Rugged CoreXY

Posted by hobbymods

|

Re: Rugged CoreXY May 31, 2016 10:00AM |

Registered: 7 years ago Posts: 168 |

Quote

lkcl

Quote

hobbymods

Sorry....Australian middle aged male....can't help you with deep and meaningful philosophy, but can I interest you in a sarcastic comment?

arrhh yeahhh!

[www.youtube.com]

Bit of insider knowledge for you:

[www.youtube.com]

|

Re: Rugged CoreXY June 01, 2016 03:26AM |

Registered: 7 years ago Posts: 51 |

From my experience in my recently build printer, if you're going linear rails you'll probably do fine. I got the CoreXY up and running at first try without any hitch.

The hardest in my opinion is the Z axis. Took me quite some time to get this up to where I want it to. Cantilevered bed will work but you have to move extra slow so that the bed end doesn't oscillate too much.That's not really a problem because the Z axis only needs to move 0.1mm/0.2mm layer height each time. Moving faster won't improve your print time.

If you're using 2mmlead lead screw, the reduction is good enough for you to carry 3-4 kgs of load using a typical nema 17 motor.

The Z axis have to be very consistent and accurate and it doesn't take much to create Z Wobble artifacts,

Edited 1 time(s). Last edit at 06/01/2016 03:28AM by Vigilant.

The hardest in my opinion is the Z axis. Took me quite some time to get this up to where I want it to. Cantilevered bed will work but you have to move extra slow so that the bed end doesn't oscillate too much.That's not really a problem because the Z axis only needs to move 0.1mm/0.2mm layer height each time. Moving faster won't improve your print time.

If you're using 2mmlead lead screw, the reduction is good enough for you to carry 3-4 kgs of load using a typical nema 17 motor.

The Z axis have to be very consistent and accurate and it doesn't take much to create Z Wobble artifacts,

Edited 1 time(s). Last edit at 06/01/2016 03:28AM by Vigilant.

|

Re: Rugged CoreXY June 01, 2016 03:58AM |

Registered: 7 years ago Posts: 51 |

Quote

lkcl

hiya hobbymods, welcome to the forum. some links to analysis that may help,

- look at what the_digital_dentist did, with son-of-megamax, his printer design is extremely comprehensive and accuracy is extremely good.

- [forums.reprap.org] for an analysis as to why you should use dual rails/rods and triple lead screws. dual screws is not enough. multiplying up the number of rails does not "fix" the problem of bed rotation about [only 2] screws, it just minimises it. triple lead screws is GUARANTEED to stop rotation, the rails (only 2 needed) stop lateral movement. anti-backlash nuts on all 3 lead screws and you're laughing.

- [forums.reprap.org] you're using rails but is there any rotation in the rail carriage part (about the x y *or* z axes) i.e is the linear carriage *perfect*? if not, take a look at rods instead, set up as described in the thread there. experimental idea so YMMV, other people may have better advice here.

- [forums.reprap.org] follow the belt layout outlined here. keep the entirety of each belt in the same plane, offset them slightly (staggered heights). make sure that the belt goes *exactly* through right-angle turns, do *NOT* be tempted to do 89.5 or anything like that. use 2 bolts in the x-ends and stagger the bearings so that the belts come in on *exactly* the same centre line which should be along the centre of gravity of the carriage... and the hotend should be exactly on that centre of gravity.

- above a 300mm span don't use 8mm rods. anywhere. they bend too much.

- i got a meanwell LRS-350-24 prices are very good, they're also quite thin which is nice. but that was for a 200x200 printbed, you may want to get a mains-operated bed heater then the LRS-350-24 would do you fine... yep that's what you're planning. don't bother with 12V any more. make sure the fan from the PSU points *away* from the printbed...

- make sure you use 0.9 degree per step NEMAs, dc42 is extremely knowledgeable about this, you get far better accuracy and can do up to 1000mm/sec with them on a corexy.

- go for a Duet NG, again, dc42 knows what he's on about, REALLY don't bother with RAMPS or anything that uses arduinos.

- put fans pointing at the Duet's stepper ICs.

- consider a Flex3Drive, they are a combination of the best of both the bowden and direct extruder worlds *and then improve on that even more*. mutley3d is an extremely knowledgeable engineer.

- [forums.reprap.org] don't for god's sake bother with a bowden, they're basically shit. i know people say "oh i have no problems at all" - these people have never had a Flex3Drive. the reality is that bowden tubes are not robust, there's far too much to go wrong, they waste filament, and every single one of the problems i listed on that post was something i encountered MULTIPLE times over an extremely intense and very annoying period of 3 weeks. but, it boils down to this: as an engineer, retract of *five* millimetres as compared to 1.5mm for a flex3drive or direct drive extruder really should tell you everything you need to know.

- based on the same analysis as for the z bed i came up with a trick to use 3 springs and 2 fixed screws for bed-levelling. just as in the z-bed analysis the 2 fixed bolts stop rotation and lateral movement, and the 3 springs allow bed-levelling. if you used smooth rods (or part-threaded M3 bolts) and got the drill holes to good tolerances you could ensure that the printbed really really does not move laterally, i have a tiny amount of potential lateral movement because the 2 fixed bolts sit in slightly oversized holes. something for me to fix later.

- enclosed you will not be able to use PLA for parts, they will melt. find a material that has a high enough temperature or just go all-aluminium.... i think you said that's what you planned

- E3Dv6 i recommend going immediately to a volcano upgrade, unless you really really have a need to use 0.3mm nozzles or below.

- i use mechanical endstops and find them to be fine, but i have no experience with anything else yet so cannot make a comparison.

errr that's alli haven't covered everything, as i am learning as i go along, so have not commented on things i don't know about (or have said "i don't know" if i have). you'll like the Duet. it has ethernet and a built-in web interface, and you can get an LCD for it as well.

there's plenty of great people here who are knowledgeable. there's some angry ones, stressed-out ones (including me) and some inexperienced ones too, but that's okay, we're all learning. enjoy

For the triple lead screw that you mentioned, do you know how does the error stack up assuming that all three lead screw Z axis error is not in phase.

If you look at Z wobble, the error is "similar" to a sine wave. If the bed is supported by 3 lead screw in a triangular fashion does the error gets averaged out?

Edited 1 time(s). Last edit at 06/01/2016 04:01AM by Vigilant.

|

Re: Rugged CoreXY June 01, 2016 05:07AM |

Registered: 7 years ago Posts: 168 |

Quote

Vigilant

From my experience in my recently build printer, if you're going linear rails you'll probably do fine. I got the CoreXY up and running at first try without any hitch.

The hardest in my opinion is the Z axis. Took me quite some time to get this up to where I want it to. Cantilevered bed will work but you have to move extra slow so that the bed end doesn't oscillate too much.That's not really a problem because the Z axis only needs to move 0.1mm/0.2mm layer height each time. Moving faster won't improve your print time.

If you're using 2mmlead lead screw, the reduction is good enough for you to carry 3-4 kgs of load using a typical nema 17 motor.

The Z axis have to be very consistent and accurate and it doesn't take much to create Z Wobble artifacts,

Yes, I'm definitely on the same page.

As I mentioned before, my business runs Zortrax M200's which are renown for print quality but sometimes unpopular due to its closed software and limited materials/options (but the best option for a business knocking out ABS end user parts).

It runs a cantilevered shelf with 2x 12mm rods and 1 lead screw and gives very good Z resolution.

I am seriously considering buying one of those busted arse Wanhao Zortrax clones and gutting it (which is all they are good for) and doing my "lift off" corexy gantry on top of the box as well as converting the Z rods to precision rails.

A cursory glance holding my E3DV6 hotend in place suggests I could get the full 200x200 build volume as well as 240-260mm height. A good improvement on the approx 180x180x180 it gives with the H gantry.

By the time I muck about building a water jet cut box and buy all the bits, I'm sure to have spent the 1200 bucks that a D6 costs.

Then there's the fact that I get steppers, power supply and display, and I can sell the motherboard and complete hot end as well.

Could be the way to go...

This might be a better chance of success with a very respectable build volume, and a much less complicated Z axis for a first time around.

|

Re: Rugged CoreXY June 02, 2016 10:02PM |

Registered: 7 years ago Posts: 51 |

Quote

hobbymods

Quote

Vigilant

From my experience in my recently build printer, if you're going linear rails you'll probably do fine. I got the CoreXY up and running at first try without any hitch.

The hardest in my opinion is the Z axis. Took me quite some time to get this up to where I want it to. Cantilevered bed will work but you have to move extra slow so that the bed end doesn't oscillate too much.That's not really a problem because the Z axis only needs to move 0.1mm/0.2mm layer height each time. Moving faster won't improve your print time.

If you're using 2mmlead lead screw, the reduction is good enough for you to carry 3-4 kgs of load using a typical nema 17 motor.

The Z axis have to be very consistent and accurate and it doesn't take much to create Z Wobble artifacts,

Yes, I'm definitely on the same page.

As I mentioned before, my business runs Zortrax M200's which are renown for print quality but sometimes unpopular due to its closed software and limited materials/options (but the best option for a business knocking out ABS end user parts).

It runs a cantilevered shelf with 2x 12mm rods and 1 lead screw and gives very good Z resolution.

I am seriously considering buying one of those busted arse Wanhao Zortrax clones and gutting it (which is all they are good for) and doing my "lift off" corexy gantry on top of the box as well as converting the Z rods to precision rails.

A cursory glance holding my E3DV6 hotend in place suggests I could get the full 200x200 build volume as well as 240-260mm height. A good improvement on the approx 180x180x180 it gives with the H gantry.

By the time I muck about building a water jet cut box and buy all the bits, I'm sure to have spent the 1200 bucks that a D6 costs.

Then there's the fact that I get steppers, power supply and display, and I can sell the motherboard and complete hot end as well.

Could be the way to go...

This might be a better chance of success with a very respectable build volume, and a much less complicated Z axis for a first time around.

If you're going through that route, you might want to consider the ultimaker clone frame.

[www.aliexpress.com]

Don't purchase the whole printer set, I think it is crap. Just the frame and then figure out a way to mount the aluminium extrusion within the frame

OR build everything again using your own components. This guy here who got both ultimaker and the ultimaker clone claimed better printing quality after using custom components on the ultimaker clone.

[www.youtube.com]

One thing after building my corexy printer, is that although it functions pretty well, it is not the prettiest to look at. In fact I'm right now trying to figure out how to make it look prettier.

|

Re: Rugged CoreXY June 03, 2016 09:25AM |

Registered: 7 years ago Posts: 168 |

Quote

Vigilant

Quote

hobbymods

Quote

Vigilant

From my experience in my recently build printer, if you're going linear rails you'll probably do fine. I got the CoreXY up and running at first try without any hitch.

The hardest in my opinion is the Z axis. Took me quite some time to get this up to where I want it to. Cantilevered bed will work but you have to move extra slow so that the bed end doesn't oscillate too much.That's not really a problem because the Z axis only needs to move 0.1mm/0.2mm layer height each time. Moving faster won't improve your print time.

If you're using 2mmlead lead screw, the reduction is good enough for you to carry 3-4 kgs of load using a typical nema 17 motor.

The Z axis have to be very consistent and accurate and it doesn't take much to create Z Wobble artifacts,

Yes, I'm definitely on the same page.

As I mentioned before, my business runs Zortrax M200's which are renown for print quality but sometimes unpopular due to its closed software and limited materials/options (but the best option for a business knocking out ABS end user parts).

It runs a cantilevered shelf with 2x 12mm rods and 1 lead screw and gives very good Z resolution.

I am seriously considering buying one of those busted arse Wanhao Zortrax clones and gutting it (which is all they are good for) and doing my "lift off" corexy gantry on top of the box as well as converting the Z rods to precision rails.

A cursory glance holding my E3DV6 hotend in place suggests I could get the full 200x200 build volume as well as 240-260mm height. A good improvement on the approx 180x180x180 it gives with the H gantry.

By the time I muck about building a water jet cut box and buy all the bits, I'm sure to have spent the 1200 bucks that a D6 costs.

Then there's the fact that I get steppers, power supply and display, and I can sell the motherboard and complete hot end as well.

Could be the way to go...

This might be a better chance of success with a very respectable build volume, and a much less complicated Z axis for a first time around.

If you're going through that route, you might want to consider the ultimaker clone frame.

[www.aliexpress.com]

Don't purchase the whole printer set, I think it is crap. Just the frame and then figure out a way to mount the aluminium extrusion within the frame

OR build everything again using your own components. This guy here who got both ultimaker and the ultimaker clone claimed better printing quality after using custom components on the ultimaker clone.

[www.youtube.com]

One thing after building my corexy printer, is that although it functions pretty well, it is not the prettiest to look at. In fact I'm right now trying to figure out how to make it look prettier.

Actually, I'm off that plan too, but I do appreciate your points.

Looking at a 500x500 cabinet footprint I can most likely get a 300x300 platform with a proper corexy gantry and 3 ballscrew Z axis.

I'm old and can't do the fancy CAD designs of what I plan to do like some here, but I had a nice big offcut of 6mm acrylic sheet left over from a laser cut fume cabinet I made, and my son and I have marked it all up for a test mockup. Looks good.

Totally get it about the looks lol....I've knick named mine the "utilitatarian".

EDIT: Sorry, read your bit about the Z axis.....seems cantilever isn't a winner with this size platform. I'll do my best to sync the 3 ballscrews and make sure the required number of pulley teeth are in touch with the (tensioned) belt. Been reading some of Jetguys stuff and he swears by this setup.

Edited 1 time(s). Last edit at 06/03/2016 09:31AM by hobbymods.

|

Re: Rugged CoreXY June 03, 2016 09:29AM |

Registered: 11 years ago Posts: 5,780 |

Most people building printers focus on the mechanism and don't consider enclosure or placement of the electronics or wiring until after they've built the mechanism. I see a lot of people trying to shoehorn the mechanism into the smallest possible space which usually means the frame gets used as part of the linear motion mechanism. That makes enclosing the printer a problem.

I've been designing a CoreXY printer with a 250 mm square bed that will be easily encloseable. It is going to have about 600 mm x 600 mm footprint which sounds ridiculous compared to the bed size, but calculate how big the enclosure has to be for a printer that uses the frame as part of the linear motion system and you'll quickly get to the same sort of size. Most of the CoreXY machines you see have open tops with the extruder cable and filament guide making a big arc that stands up over the top of the machine. How do you enclose that? You can try to keep the height down using a drag chain laid horizontally so it makes a big loop, but it's hard to feed filament through it. Maybe the machine has to be made taller...

It's always best to plan this stuff in advance. Resisting the urge to start building as soon as you get the mechanism figured out is hard to do, but worth it in the end.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I've been designing a CoreXY printer with a 250 mm square bed that will be easily encloseable. It is going to have about 600 mm x 600 mm footprint which sounds ridiculous compared to the bed size, but calculate how big the enclosure has to be for a printer that uses the frame as part of the linear motion system and you'll quickly get to the same sort of size. Most of the CoreXY machines you see have open tops with the extruder cable and filament guide making a big arc that stands up over the top of the machine. How do you enclose that? You can try to keep the height down using a drag chain laid horizontally so it makes a big loop, but it's hard to feed filament through it. Maybe the machine has to be made taller...

It's always best to plan this stuff in advance. Resisting the urge to start building as soon as you get the mechanism figured out is hard to do, but worth it in the end.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Rugged CoreXY June 03, 2016 09:36AM |

Registered: 7 years ago Posts: 168 |

Quote

the_digital_dentist

Most people building printers focus on the mechanism and don't consider enclosure or placement of the electronics or wiring until after they've built the mechanism. I see a lot of people trying to shoehorn the mechanism into the smallest possible space which usually means the frame gets used as part of the linear motion mechanism. That makes enclosing the printer a problem.

I've been designing a CoreXY printer with a 250 mm square bed that will be easily encloseable. It is going to have about 600 mm x 600 mm footprint which sounds ridiculous compared to the bed size, but calculate how big the enclosure has to be for a printer that uses the frame as part of the linear motion system and you'll quickly get to the same sort of size. Most of the CoreXY machines you see have open tops with the extruder cable and filament guide making a big arc that stands up over the top of the machine. How do you enclose that? You can try to keep the height down using a drag chain laid horizontally so it makes a big loop, but it's hard to feed filament through it. Maybe the machine has to be made taller...

It's always best to plan this stuff in advance. Resisting the urge to start building as soon as you get the mechanism figured out is hard to do, but worth it in the end.

Copy all that DD.

Certainly the machine will be tall, but I don't see a problem fitting a 300x300 platform in a 500x500 cabinet considering my early mockup stages.

Certainly the placement of electronics and wiring will be last, but I do have to consider how big I want this thing to be in conjunction with the mechanism.

I've given myself a maximum cabinet size for commercial reasons (if I am to be honest), as I am building a desktop machine albeit a big one.

But yes all sorts of monstrosities will be on top of the machine, but not inside the build chamber.

Edited 2 time(s). Last edit at 06/03/2016 09:43AM by hobbymods.

|

Re: Rugged CoreXY June 03, 2016 11:04AM |

Registered: 7 years ago Posts: 168 |

Quote

Vigilant

Quote

hobbymods

Quote

Vigilant

From my experience in my recently build printer, if you're going linear rails you'll probably do fine. I got the CoreXY up and running at first try without any hitch.

The hardest in my opinion is the Z axis. Took me quite some time to get this up to where I want it to. Cantilevered bed will work but you have to move extra slow so that the bed end doesn't oscillate too much.That's not really a problem because the Z axis only needs to move 0.1mm/0.2mm layer height each time. Moving faster won't improve your print time.

If you're using 2mmlead lead screw, the reduction is good enough for you to carry 3-4 kgs of load using a typical nema 17 motor.

The Z axis have to be very consistent and accurate and it doesn't take much to create Z Wobble artifacts,

Yes, I'm definitely on the same page.

As I mentioned before, my business runs Zortrax M200's which are renown for print quality but sometimes unpopular due to its closed software and limited materials/options (but the best option for a business knocking out ABS end user parts).

It runs a cantilevered shelf with 2x 12mm rods and 1 lead screw and gives very good Z resolution.

I am seriously considering buying one of those busted arse Wanhao Zortrax clones and gutting it (which is all they are good for) and doing my "lift off" corexy gantry on top of the box as well as converting the Z rods to precision rails.

A cursory glance holding my E3DV6 hotend in place suggests I could get the full 200x200 build volume as well as 240-260mm height. A good improvement on the approx 180x180x180 it gives with the H gantry.

By the time I muck about building a water jet cut box and buy all the bits, I'm sure to have spent the 1200 bucks that a D6 costs.

Then there's the fact that I get steppers, power supply and display, and I can sell the motherboard and complete hot end as well.

Could be the way to go...

This might be a better chance of success with a very respectable build volume, and a much less complicated Z axis for a first time around.

If you're going through that route, you might want to consider the ultimaker clone frame.

[www.aliexpress.com]

Don't purchase the whole printer set, I think it is crap. Just the frame and then figure out a way to mount the aluminium extrusion within the frame

OR build everything again using your own components. This guy here who got both ultimaker and the ultimaker clone claimed better printing quality after using custom components on the ultimaker clone.

[www.youtube.com]

One thing after building my corexy printer, is that although it functions pretty well, it is not the prettiest to look at. In fact I'm right now trying to figure out how to make it look prettier.

I must say that neither of those printers in the video are doing prints any better than I'm doing already.

I'd rather slow it down a bit and get a better print.

I do appreciate your input though.

If I'm to go to the trouble of a good corexy gantry, wouldn't a single motor/3 screw/ belt driven Z axis be the right complement for it?

|

Re: Rugged CoreXY June 03, 2016 01:27PM |

Registered: 8 years ago Posts: 622 |

Quote

hobbymods

Looking at a 500x500 cabinet footprint I can most likely get a 300x300 platform with a proper corexy gantry and 3 ballscrew Z axis.

Yes, that's what I thought too but I've had to increase the size from to 600 x 600 and with that I'll get 320 on the Y and 340 on the X maximum. Mind you, I'm planning mine around a Diamond hot end which, because it has 3 heat sinks sticking out at about 27 degrees, makes it a wide beast in all directions. I'm also planning to sling it between 2 X rails so that adds width and takes away from the maximum Y travel. Also, having all the motors and pulleys inboard so that it could easily be enclosed, takes away axis travel. I guess using a "sensible" hot end with a smaller footprint then 300x 300 platform inside a 500 x 500 frame might just be doable but it'll be tight with everything mounted inboard.

I'm also planning to use 3 lead screws but with 2 linear guides to keep the bed in position so that the screws only provide lift and can "float about". Initially, the screws will be driven by a single stepper and connected by a belt. DC42 has it on his list to do automatic bed levelling for the Duet with 3 screws and individual steppers and I'm planning the design so that I could easily change over to that at some time in the future.

|

Re: Rugged CoreXY June 03, 2016 06:13PM |

Registered: 7 years ago Posts: 168 |

Quote

deckingman

Quote

hobbymods

Looking at a 500x500 cabinet footprint I can most likely get a 300x300 platform with a proper corexy gantry and 3 ballscrew Z axis.

Yes, that's what I thought too but I've had to increase the size from to 600 x 600 and with that I'll get 320 on the Y and 340 on the X maximum. Mind you, I'm planning mine around a Diamond hot end which, because it has 3 heat sinks sticking out at about 27 degrees, makes it a wide beast in all directions. I'm also planning to sling it between 2 X rails so that adds width and takes away from the maximum Y travel. Also, having all the motors and pulleys inboard so that it could easily be enclosed, takes away axis travel. I guess using a "sensible" hot end with a smaller footprint then 300x 300 platform inside a 500 x 500 frame might just be doable but it'll be tight with everything mounted inboard.

I'm also planning to use 3 lead screws but with 2 linear guides to keep the bed in position so that the screws only provide lift and can "float about". Initially, the screws will be driven by a single stepper and connected by a belt. DC42 has it on his list to do automatic bed levelling for the Duet with 3 screws and individual steppers and I'm planning the design so that I could easily change over to that at some time in the future.

Yes I'm looking at 2 parallel X rails as well, and also 2x rail on the Z axis at the back with a floating screw (giggity) between them and one on each front corner.

Mine's all based on 15mm precision rails.

I've got a simple way that I've managed to locate the motors outside of the enclosed section, which looks like it might be a good thing, and a way I'll run the 2 belts on different levels to avoid the crossing/twisting.

Of course it's not real until it's built.

Edited 1 time(s). Last edit at 06/03/2016 06:22PM by hobbymods.

|

Re: Rugged CoreXY June 04, 2016 06:20AM |

Registered: 8 years ago Posts: 622 |

Quote

hobbymods

Quote

deckingman

Quote

hobbymods

Looking at a 500x500 cabinet footprint I can most likely get a 300x300 platform with a proper corexy gantry and 3 ballscrew Z axis.

Yes, that's what I thought too but I've had to increase the size from to 600 x 600 and with that I'll get 320 on the Y and 340 on the X maximum. Mind you, I'm planning mine around a Diamond hot end which, because it has 3 heat sinks sticking out at about 27 degrees, makes it a wide beast in all directions. I'm also planning to sling it between 2 X rails so that adds width and takes away from the maximum Y travel. Also, having all the motors and pulleys inboard so that it could easily be enclosed, takes away axis travel. I guess using a "sensible" hot end with a smaller footprint then 300x 300 platform inside a 500 x 500 frame might just be doable but it'll be tight with everything mounted inboard.

I'm also planning to use 3 lead screws but with 2 linear guides to keep the bed in position so that the screws only provide lift and can "float about". Initially, the screws will be driven by a single stepper and connected by a belt. DC42 has it on his list to do automatic bed levelling for the Duet with 3 screws and individual steppers and I'm planning the design so that I could easily change over to that at some time in the future.

Yes I'm looking at 2 parallel X rails as well, and also 2x rail on the Z axis at the back with a floating screw (giggity) between them and one on each front corner.

Mine's all based on 15mm precision rails.

I've got a simple way that I've managed to locate the motors outside of the enclosed section, which looks like it might be a good thing, and a way I'll run the 2 belts on different levels to avoid the crossing/twisting.

Of course it's not real until it's built.

Sounds like we have very similar plans but I'm basing mine on all V slot. I'm trying to keep mine so that the frame is just something rigid to hang everything off but won't be used for guides. I'll have separate guides. That way, the design can "evolve" more easily if Plan A doesn't work. I'm planning on using 20x40 for the Y, and 2 parallel 20 x 20 for the X. 2 off vertical Z guides at the front which will be 20x20 supported top, bottom and centre. 3 off lead screws, one each side at the front and one centre at the back. Like you, I'm having upper and lower belt runs for the X Y movement.

I've been teaching myself OpenScad for the last 6 months or so and I'm using that to do the design. BTW, age is not an excuse - I was born in the year of the Queens coronation

|

Re: Rugged CoreXY June 04, 2016 08:44AM |

Registered: 9 years ago Posts: 125 |

Out of curiosity, those of you planning or already having built the 3-ballscrew with a single stepper Z-axis systems, how are you attaching the pulleys to the ballscrews?

Are you just buying a cheap trapezoidal/acme leadscrew with multistart and then machining it to have a smooth bore to attach the pulley to or is there another trick to it?

Sure, one option would be to get the ballscrews from Misumi (with the ends already machined), but at ~60-70 € a piece it seems a bit too expensive.

Edit: Nevermind, found a link to an Aliexpress seller with decent prices for a ballscrew + nut combo from here: [github.com]

Edited 2 time(s). Last edit at 06/04/2016 06:37PM by Mikk36.

Are you just buying a cheap trapezoidal/acme leadscrew with multistart and then machining it to have a smooth bore to attach the pulley to or is there another trick to it?

Sure, one option would be to get the ballscrews from Misumi (with the ends already machined), but at ~60-70 € a piece it seems a bit too expensive.

Edit: Nevermind, found a link to an Aliexpress seller with decent prices for a ballscrew + nut combo from here: [github.com]

Edited 2 time(s). Last edit at 06/04/2016 06:37PM by Mikk36.

|

Re: Rugged CoreXY June 04, 2016 10:28AM |

Registered: 8 years ago Posts: 622 |

Quote

Mikk36

Out of curiosity, those of you planning or already having built the 3-ballscrew with a single stepper Z-axis systems, how are you attaching the pulleys to the ballscrews?

Are you just buying a cheap trapezoidal/acme leadscrew with multistart and then machining it to have a smooth bore to attach the pulley to or is there another trick to it?

Sure, one option would be to get the ballscrews from Misumi (with the ends already machined), but at ~60-70 € a piece it seems a bit too expensive.

Well I've order some Chinese lead screws, 8mm dia 1mm pitch single start. My thinking is that multi start and/or 8mm pitch would be too course for the z axis - we need resolution not speed. My frame size is 1,000 mm tall so I'll be needing 900 mm lead screws which'll give me about 800mm Z movement. My plan is to use 8mm bore GT2 pulleys and fix them straight to the un-machined shaft using grub screws. Don't know if this will work - it's a case of try it and see. My bearing block to support the bottom of the shaft has thrust bearings to take the weight, then normal radial bearings to take care of any sideways forces. Then the pulley will be fixed above this. This all only exists on OpenScad at the moment so I can't say if it's a good idea or not. My challenge at the moment is finding a long enough belt. The bed is 400mm square and the lead screws are outside this with the motor mounted inside that triangle. I'll use a couple of idlers along one side of the triangle to turn the belt through 90 degrees so that I can get 180 degree turn around the motor pulley. Ideally, I need a closed loop belt about 1600 mm long (or more).

|

Re: Rugged CoreXY June 04, 2016 06:40PM |

Registered: 7 years ago Posts: 168 |

Quote

Mikk36

Out of curiosity, those of you planning or already having built the 3-ballscrew with a single stepper Z-axis systems, how are you attaching the pulleys to the ballscrews?

Are you just buying a cheap trapezoidal/acme leadscrew with multistart and then machining it to have a smooth bore to attach the pulley to or is there another trick to it?

Sure, one option would be to get the ballscrews from Misumi (with the ends already machined), but at ~60-70 € a piece it seems a bit too expensive.

The ones I've seen come all set up with bearing/panel mounts top and bottom, and the bottom one has a shaft the extends down through the mount and gives you a spot for a coupler, pulley etc.

I'm considering 10-12mm, with 350-500mm Z axis travel.

I won't be going cheap, as I'm going for high quality prints.

|

Re: Rugged CoreXY June 05, 2016 04:03AM |

Registered: 7 years ago Posts: 168 |

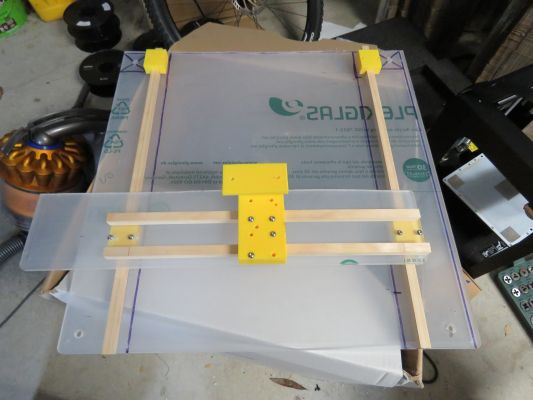

A ridiculously basic mock up with no money out but 12 bucks worth of pine square dowels.

Minister for Finance (and war, 2 portfolios) is watching me carefully these days.

My imitation Hiwin EG15's are surprisingly smooth...I should grease those dowels and sell them on ebay as "guaranteed authentic". I'll print them in green of course, I'm not a savage.

I always do this before I send a file off to the laser/water cutter. As well as the money it's the time spent waiting, so I prefer to rough it a little first.

Obviously corexy based on that pick that's getting around on thingiverse etc, frankie or something, just without bronze bushes epoxied to things as bearings.

I also hope to run a tall/double idler and some sort of extended shaft stepper with a support flange/bearing on it as well, in the hope to run both belt circuits without crossing them like that...don't like the idea of that.

Y axis will run 4x shorter carriage (2 per rail), X will run 2x longer rail.

The X axis mount plate will "horse shoe" to pick up the 2 extra carriages at the rear, which addresses clearance issues at the back and allows me to push it right up to the front as close to the belts as I can.

That's a rough 500mm square, and believe it or not I've got almost 300x300 travel there.

The bracket in the middle if fitted upside down because my jigsaw is very noisy/blunt and I can't cut out the center at the moment. It gets in underneath and is designed to fit the Bondtech extruder mount (at this stage). It actually slings pretty nicely there, and just by good luck gives a nice balance of height at the top and use of the Z height. I can see a bit of heavy ally C channel getting a bit of machining for the final mount, as well as nice places to fasten cable/conduit/whatever.

Where can I get the following?

1. Idler pulleys, including toothed/plain/single/double. Maybe some cheapies for mockup, got a bunch of ebay bits coming already. Certainly nothing I'd use in the end. So maybe some ebay and quality sellers if you know them.

2. Some sort of nema17 size bearing mount/yoke/extension wit a 5mm bearing that I can bolt on the opposite side of the plate to the long shaft motor, to add some support as the pulley will set high and I don't want it swinging unsupported. I can print something in PC, but a nice ally one off the shelf would be ideal.

3. What sort of belt would be suitable? Don't want to blindly go with 6mm GT2 on this one. Thinking more like an 8-10mm belt, and am open to different types if there's something better.

I'll aim at having something done up on CAD this month, and probably get a laser cut acrylic model first, so I can see all the gantry working clearly and address any issues.

Edited 2 time(s). Last edit at 06/05/2016 05:44AM by hobbymods.

|

Re: Rugged CoreXY June 05, 2016 05:23AM |

Registered: 11 years ago Posts: 5,780 |

Quote

deckingman

Well I've order some Chinese lead screws, 8mm dia 1mm pitch single start. My thinking is that multi start and/or 8mm pitch would be too course for the z axis - we need resolution not speed.

I have 1/2" lead screws (yes, imperial!) in the Z axis of my printer and a 20/42 pulley reduction and get flawless prints. You're going to print in 100 um (or more) layers. Why on earth would you need 3200 steps per mm in the Z axis?

Edited 1 time(s). Last edit at 06/05/2016 05:23AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Rugged CoreXY June 05, 2016 06:46AM |

Registered: 7 years ago Posts: 168 |

Quote

the_digital_dentist

Quote

deckingman

Well I've order some Chinese lead screws, 8mm dia 1mm pitch single start. My thinking is that multi start and/or 8mm pitch would be too course for the z axis - we need resolution not speed.

I have 1/2" lead screws (yes, imperial!) in the Z axis of my printer and a 20/42 pulley reduction and get flawless prints. You're going to print in 100 um (or more) layers. Why on earth would you need 3200 steps per mm in the Z axis?

So you've got 20t pully on the stepper then 42t on each of the lead screws?

That would be a fair amount of reduction in itself I'd imagine.

Any tips on my belt/pulley questions above?

Edited 1 time(s). Last edit at 06/05/2016 07:23AM by hobbymods.

|

Re: Rugged CoreXY June 05, 2016 08:59AM |

Registered: 8 years ago Posts: 622 |

Quote

the_digital_dentist

Quote

deckingman

Well I've order some Chinese lead screws, 8mm dia 1mm pitch single start. My thinking is that multi start and/or 8mm pitch would be too course for the z axis - we need resolution not speed.

I have 1/2" lead screws (yes, imperial!) in the Z axis of my printer and a 20/42 pulley reduction and get flawless prints. You're going to print in 100 um (or more) layers. Why on earth would you need 3200 steps per mm in the Z axis?

Sorry, don't understand your maths. 1mm pitch single start means 1 revolution is 1mm in height. I revolution is 360 degrees. 1 motor step is 1.8 degrees so 360 degrees is 200 steps making it 200 steps per mm. How did you make it 3,200?

|

Re: Rugged CoreXY June 05, 2016 09:25AM |

Registered: 9 years ago Posts: 125 |

1/16 microsteppingQuote

deckingman

Quote

the_digital_dentist

Quote

deckingman

Well I've order some Chinese lead screws, 8mm dia 1mm pitch single start. My thinking is that multi start and/or 8mm pitch would be too course for the z axis - we need resolution not speed.

I have 1/2" lead screws (yes, imperial!) in the Z axis of my printer and a 20/42 pulley reduction and get flawless prints. You're going to print in 100 um (or more) layers. Why on earth would you need 3200 steps per mm in the Z axis?

Sorry, don't understand your maths. 1mm pitch single start means 1 revolution is 1mm in height. I revolution is 360 degrees. 1 motor step is 1.8 degrees so 360 degrees is 200 steps making it 200 steps per mm. How did you make it 3,200?

|

Re: Rugged CoreXY June 05, 2016 11:21AM |

Registered: 11 years ago Posts: 5,780 |

Quote

hobbymods

So you've got 20t pully on the stepper then 42t on each of the lead screws?

That would be a fair amount of reduction in itself I'd imagine.

Any tips on my belt/pulley questions above?

That would be exactly 1/2.1 reduction, so with 1/2" lead, one rev of the motor will move the X axis up or down by 0.238095 inches = 6.047619 mm. At 3200 usteps/rev, each ustep will move the X axis up/down 0.00189 mm. If I were marketing my printer as a kit I would claim that it has better than 2 um resolution (total BS). I routinely print in 200 or 250 um layer thickness, and even though there is no whole number of microsteps that corresponds to those layer thicknesses, there are no visible flaws in the prints in the form of periodic Z axis lines, waves, etc. I have printed as thin as 50 um and did not see any Z axis artifacts.

I suspect you can just mount pulleys and bearings on the threaded part of the lead screw without any machining, but I haven't tried it myself. You will have to put some sort of clamp on the screw to lock the bearings in place.

Edited 1 time(s). Last edit at 06/05/2016 11:23AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Rugged CoreXY June 05, 2016 11:28AM |

Registered: 8 years ago Posts: 622 |

Ah, I guess that's what he meant although he said 3,200 steps per mm, not microsteps. Anyway, the reason for using 1mm pitch is that (as I mentioned), I'm planning on using the lead screws for bed levelling. It may not work but my thinking is that I have 3 point lifting so why not use it for bed levelling as well? The more common 2 mm pitch, 4 start screws give an effective 8mm pitch so 0.1mm will be one 80th of a turn which will be tricky even to get it approximately close. We'll see when it's built. If it doesn't work, it'll be easy enough to change (although I can't at the moment see any reason to change the Z screws for something that is 8 times more course. My existing Mendel uses 5mm threaded rod which has a pitch of 0.8mm and the Z axis moves plenty fast enough.

|

Re: Rugged CoreXY June 05, 2016 11:34AM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

Quote

hobbymods

So you've got 20t pully on the stepper then 42t on each of the lead screws?

That would be a fair amount of reduction in itself I'd imagine.

Any tips on my belt/pulley questions above?

i'm using a 20t and i 3d-printed 3 50t for each leadscrew, which is a TR8 w/2mm pitch. the 3.125 : 1 gear-down ratio more than makes up for the increased pitch of the TR8.

900mm open loop belt goes round all four pulleys, the 16t is offset by a distance of 32mm and an approximate angle of 45 degrees from the 3rd central pulley (AWAY from the front 2, so further back even than the back central lead screw). this gives an angle of around 150 degrees on the GT2-16t and around 45 degrees on that central 50t. however given that the 50t is so large the actual contact area of that 45 degrees is at least 20mm so there is no chance of slippage.

works really well, although the positioning of the z motor is distinctly... odd.

|

Re: Rugged CoreXY June 05, 2016 11:41AM |

Registered: 8 years ago Posts: 776 |

Quote

hobbymods

A ridiculously basic mock up with no money out but 12 bucks worth of pine square dowels.

totally cool. i love using cardboard for concepts (takes me under an hour to make something) but a full-size quick mockup i'm really impressed. hell with a bit more work you might actually be able to turn that into an actual working printer and sell it to people in china where they'll copy it just for a laugh

Quote

Where can I get the following?

1. Idler pulleys, including toothed/plain/single/double. Maybe some cheapies for mockup, got a bunch of ebay bits coming already. Certainly nothing I'd use in the end. So maybe some ebay and quality sellers if you know them.

2. Some sort of nema17 size bearing mount/yoke/extension wit a 5mm bearing that I can bolt on the opposite side of the plate to the long shaft motor, to add some support as the pulley will set high and I don't want it swinging unsupported. I can print something in PC, but a nice ally one off the shelf would be ideal.

3. What sort of belt would be suitable? Don't want to blindly go with 6mm GT2 on this one. Thinking more like an 8-10mm belt, and am open to different types if there's something better.

you're in australia, leetle far away from europe / usa! but, also, closer to china / taiwan so you might find word-of-mouth a good supplier, if so we wanna hear about it! i typically use alfa-tech3d.com he's adding all sorts of stuff. if you have to use GT2 6mm consider the steel-reinforced ones? digital_dentist uses 8mm then doubles up all the idler bearings, 625s i think.

|

Re: Rugged CoreXY June 05, 2016 05:18PM |

Registered: 7 years ago Posts: 168 |

Cheers both of you.

Robotdig stuff is supposedly ok and cheap so I'll use them for starters.

Don't worry about how rough that model is, I just had to put my hands to something not just think/talk about it.

It'll be like that evolution chart with the lizard crawling out of the water and becoming a monkey lol

Edited 1 time(s). Last edit at 06/05/2016 05:18PM by hobbymods.

Robotdig stuff is supposedly ok and cheap so I'll use them for starters.

Don't worry about how rough that model is, I just had to put my hands to something not just think/talk about it.

It'll be like that evolution chart with the lizard crawling out of the water and becoming a monkey lol

Edited 1 time(s). Last edit at 06/05/2016 05:18PM by hobbymods.

|

Re: Rugged CoreXY June 05, 2016 05:35PM |

Registered: 7 years ago Posts: 168 |

Interesting point will be can I get the cabinet as straight/flat as required for correct mounting of linear rails or will I need to have the surfaces machined.

Another approach might be to make the gantry drop in on mounts that have been trammed to the Z rails.

The whole project will be based around solid/consistent XYZ tramming.

Another approach might be to make the gantry drop in on mounts that have been trammed to the Z rails.

The whole project will be based around solid/consistent XYZ tramming.

|

Re: Rugged CoreXY June 05, 2016 07:15PM |

Registered: 11 years ago Posts: 5,780 |

Quote

deckingman

...Anyway, the reason for using 1mm pitch is that (as I mentioned), I'm planning on using the lead screws for bed levelling. It may not work but my thinking is that I have 3 point lifting so why not use it for bed levelling as well?

If the bed is going to be heated, you're still going to stand it off an undercarriage that's connected to the lead screws. Those fine pitch stand-off screws can be used to set the bed level when you first set up the machine.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Rugged CoreXY June 06, 2016 03:12AM |

Registered: 7 years ago Posts: 168 |

Quote

the_digital_dentist

Quote

deckingman

...Anyway, the reason for using 1mm pitch is that (as I mentioned), I'm planning on using the lead screws for bed levelling. It may not work but my thinking is that I have 3 point lifting so why not use it for bed levelling as well?

If the bed is going to be heated, you're still going to stand it off an undercarriage that's connected to the lead screws. Those fine pitch stand-off screws can be used to set the bed level when you first set up the machine.

Yes that's exactly how I plan to do it.

One reference post (been reading your stuff) and 2 adjustable, set and locked off with lock nuts.

Also after further reading and reviewing back through this, I will be definitely using the Duet board with 0.9 degree stepper motors and the matching touchscreen that comes with it....just makes sense, especially if I want to use S3D for my slicer.

Edited 1 time(s). Last edit at 06/06/2016 03:14AM by hobbymods.

|

Re: Rugged CoreXY June 06, 2016 05:40AM |

Registered: 7 years ago Posts: 168 |

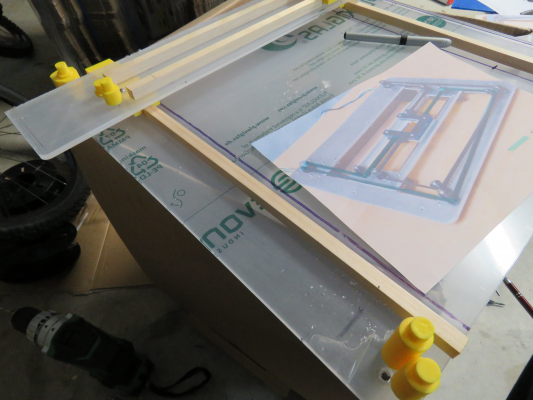

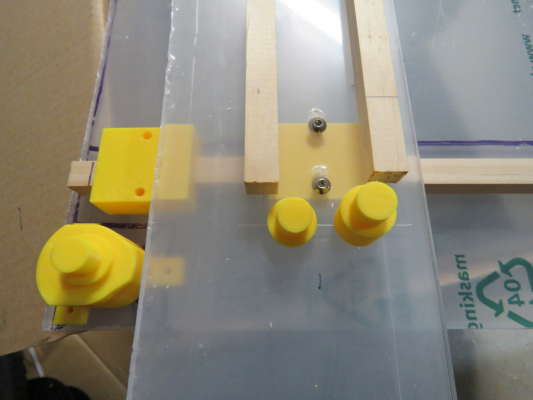

A little more jiggery today:

I'm not trying to confirm or change the principles of corexy, just looking at it in the flesh in my application.

The stepper motor extension mounts will allow an extra 5mm bearing to support a long/extended shaft stepper and put the pulleys on the same level as the X gantry plate.

The 2 circuits will be on different levels, as many have discussed here before.

I've gone off the idea of stackable pulleys, but making a single stepped pedestal with 2 shoulder bolts for the XY idlers seems an obvious thing to do.

My initial cabinet external dimensions are becoming more of a guideline, but I'm definitely very close to them.

I'll mess about a bit longer like this, and will send some files to the laser acrylic cutter. He'll want me to run a full sheet, so I'll look at a back and floor so I've got more to play with.

I'm not trying to confirm or change the principles of corexy, just looking at it in the flesh in my application.

The stepper motor extension mounts will allow an extra 5mm bearing to support a long/extended shaft stepper and put the pulleys on the same level as the X gantry plate.

The 2 circuits will be on different levels, as many have discussed here before.

I've gone off the idea of stackable pulleys, but making a single stepped pedestal with 2 shoulder bolts for the XY idlers seems an obvious thing to do.

My initial cabinet external dimensions are becoming more of a guideline, but I'm definitely very close to them.

I'll mess about a bit longer like this, and will send some files to the laser acrylic cutter. He'll want me to run a full sheet, so I'll look at a back and floor so I've got more to play with.

|

Re: Rugged CoreXY June 06, 2016 06:44AM |

Registered: 8 years ago Posts: 776 |

Quote

hobbymods

I'm not trying to confirm or change the principles of corexy, just looking at it in the flesh in my application.

offset (stack) one belt above the other, keep all parts of each belt in same plane, make all turns 90 degrees EXACTLY (except round motor of course), use 2 bolts for x-end idlers, stagger them so that belts come in to carriage exactly one above the other. check notes and links in that first reply i did.

Sorry, only registered users may post in this forum.