Foldable, portable CoreXY (Fusebox derivative)

Posted by lkcl

|

Foldable, portable CoreXY (Fusebox derivative) March 14, 2016 07:34PM |

Registered: 8 years ago Posts: 776 |

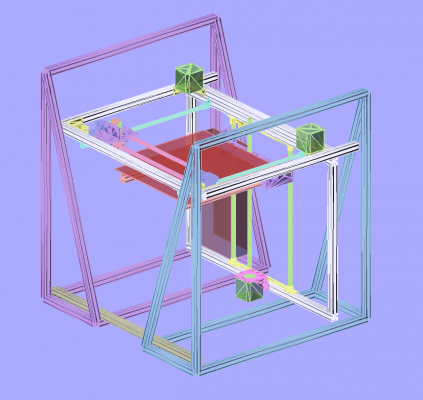

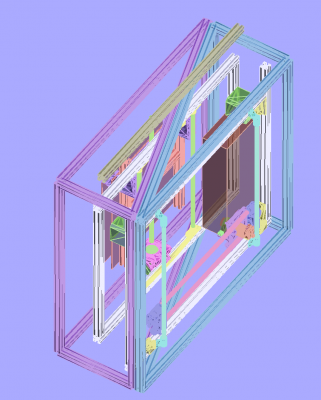

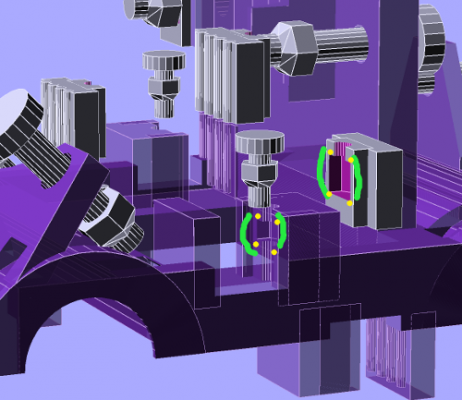

if anyone's interested i'm doing a foldable, portable 3d printer that is based on the fusebox (a corexy design). i will be moving every month for a year, to a different country each time, developing an eco-conscious laptop and i cannot be without a 3d printer. if anyone's interested do contact me. outer dimensions of the box when stowed are 457 x 405 x 150mm. CAD design is being developed here:

git clone [hands.com] and you can take a look. review assistance greatly appreciated.

Edited 2 time(s). Last edit at 03/14/2016 07:38PM by lkcl.

git clone [hands.com] and you can take a look. review assistance greatly appreciated.

Edited 2 time(s). Last edit at 03/14/2016 07:38PM by lkcl.

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 14, 2016 07:53PM |

Registered: 10 years ago Posts: 179 |

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 15, 2016 06:06AM |

Registered: 8 years ago Posts: 776 |

same as the fusebox - 200x200. i chose that design to copy because of its low cost, clear BOM, and that it used primarily 3d-printed parts. the disadvantage (not really - more like a surprise) is that the empty space surrounding the bed is, for a corexy printer, really really large. i keep looking at it and i keep wondering how it would be possible to rearrange the motors and parts to lose at least 50mm on the left and right sides.Quote

Edvardas

How big is the printbed?

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 15, 2016 08:24AM |

Registered: 11 years ago Posts: 5,780 |

A few dumb questions:

Is your folded version any more portable than the printer you started with?

What is the target for portability- fitting into a car, on an airplane, shipping in a box, carrying in a backpack?

How do you guarantee that the XY plane is orthogonal to the Z axis when the printer is reassembled?

Where are the electronics?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Is your folded version any more portable than the printer you started with?

What is the target for portability- fitting into a car, on an airplane, shipping in a box, carrying in a backpack?

How do you guarantee that the XY plane is orthogonal to the Z axis when the printer is reassembled?

Where are the electronics?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 15, 2016 09:37AM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

A few dumb questions:

there are no dumb questions - only reaally dumb answers

Quote

the_digital_dentist

Is your folded version any more portable than the printer you started with?

ohhh yeah - most definitely. the fusebox is.. what... a cube approximately 450 on a side? this is *150*mm high when stowed. i might even be able to manage 120mm if i'm careful, but given that the carryon luggage limit is 9in (220mm) i'm tempted to make available space for storing filament inside, as well as some 3ply / polycarb to make a heated chamber.

*but*, also, if i *can* make the box halves meet in the middle (currently they don't, hence the reason for that brown extra strut at the bottom) then the two box halves can be joined together (hooks or splitting-hinges) which would be great.

just have to see how it goes, there.

Quote

the_digital_dentist

What is the target for portability- fitting into a car, on an airplane, shipping in a box, carrying in a backpack?

airplane is the primary one. carrying in a backpack would be nice, although i am thinking of adding wheels and a handle so it can roll along on its own. only concern there is vibration trashing the parts and electronics, so might not do that - bit too much work and i am short on time.

Quote

the_digital_dentist

How do you guarantee that the XY plane is orthogonal to the Z axis when the printer is reassembled?

right. that's complicated to explain in words, but these videos might help - a couple of days ago i did cardboard mockups (which takes waaay less time than fracking about with CAD)... ok grab the latest 3 here [www.youtube.com]

basically, it works as follows:

- the critical criteria to satisfy is that every face of the cube is diagonally-braced in some fashion.

- the outer box (when split) left and right faces contain plywood (or other material) so left and right are sorted

- the back is the "Z assembly" which will be corner-braced then attached in FOUR places to the outer box halves (left-up, left-down, right-up, right-down).

- additional attachment - the lower strut of the "Z assembly" in TWO additional places at the bottom, to the left outer half and right outer half, provide additional back-face bracing

- the "TopCoreXY assembly" will be attached in FOUR places to two parallel rails (one on each of the outer box halves). this ensures that the top is absolutely level relative to the box

- a front brace (separate piece) shown in brown in both photos above will be attached in FOUR places, two on each of the outer box halves, to complete a front face.

- the "TopCoreXY assembly" will have corner-brace plates so that it is rigid.

so. as the box is rectangular, and the "Z-Assembly" is attached firmly to the upright of the box, and the "XY Assembly" is attached firmly to horizontal struts of the box, right-angles and stiffness are maintained.

Quote

the_digital_dentist

Where are the electronics?

i've added a mockup of those in the latest revision, i'm leaning towards the RAMBOv1.2, and it's in the opposite lower corner to the PSU (dark brown box at the back). i might move it to top-middle of the "Z-Assembly" so as to keep wires short - just have to see how that goes, i'm planning to move the Z-Rail assembly back a bit if that's at all possible.

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 15, 2016 10:45AM |

Registered: 10 years ago Posts: 179 |

Do you need 200mm of printbed space on Y plane? I would guess that you could make a printer with a 200mm wide frame in Y plane that has around 150mm of usable printbed space. Relocating the motors like on this printer would give some extra space [forums.reprap.org]

220mm that is allowed is not really something that would call for a foldable printer. 100mm would be it.

Have you considered the airport security's reaction about you bringing a reprap printer as a carry-on?

220mm that is allowed is not really something that would call for a foldable printer. 100mm would be it.

Have you considered the airport security's reaction about you bringing a reprap printer as a carry-on?

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 15, 2016 03:07PM |

Registered: 10 years ago Posts: 651 |

I'm interested in something like this. Though my reasons would be easy storage rather than travel. I'll be moving into a very small place and there won't be room to have a printer out permanently. One of the criteria would also be ease of unpacking. It would look to me like your design would require to take one of the triangular frames, detach it and flip it around for stowing. I'd also be curious how you'll attach the extrusion to one another at those sharp angles and ensure it's rigid.

I'll say that I've had multiple designs rolling around in my head, from Cartesian to Delta to Core XY, and I like the idea of a folding Core XY.

Edited 1 time(s). Last edit at 03/15/2016 03:09PM by FA-MAS.

I'll say that I've had multiple designs rolling around in my head, from Cartesian to Delta to Core XY, and I like the idea of a folding Core XY.

Edited 1 time(s). Last edit at 03/15/2016 03:09PM by FA-MAS.

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 15, 2016 05:19PM |

Registered: 8 years ago Posts: 776 |

i definitely, definitely need a full 200x200 range. the reason is because i am printing parts for the EOMA68 15.6in Libre Eco-Laptop that i'm developing, and the longest parts are 230mm x 16mm x 12mm. the diagonal of a 200x200 is 280(ish) mm. so, i'm targetting a full 200x200mm range. height is no big deal for me, so i'll be happy if i get 150mm height. it should be way more than that using 280mm screw-rods.Quote

Edvardas

Do you need 200mm of printbed space on Y plane?

ok, here's a picture (below) which shows the current rearrangement, mostly i've focussed today on the top CoreXY parts. everything's lifted up by a huge 40mm margin so that the rods sit on *top* of the Misumi1515 extrusion. what that's allowed is the entire y-assembly to fit just underneath the front idlers, the motors and the idlers themselves have moved inwards by 15mm, and i've rearranged the position of the GT2 rollers themselves to be further over... all that has resulted in the width dropping by almost *60mm*.Quote

I would guess that you could make a printer with a 200mm wide frame in Y plane that has around 150mm of usable printbed space. Relocating the motors like on this printer would give some extra space [forums.reprap.org]

yes, the motors themselves have moved further back - by about 60mm - as well as moving outwards by about 12mm, and upwards by about 25mm so that the bottom of the NEMA17s sits flush with the Misumi1515 extrusion.

what that means is that when the TopCoreXY assembly is folded back, there's nothing poking out - not even the printhead - so that the outer faces of the extrusion can sit flush against the inside of the box. also i can fit metal corner brace plates on all four corners, which is (a) crucial and (b) something that's missing on the original Fusebox design.

Quote

Have you considered the airport security's reaction about you bringing a reprap printer as a carry-on?

if they want to stow it in the hold that's fine with me. if they want me to send it by Fedex/DHL that's fine with me. i'll make sure i pack the interior with that foam stuff so that the assemblies all stay away from the box interior. as long as it arrives i'm happy.

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 15, 2016 05:34PM |

Registered: 8 years ago Posts: 776 |

cool. well, when i'm confident with each assembly i'll let you know, i'll be buying bits very soon, i am on a rather tight deadline.Quote

FA-MAS

I'm interested in something like this.

yeah my brother got a laptop - a large one - for exactly the same reason: they fold it away and put it into the bookcase.Quote

Though my reasons would be easy storage rather than travel. I'll be moving into a very small place and there won't be room to have a printer out permanently.

correct. there will be some hinge arrangements (split hinges like you get for removable doors) on the diagonals of each box half, you'd just slot them together. i haven't quite thought yet how to make sure the two halves stick together conveniently whilst also not impinging on the outer dimensions.... have to think about that a bit more...Quote

One of the criteria would also be ease of unpacking. It would look to me like your design would require to take one of the triangular frames, detach it and flip it around for stowing.

i covered the rigidity in the post to digital_dentist (above) - i want to keep the number of wing-nuts to a minimum so that they're not lost. upright posts (probably M4 or M5 part-threaded bolts), which there will be corresponding lockins that can be dropped down onto them... quite straightforward. what i might do is have the lockins be "slotted" so that you don't actually have to take the wing nut completely off... yeah it's quite straightforward really.Quote

I'd also be curious how you'll attach the extrusion to one another at those sharp angles and ensure it's rigid.

the key two areas of concern are the join between the two box halves (yes it can even be like a door hinge), and that the TopCoreXY assembly has metal corner-braces. as long as those hinges are rock-solid and the corner braces really are metal not plastic, then i am confident that this will be an incredibly stiff frame... ok, as stiff as 1515 extrusion, anyway. i belieeve i've parameterised the design enough to go to 2020... mmm... maybe i should check... oh darn, i know: screw-holes for the extrusion bolts.

well, feel free to make this one and/or help out if it's important to you, the git clone url is at the top of the thread, you'll need python2 and openscad. i'm planning to put the BOM (descriptions, urls) in the python program and have it be auto-generated - including QTY and yes that includes nuts and bolts.Quote

I'll say that I've had multiple designs rolling around in my head, from Cartesian to Delta to Core XY, and I like the idea of a folding Core XY

.

Edited 1 time(s). Last edit at 03/15/2016 05:35PM by lkcl.

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 15, 2016 06:21PM |

Registered: 10 years ago Posts: 651 |

How about placing the Z axis assembly on one of the squares of your support structure (lets say blue assembly), then you could eliminate the need for those extra extrusions to support it on it's own and also not have to worry about how you're going to attach/detach it when you're setting up/tearing down.

You could even do something similar with the XY stage, permanently hinge it to the other support structure (lets say purple one) and just make sure you've developed a solid method for fastening it to the other one when it's deployed and also when it's folded back in for being stowed.

Do that with the XY stage, then it will be connected solid at the top when deployed, all you'd have to do is develop a solid way of clamping where the blue and purple pieces meet at the bottom together.

Edited 1 time(s). Last edit at 03/15/2016 06:29PM by FA-MAS.

You could even do something similar with the XY stage, permanently hinge it to the other support structure (lets say purple one) and just make sure you've developed a solid method for fastening it to the other one when it's deployed and also when it's folded back in for being stowed.

Do that with the XY stage, then it will be connected solid at the top when deployed, all you'd have to do is develop a solid way of clamping where the blue and purple pieces meet at the bottom together.

Edited 1 time(s). Last edit at 03/15/2016 06:29PM by FA-MAS.

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 15, 2016 07:56PM |

Registered: 8 years ago Posts: 776 |

i liked this idea! so i thought about it seriously, here's what i thought would be problems:Quote

FA-MAS

How about placing the Z axis assembly on one of the squares of your support structure (lets say blue assembly)...

[snip]

wires. my main concern would be that the z-assembly and topcorexy-assembly would need to be separated (not hinged or attached), and that would mean heater, thermistor, x, y and extrusion motor wires and end-stop switches would all be dangling.

second thing: i'm trying not to replace all the original fusebox STL files, keeping them as-is. one modification required and i am replacing the part with a pyopenscad reverse-engineered alternative. it's extra work. now, the reason i mention that is because to have the z-assembly hinged and go flat against the case, it would be necessary to move all the Z-assembly parts - motor, uprights etc. - all to the *other* side. currently they are inboard: they would all need to be moved outboard, so that nothing sticks through the box when the z-assembly is rotated to "flat".

... basically it's quite a lot of thought, and redesign work.

actually, turns out, using cardboard models, you just need a hinge not a hard, solid clamp, so i plan to use something like those two-piece door hinges. the critical thing is, for that to work (hinges instead of hard-clamped attachment), all other 5 sides must *not* have any kind of shear, i.e. must be corner-braced, diagonally-braced or simply filled entirely with plywood / polycarb.Quote

all you'd have to do is develop a solid way of clamping where the blue and purple pieces meet at the bottom together.

as those criteria for all 5 sides are in fact true, disassemblable two-piece door hinge arrangements are fine. cool, huh? video showing the cardboard model is in my collection on youtube, link is above.

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 21, 2016 07:00PM |

Registered: 8 years ago Posts: 776 |

ok so progress so far is that i have all the components ordered except for wires and connectors, and i have the frame (box, zassembly, topcorexy) 100% completed except for: (a) filling in the panels in the diagonals (b) clips for when the box is stowed (c) critical corner-braces for the topcorexy assembly.

now, i bought hardboard to fill in the panels of the box halves - it was simple to source, cheap to get, easy to drill by hand, and the store cut everything to size, perfectly, including the diagonal pieces. i haven't put the diagonals in because, duh, stiffening up a triangle didn't seem like a productive use of limited time i put in *sixteen* nuts and bolts per panel, 4 along each edge, and actually the openbeam extrusion is now *exclusively* attached to the panels.

i put in *sixteen* nuts and bolts per panel, 4 along each edge, and actually the openbeam extrusion is now *exclusively* attached to the panels.

regarding the L-brackets that i got from openbeam: as structural components they are, i have to be bluntly honest here, absolutely worse than completely useless. the flat 90 degree corner plates were also absolutely useless. i've gone ahead and ordered some triangular corner braces from a random ebay supplier: they're 50mm long and 15mm deep so should be perfect.

the problem with the L-brackets is that they're made from folded sheet metal - a 90 degree bend. so if you create a square with them and push it to the side in a trapezoid, the steel simply... bends.

the problem with the 90 degree flat plates is: to ensure that a square cannot move, the bolts have to be absolutely rock solid (because the holes in the rails are 3.5mm wide and the bolts are 3.0mm).... and of course because of the amount of play, the bolts shear sideways. to overcome this it becomes necessary to tighten up the M3 bolts so hard that you risk stripping them. and they will simply shake loose anyway. and you'd end up tightening them down in the wrong shape.

so, overall, absolutely f*****g useless for the job. i tried putting both L-brackets and 90 degree plates on: worse than useless, and a waste of *NINE* nuts and bolts per pair of bars being joined together.

in complete contrast, the misumi HBLTBS3 corner braces are extruded aluminium triangles with interlocks into the rails along the centre, where you would put two bolts in the insides (just like with L brackets), and the two extrusions connected into them will make an absolutely rock-solid corner. the cheaper steel angle-corners that i got are a reasonable substitute: you have to bolt them in 4 places onto the inside of the two extrusions, and the load is transferred onto the triangle-part, meaning that just like the HBLTBS3's they won't move *at all*.

the top core xy assembly is something that i absolutely have to have absolutely rock-solid. the stiffness critically, critically depends on that top frame being rigid. having assembled the whole box (using those L-brackets for now), i tried wiggling the frame around - and indeed, the whole thing sheared around, because those L-brackets are so completely useless.

it's going to be a few days before the corner-triangular-brackets arrive off of ebay, so what i might do in the meantime is get some metal strap (you know the sort of thing - galvanised steel), and wrap one piece around each corner, bolting it down in at least two pieces per strap. that will do the job but it's not going to look pretty. i will at least have a stable frame, and i will be happy from an engineering perspective, not from an aesthetic one

now, i got so annoyed with the openbeam L-brackets and 90 degree corner plates that, when putting on the hardboard onto the box halves, i took *all* of them off. ironically it turns out that there is actually a purpose to the L-brackets: they stop the bars that they're connected to from rotating about their centre. given that the hardboard has some slight flex, it's actually possible to rotate the bars! but, the main thing is: it's not possible to shear the bars sideways, and when the x-assembly and the z-assembly are attached, the critical bars they're attached to can't rotate. so.... i'm not hugely concerned.

in a redesign i think what i will do is use little corner cubes. apart from anything, the assembly process is like a bleedin chinese puzzle box - literally! all the bars slot into 4 bolts which are pre-attached to the hardboard. however, once you have one bar in place because it is completely flush with the hardboard it *blocks* the possibility of sliding the two bars at right-angles in from that edge. so they have to slide in from the top...

.... i'll do some photos of all this, tomorrow...

anyway if i was using corner cubes, then individual bars could be removed and inserted without needing any particular order. this would be important for repairs, as right now the entire box pretty much needs to be disassembled just to fit in one replacement piece! the only down-side is that the bars then need to be cut dead-accurate, and i am using a (bloody dangerous) hand-held 20,000 RPM 125mm disc cutter. towards the end of the cutting, after an hour of use, the disc (i only had the one) began to wear out and would vibrate and buckle. scary as hell because if the metal extrusion bites into a 20,000 RPM disc it tends to fly off in the direction of travel of the disc, torquing the tool really hard, *really* fast, shattering the disc, ripping the metal out of your hand (which isn't fun because you're holding onto it really hard, at the time). you can tell, yes i've done this before, a few years ago - i did a lot of steel metalwork and welding. i had gloves, goggles and a leather apron then: i have none of that now! soo next time i will arrange for the bars to be cut to 0.1mm accuracy by someone with decent equipment, and then cubes will be feasible.

now, i bought hardboard to fill in the panels of the box halves - it was simple to source, cheap to get, easy to drill by hand, and the store cut everything to size, perfectly, including the diagonal pieces. i haven't put the diagonals in because, duh, stiffening up a triangle didn't seem like a productive use of limited time

i put in *sixteen* nuts and bolts per panel, 4 along each edge, and actually the openbeam extrusion is now *exclusively* attached to the panels.

i put in *sixteen* nuts and bolts per panel, 4 along each edge, and actually the openbeam extrusion is now *exclusively* attached to the panels.regarding the L-brackets that i got from openbeam: as structural components they are, i have to be bluntly honest here, absolutely worse than completely useless. the flat 90 degree corner plates were also absolutely useless. i've gone ahead and ordered some triangular corner braces from a random ebay supplier: they're 50mm long and 15mm deep so should be perfect.

the problem with the L-brackets is that they're made from folded sheet metal - a 90 degree bend. so if you create a square with them and push it to the side in a trapezoid, the steel simply... bends.

the problem with the 90 degree flat plates is: to ensure that a square cannot move, the bolts have to be absolutely rock solid (because the holes in the rails are 3.5mm wide and the bolts are 3.0mm).... and of course because of the amount of play, the bolts shear sideways. to overcome this it becomes necessary to tighten up the M3 bolts so hard that you risk stripping them. and they will simply shake loose anyway. and you'd end up tightening them down in the wrong shape.

so, overall, absolutely f*****g useless for the job. i tried putting both L-brackets and 90 degree plates on: worse than useless, and a waste of *NINE* nuts and bolts per pair of bars being joined together.

in complete contrast, the misumi HBLTBS3 corner braces are extruded aluminium triangles with interlocks into the rails along the centre, where you would put two bolts in the insides (just like with L brackets), and the two extrusions connected into them will make an absolutely rock-solid corner. the cheaper steel angle-corners that i got are a reasonable substitute: you have to bolt them in 4 places onto the inside of the two extrusions, and the load is transferred onto the triangle-part, meaning that just like the HBLTBS3's they won't move *at all*.

the top core xy assembly is something that i absolutely have to have absolutely rock-solid. the stiffness critically, critically depends on that top frame being rigid. having assembled the whole box (using those L-brackets for now), i tried wiggling the frame around - and indeed, the whole thing sheared around, because those L-brackets are so completely useless.

it's going to be a few days before the corner-triangular-brackets arrive off of ebay, so what i might do in the meantime is get some metal strap (you know the sort of thing - galvanised steel), and wrap one piece around each corner, bolting it down in at least two pieces per strap. that will do the job but it's not going to look pretty. i will at least have a stable frame, and i will be happy from an engineering perspective, not from an aesthetic one

now, i got so annoyed with the openbeam L-brackets and 90 degree corner plates that, when putting on the hardboard onto the box halves, i took *all* of them off. ironically it turns out that there is actually a purpose to the L-brackets: they stop the bars that they're connected to from rotating about their centre. given that the hardboard has some slight flex, it's actually possible to rotate the bars! but, the main thing is: it's not possible to shear the bars sideways, and when the x-assembly and the z-assembly are attached, the critical bars they're attached to can't rotate. so.... i'm not hugely concerned.

in a redesign i think what i will do is use little corner cubes. apart from anything, the assembly process is like a bleedin chinese puzzle box - literally! all the bars slot into 4 bolts which are pre-attached to the hardboard. however, once you have one bar in place because it is completely flush with the hardboard it *blocks* the possibility of sliding the two bars at right-angles in from that edge. so they have to slide in from the top...

.... i'll do some photos of all this, tomorrow...

anyway if i was using corner cubes, then individual bars could be removed and inserted without needing any particular order. this would be important for repairs, as right now the entire box pretty much needs to be disassembled just to fit in one replacement piece! the only down-side is that the bars then need to be cut dead-accurate, and i am using a (bloody dangerous) hand-held 20,000 RPM 125mm disc cutter. towards the end of the cutting, after an hour of use, the disc (i only had the one) began to wear out and would vibrate and buckle. scary as hell because if the metal extrusion bites into a 20,000 RPM disc it tends to fly off in the direction of travel of the disc, torquing the tool really hard, *really* fast, shattering the disc, ripping the metal out of your hand (which isn't fun because you're holding onto it really hard, at the time). you can tell, yes i've done this before, a few years ago - i did a lot of steel metalwork and welding. i had gloves, goggles and a leather apron then: i have none of that now! soo next time i will arrange for the bars to be cut to 0.1mm accuracy by someone with decent equipment, and then cubes will be feasible.

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 22, 2016 07:38AM |

Registered: 8 years ago Posts: 776 |

ok here's a link to the photos:

[lkcl.net]

FA-MAS, i've taken close-ups of the various joins - they're wing-nut-based, i'm not totally happy with all of them, in particular i thought it would be a smart idea to make a single piece of plastic that joins together both the top of the z-assembly (vertcally) with the back of the top assembly (horizontally). turns out that this is a _complete_ pain for getting at the horizontal wing-nut so that idea's a bust - i'll alter it so that they're separate, and easier to get at.

so that idea's a bust - i'll alter it so that they're separate, and easier to get at.

the frame join-parts i've added interlocks so that when the box is stowed, those frame join-parts slide together and keep the two halves of the box together. might as well do that as much as possible. the last of those photos (IMG_00026.JPG) shows how one corner of the case fits in, but i've redesigned the four parts that join the box together so that they do the same thing... *and* they lock into each other when the printer is in "assembled" mode, too.

it's getting there

[lkcl.net]

FA-MAS, i've taken close-ups of the various joins - they're wing-nut-based, i'm not totally happy with all of them, in particular i thought it would be a smart idea to make a single piece of plastic that joins together both the top of the z-assembly (vertcally) with the back of the top assembly (horizontally). turns out that this is a _complete_ pain for getting at the horizontal wing-nut

so that idea's a bust - i'll alter it so that they're separate, and easier to get at.

so that idea's a bust - i'll alter it so that they're separate, and easier to get at.the frame join-parts i've added interlocks so that when the box is stowed, those frame join-parts slide together and keep the two halves of the box together. might as well do that as much as possible. the last of those photos (IMG_00026.JPG) shows how one corner of the case fits in, but i've redesigned the four parts that join the box together so that they do the same thing... *and* they lock into each other when the printer is in "assembled" mode, too.

it's getting there

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 22, 2016 09:06PM |

Registered: 8 years ago Posts: 776 |

Quote

FA-MAS

How about placing the Z axis assembly on one of the squares of your support structure (lets say blue assembly), then you could eliminate the need for those extra extrusions to support it on it's own and also not have to worry about how you're going to attach/detach it when you're setting up/tearing down.

.

hi FA-MAS, i mentioned i liked this idea, but couldn't think at the time how it would work. i had an idea a day or so ago, to basically have a standard briefcase-style box, where the lid is split in two along the middle, so two doors like a large double-door wardrobe. then, also, a panel comes off the base, which is split down the middle and has hinges.

to assemble this concept, you would:

- orientate the box so it's upright like a large wardrobe

- open up the wardrobe-doors to 90 degrees

- take the back panel off and hinge that to 90 degrees as well

- drop the "back" panel into locks in the *bottom* of the wardrobe doors in 4 places

- rotate the x-assembly through 90 degrees and lock it in 2 places at the *top* of the wardrobe doors

- raise the printbed through 90 degrees and lock that down as well

now, the reason for taking the back panel off and putting it onto the lower-front is to ensure that the double doors create a stable box when assembled. if you had just the one panel rather than two, you end up with flex on whatever side you *don't* put the extra panel. so, if you put the panel at the bottom, then the box will flex (rotate, shear) around a line going through the front of the box. and if you only put the panel at the front, then not only will the double doors wobble trapezoid-wise (especially at the bottom), but also the box will flex (rotate, shear) around a line going through the top of the box.

the advantage of removing a back panel, is easy access to components, but also i think it might be possible to arrange to hinge the topcorexy assembly so that motors and other bits poke *outside* of the box when it's assembled.

apologies this is all in words, i'd need to model it to show you properly. but... all this is "revision 2"

i am in rather urgent need of this portable printer being ready within the next 2 weeks, i have a lot to do.

i am in rather urgent need of this portable printer being ready within the next 2 weeks, i have a lot to do.l.

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 23, 2016 03:08PM |

Registered: 10 years ago Posts: 651 |

The pictures are pretty much how I envisioned it'd work and I like the way the casing would work.

I was also thinking about the collapsible print bed. I might suggest having it fold the opposite way from what you're planning. Reasoning being is that it's already cantilevered, and the bed itself and any weight put on end further from the rods may cause it to sag. You'll want to be resisting it to sag rather than hinging it that direction, and even though not intentional, providing it further potential to sag that direction. I'm thinking there may be a less complicated, and potentially less room for error design. I might suggest looking into a design that folds the bed upward, that way when it's deployed, it folds down and hits a hard stop designed into the bed mount, maybe even adjustable to allow compensation for any potential sag.

Think of it like this, if you unfold to 90 degrees, the weight of the bed alone may push that to 92 degrees. If you say allow it to adjust to only go to 88 degrees, and the weight of the bed still takes it another 2 degrees, then you're at 90.

I'll see if I can model it up.

Edited 3 time(s). Last edit at 03/23/2016 03:24PM by FA-MAS.

I was also thinking about the collapsible print bed. I might suggest having it fold the opposite way from what you're planning. Reasoning being is that it's already cantilevered, and the bed itself and any weight put on end further from the rods may cause it to sag. You'll want to be resisting it to sag rather than hinging it that direction, and even though not intentional, providing it further potential to sag that direction. I'm thinking there may be a less complicated, and potentially less room for error design. I might suggest looking into a design that folds the bed upward, that way when it's deployed, it folds down and hits a hard stop designed into the bed mount, maybe even adjustable to allow compensation for any potential sag.

Think of it like this, if you unfold to 90 degrees, the weight of the bed alone may push that to 92 degrees. If you say allow it to adjust to only go to 88 degrees, and the weight of the bed still takes it another 2 degrees, then you're at 90.

I'll see if I can model it up.

Edited 3 time(s). Last edit at 03/23/2016 03:24PM by FA-MAS.

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 23, 2016 07:14PM |

Registered: 8 years ago Posts: 776 |

Quote

FA-MAS

The pictures are pretty much how I envisioned it'd work and I like the way the casing would work.

I was also thinking about the collapsible print bed. I might suggest having it fold the opposite way from what you're planning. Reasoning being is that it's already cantilevered, and the bed itself and any weight put on end further from the rods may cause it to sag.

right. that's why alex_f used 45mm (LM8LUU) bearings. what i've done, is, make a *second* set of sliding holders that go above those (using 25mm bearings), and then there are *four* wing-nuts that lock the upper and lower linear bearing-holders onto each other, to make two huge 75mm linear assemblies. surprisingly this huge linear assembly length doesn't restrict the travel because the z-rods are 300mm long.

so i have no fear that the sliding part is going to rotate at all.

attached to those however are *twelve* 625 bearings - six on each side. two on the bottom of the linear assembly, two on the top, and two on the bars underneath the bed:

you can see there are 50 degree short extrusions across from the bottom of the linear assemblies onto the underside of the bed's H extrusion

now, if there's any play in those bearings, then yes you'd be absolutely right, you're going to get not just sag but wobble.as well. i will be adjusting the tightness of the bolts, here, and using part-threaded bolts (when i can get them).

Quote

You'll want to be resisting it to sag rather than hinging it that direction, and even though not intentional, providing it further potential to sag that direction. I'm thinking there may be a less complicated, and potentially less room for error design. I might suggest looking into a design that folds the bed upward, that way when it's deployed, it folds down and hits a hard stop designed into the bed mount, maybe even adjustable to allow compensation for any potential sag.

Think of it like this, if you unfold to 90 degrees, the weight of the bed alone may push that to 92 degrees. If you say allow it to adjust to only go to 88 degrees, and the weight of the bed still takes it another 2 degrees, then you're at 90.

I'll see if I can model it up.

done that already

you can grab the source from the git clone link at the start of this thread. dependencies are python2 and a *recent* version of openscad, which you may need to compile up by hand but for god's sake don't use qt5, use qt4.

you can grab the source from the git clone link at the start of this thread. dependencies are python2 and a *recent* version of openscad, which you may need to compile up by hand but for god's sake don't use qt5, use qt4.now, i am really not expecting there to be 2 degrees of sag. if that's the case, then i've made a seriously bad design decision, which i'll have to live with for a while until i can design something else. simplest thing is, yes, as you suggest, have hard stops in the way, which end up slightly bending things (preferably plastic things!) - actually that would be really simple to arrange, now that i think about it. if the push-stops are attached to the underside of the bed's H extrusion they could be slid along, adjusted until at the correct point, then locked down. yeah. i like that.

the idea is, then, that, on first setup you would:

- put the whole thing together loosely

- lock down the two sets of linear assemblies rock-solid into single 75mm assemblies

- tighten up everything but the bearing-holders at each end of the 50-degree extrusion

- spirit-level and support the printbed

- move the push-stop along so that it pushes the 50-degree extrusion a bit

- finally tighten up the nuts on the bearing holders

it may be necessary to go round the loop a couple of times, loosen up the push-stops. but, finally if you're getting absolutely sick and tired of going round the loop on that, you just adjust the printbed, i got an alu mk 3 kit with the prusa spring-arrangement from reprap.me. the important thing is, as you say, to have push-stops that, when the linear-assemblies are locked together, the bed does *not* move.

sag can always be corrected for by lengthening or shortening those 50-degree extrusions. wobble *can't* be corrected for without some sort of push-stop to take up the slack in all the bearings.

btw, motors arrived today - PSU, E3D v6 extruder [niiice bit of kit], all-metal direct-drive bowden extruder, rods, rambo v1.2g, GT2 timing belt and a few other bits arrived yesterday. all i'm waiting for (by royal mail untrackable post arggggh, didn't spot that when buying from wedo3dprinting in the UK) is the LM8LUU bearings, MK8 drive gear, 625 bearings and the mechanical endstops.

once those are here i'll have everything i need, i'm about.... 75% the way through the 3d printed parts, just got the z-nut bridge and the underside of the H-bed parts to do...

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 23, 2016 07:37PM |

Registered: 8 years ago Posts: 776 |

Quote

FA-MAS

I might suggest looking into a design that folds the bed upward.

rright, slightly ahead of you here - i've been talking the "folding-upwards" idea over with a friend (over about 2-3 days). if you have pretty much the exact same design (angled supports) then no matter what you do, you're going to have play in the bearings.

what we came up with was this:

- turn the z-assembly round so that the z-motor is at the top, the z-thread hangs down

- have a pair of 130mm extrusions attached SOLIDLY to a *BOTTOM* pair of linear bearing-holders (45mm LM8LUUs), at 90 degrees.

- have the bed attached on a folding UPWARDS pair of *UPPER* linear bearing-holders (25mm LM8UUs)

- when assembled, you have 4 wing-nuts lock the print-bed's extrusions onto the 130mm extrusions sticking out from the bottom linear holders.

- to stow, you undo the 4 wing-nuts, lift the bed through 90 degrees so it is flat upwards, and then - this is the good bit, you SWING THE 130mm extrusions INWARDS - *underneath* the bottom of the z-rod - so that they too are flat.

cool, huh?

this avoids all the problems associated with play/travel in bearings, is simple to do a 1st assembly / test - just bolt those 130mm extrusions into place and the bed is guaranteed to be 90 degrees. no real need for the top linear bearings to be tightened down, in fact a little bit of play is necessary.

all the other arrangements we could think of, the z-threaded-rod was in the way. or there was the risk of breaking the printbed. the only other way we thought of doing it was a sarrus linkage, however after talking to chris (nophead), chris pointed out that the tolerances on the lengths of all the sarrus linkage bars needs to be extreme - thousandths of a millimetre - because any variation gets multiplied as the linkage extends upwards. but, the nice thing about a sarrus linkage is, just like a scissor-lift, it's flat-packable.

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 24, 2016 01:28PM |

Registered: 8 years ago Posts: 776 |

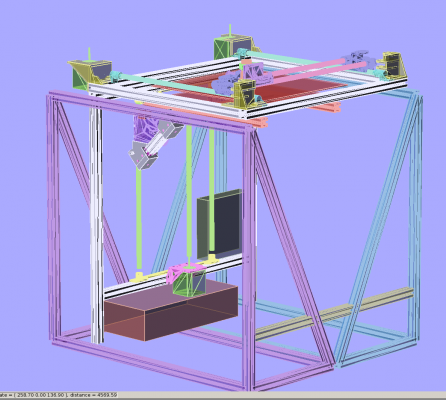

okaay so all the components arrive.... start assembly of the top corexy... can anyone spot the deliberate mistake?

yeees, that's right - i brought the damn y-rods in too far, argh, so that the belt is at an angle instead of straight. argh luckily i was designing something where there are 2 bearings which make the belt (both bits) turn 90 degrees, and the motor(s) are *inboard* by about 40-50mm. i was just planning to do this for revision 2.... and now i have to do it, oh well. all these ideas, i have, to reduce the size of this by another 20-30mm in different directions, i can't put them into practice yet because i'm on such a tight deadline! only the ones which are essential make it through... never mind....

luckily i was designing something where there are 2 bearings which make the belt (both bits) turn 90 degrees, and the motor(s) are *inboard* by about 40-50mm. i was just planning to do this for revision 2.... and now i have to do it, oh well. all these ideas, i have, to reduce the size of this by another 20-30mm in different directions, i can't put them into practice yet because i'm on such a tight deadline! only the ones which are essential make it through... never mind....

yeees, that's right - i brought the damn y-rods in too far, argh, so that the belt is at an angle instead of straight. argh

luckily i was designing something where there are 2 bearings which make the belt (both bits) turn 90 degrees, and the motor(s) are *inboard* by about 40-50mm. i was just planning to do this for revision 2.... and now i have to do it, oh well. all these ideas, i have, to reduce the size of this by another 20-30mm in different directions, i can't put them into practice yet because i'm on such a tight deadline! only the ones which are essential make it through... never mind....

luckily i was designing something where there are 2 bearings which make the belt (both bits) turn 90 degrees, and the motor(s) are *inboard* by about 40-50mm. i was just planning to do this for revision 2.... and now i have to do it, oh well. all these ideas, i have, to reduce the size of this by another 20-30mm in different directions, i can't put them into practice yet because i'm on such a tight deadline! only the ones which are essential make it through... never mind....

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 26, 2016 09:37AM |

Registered: 8 years ago Posts: 776 |

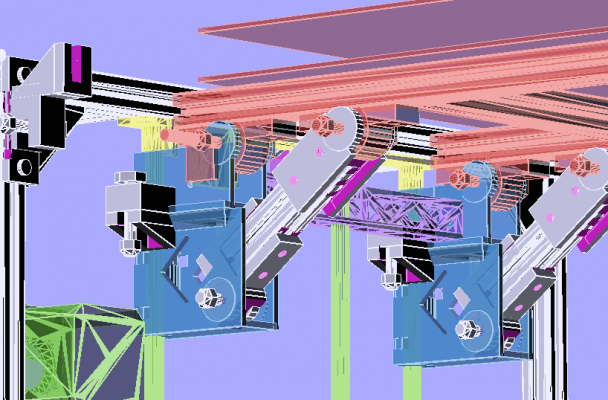

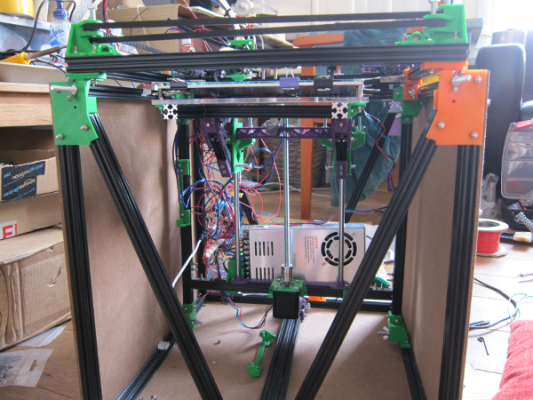

ok, sorted - you can see the motor's inboard by around 40mm, and there are two more idler bearings that turn each part of the belt through 90 degrees. i slightly messed up how close the belt gets on the outer bearing, i'll correct that shortly -there's plenty of room to do so. yay!

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 26, 2016 10:13AM |

Registered: 8 years ago Posts: 776 |

ok so here's the z-assembly, you can see the upright and folded arrangements - i had to do quite a bit of PLA cutting and filing, to get those to fit, i'll sort out the CAD to match what i had to do, but at least i have a working folding z-assembly which is the immediate requirement.

FAM - the bed ain't going anywhere. there's no play in the bearings, and the friction on all six hinges is so stiff that there's absolutely no movement. at all. i can hear something creaking when i flex the arms, but i haven't fully tightened everything up, it's not in the frame, and i haven't put the aluminium printbed on, yet.

FAM - the bed ain't going anywhere. there's no play in the bearings, and the friction on all six hinges is so stiff that there's absolutely no movement. at all. i can hear something creaking when i flex the arms, but i haven't fully tightened everything up, it's not in the frame, and i haven't put the aluminium printbed on, yet.

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 27, 2016 08:56PM |

Registered: 8 years ago Posts: 776 |

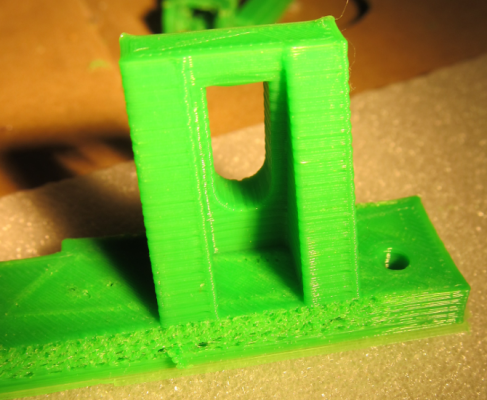

as i just explained on the Fusebox thread, i've had to redesign the carriage so that the belt locks are detachable / replaceable / reprintable. i'm using M2 pozi bolts and hex nuts because that's what i have, but the principle could be adapted to use anything up to M2.5 bolts.

basically what you do is, put the belt grabber 1/2 way into its slot, then drop an M2 bolt with its hex nut into the slot in the grabber, laying the bolt *horizontal*, and with the *nut* in the belt-grabber. you then push the belt-grabber down, and the M2 bolt pops upright as the nut is pushed downwards... that happens to push the nut into the handily-placed slot for it to fit, in the carriage.

the belt then goes in, and you then tighten up the bolt with a screwdriver. as it turns, it hits the end of the nut-slot in the belt-grabber, the nut begins to lift upwards and, when that reaches the limit of its travel, the bolt instead begins to force the belt-grabber downwards instead.

once the belt-grabber reaches *its* maximum travel, then the bolt works its way *in between* the belt-grabber and the carriage, forcing the belt-grabber to push against and compress the belt itself. also at the same time, the pozi head of the bolt comes down and keeps the belt-grabber down and in place, as well.

now, in the "small-scale" test where i printed out a tiny 15x15x20 piece of PLA just containing the part of the carriage which fitted one belt-grabber, the force of the M2 bolt between the two was enough to bend the plastic!

overall i'm much happier with this redesign. the original fusebox carriage part, when it was printed out, the gap is supposed to be something like 1.2mm. in reality, on the printer that i'm using it was between 0.0mm and 0.5mm. three hours with an xacto knife and a 1.0mm jeweller's screwdriver was *not enough* to sort out the channels. the plastic used to print out the original carriage is therefore completely wasted.

instead, in the redesign, the gap is about 3mm which is plenty of space for a mendel90 and cura to get its act together and not create any strands that might bridge over to the nearest other piece of plastic. and, if on printing up the belt-grabber parts any of them happen not to work out, then that's well below 1 gram of plastic wasted - takes about 2 minutes to print a replacement.

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 28, 2016 05:28PM |

Registered: 10 years ago Posts: 651 |

|

Re: Foldable, portable CoreXY (Fusebox derivative) March 31, 2016 12:46PM |

Registered: 8 years ago Posts: 776 |

ok nearly completed: i found that i need to redesign the extruder as it is jamming. everything else is working, despite having to jury-rig a pair of voltage divider circuits to replace the faulty ones on the Rambo v1.2g. the extruder uses 3mm PLA because i have over 400 metres of PLA still which needs using up, from the mendel90 which this printer is replacing. hence, i have had to redesign it because the all-metal one is not suitable for the OD 6mm tubing that comes with the E3Dv6 3mm kit.

nearly there!

nearly there!

|

First print on the Sandwich200 April 04, 2016 06:59AM |

Registered: 8 years ago Posts: 776 |

[youtu.be]

it's working! still a work-in-progress but it is basically working and producing useable quality prints. i am currently testing 300mm/sec - there is a little bit of zagging (diagonal breaks on outer shells) - and in stand-alone tests i managed to get an extrusion rate of 200mm/min without skipping.

to get that ridiculously-high extrusion rate i had to:

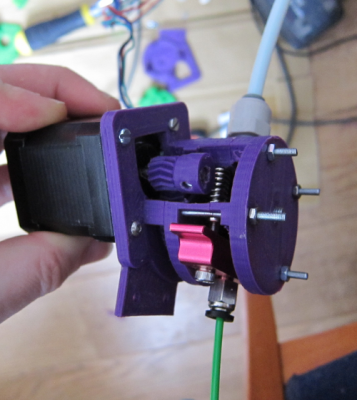

the extruder i had to create is extremely compact: the distance between gear-centres is 25mm, and the BOM is quite low: 2 625 bearings, 4 M3x50 bolts and nuts, 1 M5x40 nut, 3 M3x10mm bolts, spring, arm, and about 7 metres of PLA (i'm working on reducing that). the reason for the redesign is because the direct-drive extruder that comes with the original fusebox design was skipping even at low speeds of 50mm/sec - bear in mind that i have (at the moment) a MK9 drive gear from an all-metal MK9 kit, as well as 3mm PLA (over 400 metres of it still to be used up, from the mendel90).

given that pretty much everyone is using 1.75mm, all the bowden extruder designs that i could find were quite complex BOMs, required parts that i didn't have on-site, and were typically all 1.75mm to take much smaller OD tubing. this is what i came up with:

it's in three parts: top, middle and base. the base attaches to the motor with 3 bolts (not 4), and in the circular bit there's an indentation into which the M5 hex-bolt sits. it doesn't need a nut. the first 625 bearing sits inside the larger gear on its base, and the MK9 drive gear is pushed into the top. there's a hole for the grub screw which is not strictly necessary but is there just in case. the second 625 bearing is in the top part: it keeps the top of the nut steady. no nut or washers are needed to keep the gear in place:herringbone gears are used, so the smaller gear is what keeps the larger one from travelling along the M5 bolt.

i've ordered a MK8 drive gear (smaller diameter than the MK9), and will be adapting the extruder to suit that: this will get even higher pressure, which i would not be trying if it wasn't for the larger OD of the 3mm bowden tubing.

the right-angle brackets arrived from a random ebay supplier in HK, they're not quite suited to this design - they're 50mm triangles and the screw-holes are offset by 8mm not 7.5 (so they sit protruding 0.5mm over the edge of the 15mm makerbeam extrusion), but that's okay. as i thought would happen, even fitting just the one into the far corner has *massively* stiffened up the frame. i will be putting in the other three once i have redesigned the attachments between the box and the corexy top: the brackets, being rather large, hit the parts that i made with the wing-nuts, so cannot be installed. i needed to redesign them anyway as the wing-nuts are jamming on the extrusion.

i'm still talking with reprap.me about the Rambo v1.2g voltage-divider circuits: peter's confirmed that the measured voltage is 4.56 volts with nothing connected - it should read 5.0 volts. he's kindly offered a refund so that's good. i've decided to go with a Duet 0.8.5 instead, because i saw someone mentioning on here that they were trying faster speeds and were running into limitations of arduino PWM rates (!).

also i read this - [miscsolutions.wordpress.com] - and i could really have done with going for 24V electronics and PSU. howeverrrrr..... the 24V PSUs are extremely bulky: reprap.me have one that's 225 x 120 x 70mm, whereas the 12V i have here is 215 x 115 x 50mm.

space on this printer is extremely tight, design-wise. the top and z assemblies fold up into a space that's only about 80mm high, with the printbed sticking up on the other side by around 60mm for a total of around 140mm. when folded the PSU fits *in between* the space of the X and Y linear rails, and a 24V PSU would bash up against one of the Y rods.

... i'll work it out but for now, i have a working printer that i'm really, really happy with.

but for now, i have a working printer that i'm really, really happy with.

[updated, 200mm/min not 200mm/sec, thank you to edvardas for spotting the error]

Edited 1 time(s). Last edit at 04/04/2016 03:15PM by lkcl.

it's working! still a work-in-progress but it is basically working and producing useable quality prints. i am currently testing 300mm/sec - there is a little bit of zagging (diagonal breaks on outer shells) - and in stand-alone tests i managed to get an extrusion rate of 200mm/min without skipping.

to get that ridiculously-high extrusion rate i had to:

- reduce micro-stepping to 1/4

- increase the temperature to 225C

- create a small geared extruder with a ratio of 46:13 (3.54:1)

- increase the current setting on the Rambo v1.2g to just under 1.2 amps

the extruder i had to create is extremely compact: the distance between gear-centres is 25mm, and the BOM is quite low: 2 625 bearings, 4 M3x50 bolts and nuts, 1 M5x40 nut, 3 M3x10mm bolts, spring, arm, and about 7 metres of PLA (i'm working on reducing that). the reason for the redesign is because the direct-drive extruder that comes with the original fusebox design was skipping even at low speeds of 50mm/sec - bear in mind that i have (at the moment) a MK9 drive gear from an all-metal MK9 kit, as well as 3mm PLA (over 400 metres of it still to be used up, from the mendel90).

given that pretty much everyone is using 1.75mm, all the bowden extruder designs that i could find were quite complex BOMs, required parts that i didn't have on-site, and were typically all 1.75mm to take much smaller OD tubing. this is what i came up with:

it's in three parts: top, middle and base. the base attaches to the motor with 3 bolts (not 4), and in the circular bit there's an indentation into which the M5 hex-bolt sits. it doesn't need a nut. the first 625 bearing sits inside the larger gear on its base, and the MK9 drive gear is pushed into the top. there's a hole for the grub screw which is not strictly necessary but is there just in case. the second 625 bearing is in the top part: it keeps the top of the nut steady. no nut or washers are needed to keep the gear in place:herringbone gears are used, so the smaller gear is what keeps the larger one from travelling along the M5 bolt.

i've ordered a MK8 drive gear (smaller diameter than the MK9), and will be adapting the extruder to suit that: this will get even higher pressure, which i would not be trying if it wasn't for the larger OD of the 3mm bowden tubing.

the right-angle brackets arrived from a random ebay supplier in HK, they're not quite suited to this design - they're 50mm triangles and the screw-holes are offset by 8mm not 7.5 (so they sit protruding 0.5mm over the edge of the 15mm makerbeam extrusion), but that's okay. as i thought would happen, even fitting just the one into the far corner has *massively* stiffened up the frame. i will be putting in the other three once i have redesigned the attachments between the box and the corexy top: the brackets, being rather large, hit the parts that i made with the wing-nuts, so cannot be installed. i needed to redesign them anyway as the wing-nuts are jamming on the extrusion.

i'm still talking with reprap.me about the Rambo v1.2g voltage-divider circuits: peter's confirmed that the measured voltage is 4.56 volts with nothing connected - it should read 5.0 volts. he's kindly offered a refund so that's good. i've decided to go with a Duet 0.8.5 instead, because i saw someone mentioning on here that they were trying faster speeds and were running into limitations of arduino PWM rates (!).

also i read this - [miscsolutions.wordpress.com] - and i could really have done with going for 24V electronics and PSU. howeverrrrr..... the 24V PSUs are extremely bulky: reprap.me have one that's 225 x 120 x 70mm, whereas the 12V i have here is 215 x 115 x 50mm.

space on this printer is extremely tight, design-wise. the top and z assemblies fold up into a space that's only about 80mm high, with the printbed sticking up on the other side by around 60mm for a total of around 140mm. when folded the PSU fits *in between* the space of the X and Y linear rails, and a 24V PSU would bash up against one of the Y rods.

... i'll work it out

but for now, i have a working printer that i'm really, really happy with.

but for now, i have a working printer that i'm really, really happy with.[updated, 200mm/min not 200mm/sec, thank you to edvardas for spotting the error]

Edited 1 time(s). Last edit at 04/04/2016 03:15PM by lkcl.

|

Re: Foldable, portable CoreXY (Fusebox derivative) April 04, 2016 07:05AM |

Registered: 10 years ago Posts: 179 |

|

Re: Foldable, portable CoreXY (Fusebox derivative) April 04, 2016 01:19PM |

Registered: 8 years ago Posts: 776 |

Quote

Edvardas

What do you mean by an "extrusion rate of 200mm/s"?

hmmm, wrong units! it should be 200mm/min - thanks for noticing, edvardas, i'll edit that. i'm thinking ahead for revision 2, i might get one of the micron cobra hot-ends, they have a special "high flow-rate" kit, and the guy i spoke to there is regularly using his extruder at 250mm/sec which is pretty awesome.

|

Re: Foldable, portable CoreXY (Fusebox derivative) April 04, 2016 02:51PM |

Registered: 10 years ago Posts: 179 |

Do you notice any under-extrusion while accelerating or over-extrusion on deceleration?

I have noticed that this is a problem if I come close to extruding 10mm3 of plastic per second (which is widely considered the maximum). And with my 0.6mm nozzle and 0.3mm layer height that is already a very low 50mm/s maximum printing speed. Moving at 30mm/s gives great results and that is 6mm3 of plastic extruded per second but such a low speed is quite a shame for corexy printer.

Now I see why 0.4mm is such a popular nozzle.

Another solution would be a volcano nozzle from e3d. Now they have 0.4mm nozzles. Volcano should more than double the volume of plastic that could be extruded.

I have noticed that this is a problem if I come close to extruding 10mm3 of plastic per second (which is widely considered the maximum). And with my 0.6mm nozzle and 0.3mm layer height that is already a very low 50mm/s maximum printing speed. Moving at 30mm/s gives great results and that is 6mm3 of plastic extruded per second but such a low speed is quite a shame for corexy printer.

Now I see why 0.4mm is such a popular nozzle.

Another solution would be a volcano nozzle from e3d. Now they have 0.4mm nozzles. Volcano should more than double the volume of plastic that could be extruded.

|

Re: Foldable, portable CoreXY (Fusebox derivative) April 04, 2016 03:22PM |

Registered: 8 years ago Posts: 776 |

Quote

Edvardas

Do you notice any under-extrusion while accelerating or over-extrusion on deceleration?

I have noticed that this is a problem if I come close to extruding 10mm3 of plastic per second (which is widely considered the maximum). And with my 0.6mm nozzle and 0.3mm layer height that is already a very low 50mm/s maximum printing speed. Moving at 30mm/s gives great results and that is 6mm3 of plastic extruded per second but such a low speed is quite a shame for corexy printer.

Now I see why 0.4mm is such a popular nozzle.

Another solution would be a volcano nozzle from e3d. Now they have 0.4mm nozzles. Volcano should more than double the volume of plastic that could be extruded.

3.14159*pow(2.85/2,2)*200/60. = 21mm3/sec eek!

it was a static test, edvardas - i didn't try actually printing anything, i jwas merely trying to get.... _something_ working - the previous (direct-drive) extruder revision was stuttering at only 20mm/min. the 200mm/min test was just out of curiosity.

it was a static test, edvardas - i didn't try actually printing anything, i jwas merely trying to get.... _something_ working - the previous (direct-drive) extruder revision was stuttering at only 20mm/min. the 200mm/min test was just out of curiosity.honestly i _really_ feel that there should be some sort of PID table in firmware which takes care of under- and over- extrusion, the only thing is, i'm aware it's pretty complex - a multi-dimensional space, dependent on temperature and speed (of the head) _and_ speed of extrusion... it'd be fuuun to work out even how to calibrate that.

tell you what, i'll try one of the long, straight parts that i have, and see how it comes out. i have some parts that are thin-walled, 230mm long.

|

Re: Foldable, portable CoreXY (Fusebox derivative) April 04, 2016 04:45PM |

Registered: 8 years ago Posts: 776 |

hi edvardas, ok so this is no worse than what i get on the mendel90 - these parts are only 2mm thick, but 230mm long and 10mm high. the print speed calculated by cura for the 300mm/sec x-y travel speed says 13.5mm3/sec. the opposite side is, ironically (being the inner of the part), much better. i think i have quite a lot more experimenting to do, neh

|

Re: Foldable, portable CoreXY (Fusebox derivative) April 05, 2016 06:30PM |

Registered: 8 years ago Posts: 776 |

sorry FA-MAS, didn't notice your message, would have replied earlier

that's running at 200mm/sec with a 0.3mm nozzle (first one i've had - i can say now i really don't like them, i'm swapping out for a 0.4). you can see it's really nice at the top where cura slows down to get 5 seconds per layer, and at the bottom where there's room for the head to go much faster it's got zagging.

surprisingly, it doesn't. remember, those are 300mm rods, 10mm top and bottom taken up for the holders so that's 280mm, the z-carriage is exactly 75mm so in theory it _should_ be 205mm... buuut, i made a... choice to turn the xy assembly upside-down compared to the fusebox, blah blah bottom line i lost 10mm. i can correct that with a redesign by bringing the bed hinge mount points down by 10mm, which will give the full 200mm back.

so... 190mm for now, 200mm for the next revision.

... cool, huh?

[update: corrected to use the relative pronoun "its", not the contraction of the words "it" and "is"... ]

]

Edited 1 time(s). Last edit at 04/05/2016 06:31PM by lkcl.

Quote

FA-MAS

Sounds like you're close to getting it running. I'd like to see its first prints.

that's running at 200mm/sec with a 0.3mm nozzle (first one i've had - i can say now i really don't like them, i'm swapping out for a 0.4). you can see it's really nice at the top where cura slows down to get 5 seconds per layer, and at the bottom where there's room for the head to go much faster it's got zagging.

Quote

Also roughly how much Z travel do you estimate? It looks like the hinge system may take quite a bit.

surprisingly, it doesn't. remember, those are 300mm rods, 10mm top and bottom taken up for the holders so that's 280mm, the z-carriage is exactly 75mm so in theory it _should_ be 205mm... buuut, i made a... choice to turn the xy assembly upside-down compared to the fusebox, blah blah bottom line i lost 10mm. i can correct that with a redesign by bringing the bed hinge mount points down by 10mm, which will give the full 200mm back.

so... 190mm for now, 200mm for the next revision.

... cool, huh?

[update: corrected to use the relative pronoun "its", not the contraction of the words "it" and "is"...

]

]Edited 1 time(s). Last edit at 04/05/2016 06:31PM by lkcl.

Sorry, only registered users may post in this forum.