansion, as well as just being the right way to do it.

Edited 1 time(s). Last edit at 05/30/2016 09:27PM by hobbymods.

Back on topic (which was about a rugged corexy printer)....

A valid point that was raised was the issue of thermal expansion binding up the rails in the XY axis'.

Speaking to the linear motion guys, they seemed to think that over 3-500mm it would be negligible, but weren't sure. As no one had raised the issue with them before they seemed to think it wasn't a big issue.

They did however strongly recommend the machining of a single reference edge for one of the parallel rails, and said that while the manual shows the use of a dial gauge to align the second rail, everyone just bolts up the second rail and slides it back and forth while tightening the bolts.

They also surmised that this would reduce the chances of binding due to thermal expansion, as well as just being the right way to do it.

Edited 1 time(s). Last edit at 05/30/2016 09:27PM by hobbymods.

|

Re: Rugged CoreXY May 30, 2016 09:50PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Rugged CoreXY May 30, 2016 11:40PM |

Registered: 7 years ago Posts: 168 |

|

Re: Rugged CoreXY May 31, 2016 12:08AM |

Registered: 11 years ago Posts: 5,780 |

Mount one rail then slide the undercarriage back and forth and tighten down the second rail is how I did it and it has worked fine for a year and a half, in spite of hundreds of heating cycles and being transported in my car on multiple occasions.

I did not grind a reference shoulder into the base plate, though it would probably provide some extra stability.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I did not grind a reference shoulder into the base plate, though it would probably provide some extra stability.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Rugged CoreXY May 31, 2016 01:04AM |

Registered: 7 years ago Posts: 168 |

Quote

the_digital_dentist

Mount one rail then slide the undercarriage back and forth and tighten down the second rail is how I did it and it has worked fine for a year and a half, in spite of hundreds of heating cycles and being transported in my car on multiple occasions.

I did not grind a reference shoulder into the base plate, though it would probably provide some extra stability.

That's how I've done it when I added an extra rail to the Z axis's on my 3 UP Plus's and it worked fine as well.

But if you read all the installation guidelines with rails it's what they call for, and my linear supplier assures me it's very worthwhile.

Whether I go that way or not remains to be seen.

Got some nice scraps of 4mm acrylic today that will be nice to do some practice mockups with.

I might even print some imitation carriage blocks to run on some 15mm ply dowels or something, just so I can mess around with dimensions etc without spending up big.

|

Re: Rugged CoreXY May 31, 2016 02:49AM |

Registered: 8 years ago Posts: 622 |

Quote

hobbymods

Seriously, does it take the new guy to say "C'mon kids, play nice with each other. Don't make me come back there"?

I think the problem stems from the fact that we have 2 different schools of thought. On the one hand, there are those that build, or attempt to build rugged, reliable printers based on sound engineering principles. Of course there is nothing wrong with that if you have the budget and/or access to machining and fabricating facilities. On the other hand, these are after all the RepRap forums so such a printer will be a "Rap", but certainly not a "Rep". That is to say, that it cannot reproduce the parts that it was made from. Until these forums get renamed to "Build the best printer you can" or some such, there is bound to be conflict.

|

Re: Rugged CoreXY May 31, 2016 04:21AM |

Registered: 8 years ago Posts: 776 |

Quote

cozmicray

You forgot:

that the outside of the hotend (the place that just melted the plastic)

is very cold and the blob is not very soft, and hotend does not just plow thru the blob

and the blob is so well adhered to the bed it can't be knocked off.

i anticipated that someone might pick up on the example itself rather than why the example was given, so thought carefully about how to respond and what to emphasise if it happened.

given that these discussions are world-wide public now and forever, and will be seen by hundreds of thousands of people over the years to come, we are the ambassadors of the reprap 3d printing community. the reprap forum archives will be available for at least a decade, and after that there will be (and already is) archive.org. so there will be inexperienced people looking at this thread and going, "hmm, i should try that idea that dd recommended". but the idea that dd recommended is only a good idea if you have followed the extremely careful and comprehensive set of engineering guidelines and practices which he has spent considerable time learning and very helpfully documenting on instructables in the form of his build.

so the purpose of my reply was to give newcomers to the 3D printing world some pause and some food for thought, and to consider, just as hobbymods called it, "leaving in a safety valve". the purpose was *not* to come up with a perfect example, because just the one imperfect one will do, because that's all it takes ("For All X |=" i think the mathematical way of expressing it is: boolean logic analysis: x and y and z and w and v is false if *one* link in the chain is not true). we can discuss the merits of one particular example all day if we really wanted to, refining it and honing it, maybe demonstrating that it was unrealistic, maybe coming up with a better version.... and it would still be wasting our time (and everyone else's). why? because once we had found that the one imperfect example was to be dismissed, we would need to move on to the *next* example, and the next, and the next.

so there is no need to get into it. anyone looking at the idea of removing the bed-levelling springs if they have accurate triple lead/ball screws can assess for themselves if they have a good enough design to take the risk of removing the safety-valve that (not-too-strong) springs provide.

i am glad that that is settled.

|

Re: Rugged CoreXY May 31, 2016 04:49AM |

Registered: 8 years ago Posts: 776 |

Quote

deckingman

Quote

hobbymods

Seriously, does it take the new guy to say "C'mon kids, play nice with each other. Don't make me come back there"?

I think the problem stems from the fact that we have 2 different schools of thought. On the one hand, there are those that build, or attempt to build rugged, reliable printers based on sound engineering principles. Of course there is nothing wrong with that if you have the budget and/or access to machining and fabricating facilities. On the other hand, these are after all the RepRap forums so such a printer will be a "Rap", but certainly not a "Rep". That is to say, that it cannot reproduce the parts that it was made from. Until these forums get renamed to "Build the best printer you can" or some such, there is bound to be conflict.

key question: are we enjoying what we are doing, right now? are we getting what we wanted when we joined this forum?

as i just learned - and realised - from a discussion with realthor, someone with experience making a suggestion to use specific parts (because in their experience that's what works best) doesn't necessarily get listened to... not because of cost, not because they're irrational, not even because the explanation given (including in some cases sound engineering and mechanical design references), but because they want to *work it out for themselves*. they want to exercise their absolute god-given right to have that learning experience: "doing is learning". unless you've done it, unless you've been through the "pain", it's a plain and simple fact that the knowledge is extremely unlikely to sink in. *only when* you have been through the learning experience, *then* you can go "bl***y hell why didn't i listen to those people earlier??" and laugh about it in retrospect.... like i am doing on a regular basis right now. and the reason is, i *couldn't*. there were no hooks in my mind off of which to "hang" their words.

add to that the huge variation in budgets, experience, age, backgrounds, design requirements, time available and many other factors and it's hardly surprising if we're going "urk" every now and then.

so it's not someone being "deliberately disrespectful" when people don't "listen" to what you say, it's that they simply haven't had the experience to relate to what you're trying communicate. it just... doesn't sink in. *can't* sink in. and that's *not* your fault, and it's not *your* issue, there's no need to get angry (it only hurts you, at the very least), or frustrated, or grumpy, or hateful, or anything else that stems from our own internal expectations not quite matching up with what we each see and perceive of the outside world.

we're here to make 3D printers! we're here to ask questions and to get some answers as best we can understand them. we're *not* here to laugh at other people as a way to make ourselves look better because we trod someone else into the ground. we're not here to get angry at how other people are clearly making mistakes and are clearly and blatantly ignoring best engineering practices, therefore they're idiots and we're going to tell them that in no uncertain terms. we're not here to tell other people we hate them because they're quite clearly setting themselves up as experts over and above everybody else (yes, really, i received a message recently which said pretty much exactly that). we're not here to set ourselves up as experts over and above everybody else. we choose to be here to *learn* from each other... about how to make 3D printers.

we all have different skills, expertise, perspectives and ways to tackle engineering challenges. respecting those differences will go a long, long way towards being able to enjoy what we're doing, and achieve the goals we've set ourselves.

|

Re: Rugged CoreXY May 31, 2016 09:15AM |

Registered: 7 years ago Posts: 168 |

|

Re: Rugged CoreXY May 31, 2016 09:18AM |

Registered: 7 years ago Posts: 168 |

|

Re: Rugged CoreXY May 31, 2016 09:24AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Rugged CoreXY May 31, 2016 09:27AM |

Registered: 8 years ago Posts: 776 |

Quote

hobbymods

Sorry....Australian middle aged male....can't help you with deep and meaningful philosophy, but can I interest you in a sarcastic comment?

arrhh yeahhh!

[www.youtube.com]

Sorry, only registered users may post in this forum.