Prusa i3 Hephestos

Revision as of 08:00, 30 June 2014 by Pedro de Oro Martín (talk | contribs) (→Preparation before assembly)

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Prusa i3 Hephestos

Release status: working

| Description | |

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Translation in progress. Please visit Spanish version.

http://reprap.org/wiki/Prusa_i3_Hephestos/es

Contents

Introduction

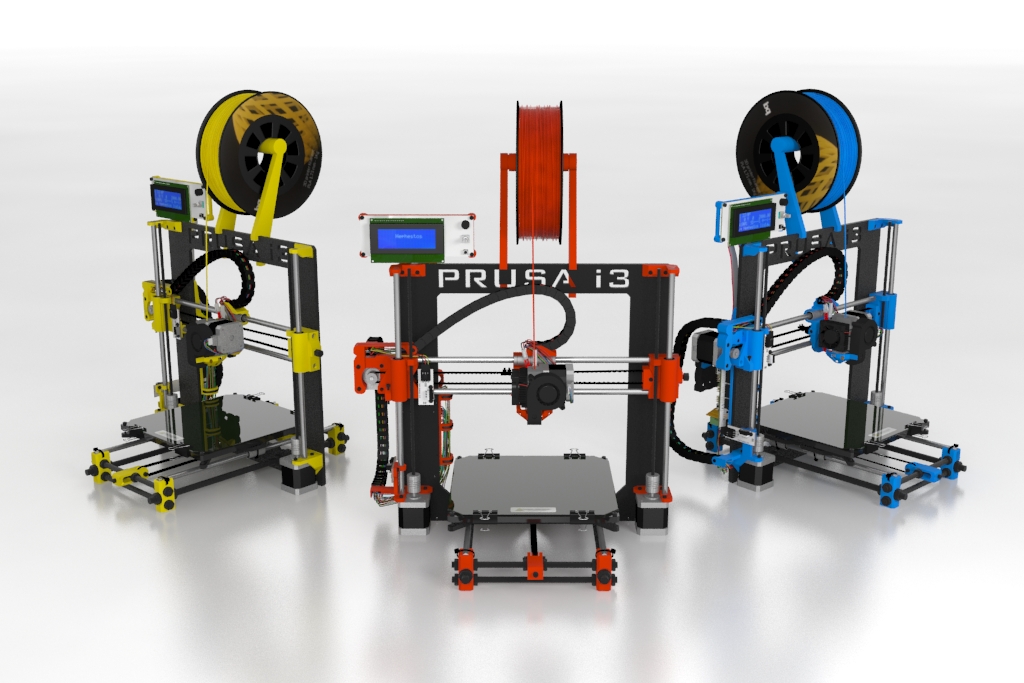

- Prusa 3D printer Hephestos is a free project 'designed and developed by the Department of Innovation and Robotics bq'. Hephestos is based on the Prusa i3 and adds several improvements learned from other printers as PowerCode users of the RepRap community, modifications to these parts and designs own department.

- This project has sought to offer a robust printer design that solves many of the shortcomings of earlier designs such as the subjection of the limit switches and cable routing. We have placed particular emphasis on providing good documentation to facilitate and more comfortable to the user installation and commissioning of the printer.

- The complete kit can be purchased from July 7, 2014 on the website http://store.bqreaders.com/es/diy/ 499 Euros with VAT in EU (European Union) Free shipping expenses.

Mounting Video (Youtube):

<videoflash type="youtube">eb74i006XIw</videoflash>

Galería

Thecnical specifications

Dimensions

- -Dimensions printer: (x) 460 x (y) x 370 (without roll z) 510 (with roll z) 583 mm

- -Dimensions printer area : (x) 215 x (y) 210 x (z) 180 mm

- -Dimensions box: (x) 400 x (y) 400 x (z) 250mm

Mechanical

- -Frame aluminum base and powder coated

- -Bars X cars for hard chrome, Y, Z

- -Linear ball bearing LM8UU for X, Y, Z

- -Axial B623ZZ bearing pulleys balls for X, Y

- -Igus Energy Chains

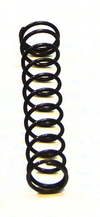

- -Flexible Couplings threaded rods of Z axis

- -System level print base with 4 points and cushioning

- -System quick change print base with Clips

- -Fans brushless axial ball bearings.

Print resolution

- -Very high: 60 microns

- -High 100 microns

- -Media 200 microns

- -Low 300 microns

Extruder Mechanics

- -Extruder own

- -0.4mm nozzle

- -Sink fins with axial fan

- -Irrigation Nozzle Part

Print speed

- -Recommended speed: 50 mm / s

- -Maximum recommended speed: 80 mm / s

Electronics

- -1.4 Ramps

- -Mega 2560

- -Display LCD and rotary encoder with pushbutton navigation

- -Cold Base Glass size 220 x 220 x 3 mm

- -Power supply 220 AC 12 DC 100W

- -Thermistor 100k extruder

- -Heating element 12V 40W

Software

- -Firmware derivative Marlin

- -Recommended environment: Cura Software

- -Supported Files:. Gcode

- -OS supported:

- Windows XP and above

- Mac OS X and above

- Linux

Communications

- -Reader Standard SD cards

- -Port USB Type B

Materials

- PLA Filament 1.75-mm

Changes with respect to other models Prusa i3

- Limit switch clamping:

- Designed by the department specifically for this model.

- Limit switch clamping:

- Belt tensioners

- Tensor X axis identical to the Power Code. Tensor Axis And http://www.thingiverse.com/thing:6818 downloaded from Thingiverse.

- Support for RAMPS

- Designed by the department specifically for this model. Includes three anchors to collect the wires on one side flanged.

- Support LCD

- Designed by the department specifically for this model. The design has been inspired by http://www.thingiverse.com/thing:121640

- Support Fan

- Designed by the department specifically for this model.

- Chain Stitch

- Pieces modified to include the chain stitch on all axes, avoiding pinching, cuts and caught the cable axis movement.

- Power supply

- Pc power supply

- Extruder

- Witbox extruder.

- Frame

- Official modified Prusa. It has a recess in the Y axis area to prevent friction may exist once the leveling of the base if the screw protrudes.

- Volume Printing

- 215x210x180 mm

Printed pieces

Thingiverse page: http://www.thingiverse.com/thing:371842

Own desings

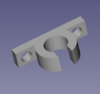

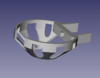

X Axis coupling chain stitch

Piece Downloads

File:Acople cadeneta Eje X.zip

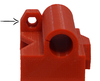

Mechanical Endstop clamping X axis

Piece Downloads

File:EjeX final de carrera.zip

Mechanical Endstop clamping Y axis

Pieces Downloads File:EjeY final carrera marco.zip File:EjeY final carrera base.zip

Mechanical Endstop clamping Z axis

Piece Downloads File:Eje Z final carrera.zip

Hot End security

Piece Downloads File:Seguridad Hot end.zip

Tools

Piece Downloads File:Llave fija impresa archivos.zip

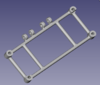

LCD support

Piece Downloads File:Soporte lcd.stl File:Bisagra lcd.stl

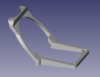

Fan support

Piece Downloads File:Soporte ventilador archivos.zip

Filament holder

Modified

X Axis carriage

- The original carriage will have made the following changes:

- -Attach to rewind Igus chain stitch at the top (above the bearings).

- -Addition of a small cap to ensure contact with the limit of X axis (on the side, next to the linear bearing carriage below)

Original Modified X Axis carriage (Power CODE) X Axis carriage (Hephestos) File:Eje X carro A archcivos.zip

Clamping the left Z Axis motor

- -Incorporated hitch chainstitch.

Original Modified Clamping the left Z Axis motor (Power CODE) Clamping the left Z Axis motor (Hephestos) File:I3-zbottom izq.stl File:Eje Z soporte inferior izquierda archivos.zip

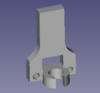

End of the X Axis motor

- To provide robustness to the screw to adjust the height in Z.

- -The base is elongated and has reduced the looseness of the nut to prevent the screw from moving.

- -Has shifted the screw hole out to get a better accuracy in mechanical Endstop activation.

Original Modified X Axis left (Power CODE) X Axis left (Hephestos) File:EjeX izquierda.zip

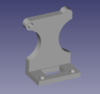

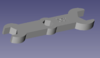

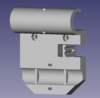

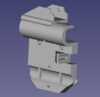

RAMPS support

- They have added three hooks. Each hook allows through a bridle, hold and collect all the cables connected to the RAMPS. By guiding the cables through the side and into the plate at the top left corner promotes cooling of drivers having no cables above the sinks.

Original Modified RAMPS support (Witbox) RAMPS support (Hephestos) File:Suplemento RAMPS(original).stl File:Soporte RAMPS archivos.zip

Complete Kit

Complete Kit pieces to Hephestos:

Bill of Materials

Tools

Electronic

Extruder

X Axis

Y Axis

Piece Name Quantity

Chromed smooth rod 8mm x 340mm 2

Black threaded rod M10x370mm 2

Black threaded rod M8 x 205mm 4

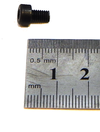

M3 x10 Screw - DIN-912 8.8 Class Black 7

M3 x16 Screw - DIN-912 8.8 Class Black 1

M3 x20 Screw - DIN-912 8.8 Class Black 1

M3 x25 Screw - DIN-912 8.8 Class Black 6

M3 Nut - DIN 934 Class 8 Black 7

M8 Nut - DIN 934 Class 8 Black 22

M10 Nut - DIN 934 Class 8 Black 12

M8 Washer - DIN-125 Class 6 Black 22

M10 Washer - DIN-125 Class 6 Black 12

Y Axis B623ZZ bearing Pulley 2

Y Axis belt holder 1

Y Axis tensor B623ZZ bearing http://www.thingiverse.com/thing:68185 1

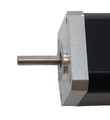

Y Axis motor 1

Y Axis Corner 1

Y Axis base Endstop 1

Y Axis frame Endstop 1

GT2 pulley (20 teeth) 1

LM8UU Linear bearing 3

Black bridle 100x2.5mm 11

GT2 belt 6mmx1m 1

Aluminum base 1

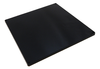

Methacrylate base 220x220x8mm holes 3.5mm 1

B623ZZ axial bearing 1

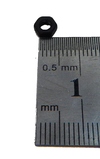

Spring (long: 30,5mm ; Outside diameter: 4,5mm; Wire thickness: 0.45mm) 4

Glass 220x220x3mm 1

Black Biinder Clip (35x10mm) 4

Black bridle 100x2.5mm 11

Z Axis

Mounting Guide

Required tools not included in the BOM

Preparation before assembly

Prepare pulleys

- Materials Needed:

- Mounting:

Preparation of the motors

- Materials Needed:

- Mounting:

Embed nuts

- Materials Needed:

- 'Montaje:

- Parts to be embed with nut: