Prusa i3 Hephestos

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Release status: working

| Description | |

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

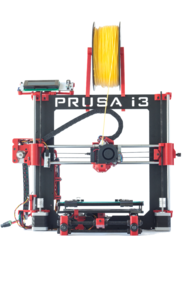

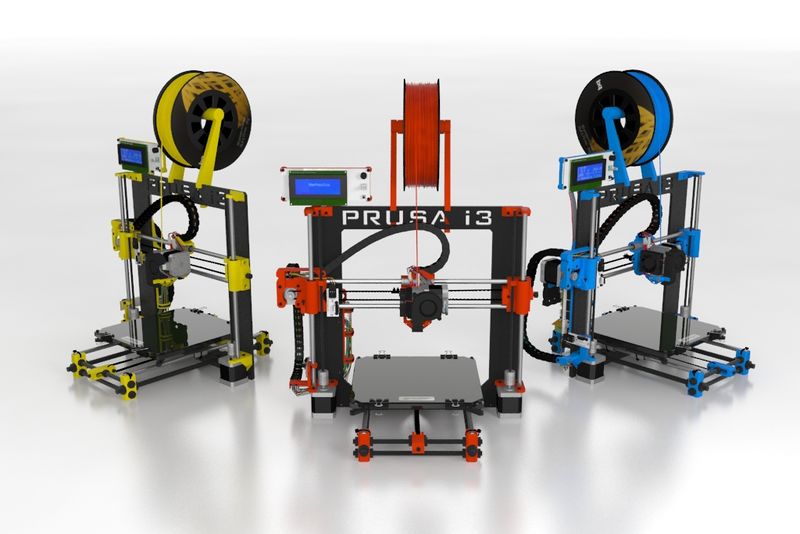

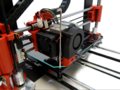

Prusa 3D printer Hephestos is an open source 3D printer designed and developed by the bq Department of Innovation and Robotics. Hephestos is based on the Prusa i3 and adds several improvements to other printers like PowerCode. Parts were developed by the RepRap community with modifications and new parts added by bq.

This project has sought to offer a robust printer design, addressing many of the shortcomings of earlier designs such as end-stop positioning and wiring routing. We have placed particular emphasis on providing good documentation to facilitate its assembly.

- Where to buy

- 3DEspana.com From Spain Worldwide Shipping kit 299€ - RepRap.me ships worldwide (pickup in Denmark), wordwide kit shipping - Orballo Printing (Prusa Steel) - bq Spanien - (Autor) - kostenloser Versand - IBEROBOTICS Shop Optional Montageservice - Leds & Chips Vormontiert - Portugal - Leds & Chips Portugal - Iniciativas 3D Spanien - wi3d Print Spanien - 3D Proditive Shop Spanien - Simac Spanien - Crea3D Italien - 3DPrinter Store Schweiz - 3Dinvasion.com From Spain & Canary Islands, free shipping, Free Online Course.

Contents

- 1 Gallery

- 2 Printed Parts

- 3 Bill of Materials

- 4 Assembly Guide

- 4.1 Required tools not included in the BOM

- 4.2 Preparation before assembly

- 4.3 Axis assembly

- 4.3.1 X Axis

- 4.3.1.1 Bearing Assembly

- 4.3.1.2 Prepare the X Axis tensioner

- 4.3.1.3 Enter the X Axis tensioner

- 4.3.1.4 Assembly of bearings on smooth rods

- 4.3.1.5 Prepare the X Axis Endstop sensor

- 4.3.1.6 Fit the X Axis Endstop sensor to the smooth rod

- 4.3.1.7 Assemble the smooth rod into the side parts

- 4.3.1.8 Mount the X Axis motor

- 4.3.1.9 Assemble the adjustment screw for the X Axis Endstop

- 4.3.1.10 Assemble the pulley onto the X Axis motor

- 4.3.2 Z Axis

- 4.3.2.1 Attach the motor support to the frame

- 4.3.2.2 Attach the Z axis motors

- 4.3.2.3 Attach the Z axis supports to the top of the frame

- 4.3.2.4 Prepare the Z Axis Endstop

- 4.3.2.5 Join X Axis with Z Axis: Insert threaded rods

- 4.3.2.6 UJoin X Axis with Z Axis: Insert smooth rod

- 4.3.2.7 Join X Axis with Z Axis: Assembly to X axis:

- 4.3.2.8 Join X Axis with Z Axis: Flexible coupling

- 4.3.2.9 Union X Axis with Z Axis: Z Axis Endstop sensor

- 4.3.3 Y Axis

- 4.3.3.1 Preparation of M10 threaded rod

- 4.3.3.2 Preparation of smooth rods

- 4.3.3.3 Assembly of smooth rods with threaded rods

- 4.3.3.4 Secure with nuts

- 4.3.3.5 Secure with cable ties

- 4.3.3.6 Preparation of Y Axis tensioner

- 4.3.3.7 Preparation of Y Axis motor

- 4.3.3.8 Preparation of the M8 threaded rods - Part 1

- 4.3.3.9 Preparation of the M8 threaded rods - Part 2

- 4.3.3.10 Assembly of the rods

- 4.3.3.11 Secure the structure with nuts

- 4.3.3.12 Preparation of the aluminum base

- 4.3.3.13 Secure the aluminium base with cable ties

- 4.3.3.14 Prepare the Endstop of the base

- 4.3.3.15 Secure the Endstop to the base

- 4.3.3.16 Attach the belt of the Axis Y

- 4.3.3.17 Tighten all nuts

- 4.3.3.18 Attach the acrylic base

- 4.3.3.19 Prepare the Y Axis Endstop

- 4.3.3.20 Secure the Y Axis Endstop to the frame

- 4.3.3.21 join Y Axis with the X and Z axes: Attach axes

- 4.3.3.22 join Y Axis with the X and Z axes: Fit and tighten nuts

- 4.3.4 Extruder

- 4.3.4.1 Prepare the carriage

- 4.3.4.2 Attach the carriage to the X axis

- 4.3.4.3 Secure the carriage with a cable tie

- 4.3.4.4 Fit the belt to the X Axis

- 4.3.4.5 Mount the Extruder support

- 4.3.4.6 Mount the extruder

- 4.3.4.7 Fit the blower nozzle and Hot end safety guard

- 4.3.4.8 Place the glass on the base

- 4.3.5 Electronic

- 4.3.6 Tuck the wires into the X Axis cable carrier

- 4.3.1 X Axis

- 4.4 Printer adjustments

- 4.5 Hello world: Your first print

- 4.6 Annex

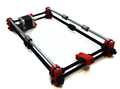

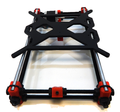

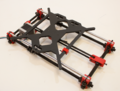

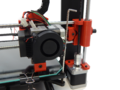

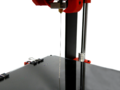

Gallery

Technical specifications

Dimensions

- Printer Dimensions: 460(X) x 370(Y) x 510 mm(Z without roll) or 583 mm(Z with roll)

- Print Area Dimensions: 215(X) x 210(Y) x 180 mm(Z)

- Box Dimensions: 400(X) x 400(Y) x 250 mm(Z)

Mechanical Construction

- Powder coated aluminium frame & base

- Smooth chrome rods for bearing carriages X, Y, Z

- Linear ball bearing LM8UU for X, Y, Z

- Axial ball bearing pulleys B623ZZ for X, Y

- Igus cable carrier chain

- Flexible aluminium coupling for threaded rods of Z Axis

- Four-point print base levelling system with cushioning

- Quick change system for print base with clips

- Brushless fans with axial ball bearings.

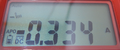

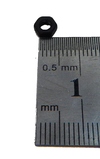

Print resolution

- Very high: 60 microns

- High 100 microns

- Medium 200 microns

- Low 300 microns

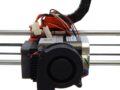

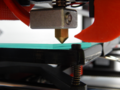

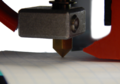

Extruder Mechanics

- Custom extruder design (Witbox)

- 0.4 mm nozzle

- Fin heatsinks with axial fan

- Part cooling nozzle

Print speed

- Recommended speed: 50 mm / s

- Maximum recommended speed: 80 mm / s

Electronics

- Any RepRap electronics conforming to RepRap Interface Standard RIS 1.

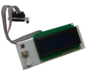

- LCD with rotary encoder and push-button navigation

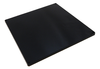

- Cold glass base (size:220 x 220 x 3 mm)

- Power supply: 220 AC 12 DC 100W

- Thermistor 100k extruder

- Heating element: 12V 40W

Software

- Firmware derivative Marlin

- Recommended environment: Cura Software

- Supported Files:. Gcode

- OS supported:

- Windows XP and above

- Mac OS X and above

- GNU/Linux

Communications

- Standard SD card reader

- USB Port Type B

Materials

- PLA Filament 1.75-mm

Changes with respect to other models Prusa i3

- Limit switch clamping:

- Designed by the department specifically for this model.

- Limit switch clamping:

- Belt tensioners

- Tensioner X axis identical to the Power Code. Tensioner Axis Ydownloaded from Thingiverse. http://www.thingiverse.com/thing:68185

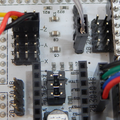

- Support for RAMPS

- Designed by the department specifically for this model. Includes three anchors to collect the wires on one side through the use of a cable tie. Guiding the cables ensures the Driver heatsinks are not covered.

- Support LCD

- Designed by the department specifically for this model. The design has been inspired by http://www.thingiverse.com/thing:121640

- Support Fan

- Designed by the department specifically for this model.

- Cable Carrier

- Parts modified to include the cable carrier on all axis, avoiding pinching, cuts and catching the cable during axis movement.

- Power supply

- Laptop power supply

- Extruder

- Witbox extruder.

- Frame

- Official Prusa design modified. A recess has been added to the Y axis area to prevent friction which previously existed during the levelling of the base plate caused by the screw protruding. File:Frame&base Hephestos.dxf.zip

- Printing volume

- 215x210x180 mm

Printed Parts

Thingiverse page: http://www.thingiverse.com/thing:371842

Own designs

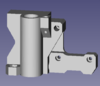

X Axis cable carrier coupling

Part Downloads

File:Acople cadeneta Eje X.zip

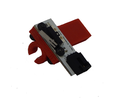

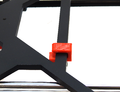

Mechanical Endstop clamping X axis

Part Downloads

File:EjeX final de carrera.zip

Mechanical Endstop clamping Y axis

Parts Downloads File:EjeY final carrera marco.zip File:EjeY final carrera base.zip

Mechanical Endstop clamping Z axis

Part Downloads File:Eje Z final carrera.zip

Hot End security

Part Downloads File:Seguridad Hot end.zip

Tools

Part Downloads File:Llave fija impresa archivos.zip

LCD support

Part Downloads File:Soporte lcd.stl File:Bisagra lcd.stl

Fan support

Part Downloads File:Soporte ventilador archivos.zip

Filament holder

Modified

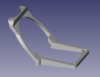

X Axis carriage

- The following changes have been made to the original carriage:

- -Attachment to rewind Igus cable carrier at the top (above the bearings).

- -Addition of a small cap to ensure contact with the limit of X axis (on the side, next to the linear bearing carriage below)

Original Modified X Axis carriage (PowerCode) X Axis carriage (Hephestos) File:Eje X carro A archcivos.zip

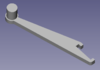

Left side motor mounting for Z-Axis

- -Incorporated coupling for cable carrier.

Original Modified Left side motor mounting for Z-Axis (PowerCode) Left side motor mounting for Z-Axis (Hephestos) File:I3-zbottom izq.stl File:Eje Z soporte inferior izquierda archivos.zip

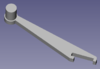

End of the X Axis motor

- Added support material to the screw which adjusts the Z axis height.

- -The base has been elongated to reduced the clearance of the nut thereby preventing the screw from moving.

- -The screw hole has been shifted outwards to improve accuracy in the mechanical Endstop activation.

Original Modified X Axis left (PowerCode) X Axis left (Hephestos) File:EjeX izquierda.zip

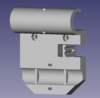

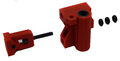

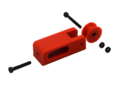

RAMPS support

- Added three hooks. Each hook works by using cable ties to hold and collect all the cables connected to the RAMPS. By guiding the cables through the side and into the plate at the top left corner it facilitates cooling of drivers by not having cables directly above the heat sinks.

Original Modified RAMPS support (Witbox) RAMPS support (Hephestos) File:Suplemento RAMPS(original).stl File:Soporte RAMPS archivos.zip

Complete Kit

Complete Part Kit for Hephestos:

Bill of Materials

Tools

Electronics

Extruder

X Axis

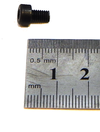

Part Name Quantity Description

Chromed smooth rod 8 mm x 370 mm 2 -

M3x10 Screw - DIN-912 8.8 Class Black 4 -

M3x16 Screw - DIN-912 8.8 Class Black 2 -

M3x20 Screw - DIN-912 8.8 Class Black 2 -

M3x25 Screw - DIN-912 8.8 Class Black 1 -

M6x40 Screw - DIN-912 8.8 Class Black 1 -

M3 Nut - DIN 934 Class 8 Black 7 -

M5 Nut - DIN 934 Class 8 Black 2 -

M6 Nut - DIN 934 Class 8 Black 3 - X Axis Carriage A 1 X axis carriage to which the extruder attaches, adapted for use with chains. PowerCode modified.

X Axis Carriage B 1 Component for fixing the chain to the X axis carriage. Powercode

X Axis B623ZZ bearing Pulley 2 X axis pulley where the radial ball bearing B623ZZ is attached. PowerCode

X Axis Right 1 Far right component of the X axis where the cable carrier tensioner is attached. PowerCode

X Axis tensioner B623ZZ bearing 1 Chain tensioner for the X axis which is joined together with the pulley and axial ball bearing B623ZZ. PowerCode

X Axis left 1 Far left component of X axis which is attached to motor Nema17 of said axis. PowerCode Modified.

X Axis left chain coupling 1 Coupling for attaching the cable carrier to the far left component of the X axis. PowerCode

X Axis Endstop (Hephestos) 1 Support part for the fixing of the Endstop to the smooth bar of the X axis. Custom Design.

B623ZZ axial ball bearing 1 -

GT2 pulley (20 teeth) 1 -

LM8UU Linear ball bearing 1 -

Black cable tie 100x2.5mm 1 -

Y Axis

Part Name Quantity Description

Chromed smooth rod 8mm x 340mm 2 -

Black threaded rod M10x370mm 2 -

Black threaded rod M8 x 205mm 4 -

M3 x10 Screw - DIN-912 8.8 Class Black 7 -

M3 x16 Screw - DIN-912 8.8 Class Black 1 -

M3 x20 Screw - DIN-912 8.8 Class Black 1 -

M3 x25 Screw - DIN-912 8.8 Class Black 6 -

M3 Nut - DIN 934 Class 8 Black 7 -

M8 Nut - DIN 934 Class 8 Black 22 -

M10 Nut - DIN 934 Class 8 Black 8 -

M8 Washer - DIN-125 Class 6 Black 22 -

M10 Washer - DIN-125 Class 6 Black 8 -

M10 serrated Nut - DIN 6923 Class 8 Black 4 -

M10 Washer - DIN-125 Class 6 Black 4 -

Y Axis B623ZZ bearing Pulley 2 Y axis pulley where the radial ball bearing B623ZZ is attached. PowerCode

Y Axis belt holder 1 Component for attaching the GT2 chain to Y axis. Prusa

Y Axis tensioner B623ZZ bearing http://www.thingiverse.com/thing:68185 1 Chain tensioner for the Y axis which is joined together with the pulley and axial ball bearing B623ZZ. PowerCode

Y Axis motor PowerCode 1 Component reinforced with 3 screws for attaching the Y axis Nema17 motor to the threaded rods. PowerCode

Y Axis Corner 1 Corner component for constructing the base and Y axis structure. PowerCode

Y Axis base Endstop (Hephestos) 1 Component attached to the base of the Y axis which includes an M3 screw & nut for regulating the total shaft travel. It works in conjunction with the part that holds the Endstop to the frame. Custom Design.

Y Axis frame Endstop (Hephestos) 1 Component for attaching the Y axis Endstop to the frame. Works in conjunction with the Y axis base Endstop. Custom Design.

GT2 pulley (20 teeth) 1 -

LM8UU Linear bearing 3 -

Black cable tie 100x2.5mm 11 -

GT2 belt 6mmx1m 1 -

Aluminium Base 1 Black powder coated aluminium base for mounting glass and acrylic.

Acrylic base 1 Acrylic base 220x220x8mm in black with 3.5mm holes

B623ZZ axial ball bearing 1 -

Spring 4 Spring (length: 30,5mm ; Outside diameter: 4,5mm; Wire thickness: 0.45mm)

Glass Plate 220x220x3mm 1 -

Black Binder Clip (35x10mm) 4 -

Black cable tie 100x2.5mm 11 -

Z Axis

Part Name Quantity Description

Chromed smooth rod 8mm x 320mm 2 -

Black threaded rod M5x300mm 2 -

M3x10 Screw - DIN-912 8.8 Class Black 16 - M3 x18 Screw - DIN-912 8.8 Class Black 2 -

M3 Nut - DIN 934 Class 8 Black 2 -

Z Axis top support PowerCode 1 Component for attaching the Ø8mm x 320mm smooth rods of the Z axis to the top part of the frame.

Z Axis bottom right support 1 Component for fixing the right hand Nema17 motor to the frame. Includes sleeve for the Ø8mm x 320mm smooth rod. PowerCode

Z Axis Endstop (Hephestos) 1 Component for the attachment of the Endstop to the smooth rods of the Z axis.

Z Axis bottom left support PowerCode modified 1 Component for fixing the left hand Nema17 motor to the frame. Includes sleeve for the Ø8mm x 320mm smooth rod and attachment for the cable carrier. PowerCode Modified

Flexible coupling 2 Flexible coupling for aluminium 5 to 5mm with 4 grub screws for adjusting the rods via a 2mm allen key.

Black aluminium frame 1 Black powder coated aluminium frame with "Prusa i3" Machined into the top part. Includes recess area in the bottom part near the Y axis to stop possible interference once the base levelling process has been completed.

Assembly Guide

Required tools not included in the BOM

Preparation before assembly

Prepare pulleys

- Materials Needed:

- Assembly:

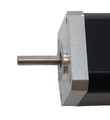

Preparation of the motors

- Materials Needed:

- Assembly:

Embed nuts

- Materials Needed:

- Assembly:

- Parts to be embed with nut:

Picture Detail Picture Name Description Nut Quantity

X Axis Right Far right component of X axis which holds chain tensioner for X axis. M5 Nut - DIN 934 Class 8 Black 1

X Axis left Far left component of X axis used to attach the Nema17 motor to the X axis. M3 Nut - DIN 934 Class 8 Black 1

X Axis left Far left component of X axis used to attach the Nema17 motor to the X axis. M5 Nut - DIN 934 Class 8 Black 1

X Axis tensioner Chain tensioner for the X axis which is joined together with the pulley and axial ball bearing B623ZZ. PowerCode M3 Nut - DIN 934 Class 8 Black 1

Y Axis tensioner Chain tensioner for the Y axis which is joined together with the pulley and axial ball bearing B623ZZ. PowerCode M3 Nut - DIN 934 Class 8 Black 1

X Axis Carriage A X axis carriage to which the extruder attaches, adapted for use with chains. PowerCode modified. M3 Nut - DIN 934 Class 8 Black 2 Fan support Support for 50x50mm fan. Located above the electronics to prevent overheating. Custom design. M3 Nut - DIN 934 Class 8 Black 2

Fan support Support for 50x50mm fan. Located above the electronics to prevent overheating. Custom design. M3 Nut - DIN 934 Class 8 Black 2

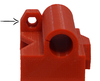

Y Axis base Endstop Component attached to the base of the Y axis which includes an M3 screw & nut for regulating the total shaft travel. It works in conjunction with the part that holds the Endstop to the frame. Custom Design. M3 Nut - DIN 934 Class 8 Black 1

Hot End Safety Guard User protection to avoid direct contact with hot extruder and prevent burns. M3 Nut - DIN 934 Class 8 Black 1

Preparation of motor cables

- Materials Needed:

- Cable length (from base of engine to end of connector)

Motor Total length (cm) Motor length (cm) Extesnion lenght(cm) X 85 30 55 Y 50 20 30 Z Right 45 15 30 Z Left 65 30 35

- Note: Cut four parts of the heat shrink tubing for the Motor wire to 2cm long.

- Note: Prepare motors of X and Y axis before mounting the engines, and the Prusa Z Axis, after mounting.

- Assembly:

- Note: Before soldering the cables of Z axis motors, pass the bare wire through the motor hole.

- Assembly:

Power supply cable preparation

- Materials Needed:

- Assembly:

Axis assembly

X Axis

Bearing Assembly

- Materials Needed:

- Assembly:

Prepare the X Axis tensioner

- Materials Needed:

- Assembly:

Enter the X Axis tensioner

- Materials Needed:

- The objective of the tensioner is to load or unload the chain easily once installed.

- Note: It is necessary to sand/file the parts. The tensioner should slide perfectly into the part that holds it.

- Assembly:

- Note: The two nuts at the end are to be tightened together. Use a nut wrench on the adjacent nut to assist. This way you can ensure that the nuts are securely fitted to the screw. Now by using the wrench as shown in the picture, crank the tensioner to the side to achieve the required tension when fitting the belt.

- Note: Use the nut wrench when fitting and tightening the nuts on the screw.

Assembly of bearings on smooth rods

- Materials Needed:

- Assembly:

Prepare the X Axis Endstop sensor

- Materials Needed:

- Assembly:

Fit the X Axis Endstop sensor to the smooth rod

- Materials Needed:

- Assembly:

Assemble the smooth rod into the side parts

- Materials Needed:

- Assembly:

- The length of the rod between the side parts (when assembled) should be approximately 31 cm.

Mount the X Axis motor

- Materials Needed:

- Assembly:

- Note: Mount the motor with the cable at the top.

Assemble the adjustment screw for the X Axis Endstop

- Materials Needed:

- Assembly:

Assemble the pulley onto the X Axis motor

- Materials Needed:

- Assembly:

- Note: Use the 2mm Allen wrench to tighten the pulley to the motor axis via the chamfered area.

Z Axis

Attach the motor support to the frame

- Materials Needed:

Note: Make sure to check that the smooth rods fit into the holes on the brackets and file the holes if necessary.

- Assembly:

Attach the Z axis motors

- Materials Needed:

- Assembly:

Note: Align the motor cable towards the frame

Attach the Z axis supports to the top of the frame

- Materials Needed:

- Assembly:

Note: The support holes will need to be lightly sanded. The longer screws go into the left side and will be used to also attach the LCD mount later.

Prepare the Z Axis Endstop

- Materials Needed:

- Assembly:

Join X Axis with Z Axis: Insert threaded rods

- Materials Needed:

- Assembly:

UJoin X Axis with Z Axis: Insert smooth rod

- Materials Needed:

- Assembly:

Join X Axis with Z Axis: Assembly to X axis:

- Materials Needed:

- Assembly:

Join X Axis with Z Axis: Flexible coupling

- Materials Needed:

- Assembly:

Union X Axis with Z Axis: Z Axis Endstop sensor

- Materials Needed:

- Assembly:

- Note: Using glue for plastics join the the assembly in Step 4 to the motor bracket.

Y Axis

Preparation of M10 threaded rod

- Materials Needed:

- Assembly:

Preparation of smooth rods

- Materials Needed:

- Assembly:

Assembly of smooth rods with threaded rods

- Materials Needed:

- Assembly:

Secure with nuts

- Materials Needed:

- Assembly:

Secure with cable ties

- Materials Needed:

- Assembly:

Preparation of Y Axis tensioner

- Materials Needed:

- Assembly:

Note: The 25 mm screw is used as shaft for the pulley and the 20mm screw for the tensioner.

Preparation of Y Axis motor

- Materials Needed:

- Assembly:

Preparation of the M8 threaded rods - Part 1

- Materials Needed:

- Assembly:

Preparation of the M8 threaded rods - Part 2

- Materials Needed:

- Assembly:

Assembly of the rods

- Materials Needed:

- Assembly:

Secure the structure with nuts

- Materials Needed:

- Assembly:

Preparation of the aluminum base

- Materials Needed:

- Assembly:

Secure the aluminium base with cable ties

- Materials Needed:

- Assembly:

Prepare the Endstop of the base

- Materials Needed:

- Assembly:

Secure the Endstop to the base

- Materials Needed:

- Assembly:

Attach the belt of the Axis Y

- Materials Needed:

- Assembly:

- Note: Rotate the assembly

- Note: Tighten the pulley using the 2mm Allen key

- Note: Turn screw anticlockwise to slacken the tensioner

- Note: Align belt

- Note: Tighten the belt by turning the screw clockwise.

Tighten all nuts

- Materials Needed:

- Assembly:

- Note: It may be necessary to file the burrs slightly so the spanner works easily.

Attach the acrylic base

- Materials Needed:

- Assembly:

- Note: It may be necessary to file the burrs slightly.

Prepare the Y Axis Endstop

- Materials Needed:

- Assembly:

Secure the Y Axis Endstop to the frame

- Materials Needed:

- Assembly:

join Y Axis with the X and Z axes: Attach axes

- Materials Needed:

- Assembly:

join Y Axis with the X and Z axes: Fit and tighten nuts

- Materials Needed:

- Assembly:

Extruder

Prepare the carriage

- Materials Needed:

- Assembly:

Attach the carriage to the X axis

- Materials Needed:

- Assembly:

Secure the carriage with a cable tie

- Materials Needed:

- Assembly:

Fit the belt to the X Axis

- Materials Needed:

- Assembly:

Mount the Extruder support

- Materials Needed:

- Assembly:

Mount the extruder

- Materials Needed:

- Assembly:

- Note: During this step it is necessary to remove the nozzle of the blower.

- Note: Secure the extruder with screws.

Fit the blower nozzle and Hot end safety guard

- Materials Needed:

- Assembly:

- Note: The Hot end security guard is an optional part and not necessary for the printer to work correctly, but its use is highly recommended to avoid burns.

Place the glass on the base

- Materials Needed:

- Assembly:

Electronic

Place the RAMPS 1.4

- Materials Needed:

Part Name Quantity

RAMPS 1.4 1

M3x20 Screw - DIN-912 Class 8.8 Black 2 Printed support for ramps 1

- Assembly:

Prepare the LCD control panel

- Materials Needed:

- Assembly:

Mount the LCD control panel on the frame

- Materials Needed:

- Assembly:

Tuck the wires into the X Axis cable carrier

- Materials Needed:

- Assembly:

- Note: Introduce the wires individually

Place the X Axis cable carrier

- Materials Needed:

- Assembly:

- Note: The 25 link cable carrier joins the X Axis carriage at the far left of the X Axis.

Introduce the Z Axis wires in to the Z Axis cable carrier.

- Materials Needed:

- Assembly:

- Note: Tuck the wires for the X axis motor and Endstop into the Z axis cable carrier.

- Note: The 27 link cable carrier joins the left hand X Axis to the Z Axis bottom left support.

Prepare the fan

- Materials Needed:

- Assembly:

Wiring and cable routing

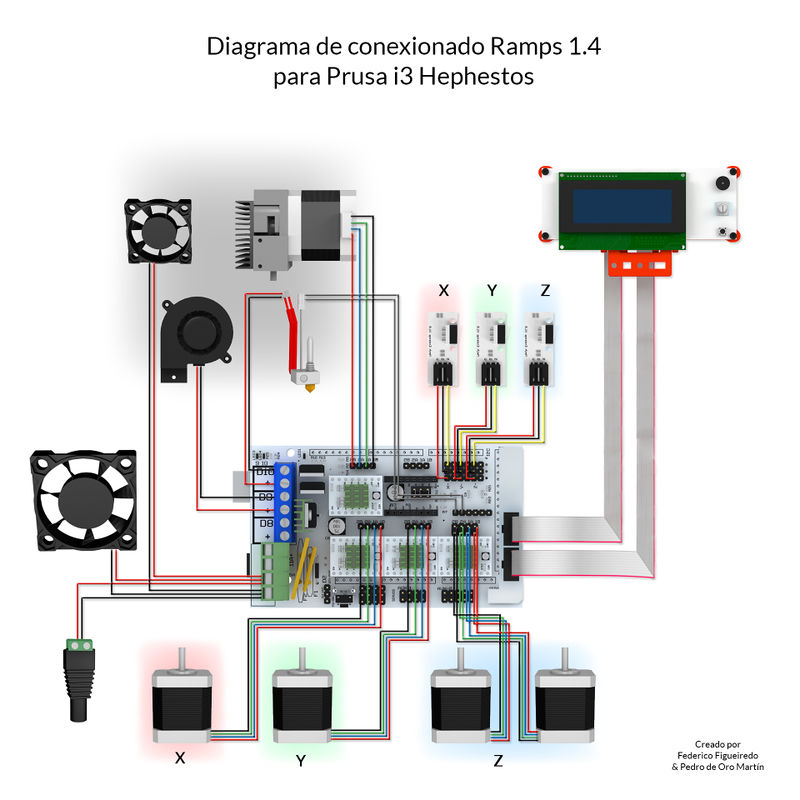

Cable connection diagram

- Materials Needed:

Extruder wiring

- Note: Use a cable tie with the extruder wires.

Motors cable routing

- Note: Use a cable tie with the motors wires.

Endstop cable routing

RAMPS Wiring and cable routing

- Note: Use the cable ties with the wires.

- Note: Guide the cables through the printed part that holds the RAMPS and secure them with the cable ties.

- Note: Connect the clamp plate, fan cables and power supply.

Attach the fan

- Materials Needed:

- Assembly:

- Note: Disconnect the Ramps LCD control panel before securing the fan and pull it through the hole in the work piece.

Mount the filament holder to the frame

- Materials Needed:

- Assembly:

Printer adjustments

Z Axis adjustment

- Before printing with your printer you must calibrate the screw that adjusts the height of the Z axis so that the extruder is at the correct height relative to the base. To do this, follow these steps:

- -Level the ends of the X Axis to the same height. Thread each axis manually until both are at the same height.

- -Tighten the set screw as much as possible without excess force to the printed parts.

- -Using the LCD control panel bring the extruder to the home position.

- Control > Move Axis > Auto home

- Note: Make sure that the Endstop sensors are being activated correctly by their respective axes.

- -Set the position of the endstop sensor adjustment screws and repeat the previous step (bringing the Z axis to home position).

- -If the adjustment isn't correct, repeat the previous step.

Levelling the plate

- Once Z Axis is adjusted, it is necessary to level the plate.

- Using the LCD control panel, start the levelling program.

- Control > Level plate

- The program moves the extruder to four points of the base, where you must adjust the screws on each corner, so that you can just pass a sheet of paper between the extruder nozzle and glass. There should be a slight feeling of resistance produced by the extruder pressing the paper down onto the glass plate.

Hot End obstruction

- If a blockage occurs in the Hot-End, follow the next step:

- You must heat the Hot End to 220 °C and insert the 0.4 mm needle into the nozzle until you see it come out the other end. Afterwards you must clean the needle of any plastic which may have stuck to it.

- If a blockage occurs in the Hot-End, follow the next step:

Hello world: Your first print

- If you followed all steps of this manual, you should have your Prusa i3 Hephestos ready to do its first print!

- First you need to find a 3D design in .stl format for printing. Then you need to slice the chosen 3D design. For this, you can follow our guides of the most common used programs.

- Slic3r guide: https://www-cdn.bq.com/file/Witbox/Manual_Slic3r_EN.pdf

- Repetier-Host guide: https://www-cdn.bq.com/file/Witbox/Manual_Repetier_EN.pdf

- Cura 3D guide: https://www-cdn.bq.com/file/Witbox/Manual_Cura_EN.pdf

- Note: Remember that Prusa i3 Hephestos printing area is 215x210x180 mm.

- Once you have the g-code file, save the file on an SD card. Insert the SD card into the LCD control panel slot. In the main menu select "Print from SD". Now select your g-code file. The printer will start automatically. You can view the progress of the part and the extrusion temperature on the LCD panel of the printer. When printing is completed, remove the glass base by removing the clamps. With the base resting on a table, remove the parts by pulling on them firmly.

- You need to apply hairspray to the glass for better adhesion of parts!

Annex

Firmware

Follow the next steps to update the firmware:

1. Download the firmware. In the RepRap wiki you can find a entire list of available firmwares:

Link: http://reprap.org/wiki/List_of_Firmware

2. Here are some of the most popular firmwares and our modification of Marlin:

Marlin: http://reprap.org/wiki/Marlin Sprinter: http://reprap.org/wiki/Sprinter Marlin Hephestos: File:Marlin Hephestos.zip

3. Download and install the Arduino software from their main site:

Link: http://www.arduino.cc/en/Main/Software

4. Inside of the firmware folder, you must open the .ino file with the Arduino IDE.

5. Once open, a tab called "configuration.h" will appear. In this file you can configure the parameters of your printer.

6. When you complete configuration, upload the program by selecting "Arduino Mega" from the list of boards and clicking the upload button.

Drivers calibration

- Materials Needed:

This step must be repeated with all drivers, you will need two motors for Z Axis driver calibration.

- Intensity for each Driver:

| Driver | Intensity (mA) |

|---|---|

| X Axis | 250 |

| Y Axis | 250 |

| Z Axis | 450 |

| Extruder | 680 |

| Arduino with RAMPS | aprox. 74 (not regulable) |

Wiring

It is necessary to connect one endstop sensor and thermistor, because of firmware firewalls.

Multimeter preparation

Connect the multimeter in serial connection between Arduino and power supply. Put multimeter in intensity measurement mode.

Multimeter adjustment

Connect the Arduino Mega to the computer. The flowing current is 74 mA approximately (this may differ between plates). Open Pronterface, select the correct port and connect to Arduino.

You must move the motor using Pronterface interface. Measure the current and regulate this using the Ceramic screw trimmer together with the mulitmeter. The current should be set to the sum of the current circulating in the PCBA and the current in the motor. For example, in X Axis current must be 74 mA + 250 mA = 324 mA.

Pre-heat or send the M302 command for completing the extruder calibration.

Arduino needs to be reset before calibrating the next driver.

Pronterface download link: http://reprap.org/wiki/Printrun