Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 25, 2016 01:14PM |

Registered: 8 years ago Posts: 98 |

Quote

paul_delta

I guess larger effector theoreticaly will have less noticeable tilt with the same rod length.

I mean it will hide rods imperfection.

I would have assumed the opposite.. More distance across the effector means more area to tilt. So if in a 2D slice the tilt was y=0.05x, then over 20mm it would be a difference of 1mm across the effector, but over 40mm it would be a difference of 2mm.

The error in angle increased dramatically with the new effector, and it's visibly noticeable at the outer edges (I really wish I had made it 10mm smaller). I really think it's the increased steps per mm in X/Y space that is causing the improvement, but I could certainly be wrong about that.. I will note that I had to do a lot more work to get the effector aligned properly. I spent a lot of time trying to get the rods spacing right (they're still off by a bit.. I really need to get calipers), and I ran about 5 hours of data point collection/calibration.

Edited 1 time(s). Last edit at 02/25/2016 01:44PM by spiffcow.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 25, 2016 02:05PM |

Registered: 8 years ago Posts: 1 |

Hello all.

I have also got Folger Tech Kossel 3D revB kit. Now It is mechanically assembled and wiring have started.

I live in Finland and here we have 220V and so called "eurosocket". Plug is possible to push into socket both way

How is Kossel related this. Is it possible to connet L and N in both way into power supply ? Or do I need to check socket before pushing plug in.

Sorry my bad english.

I have also got Folger Tech Kossel 3D revB kit. Now It is mechanically assembled and wiring have started.

I live in Finland and here we have 220V and so called "eurosocket". Plug is possible to push into socket both way

How is Kossel related this. Is it possible to connet L and N in both way into power supply ? Or do I need to check socket before pushing plug in.

Sorry my bad english.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 26, 2016 12:52AM |

Registered: 8 years ago Posts: 98 |

Quote

Captain_Tim

Quote

spiffcow

So I just thought I would mention something I discovered over the last few days...

So I had been having issues lately with the printable bed being too small (about 90mm radius). I was too cheap to order new arms, and decided to try creating a larger effector instead. I extended the arms out about 20mm and made a few other mods that were helpful to me. I got a larger build radius as expected, but what I did *not* expect was the improvement in print quality! In retrospect it makes sense -- a larger effector means more distance traveled by each arm during positioning. More distance traveled means more steps, and the resolution is proportional to the number of steps.

So by increasing the size of the effector, you not only increased your build size, but also your print quality? Now I just have one question... You going to upload that to Thingiverse? ?

As requested, it is now on Thingiverse

[www.thingiverse.com]

I plan to clean it up a lot, but thought I would post just in case anyone wants to try it out.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 26, 2016 01:42AM |

Registered: 8 years ago Posts: 63 |

Quote

dc42

Quote

Legrand

Any ideas what happened here? The interface is still working. The hot end still heats up. The axis still move.

As I said, all my printing has been in PLA so my bed temperature hasn't exceeded 65°C for weeks.

I'm not sure where to start. I have a spare bed, but this is the wiring between the power supply and the board. I don't know what could be causing it to draw so much current.

I suspect the problem is that you are using stranded core wire in the terminal block without crimping a ferrule on it first. When you do this, the screw becomes loose after a while, resulting in a poor connection. A short term fix is to check very regularly that the terminal block screws are tight, but the correct long term solution is to use a ferrule.

I just tinned mine first. I tinned everything since the soldering iron was already out for the other tasks.

There's No Place Like 127.0.0.1

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 26, 2016 02:39AM |

Registered: 8 years ago Posts: 916 |

Quote

EvilBetty

I just tinned mine first. I tinned everything since the soldering iron was already out for the other tasks.

I used to do that, until a really experienced technician I was working with showed me why that's a bad idea. Solder creeps.

Try this experiment: Unwrap some solder from your reel and bend it so that there's a foot or so angled above the desk, supporting its own weight. Now watch the end. It will slowly creep down.

The same thing happens with tinned connections under screw tension. Slowly, over time, the solder will creep and loosen the joint, until you're left with a bad connection.

Not recommended.

Just bare wires in there are fine, or use a crimped ferrule.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 26, 2016 08:41AM |

Registered: 10 years ago Posts: 56 |

Quote

Karppa

How is Kossel related this. Is it possible to connet L and N in both way into power supply ?

Hi there!

I refitted the Kossel to European AC, too, and had no problems (dont forget to switch the PSU to 220 though!). In principle it does not matter which way you connect L & N, BUT you *MUST* connect earth wire (yellow/green wire). Earth and N are connected to each other and make the whole unit (very) safe to touch. As long as earth is connected, L & N may be connected in any possible way.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 26, 2016 08:57AM |

Registered: 10 years ago Posts: 56 |

Quote

spiffcow

Quote

paul_delta

I guess larger effector theoreticaly will have less noticeable tilt with the same rod length.

I mean it will hide rods imperfection.

I would have assumed the opposite.. More distance across the effector means more area to tilt. So if in a 2D slice the tilt was y=0.05x, then over 20mm it would be a difference of 1mm across the effector, but over 40mm it would be a difference of 2mm.

The error in angle increased dramatically with the new effector, and it's visibly noticeable at the outer edges (I really wish I had made it 10mm smaller). I really think it's the increased steps per mm in X/Y space that is causing the improvement, but I could certainly be wrong about that.. I will note that I had to do a lot more work to get the effector aligned properly. I spent a lot of time trying to get the rods spacing right (they're still off by a bit.. I really need to get calipers), and I ran about 5 hours of data point collection/calibration.

A bigger spacing between rods will certainly produce less tilt: Imagine the two rods of the A tower being 190 mm and 210 mm long and move the effector to that A tower and then opposite of it: With 10 mm rod spacing, there will be tremendous tilt during that movement (20 mm / 10 mm = 2 radian), and way less tilt when increasing the rod spacing to, lets say, 100 mm (20 mm/ 100 mm = 0.2 radian). The same principle holds for the spacing between pairs of rods. The bigger the spacing, the less the impact of differing rod lengths.

I would guess by using a bigger effector and the same rod lengths, you reduced your horizontal rod radius value by quite a bit. Perhaps thats why the corners tend to get uglier as you are printing nearer to that radius? What is your horizontal rod radius right now?

Stupid question: I never checked the spacing of my rod pairs. Is that so crucial? Should I? To which accuracy should they be tuned to? And do you just tune the spacing of one rod pair after the next one or do the spacings have to be the same between all three rod pairs? Thanks!

Edited 1 time(s). Last edit at 02/26/2016 08:59AM by docpayce.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 26, 2016 12:56PM |

Registered: 8 years ago Posts: 98 |

Quote

docpayce

Quote

spiffcow

Quote

paul_delta

I guess larger effector theoreticaly will have less noticeable tilt with the same rod length.

I mean it will hide rods imperfection.

I would have assumed the opposite.. More distance across the effector means more area to tilt. So if in a 2D slice the tilt was y=0.05x, then over 20mm it would be a difference of 1mm across the effector, but over 40mm it would be a difference of 2mm.

The error in angle increased dramatically with the new effector, and it's visibly noticeable at the outer edges (I really wish I had made it 10mm smaller). I really think it's the increased steps per mm in X/Y space that is causing the improvement, but I could certainly be wrong about that.. I will note that I had to do a lot more work to get the effector aligned properly. I spent a lot of time trying to get the rods spacing right (they're still off by a bit.. I really need to get calipers), and I ran about 5 hours of data point collection/calibration.

A bigger spacing between rods will certainly produce less tilt: Imagine the two rods of the A tower being 190 mm and 210 mm long and move the effector to that A tower and then opposite of it: With 10 mm rod spacing, there will be tremendous tilt during that movement (20 mm / 10 mm = 2 radian), and way less tilt when increasing the rod spacing to, lets say, 100 mm (20 mm/ 100 mm = 0.2 radian). The same principle holds for the spacing between pairs of rods. The bigger the spacing, the less the impact of differing rod lengths.

I would guess by using a bigger effector and the same rod lengths, you reduced your horizontal rod radius value by quite a bit. Perhaps thats why the corners tend to get uglier as you are printing nearer to that radius? What is your horizontal rod radius right now?

Stupid question: I never checked the spacing of my rod pairs. Is that so crucial? Should I? To which accuracy should they be tuned to? And do you just tune the spacing of one rod pair after the next one or do the spacings have to be the same between all three rod pairs? Thanks!

I guess that makes sense. The tilt appears visibly more noticeable with the larger effector, but that may simply owe to being able to see the difference over a longer length.

My rod radius went from ~150 down to about ~135 (I don't have the current settings at the moment.. I'll check it when I get home). I have noticed more error than before toward the ends of 1/3 of the bed between the Y and Z towers, but I just printed my calibration ring and found an error of 1 degree on Y and about 1/2 degree on X, so I'll need to retest after correcting for that.

I try to get my rod spacing as close to equal as I can on the effectors and the carriages (40mm I think? I'd have to check). Right now I'm off by at least 1mm and don't have calipers, so the real amount of error is hard to determine.

My effector arms are a problem though. I'm really trying to to decide between buying a set of magnetic rods next month or putting that money towards a SmartRapCore build and quit spending money on my delta.

Edited 1 time(s). Last edit at 02/26/2016 12:57PM by spiffcow.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 26, 2016 06:43PM |

Registered: 8 years ago Posts: 98 |

Quote

docpayce

I did order a 290 mm rod set two weeks ago and will test them. For me the calculation was as following:

1) I have ok print quality in a 70 mm radius, good quality in 60 mm radius. But I would like to have ~ 100 mm radius.

2) My max printing height (at *full* radius) is appr. 240 mm. I dont need that, I am ok with 200 mm'ish.

So: I have ~40 mm spare in z and want the radius to be ~40 mm wider. As the rods are *nearly* parallel to the tower when at the tower and *nearly* perpendicular to the tower when positioned opposite to the tower -> +50 mm for good measure. 240 + 50 = 290.

Will keep you updated how that works out.

Have you gotten these yet? I'm eager to hear about how this works out, since ~290mm seems to be a fairly standard size.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 27, 2016 02:52AM |

Registered: 8 years ago Posts: 63 |

Quote

nebbian

Quote

EvilBetty

I just tinned mine first. I tinned everything since the soldering iron was already out for the other tasks.

I used to do that, until a really experienced technician I was working with showed me why that's a bad idea. Solder creeps.

Try this experiment: Unwrap some solder from your reel and bend it so that there's a foot or so angled above the desk, supporting its own weight. Now watch the end. It will slowly creep down.

The same thing happens with tinned connections under screw tension. Slowly, over time, the solder will creep and loosen the joint, until you're left with a bad connection.

Not recommended.

Just bare wires in there are fine, or use a crimped ferrule.

Spot weld then maybe.

There's No Place Like 127.0.0.1

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 27, 2016 03:16AM |

Registered: 8 years ago Posts: 63 |

Quote

EvilBetty

Quote

docpayce

I did order a 290 mm rod set two weeks ago and will test them. For me the calculation was as following:

1) I have ok print quality in a 70 mm radius, good quality in 60 mm radius. But I would like to have ~ 100 mm radius.

2) My max printing height (at *full* radius) is appr. 240 mm. I dont need that, I am ok with 200 mm'ish.

So: I have ~40 mm spare in z and want the radius to be ~40 mm wider. As the rods are *nearly* parallel to the tower when at the tower and *nearly* perpendicular to the tower when positioned opposite to the tower -> +50 mm for good measure. 240 + 50 = 290.

Will keep you updated how that works out.

I'm thinking 255mm eye to eye. As I may want to print higher.

Drying...

There's No Place Like 127.0.0.1

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 27, 2016 05:17AM |

Registered: 10 years ago Posts: 56 |

@spiffcow: Nope, not yet. Chinese new year can be a b***ch.  It will still take like a week or so. Honestly, I am thinking about using magnetic rings / steel balls instead of plain Traxxas joints when switching to the new rods. Not sure though. Would mean I got to print a lot of other stuff (new carriages, new effector etc.) and right now I am happy with the print quality... "never change a running system".

It will still take like a week or so. Honestly, I am thinking about using magnetic rings / steel balls instead of plain Traxxas joints when switching to the new rods. Not sure though. Would mean I got to print a lot of other stuff (new carriages, new effector etc.) and right now I am happy with the print quality... "never change a running system".

@EvilBetty: Niiiiice setup! Got a thingiverse link? Let us know the results!!!

Let us know the results!!!

Anybody has experience with magnetic joints instead of Traxxas? Does it make the print quality / speed significantly better?

Edited 1 time(s). Last edit at 02/27/2016 05:17AM by docpayce.

It will still take like a week or so. Honestly, I am thinking about using magnetic rings / steel balls instead of plain Traxxas joints when switching to the new rods. Not sure though. Would mean I got to print a lot of other stuff (new carriages, new effector etc.) and right now I am happy with the print quality... "never change a running system".

It will still take like a week or so. Honestly, I am thinking about using magnetic rings / steel balls instead of plain Traxxas joints when switching to the new rods. Not sure though. Would mean I got to print a lot of other stuff (new carriages, new effector etc.) and right now I am happy with the print quality... "never change a running system". @EvilBetty: Niiiiice setup! Got a thingiverse link?

Let us know the results!!!

Let us know the results!!!

Anybody has experience with magnetic joints instead of Traxxas? Does it make the print quality / speed significantly better?

Edited 1 time(s). Last edit at 02/27/2016 05:17AM by docpayce.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 27, 2016 08:37AM |

Registered: 8 years ago Posts: 432 |

Actually, to get equal rods you must use only one jig and glue them one by one...

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 27, 2016 08:46AM |

Registered: 8 years ago Posts: 432 |

PS: it's OK to make couple of them in one shot, but two of them (side rods) must be done using single jig. Having two glued rods it's OK to put another 4 between them using long M3 rod for example.

Update: I mean even if rods are not perpendicular to the M3 rods during gluing they still will be parallel to each other and equal, as well as M3 will be parallel too. Gluing all of them in one shot even using M3 rods there is a chance that you will get trapezoid, not rectangle/parallelogram.

Edited 8 time(s). Last edit at 02/27/2016 09:08AM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

Update: I mean even if rods are not perpendicular to the M3 rods during gluing they still will be parallel to each other and equal, as well as M3 will be parallel too. Gluing all of them in one shot even using M3 rods there is a chance that you will get trapezoid, not rectangle/parallelogram.

Edited 8 time(s). Last edit at 02/27/2016 09:08AM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 27, 2016 02:27PM |

Registered: 8 years ago Posts: 188 |

My Kossel seems to be printing very well now, but there are still some problems with the print quality that I'd like some ideas on how to improve. I printed a Low Poly Bulbasaur using Hatchbox green 1.75mm PLA. I think it turned out quite well, especially since I wasn't expecting much. That being said, there are some imperfections. Here is an album with photos taken of the model.

The first and second pictures show a loose and sort of layer sag with the chin. My thoughts were that the filament wasn't cooling fast enough, because I don't have a fan blowing on the print bed. I don't want to get rid of the Z-probe yet, till I have everything I need to print out pual's probe adapter. If it is a heating issue and any of you know of a fan I could add, I'd love to see it. If you guys have a different idea of what it might be, I'm all ears.

Second and Third pictures show some layer separation on the forehead as well as the bulb. Any ideas why?

The last picture shows lighter bands of colour. It's hard to see in the photo, but they're there. I have no idea what could cause those.

PLA Settings: 200C first Layer, 195C second layer. Extrusion multiplier: 1.16

Print Settings:

Any help would be great, but all in all, this is a pretty great printer.

Owner of a QUBD Two Up

And

Folger Kossel 2020

And

Tevo Tarantula

The first and second pictures show a loose and sort of layer sag with the chin. My thoughts were that the filament wasn't cooling fast enough, because I don't have a fan blowing on the print bed. I don't want to get rid of the Z-probe yet, till I have everything I need to print out pual's probe adapter. If it is a heating issue and any of you know of a fan I could add, I'd love to see it. If you guys have a different idea of what it might be, I'm all ears.

Second and Third pictures show some layer separation on the forehead as well as the bulb. Any ideas why?

The last picture shows lighter bands of colour. It's hard to see in the photo, but they're there. I have no idea what could cause those.

PLA Settings: 200C first Layer, 195C second layer. Extrusion multiplier: 1.16

Print Settings:

- Layer Height: 0.2mm

- Perimeters: 2

- Solid Layers (Top & Bottom): 3

- Infill: 20%

- Perimeter Speed: 80mm/s

- External Perimeters: 50%

- Infill Speed 55mm/s

Any help would be great, but all in all, this is a pretty great printer.

Owner of a QUBD Two Up

And

Folger Kossel 2020

And

Tevo Tarantula

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 27, 2016 02:35PM |

Registered: 8 years ago Posts: 432 |

80 mm/s for such small object and without active cooling is too much. I print with Hatchbox at 180-185C, you may try to reduce temp.

Or you can try to keep this speed if you want, but reduce layer height to 0.15 or even 0.1.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

Or you can try to keep this speed if you want, but reduce layer height to 0.15 or even 0.1.

Quote

Captain_Tim

My Kossel seems to be printing very well now, but there are still some problems with the print quality that I'd like some ideas on how to improve. I printed a Low Poly Bulbasaur using Hatchbox green 1.75mm PLA. I think it turned out quite well, especially since I wasn't expecting much. That being said, there are some imperfections. Here is an album with photos taken of the model.

The first and second pictures show a loose and sort of layer sag with the chin. My thoughts were that the filament wasn't cooling fast enough, because I don't have a fan blowing on the print bed. I don't want to get rid of the Z-probe yet, till I have everything I need to print out pual's probe adapter. If it is a heating issue and any of you know of a fan I could add, I'd love to see it. If you guys have a different idea of what it might be, I'm all ears.

Second and Third pictures show some layer separation on the forehead as well as the bulb. Any ideas why?

The last picture shows lighter bands of colour. It's hard to see in the photo, but they're there. I have no idea what could cause those.

PLA Settings: 200C first Layer, 195C second layer. Extrusion multiplier: 1.16

Print Settings:

- Layer Height: 0.2mm

- Perimeters: 2

- Solid Layers (Top & Bottom): 3

- Infill: 20%

- Perimeter Speed: 80mm/s

- External Perimeters: 50%

- Infill Speed 55mm/s

Any help would be great, but all in all, this is a pretty great printer.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 27, 2016 02:38PM |

Registered: 8 years ago Posts: 188 |

What speed would you recommend printing this at, or something similar in size?

Owner of a QUBD Two Up

And

Folger Kossel 2020

And

Tevo Tarantula

Quote

paul_delta

80 mm/s for such small object and without active cooling is too much. I print with Hatchbox at 180-185C, you may try to reduce temp.

Or you can try to keep this speed if you want, but reduce layer height to 0.15 or even 0.1.

Owner of a QUBD Two Up

And

Folger Kossel 2020

And

Tevo Tarantula

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 27, 2016 02:45PM |

Registered: 8 years ago Posts: 432 |

I usually enable slicer cooling option, so it will reduce speed automatically if one layer takes less than 5-7 seconds to print.

Edited 1 time(s). Last edit at 02/27/2016 02:45PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

Quote

paul_delta

80 mm/s for such small object and without active cooling is too much. I print with Hatchbox at 180-185C, you may try to reduce temp.

Or you can try to keep this speed if you want, but reduce layer height to 0.15 or even 0.1.

Quote

Captain_Tim

My Kossel seems to be printing very well now, but there are still some problems with the print quality that I'd like some ideas on how to improve. I printed a Low Poly Bulbasaur using Hatchbox green 1.75mm PLA. I think it turned out quite well, especially since I wasn't expecting much. That being said, there are some imperfections. Here is an album with photos taken of the model.

The first and second pictures show a loose and sort of layer sag with the chin. My thoughts were that the filament wasn't cooling fast enough, because I don't have a fan blowing on the print bed. I don't want to get rid of the Z-probe yet, till I have everything I need to print out pual's probe adapter. If it is a heating issue and any of you know of a fan I could add, I'd love to see it. If you guys have a different idea of what it might be, I'm all ears.

Second and Third pictures show some layer separation on the forehead as well as the bulb. Any ideas why?

The last picture shows lighter bands of colour. It's hard to see in the photo, but they're there. I have no idea what could cause those.

PLA Settings: 200C first Layer, 195C second layer. Extrusion multiplier: 1.16

Print Settings:

- Layer Height: 0.2mm

- Perimeters: 2

- Solid Layers (Top & Bottom): 3

- Infill: 20%

- Perimeter Speed: 80mm/s

- External Perimeters: 50%

- Infill Speed 55mm/s

Any help would be great, but all in all, this is a pretty great printer.

Edited 1 time(s). Last edit at 02/27/2016 02:45PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 27, 2016 02:59PM |

Registered: 8 years ago Posts: 432 |

Btw before my cooler mod I used regular 80mm fan hotglued right to extrusion so it blowed parallel to the bed. Worked pretty well with PLA.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 27, 2016 10:15PM |

Registered: 8 years ago Posts: 63 |

Quote

docpayce

@spiffcow: Nope, not yet. Chinese new year can be a b***ch.It will still take like a week or so. Honestly, I am thinking about using magnetic rings / steel balls instead of plain Traxxas joints when switching to the new rods. Not sure though. Would mean I got to print a lot of other stuff (new carriages, new effector etc.) and right now I am happy with the print quality... "never change a running system".

@EvilBetty: Niiiiice setup! Got a thingiverse link?Let us know the results!!!

Anybody has experience with magnetic joints instead of Traxxas? Does it make the print quality / speed significantly better?

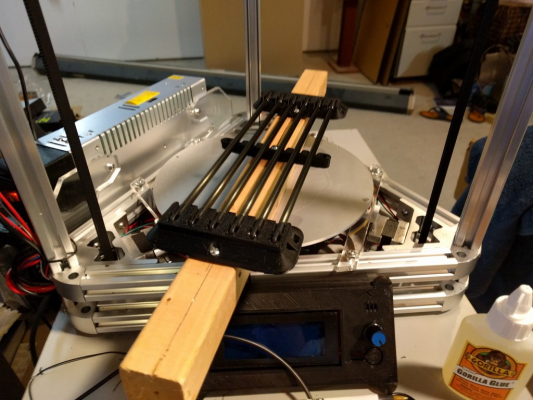

6 Pack

[www.thingiverse.com]

Single

[www.thingiverse.com]

Assembly tool.

[www.thingiverse.com]

There's No Place Like 127.0.0.1

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 27, 2016 10:20PM |

Registered: 8 years ago Posts: 63 |

Quote

paul_delta

PS: it's OK to make couple of them in one shot, but two of them (side rods) must be done using single jig. Having two glued rods it's OK to put another 4 between them using long M3 rod for example.

Update: I mean even if rods are not perpendicular to the M3 rods during gluing they still will be parallel to each other and equal, as well as M3 will be parallel too. Gluing all of them in one shot even using M3 rods there is a chance that you will get trapezoid, not rectangle/parallelogram.

I realized the potential flaw in using a 6x jig when assembling it. But I was able to get it %100 square after a lot of fiddling, and it resulted in 6 identical length rods. If I had to do it again though, I'd do them one by one.

For anyone who uses these "thick-wall" carbon tubes from TriDPrinting, using a 3.9xmm drill bit works perfect for making room for the 4mm threaded grub screws.

I actually tested this on some scrap I had left from the Folger Tech supplied tubes, and it worked well for those as well.

-EB

There's No Place Like 127.0.0.1

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 28, 2016 05:06AM |

Registered: 8 years ago Posts: 63 |

Quote

docpayce

@EvilBetty: Niiiiice setup! Got a thingiverse link?Let us know the results!!!

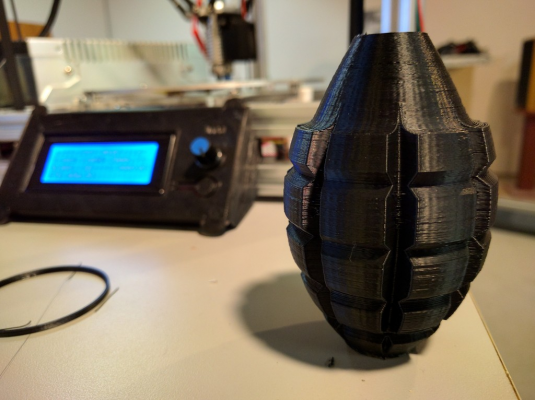

So far it looks like the new arms made a ton of difference.

They're da'bomb! (whaahaa)

There's No Place Like 127.0.0.1

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 28, 2016 02:40PM |

Registered: 8 years ago Posts: 98 |

Quote

EvilBetty

Quote

docpayce

@EvilBetty: Niiiiice setup! Got a thingiverse link?Let us know the results!!!

So far it looks like the new arms made a ton of difference.

They're da'bomb! (whaahaa)

Very nice! And that was just with a new set of traxxas arms?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 28, 2016 02:49PM |

Registered: 10 years ago Posts: 56 |

Quote

Captain_Tim

My Kossel seems to be printing very well now, but there are still some problems with the print quality that I'd like some ideas on how to improve. I printed a Low Poly Bulbasaur using Hatchbox green 1.75mm PLA. I think it turned out quite well, especially since I wasn't expecting much. That being said, there are some imperfections. Here is an album with photos taken of the model.

The first and second pictures show a loose and sort of layer sag with the chin. My thoughts were that the filament wasn't cooling fast enough, because I don't have a fan blowing on the print bed. I don't want to get rid of the Z-probe yet, till I have everything I need to print out pual's probe adapter. If it is a heating issue and any of you know of a fan I could add, I'd love to see it. If you guys have a different idea of what it might be, I'm all ears.

Second and Third pictures show some layer separation on the forehead as well as the bulb. Any ideas why?

The last picture shows lighter bands of colour. It's hard to see in the photo, but they're there. I have no idea what could cause those.

PLA Settings: 200C first Layer, 195C second layer. Extrusion multiplier: 1.16

Print Settings:

- Layer Height: 0.2mm

- Perimeters: 2

- Solid Layers (Top & Bottom): 3

- Infill: 20%

- Perimeter Speed: 80mm/s

- External Perimeters: 50%

- Infill Speed 55mm/s

Any help would be great, but all in all, this is a pretty great printer.

Hey!

In addendum to what the others already stated:

- It seems to me that you have quite some overextrusion (notice the blobs?). Maybe you want to have less of a extrusion multiplier. Even 100% is - in most cases - to much. 116% is REALLY much. Did you already calibrate your extruder steps/mm? And measure your filament diameter, too. Use that value in the slicer instead of the standard 1.75 value.

- Your temperature seems to be *a little* off. There is a little bit of stringing (= temp probably to high). Though 195 should be very fine. Retract ok? 3 mm works fine for me.

- 80 mm/s is on the really high speed side and the step down to 40 mms for external is quite steep for Bowden extruders. I tend to use 60 mm/s infill +45 mm/s for external perimeters for most prints plus a 10 sec minimum time per layer for better cooling. (8 secs also worked very fine for me). Consistent extrusion speed benefits print quality when it comes to Bowden extruders.

- Try out Cura!!!

I swear, try the same print with Cura instead of Slic3r. The result may be way better.

I swear, try the same print with Cura instead of Slic3r. The result may be way better.@Betty: THANKS!

Thats really promising to hear. I am really looking forward for mine now.

Thats really promising to hear. I am really looking forward for mine now.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 28, 2016 03:00PM |

Registered: 8 years ago Posts: 188 |

Quote

docpayce

Hey!

In addendum to what the others already stated:

- It seems to me that you have quite some overextrusion (notice the blobs?). Maybe you want to have less of a extrusion multiplier. Even 100% is - in most cases - to much. 116% is REALLY much. Did you already calibrate your extruder steps/mm? And measure your filament diameter, too. Use that value in the slicer instead of the standard 1.75 value.

- Your temperature seems to be *a little* off. There is a little bit of stringing (= temp probably to high). Though 195 should be very fine. Retract ok? 3 mm works fine for me.

- 80 mm/s is on the really high speed side and the step down to 40 mms for external is quite steep for Bowden extruders. I tend to use 60 mm/s infill +45 mm/s for external perimeters for most prints plus a 10 sec minimum time per layer for better cooling. (8 secs also worked very fine for me). Consistent extrusion speed benefits print quality when it comes to Bowden extruders.

- Try out Cura!!!I swear, try the same print with Cura instead of Slic3r. The result may be way better.

Thanks for your advice. I'll definitely try it out. I still think the print quality is pretty good for the price of the printer. Good thing I bought it when the Canadian dollar was worth more.

Owner of a QUBD Two Up

And

Folger Kossel 2020

And

Tevo Tarantula

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 28, 2016 04:14PM |

Registered: 8 years ago Posts: 432 |

I'd recommend to do single wall calibration one more time. Set the extrusion with to manual (0.5mm), measure the cube wall printed in vase mode and adjust calibration to get exactly 0.5mm wall. There is no need to measure exact filament diameter - multiplier does the trick. If you want to get very clean prints - you need to create profile for each filament spool using this method.

PS: there is a chance that the filament is not very dry and these blobs are just a steam bubbles. I'd recommend to store the filament in airtight container with a can of DumpRid. Silicagel doesn't work well but DumpRid does (calcium chloride). This way you will get very consistent prints every time.

PPS: buy fragrance free DumpRid!

Edited 3 time(s). Last edit at 02/28/2016 04:23PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

PS: there is a chance that the filament is not very dry and these blobs are just a steam bubbles. I'd recommend to store the filament in airtight container with a can of DumpRid. Silicagel doesn't work well but DumpRid does (calcium chloride). This way you will get very consistent prints every time.

PPS: buy fragrance free DumpRid!

Quote

docpayce

- It seems to me that you have quite some overextrusion (notice the blobs?). Maybe you want to have less of a extrusion multiplier. Even 100% is - in most cases - to much. 116% is REALLY much. Did you already calibrate your extruder steps/mm? And measure your filament diameter, too. Use that value in the slicer instead of the standard 1.75 value.

Edited 3 time(s). Last edit at 02/28/2016 04:23PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 28, 2016 04:41PM |

Registered: 8 years ago Posts: 432 |

deleted

Edited 1 time(s). Last edit at 02/28/2016 04:52PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

Edited 1 time(s). Last edit at 02/28/2016 04:52PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 28, 2016 05:16PM |

Registered: 8 years ago Posts: 63 |

Quote

spiffcow

Very nice! And that was just with a new set of traxxas arms?

Yes. My Folger Tech ball end / carbon tube arms were about 0.5mm off in total from each other, and were also "bent". Bent meaning the ball ends were not straight coming off the rods. Not sure if they were warped, or cross-threaded, so I though I'd give this a try.

The one test left will be printing a couple full bed calibration objects later today. If it's consistent across the bed I'll call this solved. But since I can no longer measure any effector tilt, I have high hopes.

Also the whole assembly is has almost no slop now.

-EB

There's No Place Like 127.0.0.1

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 29, 2016 05:23AM |

Registered: 10 years ago Posts: 56 |

Quote

paul_delta

I'd recommend to do single wall calibration one more time. Set the extrusion with to manual (0.5mm), measure the cube wall printed in vase mode and adjust calibration to get exactly 0.5mm wall. There is no need to measure exact filament diameter - multiplier does the trick. If you want to get very clean prints - you need to create profile for each filament spool using this method.

PS: there is a chance that the filament is not very dry and these blobs are just a steam bubbles. I'd recommend to store the filament in airtight container with a can of DumpRid. Silicagel doesn't work well but DumpRid does (calcium chloride). This way you will get very consistent prints every time.

+1 on that calcium chloride container. Works like a charm.

The benefit of measuring the filament diameter is that you will have to do the thin wall calibration once per extrusion nozzle and not once per filament roll imho. If you calibrated your thin wall to within +/- 1% flow rate for one filament, you can change to another roll by just changing the filament diameter setting in the slicer. Worked out very well for me up to now. I set the flow rate to 90% ... 92% and no matter what filament I use, I get very, very consistent results.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 01, 2016 07:13AM |

Registered: 8 years ago Posts: 26 |

Ive had a new issue with Repetier host . I've been calibrating and printing more or less successfully for the past week but the last couple of times i fired up the delta to print Repetier Host immediately force closes on startup. This happens before hooking up the usb connection. I'm running windows 7 64bit with the latest microsoft net downloads etc. I've had to completely reinstall repetier host both times to "fix" the issue. I've had no problems connecting with the arudino, etc and once I've reinstalled and replugged in my folgers parameters, repetier host works like a champ, starts and runs . I found a reference to the above behavior on the repetier host wiki and tried the suggested fixes, ie... arial font update and updating the net frame work but to no avail. What am I missing, is it some obscure corruption bug, or as is more likely, am i somehow causing this glitch? As always, a preemptive thanks to the forum for tolerating my questions.

Sorry, only registered users may post in this forum.