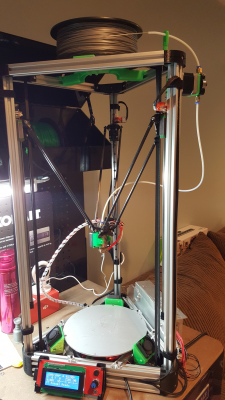

Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 09, 2015 05:45PM |

Registered: 10 years ago Posts: 14,672 |

You might want to check out my blog entry about a large delta build at [miscsolutions.wordpress.com].

Edited 1 time(s). Last edit at 08/09/2015 05:47PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 08/09/2015 05:47PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 09, 2015 09:11PM |

Registered: 9 years ago Posts: 73 |

Thanks, König and DC42! :-)

What are the largest round heat beds available? I saw one with a diameter of 33 cm. Anything larger out there?

DC, can you post URLs for the items you purchased for the modified printer in your blog? I see some but not all. And what were the prices for the various items? What you did, is exactly the same thing I have in mind for my printer. But I also want to place my electronics on top, far away from the heat bed.

And I also need a URL where to purchases custom-sized acrylic glass. I am considering to build an attractive housing for the printer.

Edited 5 time(s). Last edit at 08/09/2015 09:41PM by Sven.L.

What are the largest round heat beds available? I saw one with a diameter of 33 cm. Anything larger out there?

DC, can you post URLs for the items you purchased for the modified printer in your blog? I see some but not all. And what were the prices for the various items? What you did, is exactly the same thing I have in mind for my printer. But I also want to place my electronics on top, far away from the heat bed.

And I also need a URL where to purchases custom-sized acrylic glass. I am considering to build an attractive housing for the printer.

Edited 5 time(s). Last edit at 08/09/2015 09:41PM by Sven.L.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 09, 2015 11:09PM |

Registered: 9 years ago Posts: 309 |

Quote

Sven.L

Thanks, König and DC42! :-)

What are the largest round heat beds available? I saw one with a diameter of 33 cm. Anything larger out there?

DC, can you post URLs for the items you purchased for the modified printer in your blog? I see some but not all. And what were the prices for the various items? What you did, is exactly the same thing I have in mind for my printer. But I also want to place my electronics on top, far away from the heat bed.

And I also need a URL where to purchases custom-sized acrylic glass. I am considering to build an attractive housing for the printer.

Contact this guy Jim at 602-499-0100 and tell him what you are looking for. If they don't have one they will make one for you.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 09, 2015 11:55PM |

Registered: 9 years ago Posts: 73 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 10, 2015 12:32AM |

Registered: 9 years ago Posts: 309 |

Quote

Sven.L

TheViseAd. thanks. It's about the heat bed? Do you have an e-mail for him? I am not located in the USA, that's why.

Sorry, his website is at http://3dheatbeds.com/contact.html.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 10, 2015 02:36AM |

Registered: 9 years ago Posts: 73 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 10, 2015 07:41PM |

Registered: 9 years ago Posts: 73 |

Question: if I keep the rods long as they are now (as delivered with the Kossel 2020), without using the saw to cut them shorter, what printing area would I have, by diameter and height? Who can do these mathematics for me? Or, at least, provide me with the correct mathematical formulas so I can calculate by myself. Would be appreciated. Thanks.

Edited 2 time(s). Last edit at 08/11/2015 03:23AM by Sven.L.

Edited 2 time(s). Last edit at 08/11/2015 03:23AM by Sven.L.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 12, 2015 05:34AM |

Registered: 9 years ago Posts: 73 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 12, 2015 09:12AM |

Registered: 8 years ago Posts: 48 |

I'm having a hard time getting my first layer z height nailed down. I've calibrated each tower and the midpoint and have flat movement after homing, but when I run autoprobe I get about 1mm of "slope" in my bed. Then when I print the extruder drags on the plate, every time. I've tried raising my z_manual_offset, but I don't think that's it since I'm auto-leveling. changing z probe offset seems to help, but I'm already at 0 and the comments in marlin config say to always use negative numbers. I'm running FST sensors and a johnsl board, and that has given me much more consistency in my probe numbers, but it didn't help at all with the head being to low after autolevel.

Any thoughts?

Any thoughts?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 12, 2015 12:14PM |

Registered: 9 years ago Posts: 309 |

Quote

wrangellboy

I'm having a hard time getting my first layer z height nailed down. I've calibrated each tower and the midpoint and have flat movement after homing, but when I run autoprobe I get about 1mm of "slope" in my bed. Then when I print the extruder drags on the plate, every time. I've tried raising my z_manual_offset, but I don't think that's it since I'm auto-leveling. changing z probe offset seems to help, but I'm already at 0 and the comments in marlin config say to always use negative numbers. I'm running FST sensors and a johnsl board, and that has given me much more consistency in my probe numbers, but it didn't help at all with the head being to low after autolevel.

Any thoughts?

You have a couple of problems here, let's start by assuming you are still using the default Folgertech firmware. You should either roll your own or use a premade one such as mine with the settings you need in them.

1. Your slope on your bed indicates that your numbers are not correct. Here is how you check for your bed flatness and also assists in adjusting your bed. Assuming your end stops are correct, the bed is level (manually/[hysically leveled to the frame) and your using the proper firmware settings for your steppers.

a. Home your printer and place a piece of paper on your hot bed.

b. Turn on your hotend to your printing temperature.

c. Turn on your bed to your printing temperature.

d. Lower the bed until it "just pinches" the paper in between the tip and the bed. You should be able to slide the paper in and out, but have a "slight" drag on the paper. This indicates you are touching the paper at exactly the right height.

e. Look at your height, it should be relatively close to 0 + or - less then a mm.

f. Run your hot end in the X/Y positions by 50 mm in any direction and look for the height of the tip to be perfectly flat and maintain that drag on the paper. If it lowers or increases in height at all, follow this site until you have corrected it

2. If the tip touches the bed while printing then your Z height offset for the probe is incorrect so it is attempting to put the tip where it thinks it should be. Once your problem 1 is handled, you need to do the following.

a. Lower the servo (or whatever your using) until the probe is ready.

b. Lower the tip until the probe is activated by the bed.

c. Measure or read off the proper settings from your application and adjust the firmware and upload these settings.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 12, 2015 12:21PM |

Registered: 8 years ago Posts: 48 |

Quote

thevisad

Quote

wrangellboy

I'm having a hard time getting my first layer z height nailed down. I've calibrated each tower and the midpoint and have flat movement after homing, but when I run autoprobe I get about 1mm of "slope" in my bed. Then when I print the extruder drags on the plate, every time. I've tried raising my z_manual_offset, but I don't think that's it since I'm auto-leveling. changing z probe offset seems to help, but I'm already at 0 and the comments in marlin config say to always use negative numbers. I'm running FST sensors and a johnsl board, and that has given me much more consistency in my probe numbers, but it didn't help at all with the head being to low after autolevel.

Any thoughts?

You have a couple of problems here, let's start by assuming you are still using the default Folgertech firmware. You should either roll your own or use a premade one such as mine with the settings you need in them.

1. Your slope on your bed indicates that your numbers are not correct. Here is how you check for your bed flatness and also assists in adjusting your bed. Assuming your end stops are correct, the bed is level (manually/[hysically leveled to the frame) and your using the proper firmware settings for your steppers.

a. Home your printer and place a piece of paper on your hot bed.

b. Turn on your hotend to your printing temperature.

c. Turn on your bed to your printing temperature.

d. Lower the bed until it "just pinches" the paper in between the tip and the bed. You should be able to slide the paper in and out, but have a "slight" drag on the paper. This indicates you are touching the paper at exactly the right height.

e. Look at your height, it should be relatively close to 0 + or - less then a mm.

f. Run your hot end in the X/Y positions by 50 mm in any direction and look for the height of the tip to be perfectly flat and maintain that drag on the paper. If it lowers or increases in height at all, follow this site until you have corrected it

2. If the tip touches the bed while printing then your Z height offset for the probe is incorrect so it is attempting to put the tip where it thinks it should be. Once your problem 1 is handled, you need to do the following.

a. Lower the servo (or whatever your using) until the probe is ready.

b. Lower the tip until the probe is activated by the bed.

c. Measure or read off the proper settings from your application and adjust the firmware and upload these settings.

Thanks for the input. I'm using your firmware. I've done all the step 1 calibration you mentioned and everything looks good following those steps. It's not until after I do g29 that things get weird. I've been googling this morning and found some walkthroughs that show it being ok to use positive z probe offset values when you're using FSR's to lift the nozzle slightly above the bed. I'll try that when I get home.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 12, 2015 10:31PM |

Registered: 8 years ago Posts: 47 |

Hello everyone

I just got my aluminum base kit from Folgertech, and they are beautiful! i am wondering if anyone knows the size of bolt that is supposed to be used for the bearings on the top? I switched the bolts and T-Nuts out to M4, and they're much sturdier, but i am not sure about the bolts for the bearings that move the GT2 belts.

Thanks much for the help!

I just got my aluminum base kit from Folgertech, and they are beautiful! i am wondering if anyone knows the size of bolt that is supposed to be used for the bearings on the top? I switched the bolts and T-Nuts out to M4, and they're much sturdier, but i am not sure about the bolts for the bearings that move the GT2 belts.

Thanks much for the help!

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 12, 2015 10:39PM |

Registered: 8 years ago Posts: 48 |

Quote

wrangellboy

Quote

thevisad

Quote

wrangellboy

I'm having a hard time getting my first layer z height nailed down. I've calibrated each tower and the midpoint and have flat movement after homing, but when I run autoprobe I get about 1mm of "slope" in my bed. Then when I print the extruder drags on the plate, every time. I've tried raising my z_manual_offset, but I don't think that's it since I'm auto-leveling. changing z probe offset seems to help, but I'm already at 0 and the comments in marlin config say to always use negative numbers. I'm running FST sensors and a johnsl board, and that has given me much more consistency in my probe numbers, but it didn't help at all with the head being to low after autolevel.

Any thoughts?

You have a couple of problems here, let's start by assuming you are still using the default Folgertech firmware. You should either roll your own or use a premade one such as mine with the settings you need in them.

1. Your slope on your bed indicates that your numbers are not correct. Here is how you check for your bed flatness and also assists in adjusting your bed. Assuming your end stops are correct, the bed is level (manually/[hysically leveled to the frame) and your using the proper firmware settings for your steppers.

a. Home your printer and place a piece of paper on your hot bed.

b. Turn on your hotend to your printing temperature.

c. Turn on your bed to your printing temperature.

d. Lower the bed until it "just pinches" the paper in between the tip and the bed. You should be able to slide the paper in and out, but have a "slight" drag on the paper. This indicates you are touching the paper at exactly the right height.

e. Look at your height, it should be relatively close to 0 + or - less then a mm.

f. Run your hot end in the X/Y positions by 50 mm in any direction and look for the height of the tip to be perfectly flat and maintain that drag on the paper. If it lowers or increases in height at all, follow this site until you have corrected it

2. If the tip touches the bed while printing then your Z height offset for the probe is incorrect so it is attempting to put the tip where it thinks it should be. Once your problem 1 is handled, you need to do the following.

a. Lower the servo (or whatever your using) until the probe is ready.

b. Lower the tip until the probe is activated by the bed.

c. Measure or read off the proper settings from your application and adjust the firmware and upload these settings.

Thanks for the input. I'm using your firmware. I've done all the step 1 calibration you mentioned and everything looks good following those steps. It's not until after I do g29 that things get weird. I've been googling this morning and found some walkthroughs that show it being ok to use positive z probe offset values when you're using FSR's to lift the nozzle slightly above the bed. I'll try that when I get home.

Just in case someone has the same issue as me in the future. Setting my Z_PROBE_OFFSET_FROM_EXTRUDER to a positive value (.2 in my case) solved my issue. Printing away now...

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 13, 2015 05:20AM |

Registered: 9 years ago Posts: 73 |

Question: if I keep the rods long as they are now as delivered (Kossel 2020), without using the saw to cut them shorter, what printing area would I have, by diameter and height? Who can do these mathematics for me? Or, at least, provide me with the correct mathematical formulas so I can calculate by myself. Would be appreciated. Thanks.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 13, 2015 05:59AM |

Registered: 9 years ago Posts: 445 |

Quote

Sven.L

Question: if I keep the rods long as they are now as delivered (Kossel 2020), without using the saw to cut them shorter, what printing area would I have, by diameter and height? Who can do these mathematics for me? Or, at least, provide me with the correct mathematical formulas so I can calculate by myself. Would be appreciated. Thanks.

Just three threads down from this (at writing moment, but its been at the top for some time now) there is this thread about a delta-calculator.....

Edited 1 time(s). Last edit at 08/13/2015 05:59AM by Koenig.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 13, 2015 07:26AM |

Registered: 9 years ago Posts: 73 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 13, 2015 02:15PM |

Registered: 8 years ago Posts: 150 |

My kit (rev. A) just arrived

Box was all in one piece and most things look good, including the printed corners.

Only setback so far is the heat bed that has a damaged surface.

I have contacted Folger about the print bed.

Will check things out more thoroughly this weekend. Anything special I should look out for?

Cheers!

Box was all in one piece and most things look good, including the printed corners.

Only setback so far is the heat bed that has a damaged surface.

I have contacted Folger about the print bed.

Will check things out more thoroughly this weekend. Anything special I should look out for?

Cheers!

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 15, 2015 03:17AM |

Registered: 8 years ago Posts: 150 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 15, 2015 10:07AM |

Registered: 8 years ago Posts: 47 |

I love my hexagon extruder. Never had a jam and it's been working great. What I like about it is that there is no cavity in between the push fit connection and the filament chamber. So you know that when its in, it's in. Inexpensive and it came with everything sans the mini push fit connector. So if you get it make sure to acquire that also. I think they sell it for direct drive. But you just unscrew the little adapter on top and you can use it for Bowden.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 15, 2015 11:06AM |

Registered: 9 years ago Posts: 309 |

Quote

SlowFoot

From what I understand the extruder that come with the kit is not the best one around. So what is?

I got a Mk7 and a Mk8 pulley, a reasonably working 3D.printer and a few kg of PLA.

Cheers!

Edit typo

Nothing wrong with the hotend in this and unless you need to print something other then ABS/PLA (or higher then 235 degree) then there is no need to change it out. If you do need to change it out then you would want to use something like the e3d hot end or the budaschnozzle. These are the best hotends on the market. The primary reason is the removal of the PTFE tubing in the throat which allows the hotend to hit 400 degrees. You could do the same thing with the existing hotend by replacing the throat with a solid brass or stainless throat. I am waiting for my E3D hotend to come for my rebuild right now. It's one of the last pieces I need to complete the printer. As soon as that arrives I will wire up the hot end cable and I can start printing again on this. However, something to note, the existing hotend is not an exact duplicate of the e3d J head. The groove mount in the existing hotend is 5mm, in the e3d standard jhead it is 6mm. This means that the metal groove mounts will not work for the hotend that comes in this kit.

Edited 2 time(s). Last edit at 08/15/2015 11:14AM by thevisad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 15, 2015 11:27AM |

Registered: 9 years ago Posts: 309 |

Just an FYI, once my printer is finished being built, I will be offering for sale some of the items I have designed throughout the replacement/upgrade process. The following items will be available through me (private message) or my store site. I have a laser cutter on hand and in my basement, so there is no wait for cutting Acrylic other then if I have orders ahead of you. I can provide some of the items now, but I want to be able to show the entire printer replacement as a final piece before fully offering them. Once my CNC mill is up and running, I will be offering aluminum replacements for the end stops and rail stops as well as the upper and lower beds.

Complete custom wiring solution for the motor wiring, hot end wiring and end stop wiring all done with shielded cabling all using igus wiring, molex or JST connectors. This includes quick connects at the hot end to be able to replace parts as needed.

Replacement laser cut acrylic pieces for the existing acrylic using readily available acrylic sheets.

Upgraded laser cut acrylic pieces for optical sensor replacements, with custom engraving in the pieces (seen below)

Triangular acrylic pieces to replace the flimsy bed mount acrylic (the picture above this post shows aluminum) with custom laser engraving on the piece.

Lasercut bed insulators from fiberglass and thin paneling.

Edited 4 time(s). Last edit at 08/15/2015 11:50AM by thevisad.

Complete custom wiring solution for the motor wiring, hot end wiring and end stop wiring all done with shielded cabling all using igus wiring, molex or JST connectors. This includes quick connects at the hot end to be able to replace parts as needed.

Replacement laser cut acrylic pieces for the existing acrylic using readily available acrylic sheets.

Upgraded laser cut acrylic pieces for optical sensor replacements, with custom engraving in the pieces (seen below)

Triangular acrylic pieces to replace the flimsy bed mount acrylic (the picture above this post shows aluminum) with custom laser engraving on the piece.

Lasercut bed insulators from fiberglass and thin paneling.

Edited 4 time(s). Last edit at 08/15/2015 11:50AM by thevisad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 15, 2015 01:49PM |

Registered: 8 years ago Posts: 150 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 15, 2015 01:52PM |

Registered: 9 years ago Posts: 309 |

Quote

SlowFoot

Quote

Rattfink

Quote

thevisad

Eeee......extruder, not hot end. Other end of the bowden tube you know..

Thanks anyways

Doh!! i was reading that after waking up and didn't have a full cup of coffee in me. Yes! The extruder in this is junk, I think Tim pointed out a while ago it was designed to be on the hotend and pulling, versus pushing. I reworked this one a little and it works perfect for the job.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 15, 2015 05:45PM |

Registered: 9 years ago Posts: 110 |

Quote

thevisad

Quote

SlowFoot

Quote

Rattfink

Quote

thevisad

Eeee......extruder, not hot end. Other end of the bowden tube you know..

Thanks anyways

Doh!! i was reading that after waking up and didn't have a full cup of coffee in me. Yes! The extruder in this is junk, I think Tim pointed out a while ago it was designed to be on the hotend and pulling, versus pushing. I reworked this one a little and it works perfect for the job.

+1 On this rework. I downloaded and printed this design and works 10x better than the old extruder used to. Havent had any issues with it and prints are getting dialed in for sure. Between this and the dual fans on the hot end, everything is printing nice including overhangs which is what I was having issues with.

Notice the before and after in the Overhang at the base of these prints.

Edited 2 time(s). Last edit at 08/15/2015 05:47PM by cman8.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 15, 2015 05:49PM |

Registered: 9 years ago Posts: 110 |

Quote

thevisad

Quote

SlowFoot

From what I understand the extruder that come with the kit is not the best one around. So what is?

I got a Mk7 and a Mk8 pulley, a reasonably working 3D.printer and a few kg of PLA.

Cheers!

Edit typo

Nothing wrong with the hotend in this and unless you need to print something other then ABS/PLA (or higher then 235 degree) then there is no need to change it out. If you do need to change it out then you would want to use something like the e3d hot end or the budaschnozzle. These are the best hotends on the market. The primary reason is the removal of the PTFE tubing in the throat which allows the hotend to hit 400 degrees. You could do the same thing with the existing hotend by replacing the throat with a solid brass or stainless throat. I am waiting for my E3D hotend to come for my rebuild right now. It's one of the last pieces I need to complete the printer. As soon as that arrives I will wire up the hot end cable and I can start printing again on this. However, something to note, the existing hotend is not an exact duplicate of the e3d J head. The groove mount in the existing hotend is 5mm, in the e3d standard jhead it is 6mm. This means that the metal groove mounts will not work for the hotend that comes in this kit.

Thevisad, Mind sharing a pic of how you mounted your extruder to your frame?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 15, 2015 06:52PM |

Registered: 9 years ago Posts: 309 |

Quote

cman8

Thevisad, Mind sharing a pic of how you mounted your extruder to your frame?

Certainly

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 15, 2015 08:37PM |

Registered: 9 years ago Posts: 110 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 16, 2015 03:07AM |

Registered: 8 years ago Posts: 150 |

Quote

thevisad

Quote

SlowFoot

Quote

Rattfink

Quote

thevisad

Eeee......extruder, not hot end. Other end of the bowden tube you know..

Thanks anyways

Doh!! i was reading that after waking up and didn't have a full cup of coffee in me. Yes! The extruder in this is junk, I think Tim pointed out a while ago it was designed to be on the hotend and pulling, versus pushing. I reworked this one a little and it works perfect for the job.

Thanks thevisad! Looks very good, but I think I start with the original, with the flange. Might "borrow" the top and bottom plates you have too, we get some scrap stainless steel plates at work now and then.

Cheers!

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 16, 2015 11:21AM |

Registered: 8 years ago Posts: 150 |

Quote

cman8

Quote

thevisad

Quote

SlowFoot

Quote

Rattfink

Quote

thevisad

Eeee......extruder, not hot end. Other end of the bowden tube you know..

Thanks anyways

Doh!! i was reading that after waking up and didn't have a full cup of coffee in me. Yes! The extruder in this is junk, I think Tim pointed out a while ago it was designed to be on the hotend and pulling, versus pushing. I reworked this one a little and it works perfect for the job.

+1 On this rework. I downloaded and printed this design and works 10x better than the old extruder used to. Havent had any issues with it and prints are getting dialed in for sure. Between this and the dual fans on the hot end, everything is printing nice including overhangs which is what I was having issues with.

..................

Print cooling is also high on the improvement list, I can only spot one fan on you pic cman8.

Cheers!

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 16, 2015 03:32PM |

Registered: 8 years ago Posts: 47 |

Ok - my feeble brain has been at this all day. I feel I'm on the right track but can't seem to get my brain wrapped fully around the smooth rod offset value to level the effector. I went through the link for adjusting in a previous post, I am at z-pos 0 at center, but around 2.1mm on each tower.

So at least they're all pretty close on the towers, so this tells me that the effector is going away from the build plate as it moves to the tower? So if I adjust the end stops that would not help I am thinking because that would mess up the center z position. I read that I should adjust he smooth rod offset in smaller .5 increments. Am I on the right track?

Thanks

So at least they're all pretty close on the towers, so this tells me that the effector is going away from the build plate as it moves to the tower? So if I adjust the end stops that would not help I am thinking because that would mess up the center z position. I read that I should adjust he smooth rod offset in smaller .5 increments. Am I on the right track?

Thanks

Sorry, only registered users may post in this forum.