Folger Prusa i3 Kit from ebay

Posted by Waltermixx

|

Re: Folger Prusa i3 Kit from ebay November 13, 2014 10:36AM |

Registered: 9 years ago Posts: 110 |

Quote

deaddudehangin

thats all i did was solder to the pads at the bottom and everything seems to work ok, I am getting a temperature reading(I don't have one of those temp checkers to see if it is correct tho). The Led at the bottom of the bed u can see-ish, it shines on the acrylic so it kind of disperses the light.

Also a pro tip for putting the nuts into the acrylic, if you are having trouble putting it into one side try flipping the piece over. I think when the pieces were laser cut it sloped the holes slightly.

Thanks! I'll do that when I'm done with work and then we'll see how much further is left to go. Can't wait to start melting plastic!

Also, how many people here have mounted their printers to a piece of wood? is that recommended? I'm planning on building an enclosure for it anyway with windows on all sides (maybe even the top) and a fan to exhaust out extra heat which will be turned on by a separate thermistor when temp rises to too high, but I was wondering what everone else used to mount to. MDF? Plywood? More acrylic? Thickness? Does anyone have any advise on the exhaust fan? Mostly I want to build an enclosure because I live in a house with central air in Florida and my wife likes to keep it pretty chilly in the house and I don't want the blowing AC to affect anything that prints. Also I figure I can put a carbon filter on the exhaust fan to control fumes. Anybody have any thoughts suggestsions?

|

Re: Folger Prusa i3 Kit from ebay November 13, 2014 10:52AM |

Registered: 9 years ago Posts: 208 |

I have mine secured to a sheet of plywood, check my posts for links to my Flickr album on the Folger Prusa, my posts also include stl files for clips that secure the threaded rod down to the wood.

do a search for posts by me, and you should find what you are looking for... if you have not already read through the entire thread, lots of good tips, links to video builds of the Folger Prusa on youtube,

lots of good tips, links to video builds of the Folger Prusa on youtube,

infact the latest by bubalettow has info on installing autoleveling on this unit [www.youtube.com] he also has about 21 other video's on his experience with the Folgertech Prusa.

[www.youtube.com] he also has about 21 other video's on his experience with the Folgertech Prusa.

do a search for posts by me, and you should find what you are looking for... if you have not already read through the entire thread,

lots of good tips, links to video builds of the Folger Prusa on youtube,

lots of good tips, links to video builds of the Folger Prusa on youtube,infact the latest by bubalettow has info on installing autoleveling on this unit

[www.youtube.com] he also has about 21 other video's on his experience with the Folgertech Prusa.

[www.youtube.com] he also has about 21 other video's on his experience with the Folgertech Prusa.

|

Re: Folger Prusa i3 Kit from ebay November 13, 2014 11:46AM |

Registered: 9 years ago Posts: 5 |

Hey guys, I ordered the Folger Prusa i3 Kit a few days ago and can't wait for it to arrive. I read all the posts and there is a lot of great info. I will have to read it all again when my kit arrives.

I also ordered PLA and ABS filament and in the mean time was wondering which type of Filament I should start out with, ABS or PLA?.

I also ordered PLA and ABS filament and in the mean time was wondering which type of Filament I should start out with, ABS or PLA?.

|

Re: Folger Prusa i3 Kit from ebay November 13, 2014 01:08PM |

Registered: 9 years ago Posts: 110 |

Ok, this is going to be a brief post with my thoughts on the kit so far. I'm sure I'll give a more complete review once I've finished putting it together and run some test prints but in the meantime this will act as a place to dump my thoughts:

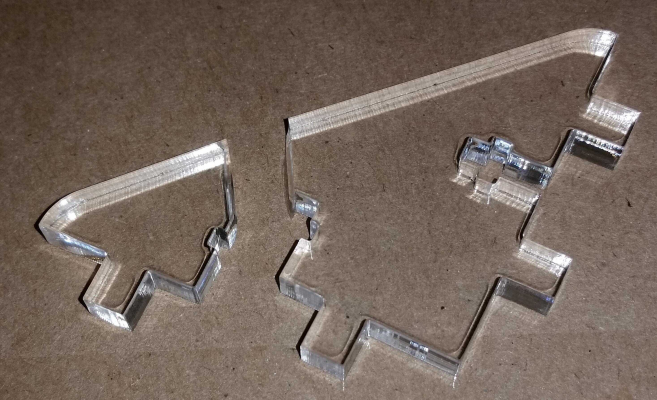

The package came and it was packaged well. All the parts are in little bags that are labeled and in some of those bags are smaller bags with more labels and what's in them. I took everything out of the box and laid the pieces down on my kitchen table and I proceeded to remove the paper from the plastic frame pieces. This is when I encountered my first problem which was a broken plastic triangle that acts as a motor mount for one of the z-axis motors. I called and left a message (it was late) asking about a replacement and I then crazy glued the parts together (pictures attached ) and continued building. The videos that they have on their google drive are very hard to follow (there is no audio on most of the videos and there is scrolling text that sometimes scrolls backwards). I almost want to strip down my printer and start rebuilding it while filming so that I can maybe give better video instructions, but I probably won't.

Before putting the frame together, please note that you will need to drill a hole for the power supply. They forewarn of this in the directions, just take a drill bit and go slow and don't press down on the drill and the hole will cut nice and cleanly.

I started putting the frame together and I will say this for everyone after me who is planning on putting this kit together, plexi-glass is fragile. REALLY. When you put tighten the screws, stop when they're snug. Don't try to give it another 1/4 turn, you will get stress fractures in the plastic. Trust me, I did it more than once. Snug seems to be plenty tight. Other than that I have no complaints about the frame. I do have a complaint about the number of screws for the frame that are provided. The frame requires 20 screws and nuts to hold everything together. The package labeled for the frame hardware only has 18. I took 2 from somewhere else in the kit, but there seems to be a lot of screws sitting in the frame kit bag that aren't used. You'll start using these in other places. So far I'm not short any screws. So far.

Next the videos move on to building the base. The person doing the video forgets to put the bearings (3 of them) on the smooth rods and has you dis-assemble 1/2 of the threaded rods to put them on. Not a big deal, but just a forewarning to anyone that is building this. What's worse is that you will probably take this apart again to slide the bearings into the y carriage clamps. Again, not a big deal and you might be able to do it manually while they are mounted, but I wound up taking it apart again. The plastic parts for this are *mostly* perfect for me. The 2 (3?) parts that give me trouble are the 2 pulley halves and the pulley yoke. The hole is way to tight to hold the pulley so I wind up cleaning it out a bit of some bits of plastic that were left behind from the print and it's still tough. I wind up using a locking plier (literally this one [www.harborfreight.com]) and my workbench to press it in place as gently as possible (adjusting how much I was pressing and slowing increasing the amount till it was in) and I get it set. I then put the pulley in the yoke and it's tight. No problem a small file can't fix and about 2 minutes later of gently examining what I'm filing and slowly taking a bit of plastic off, I have a pulley that spins freely.

The next video shows that it's time to put the stepper motor, belt and Y trolley onto the printer. But my Y trolley is not built yet *scratches head*. Well, I take the pieces that look like they belong and try to orient everything the same way it seems on the video in a still shot I've got and I start putting it together when I notice I need to drill another hole for the belt holder(?). Whatever, I pull out my square, try to keep it as square with the hole that is there and mark my hole and again drill. No problems. Finish putting the trolley together and I start attaching it to the bearings mentioned above. And that's where I remember not to try to "snap" them on as mentioned in this post many pages earlier so I try to slide them on sideways but either I can't get my hands in there to line up the bearing with the openings or something will not cooperate so I take the base apart again and remove the rods, remove the bearings, slide the bearings (very tight) into the trolley bearing clamps and then back onto the smooth rods. Then I realize that I have the braces too far apart, no big deal, we knew this was coming so adjust till the rods slide in nicely and keep adjusting till the y trolley slides smoothly across the whole thing. Next, mount the geared pulley to the stepper motor (this one is the big one) and the stepper motor to the motor mount on the base and don't make the same mistake I made. The video doesn't mention it till the end, but I'll mention it now, make sure the plug for the motor is someplace accesible, preferably pointing in to the middle of the base. Once you've got that mounted, you'll flip the whole thing upside down and attach the belt. Again, don't make the same mistake I made (just ordered more belt cause I'm an idiot). When you run the belt over and across and through everything, you need to leave yourself enough belt sticking out of the belt clamp on the trolley to zip tie it down back to the belt under the trolley. I didn't leave enough on one side cause I'm an idiot and it was like 1 am and I should've stopped working on it an hour earlier and gone to bed *sigh*. I'll never learn. Anyway once you have that mounted you'll notice that you're belt is taking a very interesting path and you're going to have to adjust your pulley and stepper motor so everything lines up perfectly. You should expect this. Loosen/tighten what you need to until everything is straight and then you're ready to move on to the next video, which is "electronics".

In this video, They start out with the Ramps attached to the Arduino. My ramps and Arduino came separate so I had to put them together first. Make sure your plugs and connectors face down. Again, this was something that was shown at the end and luckily I didn't screw this up. This is attached with three of the long m3 bolts and the nylon lock nuts. Next, mount the power supply on the opposite side and again make sure that you face the connectors down. And remember to use the hole you drilled to hold it in place (I drilled 2 holes and used different screws to mount it since I liked the bigger holes in the middle of the case better). And that's it for this video. One video left in their series. Hopefully it's the X-Axis.

And, it's not the X-Axis. It's not more electronics either. No, the last video tells you how to build your Y trolley. You know, the one that is already together 2 videos ago that I figured out how to put together based on a picture and drilled my hole in to line up that belt holder? Yeah, the beginning of this video actually tells you you may need to drill a hole for that. This video should have been named "Assembly 3" and they should increase the numbers of 3 and 4 to 4 and 5 to keep this more in line. Oh well, that's the end of this video series, guess I'll follow other videos online now to finish this up. But first bed.

My thoughts on the kit, so far, very good for a beginner kit, the parts are almost all clean and ready to mount. The only parts I've found to be a problem are the pulley halves and the pulley yoke but they were easy to clean up, and the broken motor mount. The videos were useful for what they were but I think they could have been better (ie, audio, better lighting, higher resolution) and also could have had clearer instructions (and been in the right order). The fact that this is an open source project does make it pretty easy to find information online so it isn't really that big of a deal, but the information on putting together their frame I think is necessary. Not that it's hard, but the plastic is cut in such a way that the nuts only fit from one direction in the slots and if you don't know that you might try fighting a losing battle.

Tonight I'll continue the build process and post more thoughts tomorrow. I'm hoping that I'll be done with all the wiring and building tonight (no later than day after tomorrow for sure though) and then I'll be ready for calibration.

Thanks for reading

Oh, almost forgot, looks like Folger is getting their parts in some serious bulk. I saw this on the bottom of the stepper motors:

Edited 1 time(s). Last edit at 11/13/2014 01:11PM by louspinuso.

The package came and it was packaged well. All the parts are in little bags that are labeled and in some of those bags are smaller bags with more labels and what's in them. I took everything out of the box and laid the pieces down on my kitchen table and I proceeded to remove the paper from the plastic frame pieces. This is when I encountered my first problem which was a broken plastic triangle that acts as a motor mount for one of the z-axis motors. I called and left a message (it was late) asking about a replacement and I then crazy glued the parts together (pictures attached ) and continued building. The videos that they have on their google drive are very hard to follow (there is no audio on most of the videos and there is scrolling text that sometimes scrolls backwards). I almost want to strip down my printer and start rebuilding it while filming so that I can maybe give better video instructions, but I probably won't.

Before putting the frame together, please note that you will need to drill a hole for the power supply. They forewarn of this in the directions, just take a drill bit and go slow and don't press down on the drill and the hole will cut nice and cleanly.

I started putting the frame together and I will say this for everyone after me who is planning on putting this kit together, plexi-glass is fragile. REALLY. When you put tighten the screws, stop when they're snug. Don't try to give it another 1/4 turn, you will get stress fractures in the plastic. Trust me, I did it more than once. Snug seems to be plenty tight. Other than that I have no complaints about the frame. I do have a complaint about the number of screws for the frame that are provided. The frame requires 20 screws and nuts to hold everything together. The package labeled for the frame hardware only has 18. I took 2 from somewhere else in the kit, but there seems to be a lot of screws sitting in the frame kit bag that aren't used. You'll start using these in other places. So far I'm not short any screws. So far.

Next the videos move on to building the base. The person doing the video forgets to put the bearings (3 of them) on the smooth rods and has you dis-assemble 1/2 of the threaded rods to put them on. Not a big deal, but just a forewarning to anyone that is building this. What's worse is that you will probably take this apart again to slide the bearings into the y carriage clamps. Again, not a big deal and you might be able to do it manually while they are mounted, but I wound up taking it apart again. The plastic parts for this are *mostly* perfect for me. The 2 (3?) parts that give me trouble are the 2 pulley halves and the pulley yoke. The hole is way to tight to hold the pulley so I wind up cleaning it out a bit of some bits of plastic that were left behind from the print and it's still tough. I wind up using a locking plier (literally this one [www.harborfreight.com]) and my workbench to press it in place as gently as possible (adjusting how much I was pressing and slowing increasing the amount till it was in) and I get it set. I then put the pulley in the yoke and it's tight. No problem a small file can't fix and about 2 minutes later of gently examining what I'm filing and slowly taking a bit of plastic off, I have a pulley that spins freely.

The next video shows that it's time to put the stepper motor, belt and Y trolley onto the printer. But my Y trolley is not built yet *scratches head*. Well, I take the pieces that look like they belong and try to orient everything the same way it seems on the video in a still shot I've got and I start putting it together when I notice I need to drill another hole for the belt holder(?). Whatever, I pull out my square, try to keep it as square with the hole that is there and mark my hole and again drill. No problems. Finish putting the trolley together and I start attaching it to the bearings mentioned above. And that's where I remember not to try to "snap" them on as mentioned in this post many pages earlier so I try to slide them on sideways but either I can't get my hands in there to line up the bearing with the openings or something will not cooperate so I take the base apart again and remove the rods, remove the bearings, slide the bearings (very tight) into the trolley bearing clamps and then back onto the smooth rods. Then I realize that I have the braces too far apart, no big deal, we knew this was coming so adjust till the rods slide in nicely and keep adjusting till the y trolley slides smoothly across the whole thing. Next, mount the geared pulley to the stepper motor (this one is the big one) and the stepper motor to the motor mount on the base and don't make the same mistake I made. The video doesn't mention it till the end, but I'll mention it now, make sure the plug for the motor is someplace accesible, preferably pointing in to the middle of the base. Once you've got that mounted, you'll flip the whole thing upside down and attach the belt. Again, don't make the same mistake I made (just ordered more belt cause I'm an idiot). When you run the belt over and across and through everything, you need to leave yourself enough belt sticking out of the belt clamp on the trolley to zip tie it down back to the belt under the trolley. I didn't leave enough on one side cause I'm an idiot and it was like 1 am and I should've stopped working on it an hour earlier and gone to bed *sigh*. I'll never learn. Anyway once you have that mounted you'll notice that you're belt is taking a very interesting path and you're going to have to adjust your pulley and stepper motor so everything lines up perfectly. You should expect this. Loosen/tighten what you need to until everything is straight and then you're ready to move on to the next video, which is "electronics".

In this video, They start out with the Ramps attached to the Arduino. My ramps and Arduino came separate so I had to put them together first. Make sure your plugs and connectors face down. Again, this was something that was shown at the end and luckily I didn't screw this up. This is attached with three of the long m3 bolts and the nylon lock nuts. Next, mount the power supply on the opposite side and again make sure that you face the connectors down. And remember to use the hole you drilled to hold it in place (I drilled 2 holes and used different screws to mount it since I liked the bigger holes in the middle of the case better). And that's it for this video. One video left in their series. Hopefully it's the X-Axis.

And, it's not the X-Axis. It's not more electronics either. No, the last video tells you how to build your Y trolley. You know, the one that is already together 2 videos ago that I figured out how to put together based on a picture and drilled my hole in to line up that belt holder? Yeah, the beginning of this video actually tells you you may need to drill a hole for that. This video should have been named "Assembly 3" and they should increase the numbers of 3 and 4 to 4 and 5 to keep this more in line. Oh well, that's the end of this video series, guess I'll follow other videos online now to finish this up. But first bed.

My thoughts on the kit, so far, very good for a beginner kit, the parts are almost all clean and ready to mount. The only parts I've found to be a problem are the pulley halves and the pulley yoke but they were easy to clean up, and the broken motor mount. The videos were useful for what they were but I think they could have been better (ie, audio, better lighting, higher resolution) and also could have had clearer instructions (and been in the right order). The fact that this is an open source project does make it pretty easy to find information online so it isn't really that big of a deal, but the information on putting together their frame I think is necessary. Not that it's hard, but the plastic is cut in such a way that the nuts only fit from one direction in the slots and if you don't know that you might try fighting a losing battle.

Tonight I'll continue the build process and post more thoughts tomorrow. I'm hoping that I'll be done with all the wiring and building tonight (no later than day after tomorrow for sure though) and then I'll be ready for calibration.

Thanks for reading

Oh, almost forgot, looks like Folger is getting their parts in some serious bulk. I saw this on the bottom of the stepper motors:

Edited 1 time(s). Last edit at 11/13/2014 01:11PM by louspinuso.

|

Re: Folger Prusa i3 Kit from ebay November 13, 2014 01:14PM |

Registered: 9 years ago Posts: 110 |

Quote

Waltermixx

I have mine secured to a sheet of plywood, check my posts for links to my Flickr album on the Folger Prusa, my posts also include stl files for clips that secure the threaded rod down to the wood.

do a search for posts by me, and you should find what you are looking for... if you have not already read through the entire thread,lots of good tips, links to video builds of the Folger Prusa on youtube,

infact the latest by bubalettow has info on installing autoleveling on this unit[www.youtube.com] he also has about 21 other video's on his experience with the Folgertech Prusa.

Oh, I've read the whole thread and skimmed it a second time. I've seen your Flickr feed and some of your prints and I think I'll be printing those clips up. I'll probably bolt those clips on to my base and add rubber feet to absorb some of the extra vibration on my case.

I've seen the bubalettow videos, but not this one. Thanks.

|

Re: Folger Prusa i3 Kit from ebay November 13, 2014 11:59PM |

Registered: 9 years ago Posts: 19 |

Quote

czmorris

FYI, something to keep an eye on if you are running using a box or enclosure over your printer with the standard PLA printed parts. PLA parts changing size/expanding.

I had been running a series of batches for about a week before leaving town for the weekend. I had been using a large cardboard box with a window cut in it and some clear plastic to cover the window. I had been getting great prints this way before I left but when I came back I noticed that the printer was misbehaving. On closer inspection I found that the PLA parts seem to have expanded or changed shape in several locations. The Y-axis to X-axis printed parts expanded enough that they "let go" of the bearings. The X carriage also seemed to have changed enough to allow the extruder screws to loosen even though they were plenty tight before. My endstops had all loosened. Lock washers were in place on everything. The printer seemed to be fine after my last print before leaving but after resting for about 3 days everything loosened up. Most issues could be fixed by just tightening stuff but the biggest issue (bearings coming loose) will require some replacement parts.

Ironically the bed was still nice and tight on the ABS printed test bearing holders even without zip ties.

I will be reprinting the X axis parts again soon. Most likely printed in ABS this time.

I printed the Herringbone gears last night to get ready for the Geared Extruder. I kept having one corner lift so I looked at the bed. I tried to adjust it to get it back level, turns out one of corners on the acrylic bed warped a bit. Decided to pick up a piece of MDF for the time being until I figure out what I want to do next. Worst part is I have a silicone sheet in the cupboard that was intended to prevent this...

|

Re: Folger Prusa i3 Kit from ebay November 14, 2014 12:07AM |

Registered: 9 years ago Posts: 110 |

Ok, I didn't get as much in tonight as I was planning due to unforeseen circumstances so let's cover what I did do.

Wired up the heated bed and mounted it. Pretty straight forward except for when I opened the bag of parts they went flying everywhere. I really should sleep more.

Put together the x axis. I had to clean up the bearing pulley so that it would slide into the end cleanly and spin freely. If I didn't do that it would have been extremely tight and I would have had to force it in place. The motor mount side went pretty smooth. I had a few of teh ball bearings fall out of the bearings as I slid them on the shafts. I'm hoping this isn't going to be a problem, but it was not pretty. Mounting the direct drive extruder was a bit of a chore. The bracket for the extruder had holes that were way too small for the bolts to pass through so I had to drill them out and then I found that the bolts weren't lining up with the mounting holes in the motor. Back to the drill and use a slightly larger bit and was finally able to get them in to the mounting holes, but I had to push the heads into the small hexagonally shaped nut holders to get them to catch threads in the motor. It was a bit of a pain. Also that same part has the belt clip in it and this one seems MUCH tighter than the one for the Y trolley so that was a bit of a fight, but I managed to get it on. It was at this point that I noticed that I had not installed either of the belt tensioners. Oh well we'll see what happens and I'll pop them on if I need them.

And that's about it. I'm hoping that tomorrow I'll be able to get the wiring done and finished so that I can start printing by the end of the weekend.

Wired up the heated bed and mounted it. Pretty straight forward except for when I opened the bag of parts they went flying everywhere. I really should sleep more.

Put together the x axis. I had to clean up the bearing pulley so that it would slide into the end cleanly and spin freely. If I didn't do that it would have been extremely tight and I would have had to force it in place. The motor mount side went pretty smooth. I had a few of teh ball bearings fall out of the bearings as I slid them on the shafts. I'm hoping this isn't going to be a problem, but it was not pretty. Mounting the direct drive extruder was a bit of a chore. The bracket for the extruder had holes that were way too small for the bolts to pass through so I had to drill them out and then I found that the bolts weren't lining up with the mounting holes in the motor. Back to the drill and use a slightly larger bit and was finally able to get them in to the mounting holes, but I had to push the heads into the small hexagonally shaped nut holders to get them to catch threads in the motor. It was a bit of a pain. Also that same part has the belt clip in it and this one seems MUCH tighter than the one for the Y trolley so that was a bit of a fight, but I managed to get it on. It was at this point that I noticed that I had not installed either of the belt tensioners. Oh well we'll see what happens and I'll pop them on if I need them.

And that's about it. I'm hoping that tomorrow I'll be able to get the wiring done and finished so that I can start printing by the end of the weekend.

|

Re: Folger Prusa i3 Kit from ebay November 14, 2014 01:20AM |

Registered: 9 years ago Posts: 58 |

Quote

AKFoddy7

Quote

czmorris

FYI, something to keep an eye on if you are running using a box or enclosure over your printer with the standard PLA printed parts. PLA parts changing size/expanding.

I had been running a series of batches for about a week before leaving town for the weekend. I had been using a large cardboard box with a window cut in it and some clear plastic to cover the window. I had been getting great prints this way before I left but when I came back I noticed that the printer was misbehaving. On closer inspection I found that the PLA parts seem to have expanded or changed shape in several locations. The Y-axis to X-axis printed parts expanded enough that they "let go" of the bearings. The X carriage also seemed to have changed enough to allow the extruder screws to loosen even though they were plenty tight before. My endstops had all loosened. Lock washers were in place on everything. The printer seemed to be fine after my last print before leaving but after resting for about 3 days everything loosened up. Most issues could be fixed by just tightening stuff but the biggest issue (bearings coming loose) will require some replacement parts.

Ironically the bed was still nice and tight on the ABS printed test bearing holders even without zip ties.

I will be reprinting the X axis parts again soon. Most likely printed in ABS this time.

I printed the Herringbone gears last night to get ready for the Geared Extruder. I kept having one corner lift so I looked at the bed. I tried to adjust it to get it back level, turns out one of corners on the acrylic bed warped a bit. Decided to pick up a piece of MDF for the time being until I figure out what I want to do next. Worst part is I have a silicone sheet in the cupboard that was intended to prevent this...

Warping parts is pretty common when printing. Many solutions such as hairspray, perfboard, enclosure, bed leveling ect... In my case it wasn't the parts I was printing that deformed rather it was the printed PLA parts from Folger on the printer itself. I use a covering to get more consistent prints. The air temp inside only gets to a max of 110 f so I was surprised that it caused the printer parts to deform as much as they did. I know PLA can get soft when warm but expected that to happen closer to 70 c not 45. I reprinted the x-axis parts in ABS which doesn't soften as low as PLA so hopefully that will keep it from happening again. No issues with any of my acrylic parts warping. Must be a pretty bad if the leveling screws cannot adjust it out on yours.

|

Re: Folger Prusa i3 Kit from ebay November 14, 2014 07:39AM |

Registered: 9 years ago Posts: 1,011 |

Hi all, nice topic thx ! I'm also a Folger i3 owner. I'll post some pictures when eveything will be ok. I think there's a lack of building and configuration information with this kit, and the way to put all the eggs in the same google drive basket seemed rubbish to me, and especialy boring when you have to download the Marlin firmawre file to file.

Did you noticed the Marlin provided bu Folger is a light and old version ? Not all the screens are implemented, no autobed leveling, antique PID, and so on... I think it's surely better to don't use it and download a proper version of Marlin instead, and spend some time to configure it right.

I have some trouble while installing a RepRapDiscount Full Graphic Smart Controller (red pcb). Or maybe my stuff is out of order. To be sure, if one of you have that display implemented on his machine, I would realy appreciate if he would share his Marlin configuration with me into a Zip. So I'll be able so see if the display is to blame. Thx !

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Did you noticed the Marlin provided bu Folger is a light and old version ? Not all the screens are implemented, no autobed leveling, antique PID, and so on... I think it's surely better to don't use it and download a proper version of Marlin instead, and spend some time to configure it right.

I have some trouble while installing a RepRapDiscount Full Graphic Smart Controller (red pcb). Or maybe my stuff is out of order. To be sure, if one of you have that display implemented on his machine, I would realy appreciate if he would share his Marlin configuration with me into a Zip. So I'll be able so see if the display is to blame. Thx !

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Folger Prusa i3 Kit from ebay November 14, 2014 09:47AM |

Registered: 9 years ago Posts: 208 |

Quote

Zavashier

Hi all, nice topic thx ! I'm also a Folger i3 owner. I'll post some pictures when eveything will be ok. I think there's a lack of building and configuration information with this kit, and the way to put all the eggs in the same google drive basket seemed rubbish to me, and especialy boring when you have to download the Marlin firmawre file to file.

Did you noticed the Marlin provided bu Folger is a light and old version ? Not all the screens are implemented, no autobed leveling, antique PID, and so on... I think it's surely better to don't use it and download a proper version of Marlin instead, and spend some time to configure it right.

I have some trouble while installing a RepRapDiscount Full Graphic Smart Controller (red pcb). Or maybe my stuff is out of order. To be sure, if one of you have that display implemented on his machine, I would realy appreciate if he would share his Marlin configuration with me into a Zip. So I'll be able so see if the display is to blame. Thx !

i provided my configureation.h on page 11 of this thread, and I use the same RepRapDiscount Full Graphic Smart Controler. do take the time to read through

I'm pretty sure I mentioned earlier in the thread that TOM has a youtube video on configuring, configuration.h in general and one on adding an LCD to Marlin

Edited 1 time(s). Last edit at 11/14/2014 10:35AM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay November 14, 2014 12:21PM |

Registered: 9 years ago Posts: 1,011 |

Yeah. I apologize, I've read the 13 pages as fast as possible. Some informations may have been missed. Well Tom has some videos, fine. I've watched all of them. Through, I was not complaining but comparing versus other prusa i3 sellers which provide a much more complete documentation. The Czar documentation helped me much more, for example. Anyway, thanx for your message and again for the topic. I'll visit page 11 and give your configuration.h a try, even if it's only a part of the marlin file. Is it from the Folger Gdrive or did you start form a generic Marlin version ?

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Folger Prusa i3 Kit from ebay November 14, 2014 02:26PM |

Registered: 9 years ago Posts: 18 |

|

Re: Folger Prusa i3 Kit from ebay November 14, 2014 04:29PM |

Registered: 9 years ago Posts: 208 |

Quote

Zavashier

Yeah. I apologize, I've read the 13 pages as fast as possible. Some informations may have been missed. Well Tom has some videos, fine. I've watched all of them. Through, I was not complaining but comparing versus other prusa i3 sellers which provide a much more complete documentation. The Czar documentation helped me much more, for example. Anyway, thanx for your message and again for the topic. I'll visit page 11 and give your configuration.h a try, even if it's only a part of the marlin file. Is it from the Folger Gdrive or did you start form a generic Marlin version ?

No need to apologize I was nearly indicating it might be good to read throught the thread... I too used the 3dczar documentation for reference.

My marlin came from the github, latest version, and the confirmation.h files is also from the github, then dooms101 made some changes and uploaded a copy, then I made more changes and uploaded mine, It's no from the folgertech google drive.

Hope this helps...

Dooms101 started another thread with an enquiry, then I stared a dedicated thread on the Folgertech. Dooms101 posted lots of great answers to my question along with the other guys.

|

Re: Folger Prusa i3 Kit from ebay November 14, 2014 05:00PM |

Registered: 9 years ago Posts: 1,011 |

Yes, sure. All the awnsers on your thread are very usefull. I used your Configuration.h inside the Forlger's Marlin with a huge amount of compillation errors. Then I did the same on a proper Github Marlin version and it worked perfectly. Many thanks, I'll be back with pictures of my i3. I would like to have a clean printer with some nice cable management before to post anything. Cya TC

Edited 2 time(s). Last edit at 11/14/2014 05:01PM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Edited 2 time(s). Last edit at 11/14/2014 05:01PM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Folger Prusa i3 Kit from ebay November 14, 2014 11:58PM |

Registered: 9 years ago Posts: 110 |

UGH!!! I have all the electonics plugged in but I don't have the endstops tightened down. Also, I don't have the connector cable for my screen that I ordered so I have to get my hands on one of that soon, but at the very least I should be uploading Marlin firmware tomorrow and getting things working just frustrated about the display not being hooked up.

Also, Walter, how did you hook up your y stop? Either I don't have the right plastic pieces or I'm not looking at it right.

thanks for the help all!

Also, Walter, how did you hook up your y stop? Either I don't have the right plastic pieces or I'm not looking at it right.

thanks for the help all!

|

Re: Folger Prusa i3 Kit from ebay November 15, 2014 12:23AM |

Registered: 9 years ago Posts: 208 |

I printed out a different one for use with my kit. When I purchased my kit, it was missing the printed plastic parts, so while waiting for them to be sent in the mail, and after Folger made the .stl files available online, I started printing what I needed, and substituted parts for other ones... My Y-axis belt holder for the bed is one that has three holes and I ended up printing a different kind of Y-axis end stop, as I found the encluded one to be a bit challenging. I posted .stl files for both the Y-axis belt holder and the y-axis end stop i ended up using... A bit tricky if you dont have another printer to print them with, but I was lucky...

Edited 1 time(s). Last edit at 11/15/2014 12:24AM by Waltermixx.

Edited 1 time(s). Last edit at 11/15/2014 12:24AM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay November 15, 2014 12:52AM |

Registered: 9 years ago Posts: 208 |

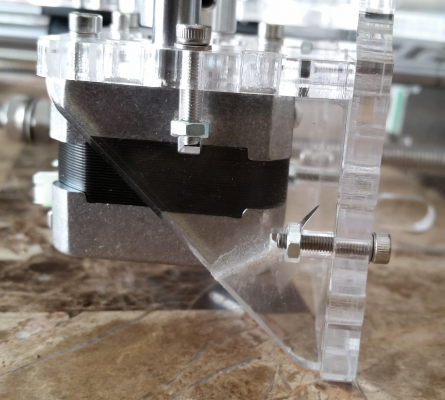

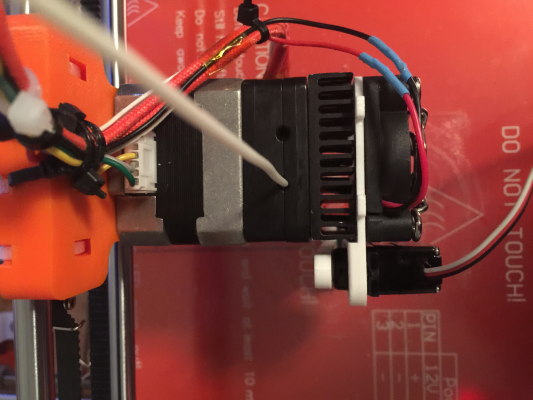

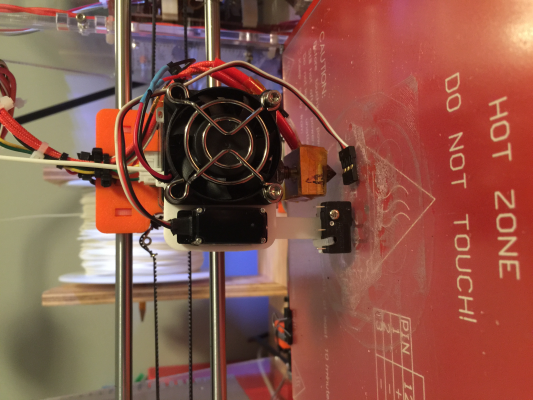

Okie doke I started working on Auto Tramming/Leveling the heated build plate.

I remixed this Servo Mount for a QU-BD 40mm cooling fan servo + Z-probe bracket for ord bot hadron:

[www.thingiverse.com]

- i reduced the thickness of the fan mount portion, and flipped it 180 degrees so the servo is on the right side,

and the fan mount is between the fan and the heat sink, sandwiched in nice and tight... ( I made it much thinner ) it is held in securly and puts the probe closer to the

hot end during probing. there are also built in zip tie clips at the top to manage wires... The credit for the design goes to the original designer, I just made it thinner,

and changed the mounting point. The probe is from here: [www.thingiverse.com] it will need shortening because the top of the probe will bump into the

The probe is from here: [www.thingiverse.com] it will need shortening because the top of the probe will bump into the

fan when it's in "out of the way" position... so I have to trim the lenth.

please see my thingiverse link below for the parts

I have to be honest, I am doing this for fun really, i have not had any issues with manually leveling, and I only do it about once every 10 prints... so this is more

proof of concept, and I like the idea of it being automated, certainly not a necessity, but i had a 9g server kicking around

but i had a 9g server kicking around

Cheers. a few more pictures in that feed.

a few more pictures in that feed.  [www.flickr.com]

[www.flickr.com]

I created a thing site for it, giving credit where credit is due listed as a remix.

[www.thingiverse.com]

Edited 3 time(s). Last edit at 11/15/2014 01:33AM by Waltermixx.

I remixed this Servo Mount for a QU-BD 40mm cooling fan servo + Z-probe bracket for ord bot hadron:

[www.thingiverse.com]

- i reduced the thickness of the fan mount portion, and flipped it 180 degrees so the servo is on the right side,

and the fan mount is between the fan and the heat sink, sandwiched in nice and tight... ( I made it much thinner ) it is held in securly and puts the probe closer to the

hot end during probing. there are also built in zip tie clips at the top to manage wires... The credit for the design goes to the original designer, I just made it thinner,

and changed the mounting point.

The probe is from here: [www.thingiverse.com] it will need shortening because the top of the probe will bump into the

The probe is from here: [www.thingiverse.com] it will need shortening because the top of the probe will bump into the fan when it's in "out of the way" position... so I have to trim the lenth.

please see my thingiverse link below for the parts

I have to be honest, I am doing this for fun really, i have not had any issues with manually leveling, and I only do it about once every 10 prints... so this is more

proof of concept, and I like the idea of it being automated, certainly not a necessity,

but i had a 9g server kicking around

but i had a 9g server kicking around

Cheers.

a few more pictures in that feed.

a few more pictures in that feed.  [www.flickr.com]

[www.flickr.com]I created a thing site for it, giving credit where credit is due listed as a remix.

[www.thingiverse.com]

Edited 3 time(s). Last edit at 11/15/2014 01:33AM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay November 15, 2014 02:55PM |

Registered: 9 years ago Posts: 110 |

Wow Walter, looks great!

I have a quick question I'm hoping someone can help me with. In the Arduino Software, what hardware are you all selecting? I have an Arduino 2560 (clone?) board but I don't know if I should select the Arduino Mega 2560 or one of the handful of "Sanguino w/ Arduino xxx" options that came with the Marlin firmware, or if there is something else I should be grabbing from somewhere else. I just don't want to fry anything before I hook it up.

Lou

I have a quick question I'm hoping someone can help me with. In the Arduino Software, what hardware are you all selecting? I have an Arduino 2560 (clone?) board but I don't know if I should select the Arduino Mega 2560 or one of the handful of "Sanguino w/ Arduino xxx" options that came with the Marlin firmware, or if there is something else I should be grabbing from somewhere else. I just don't want to fry anything before I hook it up.

Lou

|

Re: Folger Prusa i3 Kit from ebay November 15, 2014 03:01PM |

Registered: 9 years ago Posts: 12 |

I also tried autolevel, but I could not make the software part work! I could not find any guide for the latest adition of the marlin and how to configure the slicing program.

Did you make it work?

Did you make it work?

Quote

Waltermixx

Okie doke I started working on Auto Tramming/Leveling the heated build plate.

I remixed this Servo Mount for a QU-BD 40mm cooling fan servo + Z-probe bracket for ord bot hadron:

[www.thingiverse.com]

- i reduced the thickness of the fan mount portion, and flipped it 180 degrees so the servo is on the right side,

and the fan mount is between the fan and the heat sink, sandwiched in nice and tight... ( I made it much thinner ) it is held in securly and puts the probe closer to the

hot end during probing. there are also built in zip tie clips at the top to manage wires... The credit for the design goes to the original designer, I just made it thinner,

and changed the mounting point.The probe is from here: [www.thingiverse.com] it will need shortening because the top of the probe will bump into the

fan when it's in "out of the way" position... so I have to trim the lenth.

please see my thingiverse link below for the parts

I have to be honest, I am doing this for fun really, i have not had any issues with manually leveling, and I only do it about once every 10 prints... so this is more

proof of concept, and I like the idea of it being automated, certainly not a necessity,but i had a 9g server kicking around

Cheers.a few more pictures in that feed.

[www.flickr.com]

I created a thing site for it, giving credit where credit is due listed as a remix.

[www.thingiverse.com]

thing:545911

|

Re: Folger Prusa i3 Kit from ebay November 15, 2014 05:55PM |

Registered: 9 years ago Posts: 110 |

Ok, so I'm trying to use the config.h file that was uploaded by Walter and I found that the latest Marlin, which was uploaded about 3 days ago, throws errors when I use that configuration.h file (it compiles fine with it's own original config.h file). I'm going to try to dig through this code a line at a time and see if I can figure out what is missing, but in the meantime if someone can post a link to what the newest marlin firmware was before 3 days ago, that would be awesome.

|

Re: Folger Prusa i3 Kit from ebay November 15, 2014 06:00PM |

Registered: 12 years ago Posts: 76 |

|

Re: Folger Prusa i3 Kit from ebay November 15, 2014 06:23PM |

Registered: 9 years ago Posts: 110 |

I am such an idiot. The error I got from the Config.h file is that I don't have the full lcd screen and didn't grab the lib file for the lcd screen.

I think that I will be using a different LCD screen than Walter so when I get my connectors and cables and hook it up, I'll put my version of the configuration.h up.

Slow but steady but so far I've been able to upload the firmware and verify the temperature on the sensors is right. I'm still scared to actually plut it into power, but I'm going to in just a few minutes here.

Wish me luck

I think that I will be using a different LCD screen than Walter so when I get my connectors and cables and hook it up, I'll put my version of the configuration.h up.

Slow but steady but so far I've been able to upload the firmware and verify the temperature on the sensors is right. I'm still scared to actually plut it into power, but I'm going to in just a few minutes here.

Wish me luck

|

Re: Folger Prusa i3 Kit from ebay November 15, 2014 06:24PM |

Registered: 9 years ago Posts: 110 |

|

Re: Folger Prusa i3 Kit from ebay November 15, 2014 06:26PM |

Registered: 9 years ago Posts: 208 |

Good luck... remember motors usually wont move initially unless it has been homed...

then it moves until it hits the end stop... if your endstops are in a different position, and if your motors are wired differently,

it may head in another direction... get ready to litterally pull the plug... or at least hit the end stop manually with your finger...

my end stops are on the right of the x-axis and on the front of the Y-axis...

my end stops are on the right of the x-axis and on the front of the Y-axis...

keep this in mind

then it moves until it hits the end stop... if your endstops are in a different position, and if your motors are wired differently,

it may head in another direction... get ready to litterally pull the plug... or at least hit the end stop manually with your finger...

my end stops are on the right of the x-axis and on the front of the Y-axis...

my end stops are on the right of the x-axis and on the front of the Y-axis...

keep this in mind

|

Re: Folger Prusa i3 Kit from ebay November 15, 2014 07:06PM |

Registered: 9 years ago Posts: 110 |

Quote

Waltermixx

Good luck... remember motors usually wont move initially unless it has been homed...

then it moves until it hits the end stop... if your endstops are in a different position, and if your motors are wired differently,

it may head in another direction... get ready to litterally pull the plug... or at least hit the end stop manually with your finger...

my end stops are on the right of the x-axis and on the front of the Y-axis...

keep this in mind

yeah, my end stops are in the same spots. I need to adjust my vrefs for the motors but the missus is dragging me out for the night so that will have to wait till, probably, Monday after work (have a few things planned for Sunday).

Thanks for all the help and support!

|

Re: Folger Prusa i3 Kit from ebay November 16, 2014 02:12AM |

Registered: 9 years ago Posts: 110 |

Ok, so now I've got power to the printer, uploaded the config files, verified that I have all 3 jumpers set under each stepper controller and verified that the vRef's are indeed what they are listed as on page 3 (x = .33, y = .55, z = .35, extruder = .35). I've got the nozzle set to as close to 0,0,0 as possible and I have the z and x endstops hit (the y is difficult for me to get to hit so I'm hoping I can print a new mount for it soon) and when I try to move any of the motors that have endstops associated, they won't move in either direction if the end stop is activated. As soon as I move the endstop so it's not activated, I can move the various bits, but only just so and some in only one direction before I start getting messages that say "x-axis endstop -1.40" or something similair.

It's the very early morning and I'm very tired so I'm going to go to bed. Maybe I need a new battery in my multimeter, but if anyone has any suggestions or a pointer to a good read on what I should be expecting, that would be great.

Thanks.

It's the very early morning and I'm very tired so I'm going to go to bed. Maybe I need a new battery in my multimeter, but if anyone has any suggestions or a pointer to a good read on what I should be expecting, that would be great.

Thanks.

|

Re: Folger Prusa i3 Kit from ebay November 16, 2014 09:11AM |

Registered: 9 years ago Posts: 7 |

Quote

louspinuso

Ok, so now I've got power to the printer, uploaded the config files, verified that I have all 3 jumpers set under each stepper controller and verified that the vRef's are indeed what they are listed as on page 3 (x = .33, y = .55, z = .35, extruder = .35). I've got the nozzle set to as close to 0,0,0 as possible and I have the z and x endstops hit (the y is difficult for me to get to hit so I'm hoping I can print a new mount for it soon) and when I try to move any of the motors that have endstops associated, they won't move in either direction if the end stop is activated. As soon as I move the endstop so it's not activated, I can move the various bits, but only just so and some in only one direction before I start getting messages that say "x-axis endstop -1.40" or something similair.

It's the very early morning and I'm very tired so I'm going to go to bed. Maybe I need a new battery in my multimeter, but if anyone has any suggestions or a pointer to a good read on what I should be expecting, that would be great.

Thanks.

Make sure you have the max endstps disabled. I had this problem when I first set everything up using the newset version of the firmware with the settings copied from the version provided by Folger Tech.

|

Re: Folger Prusa i3 Kit from ebay November 16, 2014 12:29PM |

Registered: 9 years ago Posts: 19 |

|

Re: Folger Prusa i3 Kit from ebay November 16, 2014 12:37PM |

Registered: 9 years ago Posts: 208 |

Konto, i have not tried enabling the auto leveling software yet, I just wanted to sort out the mechanical parts first.

it figures that I cannot find the set of wheels, levers and screws for that 9g servo, as I have had it for years...

once i have my Probe securely connected to the servo i will give it a shot.

it figures that I cannot find the set of wheels, levers and screws for that 9g servo, as I have had it for years...

once i have my Probe securely connected to the servo i will give it a shot.

|

Re: Folger Prusa i3 Kit from ebay November 17, 2014 04:40PM |

Registered: 9 years ago Posts: 19 |

Hi, I'm getting to place my order for my Folger Tech Prusa i3 kit but i also want to order a lcd display. I was going to order the lcd graphical display but it doesn't say if the sdramps is included with that display. So has anyone bought the graphical display and does it include the sd card slot?

Edited 1 time(s). Last edit at 11/17/2014 04:41PM by Nlh205.

Edited 1 time(s). Last edit at 11/17/2014 04:41PM by Nlh205.

Sorry, only registered users may post in this forum.