Rugged CoreXY

Posted by hobbymods

|

Re: Rugged CoreXY June 07, 2016 07:23AM |

Registered: 7 years ago Posts: 168 |

Quote

lkcl

Quote

hobbymods

Yep I'm feeling this one too.

I'm really leaning towards using 2x 10mm ground rods across the center (X) axis, there's just so many reasons.

Of course there's the fact that it'll cost 10% of what my precision rail setup would, but then there's probably half the weight, 2 less major machining/tool making steps, the ability to slide the rods out and change carriages (CNC/laser engraver attachment) and the fact that it'll probably work just as well using proper ground/hardened rod and 4x brand name LM10U bearings.

I think I'll go this way and see if it all works out.

talked this one through with realthor just over a week ago, we figured that if you use linear bearings, as long as you keep the linear bearings as far apart as you dare, any "play" in them will not result in significant rotation of the carriage. if there _is_ any play, gravity shouuuld keep it down, but even if there is, the further apart the bearings are the less effect any up/down will have... as long as the hotend is as close to the dead-centre-point of the carriage bearings as you dare. having the bearings so close to the printbed that they knock bits of plastic off is clearly bad...

Yes, plus using 4 of them (1 in each corner) and centered as you mention should be all right.

One of my filament suppliers told me that he had a machine come through new that had too much play, and when he changed the brand new 8mm linear bearings with good name brand from the bearing supplier the difference was night and day.

I'm also talking 10 mm hardened rod over a 400mm max span.

Not sure yet, but being able to remove the carriage without upsetting everything and more room to see/reach into the top would be appealing.

|

Re: Rugged CoreXY June 07, 2016 07:32AM |

Registered: 8 years ago Posts: 776 |

Quote

hobbymods

One of my filament suppliers told me that he had a machine come through new that had too much play, and when he changed the brand new 8mm linear bearings with good name brand from the bearing supplier the difference was night and day.

I'm also talking 10 mm hardened rod over a 400mm max span.

Not sure yet, but being able to remove the carriage without upsetting everything and more room to see/reach into the top would be appealing.

watch out for incorrect-spec rods, too. use a more expensive supplier. my supplier buys hardened chrome-plated bars from china, in 3 metre lengths, cuts them up and chucks the ends. buuut, although the 12mm rods were in spec (12.000 +/- 0.004mm) they were pretty much exactly on the 12.004 limit... and they were useless. even when in spec it's really that close. so he got me some that were cut from the middle, which are closer to the 12.000, and they're perfect.

so just fyi, it's not just the bearings, it's the rods you have to watch, too.

on the sandwich200v2 i had to arrange for the Flex3Drive to be removable, it has 6 bolts, if you arrange everything you need (cables-wise) down to a separate "block" that has the hotend, fans, endstops (if you're going to put them on the carriage, which is recommended, because it avoids silly wiring looms just to the x-ends), then you can unmount that and service the hotend / change it / etc / etc.

the mendel90 by nophead has the carriage wiring (it's a direct extruder) actually on a 19-pin D-Sub so you can interchange them easily. removable hotend assemblies is really just common sense if you ask me.

but, nice thing about a separate hotend assembly that bolts to the carriage is, you wouldn't need to do a total disassembly job of the x-end rods or carriage just to service the hotend (or whatever)

|

Re: Rugged CoreXY June 07, 2016 08:36AM |

Registered: 7 years ago Posts: 168 |

Yes I'm well aware of Chinese spec rods, I own a Wanhao D5S, the most disgracefully built machine there is I think.

I buy my rods cut to length from the Australian Hiwin distributor, and it's perfectly in spec.

I'm still flip flopping on this, as I run it past my son who expressed his disapproval at not using rails...important

Got the Australian Gates guy on the job, and this guy knows his stuff!

Plus he seems to be genuinely interested and helpful all around, sent me tonnes of stuff I just can't sift through, but I'm tipping if I send him some pics of the stacked belt but not crossed designs he'll rattle off a list of part numbers for me.

Edited 2 time(s). Last edit at 06/07/2016 09:51AM by hobbymods.

I buy my rods cut to length from the Australian Hiwin distributor, and it's perfectly in spec.

I'm still flip flopping on this, as I run it past my son who expressed his disapproval at not using rails...important

Got the Australian Gates guy on the job, and this guy knows his stuff!

Plus he seems to be genuinely interested and helpful all around, sent me tonnes of stuff I just can't sift through, but I'm tipping if I send him some pics of the stacked belt but not crossed designs he'll rattle off a list of part numbers for me.

Edited 2 time(s). Last edit at 06/07/2016 09:51AM by hobbymods.

|

Re: Rugged CoreXY June 07, 2016 01:31PM |

Registered: 9 years ago Posts: 346 |

@ Ikcl - I like your focus on reducing the length from center of X rods to edge of out nozzle. I have never understood that it was not given more attention. Mine is 33mm from center of rods to nozzle edge, I wish it was less, but it is hard to design something printable and something that won't melt and then I wanted the dual nozzles...

But sometimes I see some designs that makes me confused... Like this Kickstarter campaign: [www.kickstarter.com] - How does that nozzle not go 1-2 mm from side to side?

@ Hobbymods - Personally, if I was making a new printer, I would use linear rails. Not smooth rods. Especially if you can design it with only one rail for the X axis. Makes so many things so much easier I think.

Mine I posted pictures of earlier (the one with crossed belts) was my attempt at making my own linear rails, it has some ball bearings rolling on the 2020 profile with springs applying pressure - It prints and have been working reliably, all the orange parts in pictures are printed with it, but the quality is just not good enough... I purchased a "real" linear rail some time ago, just to get a feel for it, and it is a different world, so compact yet so exact and smooth. And the ease for mounting on a linear rail compared to having to clamp a smooth rod bearing... mmmhm. But it is costly.

But sometimes I see some designs that makes me confused... Like this Kickstarter campaign: [www.kickstarter.com] - How does that nozzle not go 1-2 mm from side to side?

@ Hobbymods - Personally, if I was making a new printer, I would use linear rails. Not smooth rods. Especially if you can design it with only one rail for the X axis. Makes so many things so much easier I think.

Mine I posted pictures of earlier (the one with crossed belts) was my attempt at making my own linear rails, it has some ball bearings rolling on the 2020 profile with springs applying pressure - It prints and have been working reliably, all the orange parts in pictures are printed with it, but the quality is just not good enough... I purchased a "real" linear rail some time ago, just to get a feel for it, and it is a different world, so compact yet so exact and smooth. And the ease for mounting on a linear rail compared to having to clamp a smooth rod bearing... mmmhm. But it is costly.

|

Re: Rugged CoreXY June 07, 2016 09:00PM |

Registered: 7 years ago Posts: 168 |

Quote

LarsK

@ Ikcl - I like your focus on reducing the length from center of X rods to edge of out nozzle. I have never understood that it was not given more attention. Mine is 33mm from center of rods to nozzle edge, I wish it was less, but it is hard to design something printable and something that won't melt and then I wanted the dual nozzles...

But sometimes I see some designs that makes me confused... Like this Kickstarter campaign: [www.kickstarter.com] - How does that nozzle not go 1-2 mm from side to side?

@ Hobbymods - Personally, if I was making a new printer, I would use linear rails. Not smooth rods. Especially if you can design it with only one rail for the X axis. Makes so many things so much easier I think.

Mine I posted pictures of earlier (the one with crossed belts) was my attempt at making my own linear rails, it has some ball bearings rolling on the 2020 profile with springs applying pressure - It prints and have been working reliably, all the orange parts in pictures are printed with it, but the quality is just not good enough... I purchased a "real" linear rail some time ago, just to get a feel for it, and it is a different world, so compact yet so exact and smooth. And the ease for mounting on a linear rail compared to having to clamp a smooth rod bearing... mmmhm. But it is costly.

Yes, might have had a lapse of reason there...

Problem is that I don't agree with a single rail (especially unsupported) on the X axis, as they are designed to generally be run as 2 parallel rails. I feel I've stretched the rules a bit just using one carriage on each rail, but will use the longer carriage on the X axis.

What I'm looking at here is a pretty heavy X axis, but I did say I wasn't going for speed I guess. I'll keep going with the rails and see how it plays out.

|

Re: Rugged CoreXY June 07, 2016 10:20PM |

Registered: 13 years ago Posts: 268 |

Quote

hobbymods

Quote

LarsK

@ Ikcl - I like your focus on reducing the length from center of X rods to edge of out nozzle. I have never understood that it was not given more attention. Mine is 33mm from center of rods to nozzle edge, I wish it was less, but it is hard to design something printable and something that won't melt and then I wanted the dual nozzles...

But sometimes I see some designs that makes me confused... Like this Kickstarter campaign: [www.kickstarter.com] - How does that nozzle not go 1-2 mm from side to side?

@ Hobbymods - Personally, if I was making a new printer, I would use linear rails. Not smooth rods. Especially if you can design it with only one rail for the X axis. Makes so many things so much easier I think.

Mine I posted pictures of earlier (the one with crossed belts) was my attempt at making my own linear rails, it has some ball bearings rolling on the 2020 profile with springs applying pressure - It prints and have been working reliably, all the orange parts in pictures are printed with it, but the quality is just not good enough... I purchased a "real" linear rail some time ago, just to get a feel for it, and it is a different world, so compact yet so exact and smooth. And the ease for mounting on a linear rail compared to having to clamp a smooth rod bearing... mmmhm. But it is costly.

Yes, might have had a lapse of reason there...

Problem is that I don't agree with a single rail (especially unsupported) on the X axis, as they are designed to generally be run as 2 parallel rails. I feel I've stretched the rules a bit just using one carriage on each rail, but will use the longer carriage on the X axis.

What I'm looking at here is a pretty heavy X axis, but I did say I wasn't going for speed I guess. I'll keep going with the rails and see how it plays out.

There are very specific types of rails "designed" to be used in pairs. Typically these have unequal load capacities in all directions and are set up in opposing pairs. These are not the styles you are talking about. More typical "equal load" rails are designed to run singly just fine, they have listed moment loads singly for a good reason.

|

Re: Rugged CoreXY June 07, 2016 10:51PM |

Registered: 7 years ago Posts: 168 |

Quote

Koko76

Quote

hobbymods

Quote

LarsK

@ Ikcl - I like your focus on reducing the length from center of X rods to edge of out nozzle. I have never understood that it was not given more attention. Mine is 33mm from center of rods to nozzle edge, I wish it was less, but it is hard to design something printable and something that won't melt and then I wanted the dual nozzles...

But sometimes I see some designs that makes me confused... Like this Kickstarter campaign: [www.kickstarter.com] - How does that nozzle not go 1-2 mm from side to side?

@ Hobbymods - Personally, if I was making a new printer, I would use linear rails. Not smooth rods. Especially if you can design it with only one rail for the X axis. Makes so many things so much easier I think.

Mine I posted pictures of earlier (the one with crossed belts) was my attempt at making my own linear rails, it has some ball bearings rolling on the 2020 profile with springs applying pressure - It prints and have been working reliably, all the orange parts in pictures are printed with it, but the quality is just not good enough... I purchased a "real" linear rail some time ago, just to get a feel for it, and it is a different world, so compact yet so exact and smooth. And the ease for mounting on a linear rail compared to having to clamp a smooth rod bearing... mmmhm. But it is costly.

Yes, might have had a lapse of reason there...

Problem is that I don't agree with a single rail (especially unsupported) on the X axis, as they are designed to generally be run as 2 parallel rails. I feel I've stretched the rules a bit just using one carriage on each rail, but will use the longer carriage on the X axis.

What I'm looking at here is a pretty heavy X axis, but I did say I wasn't going for speed I guess. I'll keep going with the rails and see how it plays out.

There are very specific types of rails "designed" to be used in pairs. Typically these have unequal load capacities in all directions and are set up in opposing pairs. These are not the styles you are talking about. More typical "equal load" rails are designed to run singly just fine, they have listed moment loads singly for a good reason.

Yes and that's all well and good, but I am assured by my contact at Hiwin that these specific rails that I'm talking about will give best results installed in parallel on a horizontal surface. I am well aware of the moment loads as well, and most if not all printers wouldn't come close to them, but I'm chasing long term continuous duty operation in a workshop environment as well as quiet as possible operation.

But I do appreciate what you are explaining to me and the reasons behind the explanation (saving money and weight).

Is there any reason I see the XY steppers installed on peoples corexy builds at 45 deg?

That would actually be quite good for me design wise, but I'd only want to do it if there was a solid reason to do so.

|

Re: Rugged CoreXY June 08, 2016 12:11AM |

Registered: 13 years ago Posts: 268 |

Quote

hobbymods

Quote

Koko76

Quote

hobbymods

Quote

LarsK

@ Ikcl - I like your focus on reducing the length from center of X rods to edge of out nozzle. I have never understood that it was not given more attention. Mine is 33mm from center of rods to nozzle edge, I wish it was less, but it is hard to design something printable and something that won't melt and then I wanted the dual nozzles...

But sometimes I see some designs that makes me confused... Like this Kickstarter campaign: [www.kickstarter.com] - How does that nozzle not go 1-2 mm from side to side?

@ Hobbymods - Personally, if I was making a new printer, I would use linear rails. Not smooth rods. Especially if you can design it with only one rail for the X axis. Makes so many things so much easier I think.

Mine I posted pictures of earlier (the one with crossed belts) was my attempt at making my own linear rails, it has some ball bearings rolling on the 2020 profile with springs applying pressure - It prints and have been working reliably, all the orange parts in pictures are printed with it, but the quality is just not good enough... I purchased a "real" linear rail some time ago, just to get a feel for it, and it is a different world, so compact yet so exact and smooth. And the ease for mounting on a linear rail compared to having to clamp a smooth rod bearing... mmmhm. But it is costly.

Yes, might have had a lapse of reason there...

Problem is that I don't agree with a single rail (especially unsupported) on the X axis, as they are designed to generally be run as 2 parallel rails. I feel I've stretched the rules a bit just using one carriage on each rail, but will use the longer carriage on the X axis.

What I'm looking at here is a pretty heavy X axis, but I did say I wasn't going for speed I guess. I'll keep going with the rails and see how it plays out.

There are very specific types of rails "designed" to be used in pairs. Typically these have unequal load capacities in all directions and are set up in opposing pairs. These are not the styles you are talking about. More typical "equal load" rails are designed to run singly just fine, they have listed moment loads singly for a good reason.

Yes and that's all well and good, but I am assured by my contact at Hiwin that these specific rails that I'm talking about will give best results installed in parallel on a horizontal surface. I am well aware of the moment loads as well, and most if not all printers wouldn't come close to them, but I'm chasing long term continuous duty operation in a workshop environment as well as quiet as possible operation.

But I do appreciate what you are explaining to me and the reasons behind the explanation (saving money and weight).

Is there any reason I see the XY steppers installed on peoples corexy builds at 45 deg?

That would actually be quite good for me design wise, but I'd only want to do it if there was a solid reason to do so.

You've been talking about pairs of 15mm rails. I designed and built built a drill rig recently for a customer that used a pair of 15mm rails to drill into a hardened bearing race to pin a >1meter diameter bearing. Those rails were able to keep the carbide tipped drills pretty stable too. There's simply no need to have the weight and space for all that hardware in your application. Weight adds wear to components too.

|

Re: Rugged CoreXY June 08, 2016 12:52AM |

Registered: 7 years ago Posts: 168 |

Quote

Koko76

Quote

hobbymods

Quote

Koko76

Quote

hobbymods

Quote

LarsK

@ Ikcl - I like your focus on reducing the length from center of X rods to edge of out nozzle. I have never understood that it was not given more attention. Mine is 33mm from center of rods to nozzle edge, I wish it was less, but it is hard to design something printable and something that won't melt and then I wanted the dual nozzles...

But sometimes I see some designs that makes me confused... Like this Kickstarter campaign: [www.kickstarter.com] - How does that nozzle not go 1-2 mm from side to side?

@ Hobbymods - Personally, if I was making a new printer, I would use linear rails. Not smooth rods. Especially if you can design it with only one rail for the X axis. Makes so many things so much easier I think.

Mine I posted pictures of earlier (the one with crossed belts) was my attempt at making my own linear rails, it has some ball bearings rolling on the 2020 profile with springs applying pressure - It prints and have been working reliably, all the orange parts in pictures are printed with it, but the quality is just not good enough... I purchased a "real" linear rail some time ago, just to get a feel for it, and it is a different world, so compact yet so exact and smooth. And the ease for mounting on a linear rail compared to having to clamp a smooth rod bearing... mmmhm. But it is costly.

Yes, might have had a lapse of reason there...

Problem is that I don't agree with a single rail (especially unsupported) on the X axis, as they are designed to generally be run as 2 parallel rails. I feel I've stretched the rules a bit just using one carriage on each rail, but will use the longer carriage on the X axis.

What I'm looking at here is a pretty heavy X axis, but I did say I wasn't going for speed I guess. I'll keep going with the rails and see how it plays out.

There are very specific types of rails "designed" to be used in pairs. Typically these have unequal load capacities in all directions and are set up in opposing pairs. These are not the styles you are talking about. More typical "equal load" rails are designed to run singly just fine, they have listed moment loads singly for a good reason.

Yes and that's all well and good, but I am assured by my contact at Hiwin that these specific rails that I'm talking about will give best results installed in parallel on a horizontal surface. I am well aware of the moment loads as well, and most if not all printers wouldn't come close to them, but I'm chasing long term continuous duty operation in a workshop environment as well as quiet as possible operation.

But I do appreciate what you are explaining to me and the reasons behind the explanation (saving money and weight).

Is there any reason I see the XY steppers installed on peoples corexy builds at 45 deg?

That would actually be quite good for me design wise, but I'd only want to do it if there was a solid reason to do so.

You've been talking about pairs of 15mm rails. I designed and built built a drill rig recently for a customer that used a pair of 15mm rails to drill into a hardened bearing race to pin a >1meter diameter bearing. Those rails were able to keep the carbide tipped drills pretty stable too. There's simply no need to have the weight and space for all that hardware in your application. Weight adds wear to components too.

Ok.

Well I'm already printing a housing to run 2, but I will take your advice and also make a single rail version.

It certainly would make life easier.

I take it you're a machinist/toolmaker of some sort?

What I don't want to use is the MG rails, as they only have one bearing race as opposed to the EG series which has 2, and can be supplied with a grease nipple (I build everything to be serviced).

Please don't think I'm not one to listen, I'm just so used to hearing "naaahhhh....you don't worry about that shit, just use this paddle pop stick and a rubber band", which is just not how I roll.

I'd still use the single X carriage horizontally mounted, because it would be easier to marry up to my Y axis, with a machined L bracket dropping down into the build area.

Lots of advantages this way in addition to weight/cost....access to the extruder, ability to mount some sort of engraver for a different application, as well as simply looking better.

So cheers for that.

|

Re: Rugged CoreXY June 08, 2016 05:24AM |

Registered: 7 years ago Posts: 168 |

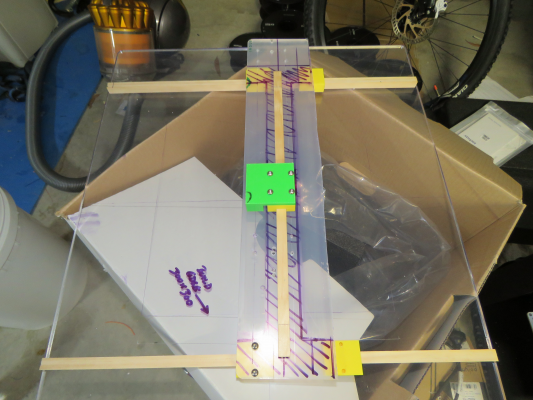

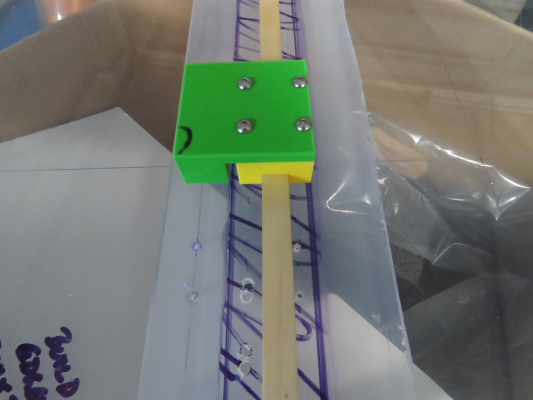

Home alone today, so my second piece of acrylic got molested.

Did what I should have done first time and worked out from the center, spacing everything about the 300x300 build size I want.

I'm following Koko's advice regarding the X axis because I'm sure he's correct.

I'm definitely running 4 short carriages on the Y axis because I can, and will stretch the "dog bone" plate forward/backward as required to get maximum span for my 300x300 build. I know it's miles over engineered, but should track true forever.

The thick part of the green bracket is the same 21mm thick that the printed Bondtech bracket is, and will extend down into the work area to a distance that will work with the extruder once it lands. I will machine the same radius into that piece and make a matching clamp to lock the extruder onto it.

It may then be possible to extend the clamp body down to incorporate a mount for the E3DV6 incorporating the heat break fan and print fans, all locked solid. Don't really like seeing that hot end connected my that collar at the top only.

Looking at the drawings Martin from Bondtech sent me showing the dimensions and placement of the stepper motor, it should be easy to balance it so that the center of gravity is exactly below the X rail.

Got an engineer mate looking through his catalogs to work out some pulley arrangements that comply with the corexy rules mentioned in previous posts, and give me some part numbers etc. He's got more than a few tricks up his sleeve this guy.

Some questions are:

1. Where can I get Nema 17 stepper motors with a 100mm long shaft? Don't care about the spec, looking for chinese cheapies to let me design my support pedestal etc. As long as possible is fine, as it's just for props (guess I could print a dummy and put a bit of rod through it).

2. Are there any pros/cons to mounting the XY steppers at 45 deg like I've seen a couple do? It would kind of help me do what I want to, but I don't want to do it if it's a compromise of some sort.

Glad my toes are clean....hate it when that happens.

Edited 3 time(s). Last edit at 06/08/2016 05:29AM by hobbymods.

Did what I should have done first time and worked out from the center, spacing everything about the 300x300 build size I want.

I'm following Koko's advice regarding the X axis because I'm sure he's correct.

I'm definitely running 4 short carriages on the Y axis because I can, and will stretch the "dog bone" plate forward/backward as required to get maximum span for my 300x300 build. I know it's miles over engineered, but should track true forever.

The thick part of the green bracket is the same 21mm thick that the printed Bondtech bracket is, and will extend down into the work area to a distance that will work with the extruder once it lands. I will machine the same radius into that piece and make a matching clamp to lock the extruder onto it.

It may then be possible to extend the clamp body down to incorporate a mount for the E3DV6 incorporating the heat break fan and print fans, all locked solid. Don't really like seeing that hot end connected my that collar at the top only.

Looking at the drawings Martin from Bondtech sent me showing the dimensions and placement of the stepper motor, it should be easy to balance it so that the center of gravity is exactly below the X rail.

Got an engineer mate looking through his catalogs to work out some pulley arrangements that comply with the corexy rules mentioned in previous posts, and give me some part numbers etc. He's got more than a few tricks up his sleeve this guy.

Some questions are:

1. Where can I get Nema 17 stepper motors with a 100mm long shaft? Don't care about the spec, looking for chinese cheapies to let me design my support pedestal etc. As long as possible is fine, as it's just for props (guess I could print a dummy and put a bit of rod through it).

2. Are there any pros/cons to mounting the XY steppers at 45 deg like I've seen a couple do? It would kind of help me do what I want to, but I don't want to do it if it's a compromise of some sort.

Glad my toes are clean....hate it when that happens.

Edited 3 time(s). Last edit at 06/08/2016 05:29AM by hobbymods.

|

Re: Rugged CoreXY June 08, 2016 06:11AM |

Registered: 13 years ago Posts: 268 |

Machinist/Toolmaker is pretty close. I'm not one to cut corners either, the rails in my delta cost more than what most people spend on a whole printer (they are used singly and are of the single bearing race variety). That's why I keep talking about the rated load and moments. If you stay within those, then you get the rated service life as well, and typically even those are rated moving the rails at speeds you won't see while printing. There are also options for lubrication for smaller series rails. The THK rails I use in my machines can be supplied with lubrication ports, but I usually just oil the rails. They also are of a slightly different design which separate the balls with a cage that keeps them quieter and traps lubrication.Quote

hobbymods

Well I'm already printing a housing to run 2, but I will take your advice and also make a single rail version.

It certainly would make life easier.

I take it you're a machinist/toolmaker of some sort?

What I don't want to use is the MG rails, as they only have one bearing race as opposed to the EG series which has 2, and can be supplied with a grease nipple (I build everything to be serviced).

Please don't think I'm not one to listen, I'm just so used to hearing "naaahhhh....you don't worry about that shit, just use this paddle pop stick and a rubber band", which is just not how I roll.

I'd still use the single X carriage horizontally mounted, because it would be easier to marry up to my Y axis, with a machined L bracket dropping down into the build area.

Lots of advantages this way in addition to weight/cost....access to the extruder, ability to mount some sort of engraver for a different application, as well as simply looking better.

So cheers for that.

I get wanting to do it right, but again in this case it's really not needed for this application.

|

Re: Rugged CoreXY June 08, 2016 06:43AM |

Registered: 7 years ago Posts: 168 |

Quote

Koko76

Machinist/Toolmaker is pretty close. I'm not one to cut corners either, the rails in my delta cost more than what most people spend on a whole printer (they are used singly and are of the single bearing race variety). That's why I keep talking about the rated load and moments. If you stay within those, then you get the rated service life as well, and typically even those are rated moving the rails at speeds you won't see while printing. There are also options for lubrication for smaller series rails. The THK rails I use in my machines can be supplied with lubrication ports, but I usually just oil the rails. They also are of a slightly different design which separate the balls with a cage that keeps them quieter and traps lubrication.Quote

hobbymods

Well I'm already printing a housing to run 2, but I will take your advice and also make a single rail version.

It certainly would make life easier.

I take it you're a machinist/toolmaker of some sort?

What I don't want to use is the MG rails, as they only have one bearing race as opposed to the EG series which has 2, and can be supplied with a grease nipple (I build everything to be serviced).

Please don't think I'm not one to listen, I'm just so used to hearing "naaahhhh....you don't worry about that shit, just use this paddle pop stick and a rubber band", which is just not how I roll.

I'd still use the single X carriage horizontally mounted, because it would be easier to marry up to my Y axis, with a machined L bracket dropping down into the build area.

Lots of advantages this way in addition to weight/cost....access to the extruder, ability to mount some sort of engraver for a different application, as well as simply looking better.

So cheers for that.

I get wanting to do it right, but again in this case it's really not needed for this application.

The THK rails get pretty pricey in Australia. Hiwin's the best quality vs price in this country.

They have told me they can actually do me the EG 15's cheaper than they can do me the MG's. It is what it is I guess

|

Re: Rugged CoreXY June 08, 2016 07:13AM |

Registered: 9 years ago Posts: 1,873 |

I always find it difficult to think in terms of single linear rails. Even if the turning moments are well within spec it feels more natural to design so that as much of the force as possible falls on the primary load bearing axis. Typically that would allow sizing for much smaller rails as the primary axis will typically take a load orders of magnitude above the torque load, but things start getting odd when the smaller parts cost more than the big ones. I'm still not sure I could ever bring myself to hang things off the side of a single rail though - it just feels like an unnatural act dammit!

|

Re: Rugged CoreXY June 08, 2016 07:42AM |

Registered: 13 years ago Posts: 268 |

Lots of feels. You certainly try to minimize unwanted forces acting in ways you don't want, but you use a bearing to provide lower friction while resisting load of some kind while not wearing "too much*". Otherwise you could use a few flat pieces of closely sized material, slap some lube on it and call it a day. Small stuff costs more to make and hold tolerance on.Quote

JamesK

I always find it difficult to think in terms of single linear rails. Even if the turning moments are well within spec it feels more natural to design so that as much of the force as possible falls on the primary load bearing axis. Typically that would allow sizing for much smaller rails as the primary axis will typically take a load orders of magnitude above the torque load, but things start getting odd when the smaller parts cost more than the big ones. I'm still not sure I could ever bring myself to hang things off the side of a single rail though - it just feels like an unnatural act dammit!

For me size and to a lesser degree weight are driving factors. My current build uses 9mm rails for x and y, I would have used 7s on the double rail axis but I couldn't get rails the length I wanted at that size without months of wait. Reliability and service life of any of these exceeds anything I'll do to it.

*too much is subjective but again a good guide is the service life calcs that most quality manufacturers provide. Generally well beyond the life of a printer.

|

Re: Rugged CoreXY June 08, 2016 08:22AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Rugged CoreXY June 08, 2016 08:53AM |

Registered: 9 years ago Posts: 346 |

As a general comment to the above - We return to the predicament that nobody really knows the load at the hotend. The belts/pulley system we can at least approximate with the stepper motors torque values and assuming a pre-loading on the belts.

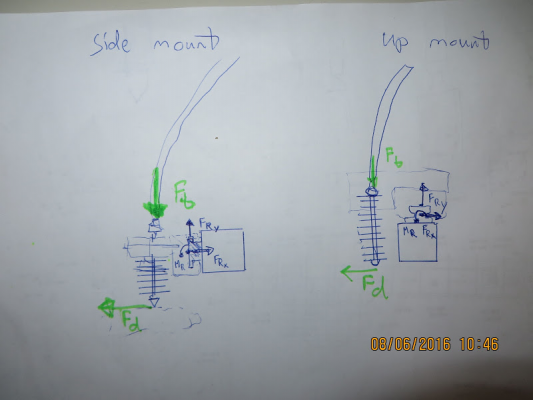

But what are the forces exerted through the hot-end drag on the plastic and what is the force (and thus induced turning moment) from the bowden into the extruder? Now, on the muck-up you made, you are setting the rail up, but why not mount it sideways?

Does anybody have even the slightest idea what Fb and Fd is in those diagrams???

Or is it, in the end, just the single event calculation of a Z height set wrong where the bed hamemers into the nozzle, that sets the design limits? Because that would be easier, seeing how that would just be the torque value of the bed motor...

Edited 1 time(s). Last edit at 06/08/2016 08:55AM by LarsK.

But what are the forces exerted through the hot-end drag on the plastic and what is the force (and thus induced turning moment) from the bowden into the extruder? Now, on the muck-up you made, you are setting the rail up, but why not mount it sideways?

Does anybody have even the slightest idea what Fb and Fd is in those diagrams???

Or is it, in the end, just the single event calculation of a Z height set wrong where the bed hamemers into the nozzle, that sets the design limits? Because that would be easier, seeing how that would just be the torque value of the bed motor...

Edited 1 time(s). Last edit at 06/08/2016 08:55AM by LarsK.

|

Re: Rugged CoreXY June 08, 2016 08:58AM |

Registered: 9 years ago Posts: 346 |

|

Re: Rugged CoreXY June 08, 2016 09:06AM |

Registered: 9 years ago Posts: 1,873 |

Oh Lord, is it ok for me to offer more uninformed opinions and guesswork? I would hope that the force from the bowden is negligible or at least well within spec of any likely linear motion system. Similarly for Fd when things are working correctly as the nozzle/print interface is lubricated by liquid filament. Obviously Fd can go through the roof when things start going wrong and the nozzle runs into cold hard plastic above the plane. I like your idea of using the motor torque to get a limiting figure for these error cases - I hadn't thought of that. The force we could have a go at calculating (that is happening throughout normal printing and will torque the X bearings) is that required to accelerate the print head in the Y axis. You'd need to know the mass of the head, the acceleration and the position of the centre of gravity to calculate the moment.

(Ugh, can't believe I forgot the most obvious torque - due to gravity acting on the CoG if not over the carriage. At least that one is static)

Edited 1 time(s). Last edit at 06/08/2016 09:15AM by JamesK.

(Ugh, can't believe I forgot the most obvious torque - due to gravity acting on the CoG if not over the carriage. At least that one is static)

Edited 1 time(s). Last edit at 06/08/2016 09:15AM by JamesK.

|

Re: Rugged CoreXY June 08, 2016 09:57AM |

Registered: 7 years ago Posts: 168 |

Mounted vertically or horizontally, one side is getting more pitch and yaw forces.

The point Koko is making I feel is that our pissy little extruders weigh and exert forces MILES under the extremes these precision rails are made to take continuously.

Wear is going to happen regardless of what you use, friction is a by product of motion. Lubricate as per manufacturers recommendations is the key.

I've just a brilliant article about fully qualified engineers falling into the trap of throwing high end components at low spec requirement jobs as "cheap insurance", but skimping on the installation steps and therefore causing the high end component to become a liability. False economy.

I'll spend money on machining the required reference edges and dial gauge alignment of the rails/carriages during initial installation, as well as little things like the balance center I was talking about.

I've done all I can now without a bit of spending.

Once my mate gets back to me with my pulley specs, or even "finds" them for me, I really need to buy the rails and get a laser cut acrylic mockup to proceed.

Time to stop cyberjerking and pull the wallet out lol.

Anyone got answers for that couple of questions I asked above?

Edited 2 time(s). Last edit at 06/08/2016 10:01AM by hobbymods.

The point Koko is making I feel is that our pissy little extruders weigh and exert forces MILES under the extremes these precision rails are made to take continuously.

Wear is going to happen regardless of what you use, friction is a by product of motion. Lubricate as per manufacturers recommendations is the key.

I've just a brilliant article about fully qualified engineers falling into the trap of throwing high end components at low spec requirement jobs as "cheap insurance", but skimping on the installation steps and therefore causing the high end component to become a liability. False economy.

I'll spend money on machining the required reference edges and dial gauge alignment of the rails/carriages during initial installation, as well as little things like the balance center I was talking about.

I've done all I can now without a bit of spending.

Once my mate gets back to me with my pulley specs, or even "finds" them for me, I really need to buy the rails and get a laser cut acrylic mockup to proceed.

Time to stop cyberjerking and pull the wallet out lol.

Anyone got answers for that couple of questions I asked above?

Edited 2 time(s). Last edit at 06/08/2016 10:01AM by hobbymods.

|

Re: Rugged CoreXY June 08, 2016 10:23AM |

Registered: 9 years ago Posts: 1,873 |

Quote

The point Koko is making I feel is that our pissy little extruders weigh and exert forces MILES under the extremes these precision rails are made to take continuously

Yes, looks like you are right. A quick back of the envelope calculation suggests that the static rated moment specs for mgn 15 in all 3 axis are ~2 orders of magnitude over anything the print-head is likely to experience during normal operation, even making fairly wild assumptions about head weight and CoG position. No question these are pretty impressive parts.

|

Re: Rugged CoreXY June 08, 2016 10:39AM |

Registered: 7 years ago Posts: 168 |

Quote

JamesK

Quote

The point Koko is making I feel is that our pissy little extruders weigh and exert forces MILES under the extremes these precision rails are made to take continuously

Yes, looks like you are right. A quick back of the envelope calculation suggests that the static rated moment specs for mgn 15 in all 3 axis are ~2 orders of magnitude over anything the print-head is likely to experience during normal operation, even making fairly wild assumptions about head weight and CoG position. No question these are pretty impressive parts.

Yes.

And if you check out the specs on the EG15's, which is the precision rail I'm referring to, you'll find several more orders of magnitude again over the MG15's, due to the second race of bearings and tighter tolerances.

Point of interest was that the Hiwin guys I spoke to told me that if I could fit it the EG's were a much better rail and cheaper than the MG's.

|

Re: Rugged CoreXY June 08, 2016 11:19AM |

Registered: 13 years ago Posts: 268 |

I dare say that 20 or 25mm rails would be better still in performance. But "better" is application dependent. If you can fit them and don't mind the penalties you pay for moving more mass then great!Quote

hobbymods

Quote

JamesK

Quote

The point Koko is making I feel is that our pissy little extruders weigh and exert forces MILES under the extremes these precision rails are made to take continuously

Yes, looks like you are right. A quick back of the envelope calculation suggests that the static rated moment specs for mgn 15 in all 3 axis are ~2 orders of magnitude over anything the print-head is likely to experience during normal operation, even making fairly wild assumptions about head weight and CoG position. No question these are pretty impressive parts.

Yes.

And if you check out the specs on the EG15's, which is the precision rail I'm referring to, you'll find several more orders of magnitude again over the MG15's, due to the second race of bearings and tighter tolerances.

Point of interest was that the Hiwin guys I spoke to told me that if I could fit it the EG's were a much better rail and cheaper than the MG's.

My bearing guy is pretty good on rotary stuff but he knows jack about linear. Even still he isn't (and shouldn't) be suggesting applications without understanding the loads involved.

|

Re: Rugged CoreXY June 08, 2016 05:39PM |

Registered: 7 years ago Posts: 168 |

Quote

Koko76

I dare say that 20 or 25mm rails would be better still in performance. But "better" is application dependent. If you can fit them and don't mind the penalties you pay for moving more mass then great!Quote

hobbymods

Quote

JamesK

Quote

The point Koko is making I feel is that our pissy little extruders weigh and exert forces MILES under the extremes these precision rails are made to take continuously

Yes, looks like you are right. A quick back of the envelope calculation suggests that the static rated moment specs for mgn 15 in all 3 axis are ~2 orders of magnitude over anything the print-head is likely to experience during normal operation, even making fairly wild assumptions about head weight and CoG position. No question these are pretty impressive parts.

Yes.

And if you check out the specs on the EG15's, which is the precision rail I'm referring to, you'll find several more orders of magnitude again over the MG15's, due to the second race of bearings and tighter tolerances.

Point of interest was that the Hiwin guys I spoke to told me that if I could fit it the EG's were a much better rail and cheaper than the MG's.

My bearing guy is pretty good on rotary stuff but he knows jack about linear. Even still he isn't (and shouldn't) be suggesting applications without understanding the loads involved.

My choice reasons are simple.

I went to a linear mob and they recommended this particular size and variant, for both performance and price for this application.

They did ask about the "moment load" and I couldn't give them a figure....what would we be looking at here?

I would imagine I'd be swinging 400-600 grams off that central carriage, certainly not a kilogram, but I'll run it past them again and estimate a kilo load and see what they say.

I've said from the start I'm more interested in print quality than speed. I've heard it said that my Zortrax only prints at about 40-50mm/sec (don't know), and if I got 25% more speed and a bit better print quality along with the ability to do large prints I'd be pretty happy.

|

Re: Rugged CoreXY June 08, 2016 06:08PM |

Registered: 7 years ago Posts: 168 |

|

Re: Rugged CoreXY June 08, 2016 06:18PM |

Registered: 13 years ago Posts: 268 |

I guess I thought when you said "I'm well aware of moment loads" earlier in the thread that you were familiar with them. It's not "x amount of kilos", it's force at a distance, in SI expressed as newton meter (Nm). You have static moment loads when a torque is exerted in on an axis such as mounting the rail to a vertical surface and hanging the carriage off of that, in that case the force is gravity. Then there is dynamic moment, which happens as the system moves. Now you have mass and therefore inertia of the components, which must be accelerated. The faster you print and the higher your acceleration, the higher the dynamic moment load.

I understand that you have salespeople advising you and that's great. If my comments aren't helpful and you are just gonna do what they say because they said it, that's cool, I'll not bother. I just thought you might like to better understand the how and why of the system you are trying to build.

I understand that you have salespeople advising you and that's great. If my comments aren't helpful and you are just gonna do what they say because they said it, that's cool, I'll not bother. I just thought you might like to better understand the how and why of the system you are trying to build.

|

Re: Rugged CoreXY June 08, 2016 06:53PM |

Registered: 7 years ago Posts: 168 |

Quote

Koko76

I guess I thought when you said "I'm well aware of moment loads" earlier in the thread that you were familiar with them. It's not "x amount of kilos", it's force at a distance, in SI expressed as newton meter (Nm). You have static moment loads when a torque is exerted in on an axis such as mounting the rail to a vertical surface and hanging the carriage off of that, in that case the force is gravity. Then there is dynamic moment, which happens as the system moves. Now you have mass and therefore inertia of the components, which must be accelerated. The faster you print and the higher your acceleration, the higher the dynamic moment load.

I understand that you have salespeople advising you and that's great. If my comments aren't helpful and you are just gonna do what they say because they said it, that's cool, I'll not bother. I just thought you might like to better understand the how and why of the system you are trying to build.

Mate bit touchy there, take it easy.

By well aware I meant I'd heard of them and discussed it with the guys at the importer, but yes fair enough on that point.

Based on this discussion I had just sent a picture of the X axis application, with weight/speed and acceleration estimates for him to clarify further (and that's before all this).

The guy advising me is not just a salesman (I asked) he's a machinist and seasoned installer of this stuff.

You are a stranger on the internet, so how would I know if you're right? Don't mean to sound brutal, but there's no harm in a second opinion, including but not only yours.

I don't know where you get that I'm not listening to you, as I changed the design based on what you said TWICE and acknowledged your points publicly both times, so you might be being a little precious there.

And to be honest you haven't made a solid recommendation or point since then....so yes please, what are you saying?

It seems to me that you're saying I should use MG15 rails, and all I have done is tell you that they have told me that the EG15 is not much bigger, a higher spec with 2 ball races per side (as opposed to the MG's 1 race per side of the rail) and CHEAPER.

If you look at the manual I posted in the start it gives applications for each model, and the EG's seem right in the middle of the HG's and MG's for specs.

So what am I missing here?

What do you feel is wrong?

Edited 3 time(s). Last edit at 06/08/2016 07:12PM by hobbymods.

|

Re: Rugged CoreXY June 08, 2016 07:19PM |

Registered: 13 years ago Posts: 268 |

I'm not touchy or annoyed. It's your money, your design, your printer. You asked for help and input, you keep applying value judgements like "better" without being able to quantify them. I've made a couple suggestions to help you be able to better qualify and quantify "better" for yourself. It does not appear to me from your replies that you understand what I'm saying. Perhaps it is a continents difference in the "same" language. I suggested that if you aren't finding what I say helpful, that's fine with me, I'll stop bothering you. If so I apologize, as I'm really not trying to be rude. If someone were to reply to me here IRL "I'm well aware" of something, I would take it to mean that they had working knowledge of the subject, and depending on tone that they were somewhat annoyed that I had raised the issue.

My recommendation is that 15mm guides of either type are un-needed and frankly unhelpful weight. At most I would suggest 12mm miniature type. They might cost more, you did also say several times that cost was not a deterrent (may have different continents words there too sorry). But they will contribute less to system loads, making things quieter and improving print quality. I personally am using 9mm guides for my X and Y in the H bot that I am building. It will have a printable area of just about 165x165 in X and Y. In the dual rail direction I would have used the 7mm rails but they weren't available in the length I needed anything but a custom order that would have taken longer than I'd like. For Z I have a single rail which IS a 15mm miniature type, but it is a wide variant, 30mm wide but the height of a 15mm miniature (similar carriage too, just wider). I know you aren't planning that type of construction, but I wanted to give an example of where I felt the load capacity would be appropriate. That will hold a 200 mm square bed 8mm thick (at least, might go thicker for parts of it).

Again, If I've been rude I apologize, it's not my intent.

My recommendation is that 15mm guides of either type are un-needed and frankly unhelpful weight. At most I would suggest 12mm miniature type. They might cost more, you did also say several times that cost was not a deterrent (may have different continents words there too sorry). But they will contribute less to system loads, making things quieter and improving print quality. I personally am using 9mm guides for my X and Y in the H bot that I am building. It will have a printable area of just about 165x165 in X and Y. In the dual rail direction I would have used the 7mm rails but they weren't available in the length I needed anything but a custom order that would have taken longer than I'd like. For Z I have a single rail which IS a 15mm miniature type, but it is a wide variant, 30mm wide but the height of a 15mm miniature (similar carriage too, just wider). I know you aren't planning that type of construction, but I wanted to give an example of where I felt the load capacity would be appropriate. That will hold a 200 mm square bed 8mm thick (at least, might go thicker for parts of it).

Again, If I've been rude I apologize, it's not my intent.

|

Re: Rugged CoreXY June 08, 2016 07:43PM |

Registered: 7 years ago Posts: 168 |

Quote

Koko76

I'm not touchy or annoyed. It's your money, your design, your printer. You asked for help and input, you keep applying value judgements like "better" without being able to quantify them. I've made a couple suggestions to help you be able to better qualify and quantify "better" for yourself. It does not appear to me from your replies that you understand what I'm saying. Perhaps it is a continents difference in the "same" language. I suggested that if you aren't finding what I say helpful, that's fine with me, I'll stop bothering you. If so I apologize, as I'm really not trying to be rude. If someone were to reply to me here IRL "I'm well aware" of something, I would take it to mean that they had working knowledge of the subject, and depending on tone that they were somewhat annoyed that I had raised the issue.

My recommendation is that 15mm guides of either type are un-needed and frankly unhelpful weight. At most I would suggest 12mm miniature type. They might cost more, you did also say several times that cost was not a deterrent (may have different continents words there too sorry). But they will contribute less to system loads, making things quieter and improving print quality. I personally am using 9mm guides for my X and Y in the H bot that I am building. It will have a printable area of just about 165x165 in X and Y. In the dual rail direction I would have used the 7mm rails but they weren't available in the length I needed anything but a custom order that would have taken longer than I'd like. For Z I have a single rail which IS a 15mm miniature type, but it is a wide variant, 30mm wide but the height of a 15mm miniature (similar carriage too, just wider). I know you aren't planning that type of construction, but I wanted to give an example of where I felt the load capacity would be appropriate. That will hold a 200 mm square bed 8mm thick (at least, might go thicker for parts of it).

Again, If I've been rude I apologize, it's not my intent.

OK, so let's both take a deep breath and relax.

And yes, my "I'm well aware" comment was a little bit of an expression of annoyance as the way you came across did grind my gears a little. And if I'm to be honest while I might be aware of the concept, I don't fully understand it.

I haven't used the term "better" all the time, you pulled someone else on that didn't you? I'm not going into reading back through every comment as I'm not that bothered.

I've forwarded your points on to the supplier, but when it costs less, is a higher spec and is what they recommended I do have to consider that don't I?

I'm going for a 300x300 bed, and yes if it was 165x165 I would certainly use MG7's myself. I've got some here that I used to add an extra Z rail to my UP Plus 2's, to replace that stupid little plastic roller thing they put in there.

I will also look at the weight differences and see what we're talking about here, but I'm not hugely fussed about that.

The Zortrax does awesome prints at an acceptable speed (little faster would be better) and its carriage weighs a ton.

I think we've covered this now and run the risk of derailing a constructive thread, so please rest assured that your comments have been appreciated and heard.

I'm still jerking around with paddle pop sticks and plastic blocks at this stage, it's early days lol.

And I apologize if I offended as well, also not intended.

Edited 2 time(s). Last edit at 06/08/2016 07:44PM by hobbymods.

|

Re: Rugged CoreXY June 08, 2016 08:12PM |

Registered: 9 years ago Posts: 1,873 |

Internet forums like this are legendary for misunderstandings that wouldn't be an issue if we were all chatting over a beer. Stuff gets written in haste, words have different meaning or emphasis in different locations, and we're deprived of all the body language that helps decode intent. It's surprising it works as well as it does

It's more common for coreXY to be built with remote extruders and bowden feeds, so print head weight is likely to be well under 500g. For a single extruder it's probably closer to 100g (not including the linear bearing itself), so you could probably take 500g as a worst case scenario. The position of the centre of gravity is harder to estimate without looking at an actual design, but for the sake of argument I went with 10cm offset from the bearing. It's hard to imagine it would be more than that. The static moment due to gravity is (I think - please correct me if I get it wrong)

mass * distance * Acceleration in Kg, meters and meters/s^2 respectively, so

0.5 * 0.1 * 9.8 or roughly 0.5 Nm

If you assume that the vertical offset of the CoG is also 10 cm (again, difficult to imagine it would really be this bad), you can do the same thing for the dynamic force due to accelerating the Y axis. I'm used to relatively low accelerations on my print between 500 to 1000 mm/s^2 - I'm not sure what people use on coreXY setups. Does anyone use as much as 5000mm/s^2? That would come out to 0.25 Nm. Unless I've goofed the maths, these are all small compared to the rated loads for even MGN series rails. MGN9C are 11/7/7 Nm for the three torque axis, and EGH15C are 130/100/100 Nm! Excuse me while I drool.

Quote

They did ask about the "moment load" and I couldn't give them a figure....what would we be looking at here?

I would imagine I'd be swinging 400-600 grams off that central carriage, certainly not a kilogram, but I'll run it past them again and estimate a kilo load and see what they say.

It's more common for coreXY to be built with remote extruders and bowden feeds, so print head weight is likely to be well under 500g. For a single extruder it's probably closer to 100g (not including the linear bearing itself), so you could probably take 500g as a worst case scenario. The position of the centre of gravity is harder to estimate without looking at an actual design, but for the sake of argument I went with 10cm offset from the bearing. It's hard to imagine it would be more than that. The static moment due to gravity is (I think - please correct me if I get it wrong)

mass * distance * Acceleration in Kg, meters and meters/s^2 respectively, so

0.5 * 0.1 * 9.8 or roughly 0.5 Nm

If you assume that the vertical offset of the CoG is also 10 cm (again, difficult to imagine it would really be this bad), you can do the same thing for the dynamic force due to accelerating the Y axis. I'm used to relatively low accelerations on my print between 500 to 1000 mm/s^2 - I'm not sure what people use on coreXY setups. Does anyone use as much as 5000mm/s^2? That would come out to 0.25 Nm. Unless I've goofed the maths, these are all small compared to the rated loads for even MGN series rails. MGN9C are 11/7/7 Nm for the three torque axis, and EGH15C are 130/100/100 Nm! Excuse me while I drool.

|

Re: Rugged CoreXY June 08, 2016 08:42PM |

Registered: 9 years ago Posts: 346 |

I am not sure I understand how you just went and entirely disregarded the force exerted by the plastic through the bowden tube? Lets say you put a stepper with 0.4Nm as extruder. Then you have a 10mm hubbed bolt. That is a radius of 5mm. This gives a forward force of 80 N (!) on the plastic. Even if only half of the 0.4Nm is exerted or makes it through the bowden, then that is still 40 N or ~4kg force. Way more then the parts weight.

I am probably missing something really obvious that I should have realized - But what am I doing wrong? Personally I remember from my delta pushing out the effector from its joints because I helped the motor push the plastic.

I am probably missing something really obvious that I should have realized - But what am I doing wrong? Personally I remember from my delta pushing out the effector from its joints because I helped the motor push the plastic.

Sorry, only registered users may post in this forum.