An alternative to buying a bad kit for $300-500

Posted by the_digital_dentist

|

Re: An alternative to buying a bad kit for $300-500 November 07, 2019 03:20AM |

Registered: 9 years ago Posts: 893 |

|

Re: An alternative to buying a bad kit for $300-500 November 09, 2019 06:19PM |

Registered: 4 years ago Posts: 10 |

|

Re: An alternative to buying a bad kit for $300-500 November 10, 2019 02:46AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

wallaceowen

I've got one here you can have, if you still need it.

(sorry, this is in reply to an old old post by user Rlewisrlou666).

If you press 'quote' under the post you're replying to, you can get the original post linked in your reply just like this one. Makes it easier for everyone to understand what you're talking about

http://www.marinusdebeer.nl/

|

Re: An alternative to buying a bad kit for $300-500 January 21, 2020 01:46PM |

Registered: 5 years ago Posts: 29 |

Used my Cubex RepRap Tango to make a Mostly Printed CNC, Turned out great.

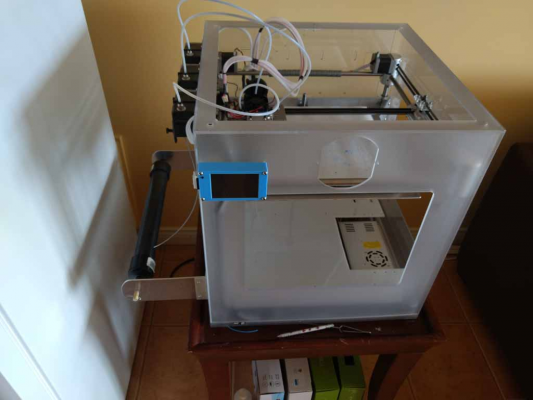

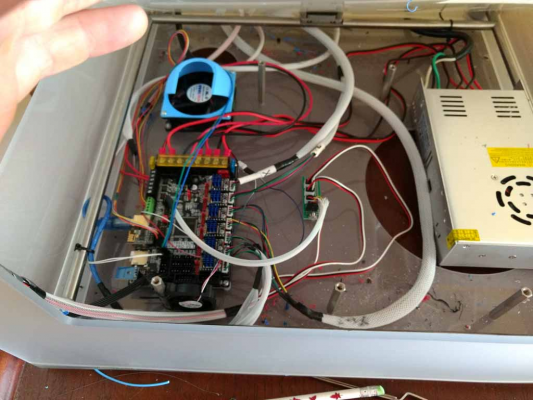

My new project is my second Cubex duo conversion (I bought two originally for $220 IIRC for the pair).

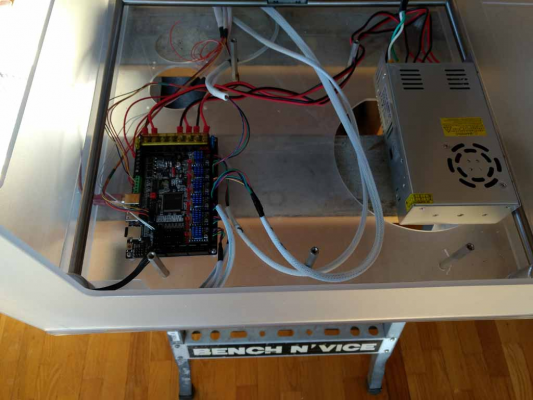

This one is based on a BIQU SKR Pro v1.1 with TMC2209 stepper drivers and a diamond triple extrusion single nozzle head.

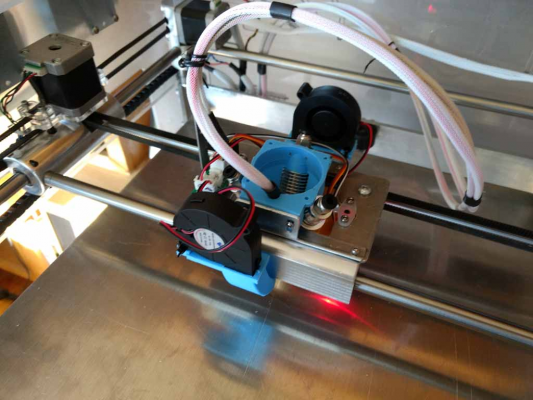

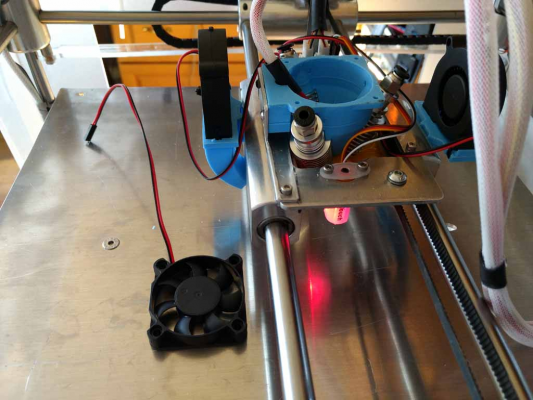

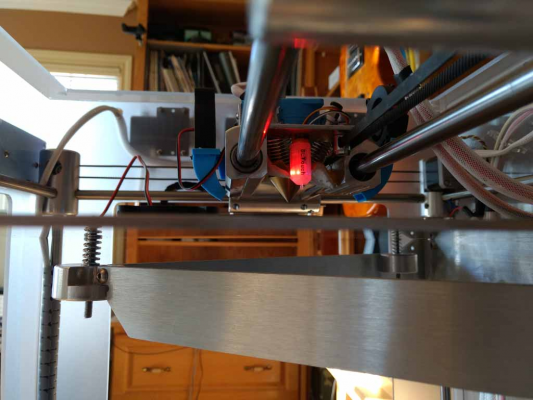

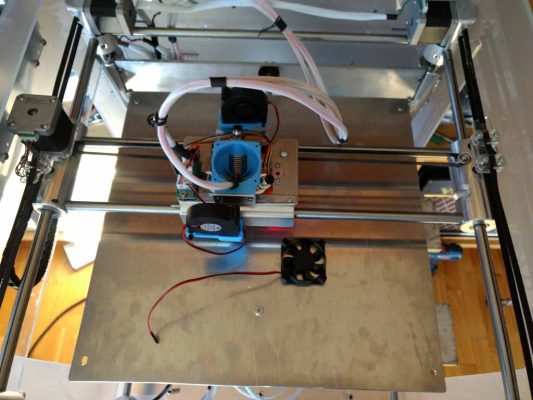

I stripped the carriage down completely and removed the sliders/bearings. I got myself a little hobby mill and removed a ton of aluminum off each slider and removed the extruder/fans and SS plates resulting in around 3lb reduction in the carriage weight.

I also replace the Z axis plastic back bar with 1/4 Aluminum plate.

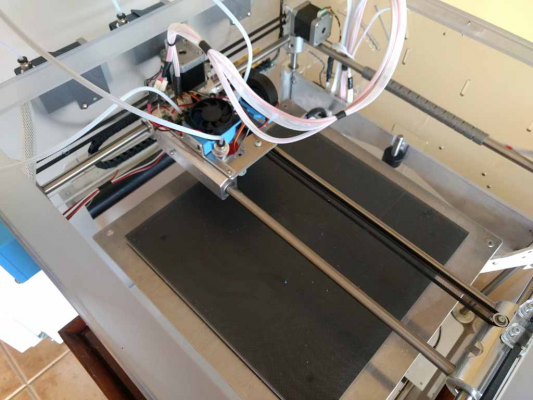

Refitted with smaller lighter fans and the diamond head (Bowden) in a pla housing and placed 3 BMG style Bowdon extriders and the stepper motors on the RHS of the cabinet.

Added a Antclabs BLTouch for levelling and removed all endstops and use the stallguard function of the TMC2209.

Everything is 24v (600W Power supply).

I am awaiting delivery of a 310x310 heated 24v Bed (they sent a 12v by mistake) Oh and I replaced the sprung bed plate with a roughly 400x400x3.5mm Aluminum plate.

Also awaiting 3 filament runout sensors.

Btw on my previous duo rebuild I reused the cubex extruder with a e3d head and managed to utilise the cubex duo standard filament run sensor.

Marlin 2 is working well to date, homing working, double z of SKR Pro switched to double Y, BLTouch working .

3.5 TFT is nice.

Still to do: Heated bed fitting, inner base cover and cooling for controller, triple extruder testing and runout sensors to be fitted and set up. Oh and a triple spool holder to bolt to lower LHS of cube. Interior light.

And I still have to work out how to fit/support the bowden tubes and wires to the carriage. Any ideas?

Edited 1 time(s). Last edit at 01/21/2020 01:46PM by jimboh3.

My new project is my second Cubex duo conversion (I bought two originally for $220 IIRC for the pair).

This one is based on a BIQU SKR Pro v1.1 with TMC2209 stepper drivers and a diamond triple extrusion single nozzle head.

I stripped the carriage down completely and removed the sliders/bearings. I got myself a little hobby mill and removed a ton of aluminum off each slider and removed the extruder/fans and SS plates resulting in around 3lb reduction in the carriage weight.

I also replace the Z axis plastic back bar with 1/4 Aluminum plate.

Refitted with smaller lighter fans and the diamond head (Bowden) in a pla housing and placed 3 BMG style Bowdon extriders and the stepper motors on the RHS of the cabinet.

Added a Antclabs BLTouch for levelling and removed all endstops and use the stallguard function of the TMC2209.

Everything is 24v (600W Power supply).

I am awaiting delivery of a 310x310 heated 24v Bed (they sent a 12v by mistake) Oh and I replaced the sprung bed plate with a roughly 400x400x3.5mm Aluminum plate.

Also awaiting 3 filament runout sensors.

Btw on my previous duo rebuild I reused the cubex extruder with a e3d head and managed to utilise the cubex duo standard filament run sensor.

Marlin 2 is working well to date, homing working, double z of SKR Pro switched to double Y, BLTouch working .

3.5 TFT is nice.

Still to do: Heated bed fitting, inner base cover and cooling for controller, triple extruder testing and runout sensors to be fitted and set up. Oh and a triple spool holder to bolt to lower LHS of cube. Interior light.

And I still have to work out how to fit/support the bowden tubes and wires to the carriage. Any ideas?

Edited 1 time(s). Last edit at 01/21/2020 01:46PM by jimboh3.

|

Re: An alternative to buying a bad kit for $300-500 January 21, 2020 01:55PM |

Registered: 7 years ago Posts: 47 |

|

Re: An alternative to buying a bad kit for $300-500 January 22, 2020 02:03PM |

Admin Registered: 11 years ago Posts: 3,096 |

@jimboh3

That's a great price! Here in the Netherlands some really dumb people are still selling their machines for over €1200/piece. Very unrealistic.

http://www.marinusdebeer.nl/

That's a great price! Here in the Netherlands some really dumb people are still selling their machines for over €1200/piece. Very unrealistic.

http://www.marinusdebeer.nl/

|

Re: An alternative to buying a bad kit for $300-500 January 25, 2020 06:34AM |

Registered: 4 years ago Posts: 1 |

|

Re: An alternative to buying a bad kit for $300-500 October 04, 2020 07:12AM |

Registered: 3 years ago Posts: 1 |

Greetings Gentlemens,

yesterday i read the whole topic. There is a lot of useful information. Because i'm not an expert i not totally convinced about my knowledge. I want to ask some suggestion. According to the datashet of the stepper motors can i use A4988 or better to choose other which can handle higher current like TMC5160 61 for the Z axis stepper? Thanks in advance.

yesterday i read the whole topic. There is a lot of useful information. Because i'm not an expert i not totally convinced about my knowledge. I want to ask some suggestion. According to the datashet of the stepper motors can i use A4988 or better to choose other which can handle higher current like TMC5160 61 for the Z axis stepper? Thanks in advance.

|

Re: An alternative to buying a bad kit for $300-500 August 08, 2021 09:48PM |

Registered: 8 years ago Posts: 105 |

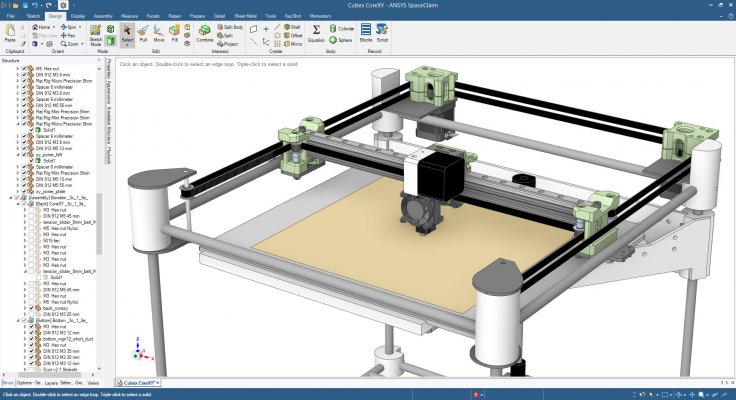

Don't know if anyone is still tracking this thread, but working on a CoreXY conversion based on the open source Rat Rig printer

Will post pics and files when I have it working

Will post pics and files when I have it working

|

Re: An alternative to buying a bad kit for $300-500 August 09, 2021 07:56AM |

Registered: 7 years ago Posts: 47 |

|

Re: An alternative to buying a bad kit for $300-500 August 09, 2021 11:43AM |

Registered: 5 years ago Posts: 9 |

|

Re: An alternative to buying a bad kit for $300-500 August 09, 2021 11:57AM |

Admin Registered: 16 years ago Posts: 13,891 |

... I have a RADDS board (standard 6 sockets) with two different expansion modules, adding 2 or 3 more sockets - so with 3 more sockets it will support 3 axes and 6 extruders motors ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: An alternative to buying a bad kit for $300-500 August 09, 2021 11:59AM |

Registered: 5 years ago Posts: 29 |

Me Too.

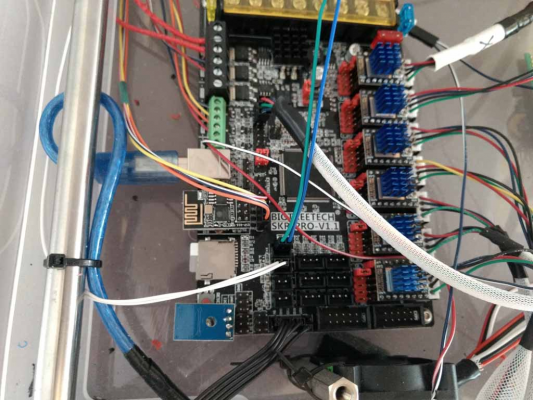

@GT500 I use the 32bit BIQU SKR Pro v1.1 with TMC2209 stepper drivers and a diamond triple extrusion single nozzle head (see my post a few up). Its all built and running well now, only thing not fully up is the 3 filament runout sensors because Marlin wasn't fully supporting when I was finishing this. Should try again but I tend to do most of my 3d printer stuff in the winter. See last pic. I have the wifi board and ic2 daughter boards on (Ic2 for config storage).

Edited 1 time(s). Last edit at 08/09/2021 12:00PM by jimboh3.

@GT500 I use the 32bit BIQU SKR Pro v1.1 with TMC2209 stepper drivers and a diamond triple extrusion single nozzle head (see my post a few up). Its all built and running well now, only thing not fully up is the 3 filament runout sensors because Marlin wasn't fully supporting when I was finishing this. Should try again but I tend to do most of my 3d printer stuff in the winter. See last pic. I have the wifi board and ic2 daughter boards on (Ic2 for config storage).

Edited 1 time(s). Last edit at 08/09/2021 12:00PM by jimboh3.

|

Re: An alternative to buying a bad kit for $300-500 August 09, 2021 12:13PM |

Registered: 5 years ago Posts: 9 |

@Jomboh3

Nice set up!

Maybe sometime you can post the firmware for the board? I have limited luck with marlin compiles at times depending on the board. I currently have mine with 2 extruders as the controller board for the display never updated that board to allow 3 extruders... What is your display you are using? I'll look into the board you have, good to know it's do-able. I had almost given up hope...

Bill

Nice set up!

Maybe sometime you can post the firmware for the board? I have limited luck with marlin compiles at times depending on the board. I currently have mine with 2 extruders as the controller board for the display never updated that board to allow 3 extruders... What is your display you are using? I'll look into the board you have, good to know it's do-able. I had almost given up hope...

Bill

|

Re: An alternative to buying a bad kit for $300-500 August 09, 2021 12:24PM |

Registered: 5 years ago Posts: 29 |

BIQU (Bigtreetech) have newer boards now with even more functionality. I bough all my stuff on Aliexpress. Bit of a wait but cheap.

Sure I can let you have my marlin config. As a starting point maybe. Its not much use unless you have the same board with the same steppers and number of extruders etc.

Marlin configs are very specific to a build I find. Display is a BIQU TFT3.5. They also have a 5" and a 7". They are touch screen as well which is really useful. The latest versions include the rotary encoder and you can boot them up to either run in standard Marlin mode (without touch but with encoder) or in Touch mode. I use Touch and am more than happy with it.

The wifi daughter board is an ESP device and the software will interface with your pc (using wifi) and you won't need Octoprint. Its called ESP3D.

The IC2 card gets round problems with marlin and the Pro 1.1 not being able to save config to the SD cards.

Edited 1 time(s). Last edit at 08/09/2021 12:38PM by jimboh3.

Sure I can let you have my marlin config. As a starting point maybe. Its not much use unless you have the same board with the same steppers and number of extruders etc.

Marlin configs are very specific to a build I find. Display is a BIQU TFT3.5. They also have a 5" and a 7". They are touch screen as well which is really useful. The latest versions include the rotary encoder and you can boot them up to either run in standard Marlin mode (without touch but with encoder) or in Touch mode. I use Touch and am more than happy with it.

The wifi daughter board is an ESP device and the software will interface with your pc (using wifi) and you won't need Octoprint. Its called ESP3D.

The IC2 card gets round problems with marlin and the Pro 1.1 not being able to save config to the SD cards.

Edited 1 time(s). Last edit at 08/09/2021 12:38PM by jimboh3.

|

Re: An alternative to buying a bad kit for $300-500 August 09, 2021 12:27PM |

Registered: 5 years ago Posts: 9 |

|

Re: An alternative to buying a bad kit for $300-500 August 09, 2021 12:52PM |

Registered: 5 years ago Posts: 29 |

|

Re: An alternative to buying a bad kit for $300-500 August 09, 2021 01:15PM |

Registered: 7 years ago Posts: 55 |

|

Re: An alternative to buying a bad kit for $300-500 August 09, 2021 01:38PM |

Registered: 5 years ago Posts: 9 |

I know my board has six steppers as well. I'm driving the Y's off one stepper, that left the other three available for the extruders. But I've yet to find a display module that works with it. That's why I'm only using two. I'll have to look at it tonight when I get home.

PS sorry for the delays oh, I'm only answering when I stop, as I said I'm driving.

PS sorry for the delays oh, I'm only answering when I stop, as I said I'm driving.

|

Re: An alternative to buying a bad kit for $300-500 August 10, 2021 12:22AM |

Registered: 5 years ago Posts: 9 |

@jimboh3,

Sorry, I've forgotten how much I needed to take apart to get to the motherboard. I still have the white tray cover re-installed in my unit (I think because I thought it would help with cooling.) The board I'm using is a Makerbase MKS Rumba v1.0 with 8825 drivers. I'm open to changing the board to the one you are using and use the same drivers if that gets me a third extruter. I'll use this one in one of my Ender3's to drive a duel extruder. Can you control the extruters from your display? What display are you using, I couldn't find one that allowed 3 extruters? Sorry for so many questions but I've had the unit over a year and would love to have 3 working extruters. Thanks for all the help,

Bill

Sorry, I've forgotten how much I needed to take apart to get to the motherboard. I still have the white tray cover re-installed in my unit (I think because I thought it would help with cooling.) The board I'm using is a Makerbase MKS Rumba v1.0 with 8825 drivers. I'm open to changing the board to the one you are using and use the same drivers if that gets me a third extruter. I'll use this one in one of my Ender3's to drive a duel extruder. Can you control the extruters from your display? What display are you using, I couldn't find one that allowed 3 extruters? Sorry for so many questions but I've had the unit over a year and would love to have 3 working extruters. Thanks for all the help,

Bill

|

Re: An alternative to buying a bad kit for $300-500 August 10, 2021 11:39AM |

Registered: 5 years ago Posts: 29 |

I am a little confused as to why you are concerned with what display to use. Assuming you are using Marlin the control of extruders will be software and configuration controlled.

The rumba board if I recall has 6 stepper controllers so with the cube that could be X, 2xY, Z, E0, E1 and E2 (using the Y output to drive both cube Y steppers).

Marlin 2.0 is capable of then driving 3 extruders and you would be able to select the third extruder the same way as you would currently do with the first and second.

My setup has 3 extruders but only one printer nozzle so the set up/configuration is very different for three extruders with 3 heads. I assume you are still using the original extruders and nozzles from the Cube. I didn't want to go that way because of all the weight on the carriage and also would think Z alignment to be a real headache with that set up.

The rumba board if I recall has 6 stepper controllers so with the cube that could be X, 2xY, Z, E0, E1 and E2 (using the Y output to drive both cube Y steppers).

Marlin 2.0 is capable of then driving 3 extruders and you would be able to select the third extruder the same way as you would currently do with the first and second.

My setup has 3 extruders but only one printer nozzle so the set up/configuration is very different for three extruders with 3 heads. I assume you are still using the original extruders and nozzles from the Cube. I didn't want to go that way because of all the weight on the carriage and also would think Z alignment to be a real headache with that set up.

|

Re: An alternative to buying a bad kit for $300-500 August 11, 2021 03:15PM |

Registered: 5 years ago Posts: 9 |

Sorry I didn't answer yesterday, Just back online, limited internet here.

I use the control panel to preheat the nozzles so I can load and unload filaments.

Also I monitor the temps as I have one filament that if it gets too hot, will always jam! (cheap but bonds well)...

Yes, I'm using the original head/nozzles but open to replacing them as well...

All in all, I'm happy with my set up with 2 extruders, I like the thing you did with swapping the Z and Y axes if the set up allows for two motors without the use of an external board.

It's been a true learning curve for me as I didn't really have much in the way of 3d printing experience before, now I have many Ender 3's and one Monoprice Mini and love to make stuff.

The CubeX was my first try at converting to standard filaments, got it working for the most part.

You are correct about the head alignment, PITA, even with just 2 working...

Thanks again for the help,

Bill

I use the control panel to preheat the nozzles so I can load and unload filaments.

Also I monitor the temps as I have one filament that if it gets too hot, will always jam! (cheap but bonds well)...

Yes, I'm using the original head/nozzles but open to replacing them as well...

All in all, I'm happy with my set up with 2 extruders, I like the thing you did with swapping the Z and Y axes if the set up allows for two motors without the use of an external board.

It's been a true learning curve for me as I didn't really have much in the way of 3d printing experience before, now I have many Ender 3's and one Monoprice Mini and love to make stuff.

The CubeX was my first try at converting to standard filaments, got it working for the most part.

You are correct about the head alignment, PITA, even with just 2 working...

Thanks again for the help,

Bill

Sorry, only registered users may post in this forum.