Folger Prusa i3 Kit from ebay

Posted by Waltermixx

|

Re: Folger Prusa i3 Kit from ebay October 18, 2014 07:19PM |

Registered: 9 years ago Posts: 36 |

I was having some fun until I started printing calibration shapes ....

Here's a photo of the steps shape I'm having trouble with:

Steps

Something goes wrong at the very top step: it looks like too much material is being extruded (or perhaps the infill is wrong), as the step bulges out. The measurements aren't too bad, roughly 5mm for all layers, but only to within 0.1mm or so.

Also, the tracks extruded over the cutout on the second layer are drooping (not sure if you can see that in the photo). Oddly, with the same settings but a different reel of PLA, I didn't see this.

My settings are: bed 65C, nozzle 190C, 0.2mm layer height.

Any ideas - is my nozzle too hot perhaps?

Here's a photo of the steps shape I'm having trouble with:

Steps

Something goes wrong at the very top step: it looks like too much material is being extruded (or perhaps the infill is wrong), as the step bulges out. The measurements aren't too bad, roughly 5mm for all layers, but only to within 0.1mm or so.

Also, the tracks extruded over the cutout on the second layer are drooping (not sure if you can see that in the photo). Oddly, with the same settings but a different reel of PLA, I didn't see this.

My settings are: bed 65C, nozzle 190C, 0.2mm layer height.

Any ideas - is my nozzle too hot perhaps?

|

Re: Folger Prusa i3 Kit from ebay October 18, 2014 07:49PM |

Registered: 9 years ago Posts: 208 |

Quote

Wpflum

It wasn't this thread it was [forums.reprap.org] where he asked about getting listed as a US supplier back in July.

Oh Cool, I had no idea

Just sent him a PM saying hi, and asked him to check out the thread.

cheers.

Edited 1 time(s). Last edit at 10/18/2014 08:02PM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay October 18, 2014 09:34PM |

Registered: 9 years ago Posts: 36 |

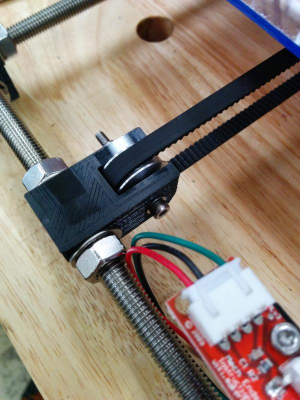

I had a hard time using the provided Y endstop, or finding a suitable replacement online - I wanted one that would sit at the rear of the printer and be activated by the edge of the bed itself.

In the end I modified an existing design - and although it's not pretty, it works well.

The STL files and a photo are on Tinkercad: Extra Height Y Endstop for Folger Prusa i3

In the end I modified an existing design - and although it's not pretty, it works well.

The STL files and a photo are on Tinkercad: Extra Height Y Endstop for Folger Prusa i3

|

Re: Folger Prusa i3 Kit from ebay October 19, 2014 02:10AM |

Registered: 9 years ago Posts: 58 |

@jjbunn,

Looking at your print I can't see the bulge part clear enough to really make any guesses. One thing I do notice is that your prints have a very wavy look to them. Under a microscope I would guess that you can see separation or poor bonding of the layers. I corrected this problem on my machine by moving the lead screws further up in the flex coupling so that the connection would be less stiff. This allows the lead screw to move without putting tension on the rod.

Other things that I have seen cause similar issues are the stepper vrefs being off or something on the printer is causing too much vibration.

A few examples of microscope shots can be found on my google drive. A few shots there show what I am talking about.

This is how I used the end-stops that came with my kit for the y axis. I doesn't actually touch the bed but it does touch the carriage in the corner. This has been very reliable for me so far.

Your end-stop mod looks like it should work out pretty well. Let us know if you have any issues.

Prusa y endstop by czmorris, on Flickr

Edited 1 time(s). Last edit at 10/19/2014 02:11AM by czmorris.

Looking at your print I can't see the bulge part clear enough to really make any guesses. One thing I do notice is that your prints have a very wavy look to them. Under a microscope I would guess that you can see separation or poor bonding of the layers. I corrected this problem on my machine by moving the lead screws further up in the flex coupling so that the connection would be less stiff. This allows the lead screw to move without putting tension on the rod.

Other things that I have seen cause similar issues are the stepper vrefs being off or something on the printer is causing too much vibration.

A few examples of microscope shots can be found on my google drive. A few shots there show what I am talking about.

This is how I used the end-stops that came with my kit for the y axis. I doesn't actually touch the bed but it does touch the carriage in the corner. This has been very reliable for me so far.

Your end-stop mod looks like it should work out pretty well. Let us know if you have any issues.

Prusa y endstop by czmorris, on Flickr

Edited 1 time(s). Last edit at 10/19/2014 02:11AM by czmorris.

|

Re: Folger Prusa i3 Kit from ebay October 19, 2014 02:46AM |

Registered: 9 years ago Posts: 36 |

Quote

czmorris

@jjbunn,

Looking at your print I can't see the bulge part clear enough to really make any guesses. One thing I do notice is that your prints have a very wavy look to them. Under a microscope I would guess that you can see separation or poor bonding of the layers. I corrected this problem on my machine by moving the lead screws further up in the flex coupling so that the connection would be less stiff. This allows the lead screw to move without putting tension on the rod.

Other things that I have seen cause similar issues are the stepper vrefs being off or something on the printer is causing too much vibration.

A few examples of microscope shots can be found on my google drive. A few shots there show what I am talking about.

This is how I used the end-stops that came with my kit for the y axis. I doesn't actually touch the bed but it does touch the carriage in the corner. This has been very reliable for me so far.

Your end-stop mod looks like it should work out pretty well. Let us know if you have any issues.

Prusa y endstop by czmorris, on Flickr

Thanks for the comments and advice. I'm going to check my Vref on the Z controller tomorrow.I do have good clearance between the motor axle and the threaded rod, inside both couplers. Interestingly, I printed a 12cm tall thick tube without any issues: the sides were flat and showed no issues, and the top was equally good.

It looks like the problem only occurs when the print terminates on a small filled area.

I took some photos under the microscope: here's one showing the layers up the side of the print microscopic, and another showing the bulging on the top layer: bulging

The same problem occurred on a different model, a pyramid - the top became a hot gooey mass as the nozzle squirted around in it: gooey mess

|

Re: Folger Prusa i3 Kit from ebay October 19, 2014 11:32AM |

Registered: 9 years ago Posts: 58 |

|

Re: Folger Prusa i3 Kit from ebay October 19, 2014 02:38PM |

Registered: 9 years ago Posts: 58 |

Here are a few shots of what I believe is that same 5mm stepped print on my machine. In this case printed in ABS.

Pictures of Step Calibration

Pictures of Step Calibration

|

Re: Folger Prusa i3 Kit from ebay October 19, 2014 03:15PM |

Registered: 9 years ago Posts: 58 |

Second mod to the bearing holder. When I got a chance to look at it closely it looked like there would be clearance issues. I Modified it to work with zip ties instead as suggested. Instead of making it such that the ties have to go through the bed I added a channel in the back of the part that connects to the bed for the tip tie to rest in. I have no plans to change mine currently as it isn't giving me any issues. Again if someone tries it out and it works let me know and I will see what I can do about posting it on Thingiverse. I'm sure the source files are under an open source license but I'm not sure of the original source. If anyone knows if Folger got these from somewhere that I can source please let me know.

Here is the link

Here is the link

|

Re: Folger Prusa i3 Kit from ebay October 19, 2014 04:33PM |

Registered: 12 years ago Posts: 76 |

I don't think I'm supposed to make a wire chain for this printer, 3 tries, 3 failures. Last nights try wound up with me checking it at 2 in the morning after 3 hours of printing only to find it air printing and that it looked like it had only printed about 1/4 inch of the 36 links. It was happily chugging along with no errors and no issues with the filament but the nozzle was half an inch above the last layer. I just pulled the plug and went back to bed. Today I got asked to make a smaller food tray for our new bird, the existing one is so deep that he sits in it to eat so swmbo wanted me to print a shallower one. I warned her that I was having issues but I'd give it a try. 2 hours later I had a model in freecad based off the existing tray and I went to the shop to see what was wrong with the printer so I could fix it and print the new tray out. NOTHING! I could find absolutely NOTHING wrong, I heated up the extruder and pushed out a bit of ABS and everything looked good so I have no idea other than the ABS Gods of 3D printers were bored and have decided to screw with me. It's been almost 2 hours and the tray is printing nicely. This is also the first print where I've paused it to fix an issue and then restarted and it kept going like nothing happened. I noticed when it put down the skirt towards the back of the bed the nozzle seemed too high, the layer was squiggly compared to the front one so I paused and turn the back two bed levelers up a turn and a half. Seemed to work as the next layers in the back looked good. I don't have a reason for the bed height change since I had leveled it again when I put it back on after adding the zip ties to the bearing mounts but I'm sure it was just me reading the meter wrong.

Hopefully all goes well and I get to prove that getting a printer was really worth it, at least to my wife The only down side is that I'm going to get more 'Honey Do' prints but that will justify more filament colors and extra parts as well so it will all work out.

The only down side is that I'm going to get more 'Honey Do' prints but that will justify more filament colors and extra parts as well so it will all work out.

Hopefully all goes well and I get to prove that getting a printer was really worth it, at least to my wife

The only down side is that I'm going to get more 'Honey Do' prints but that will justify more filament colors and extra parts as well so it will all work out.

The only down side is that I'm going to get more 'Honey Do' prints but that will justify more filament colors and extra parts as well so it will all work out.

|

Re: Folger Prusa i3 Kit from ebay October 19, 2014 04:36PM |

Registered: 12 years ago Posts: 76 |

That looks good. I'm not planning on changing out mine unless I have issues again, they seem to want to stay nice and tight with the zip ties in place. I also thought it might help with keeping the mounts tight on the bed since when I disassembled my bed I found ALL of the nuts loose even with the lock washers on. I tightened every one tighter than before so maybe that wont happen again.

|

Re: Folger Prusa i3 Kit from ebay October 19, 2014 04:54PM |

Registered: 9 years ago Posts: 36 |

Quote

czmorris

Here are a few shots of what I believe is that same 5mm stepped print on my machine. In this case printed in ABS.

Pictures of Step Calibration

Very nice indeed - wow!

I notice you have a bed underneath the model - how did you set that up?

After adjusting Vref on Z a little (I upped it to 0.400 from 0.350) I ran another print, with no improvement. I also tried a slightly lower temperature of 185 for the PLA, but had trouble with bed adhesion.

So, I started looking at mechanical issues, and I think that I may have a problem. Here's the situation

1) At Z Home, Z axis couplers are set up so that threaded rod is a good 5mm away from the motor shaft, inside the coupler. All the coupler's grub screws are tight.

2) I do a long print, with significant height

3) I return the printer to Z Home

4) If I now loosen the grub screws on the right hand coupler's threaded rod, there is clearly some tension, and the right hand X axis support drops with a "clonk", I'd guess about 5mm.

This suggests to me that either the Z motors aren't running at quite the same rate, or there is some other issue, like slipping.

What do you think?

|

Re: Folger Prusa i3 Kit from ebay October 19, 2014 05:23PM |

Registered: 9 years ago Posts: 58 |

Quote

jjbunn

Quote

czmorris

Here are a few shots of what I believe is that same 5mm stepped print on my machine. In this case printed in ABS.

Pictures of Step Calibration

Very nice indeed - wow!

I notice you have a bed underneath the model - how did you set that up?

After adjusting Vref on Z a little (I upped it to 0.400 from 0.350) I ran another print, with no improvement. I also tried a slightly lower temperature of 185 for the PLA, but had trouble with bed adhesion.

So, I started looking at mechanical issues, and I think that I may have a problem. Here's the situation

1) At Z Home, Z axis couplers are set up so that threaded rod is a good 5mm away from the motor shaft, inside the coupler. All the coupler's grub screws are tight.

2) I do a long print, with significant height

3) I return the printer to Z Home

4) If I now loosen the grub screws on the right hand coupler's threaded rod, there is clearly some tension, and the right hand X axis support drops with a "clonk", I'd guess about 5mm.

This suggests to me that either the Z motors aren't running at quite the same rate, or there is some other issue, like slipping.

What do you think?

The stuff under the model is called rafting. You should be able to find it in your slicer settings somewhere. If you are using Slic3r and Repetier host this is found by going into the Slicer configuration -> Print Settings Tab -> Support Material -> Raft layers. In the case of this print I was using pay software (Simplify3D) but the settings are pretty much the same. I you are having good adhesion on the glass bed I wouldn't bother with rafting though. In my case I use it because I am using a perf-board bed rather than glass.

For your other issue. You might check the nuts which the lead screws are going through on the printed parts which hold the X-axis. I accidently drove the nozzle too far down once and wound up pushing one of these nuts half way out. For several prints it seemed like my Z axis wasn't repeatably homing. I was constantly having to re-level the bed. Then it came out completely which made it obvious. If those are loose and not pressed in firmly they can cause all kinds of issues.

|

Re: Folger Prusa i3 Kit from ebay October 19, 2014 06:18PM |

Registered: 9 years ago Posts: 36 |

Quote

czmorris

Quote

jjbunn

Quote

czmorris

Here are a few shots of what I believe is that same 5mm stepped print on my machine. In this case printed in ABS.

Pictures of Step Calibration

Very nice indeed - wow!

I notice you have a bed underneath the model - how did you set that up?

After adjusting Vref on Z a little (I upped it to 0.400 from 0.350) I ran another print, with no improvement. I also tried a slightly lower temperature of 185 for the PLA, but had trouble with bed adhesion.

So, I started looking at mechanical issues, and I think that I may have a problem. Here's the situation

1) At Z Home, Z axis couplers are set up so that threaded rod is a good 5mm away from the motor shaft, inside the coupler. All the coupler's grub screws are tight.

2) I do a long print, with significant height

3) I return the printer to Z Home

4) If I now loosen the grub screws on the right hand coupler's threaded rod, there is clearly some tension, and the right hand X axis support drops with a "clonk", I'd guess about 5mm.

This suggests to me that either the Z motors aren't running at quite the same rate, or there is some other issue, like slipping.

What do you think?

The stuff under the model is called rafting. You should be able to find it in your slicer settings somewhere. If you are using Slic3r and Repetier host this is found by going into the Slicer configuration -> Print Settings Tab -> Support Material -> Raft layers. In the case of this print I was using pay software (Simplify3D) but the settings are pretty much the same. I you are having good adhesion on the glass bed I wouldn't bother with rafting though. In my case I use it because I am using a perf-board bed rather than glass.

For your other issue. You might check the nuts which the lead screws are going through on the printed parts which hold the X-axis. I accidently drove the nozzle too far down once and wound up pushing one of these nuts half way out. For several prints it seemed like my Z axis wasn't repeatably homing. I was constantly having to re-level the bed. Then it came out completely which made it obvious. If those are loose and not pressed in firmly they can cause all kinds of issues.

I'll check the nut - thanks. I read somewhere else of people having exactly that problem on the Prusa. I wonder if there is a better X axis support piece I should print, one that captures the nut on both ends?

|

Re: Folger Prusa i3 Kit from ebay October 19, 2014 09:52PM |

Registered: 9 years ago Posts: 58 |

|

Re: Folger Prusa i3 Kit from ebay October 19, 2014 11:35PM |

Registered: 9 years ago Posts: 4 |

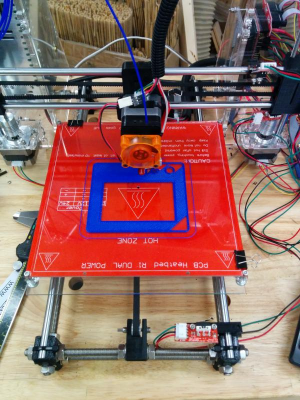

well i've been following along with this thread for awhile.. thanks for everyones input to putting it together the videos from folgertech were good but not for knowing which m3 screw went where. or the electronics and wiring. could of put the endstops on and went poof bye bye arduino board .my pictures at my awesome printer provide a lemon of a kit? no smd thermistor but they shipped a leaded one out promptly and no m10 screws but they were printed on the bag as m10 but they were all m8's.. which lead me to drilling out the plastic pieces to fit..quite a mod . other than that it went together great got a few good prints from the supplied abs filament..

my hotend has one nut close to the hotend i believe the purpose of the nut is to act as a heatsink.. i think there is a ptfe tube inside that threaded piece? when i tried to drill out the old plastic.. i got white stuff not sure if it was the filament or a ptfe tube....

another note.. make sure all m8 nuts are tight when moving around i ended up breaking every Y carriage.. but supergluing them and the bearings in place seemed to have worked so far.. every screw on the Y carriages also came loose i noticed when taking the heated bed off after printing the very few things i have pictured.. no lock washers on them however.. so i may put nylocs on them in the future if it is a problem i tightened them quite well without lock washers..and making sure taping or securing the thermistor and heater carriage wires is good. my thermistor wire broke and i ended up taking it out and breaking it and am now waiting for a replacement.. i read your post about the heated bed having this problem but didnt think about the hotend ..does anyone recommend a way to put a thermistor back in the hotend? ptfe tape or such? this had a brass tube squished around the thermistor....this has been quiet a fun project with all the abuse i gave it i'm surprized it still alive lol..

now with the extruder.. does all yours make a clicking noise or thumping like it can't push the filament in enough when it starts to air print or sometime around that? mine does.. and upon reading about it there are a number of things to do about it. but maybe i have bad filament or the extrude temp isnt right. or the vref on the extruder motor isnt right. or trying to extrude to fast and the hotend can't melt the plastic fast enough... i'm not sure about the tension as there is no way to adjust it. as with direct drive. the filament is suppose to be the tensioner..if it is tension i'm up for a spring extruder..and looking around this extruder is a mk7 style ..but the supplied abs filament worked great.switching from abs to pla seems to have had problems.. well gotta go happy reading and btw that trex skull looks awesome i want one..soon soon....28 bucks sainsmart black abs plastic off of ebay the same one on amazon for 46?

Edited 1 time(s). Last edit at 10/21/2014 12:03PM by amphiox.

my hotend has one nut close to the hotend i believe the purpose of the nut is to act as a heatsink.. i think there is a ptfe tube inside that threaded piece? when i tried to drill out the old plastic.. i got white stuff not sure if it was the filament or a ptfe tube....

another note.. make sure all m8 nuts are tight when moving around i ended up breaking every Y carriage.. but supergluing them and the bearings in place seemed to have worked so far.. every screw on the Y carriages also came loose i noticed when taking the heated bed off after printing the very few things i have pictured.. no lock washers on them however.. so i may put nylocs on them in the future if it is a problem i tightened them quite well without lock washers..and making sure taping or securing the thermistor and heater carriage wires is good. my thermistor wire broke and i ended up taking it out and breaking it and am now waiting for a replacement.. i read your post about the heated bed having this problem but didnt think about the hotend ..does anyone recommend a way to put a thermistor back in the hotend? ptfe tape or such? this had a brass tube squished around the thermistor....this has been quiet a fun project with all the abuse i gave it i'm surprized it still alive lol..

now with the extruder.. does all yours make a clicking noise or thumping like it can't push the filament in enough when it starts to air print or sometime around that? mine does.. and upon reading about it there are a number of things to do about it. but maybe i have bad filament or the extrude temp isnt right. or the vref on the extruder motor isnt right. or trying to extrude to fast and the hotend can't melt the plastic fast enough... i'm not sure about the tension as there is no way to adjust it. as with direct drive. the filament is suppose to be the tensioner..if it is tension i'm up for a spring extruder..and looking around this extruder is a mk7 style ..but the supplied abs filament worked great.switching from abs to pla seems to have had problems.. well gotta go happy reading and btw that trex skull looks awesome i want one..soon soon....28 bucks sainsmart black abs plastic off of ebay the same one on amazon for 46?

Edited 1 time(s). Last edit at 10/21/2014 12:03PM by amphiox.

|

Re: Folger Prusa i3 Kit from ebay October 20, 2014 01:33AM |

Registered: 9 years ago Posts: 208 |

Well completed an 8 hour print with my prusa i3. turned out really good... it's a chest buster from Alien.

[www.thingiverse.com]

interesting, when I sliced it using repetier, it said it would only take 4 hours. but it took 8 hours.

not sure why? at any rate it turned out pretty good and no air printing, no clicking of the extruder stepper,

and oddly enough, no warping of the base... ( I guess a fresh spray of fructice on the glass build plate helped.

not sure why but iphone pics come insideways, but when you click it for the full version it's the correct orientation:

[www.thingiverse.com]

interesting, when I sliced it using repetier, it said it would only take 4 hours. but it took 8 hours.

not sure why? at any rate it turned out pretty good and no air printing, no clicking of the extruder stepper,

and oddly enough, no warping of the base... ( I guess a fresh spray of fructice on the glass build plate helped.

not sure why but iphone pics come insideways, but when you click it for the full version it's the correct orientation:

|

Re: Folger Prusa i3 Kit from ebay October 20, 2014 01:01PM |

Registered: 10 years ago Posts: 477 |

Quote

Waltermixx

Well completed an 8 hour print with my prusa i3. turned out really good... it's a chest buster from Alien.

[www.thingiverse.com]

interesting, when I sliced it using repetier, it said it would only take 4 hours. but it took 8 hours.

not sure why?

I think the time difference is that the slicing programs can't/don't calculate accelleration/decelleration times.

Good to see that you can do a long print with no issues.

Steve

|

Re: Folger Prusa i3 Kit from ebay October 20, 2014 06:02PM |

Registered: 9 years ago Posts: 36 |

Hey Guys!

Sorry it has taken me so long to notice this thread, we have been very busy over at Folger Technologies. It was very exciting to read through this forum and see some of the cool prints you have printed with our i3 kit (especially the alien that Walter printed). I am trying to get John on here he is the owner of the company and the brains behind the whole operation here. We have been pretty busy we just moved into a new building and it has us working double time to keep up with orders and setting up our new facility. Those of you that are having issues can always reach out to us via email or Skype and we will do our best to help you get your issues sorted out.

I am following this thread now. We are open to suggestions as we are going to start selling revision B of our kit soon and your input would be greatly appreciated!

Keep up the good work guys!

Dan

Sorry it has taken me so long to notice this thread, we have been very busy over at Folger Technologies. It was very exciting to read through this forum and see some of the cool prints you have printed with our i3 kit (especially the alien that Walter printed). I am trying to get John on here he is the owner of the company and the brains behind the whole operation here. We have been pretty busy we just moved into a new building and it has us working double time to keep up with orders and setting up our new facility. Those of you that are having issues can always reach out to us via email or Skype and we will do our best to help you get your issues sorted out.

I am following this thread now. We are open to suggestions as we are going to start selling revision B of our kit soon and your input would be greatly appreciated!

Keep up the good work guys!

Dan

|

Re: Folger Prusa i3 Kit from ebay October 20, 2014 06:08PM |

Registered: 9 years ago Posts: 36 |

Quote

dooms101

Looks like your prints are coming along, 4.5hrs without a hiccup sounds great! Perhaps my modifications were too much?

Well either way, I have designed (thingivese page) and printed a spacer/shroud so that you can turn the cold block 180 degrees and still have things line up. It also redirects the air properly and exhausts outwards instead of downwards to prevent warping.

Here is my latest print:

[attachment 41913 2014-10-1413.03.25.jpg]

Looks good, yes?

Such an awesome print! I collect things T-Rex related as I was cursed with short arms. Great work!

|

Re: Folger Prusa i3 Kit from ebay October 20, 2014 06:47PM |

Registered: 9 years ago Posts: 208 |

Congrats on the new space! Very happy You guys are expanding. Glad to see you guys checking into this thread as well,

Lots of positive comments and folks helping each other out.

I think the kit is great. I have learned so much about the guts of 3d printers. Building it was fun, I tried to draw out the build as long as possible, I really enjoyed it.

It's seems to be rock solid now.

Cheers!

Lots of positive comments and folks helping each other out.

I think the kit is great. I have learned so much about the guts of 3d printers. Building it was fun, I tried to draw out the build as long as possible, I really enjoyed it.

It's seems to be rock solid now.

Cheers!

|

Re: Folger Prusa i3 Kit from ebay October 20, 2014 11:41PM |

Registered: 9 years ago Posts: 208 |

Just printed some 60mm fan brackets to replace the 40mm brackets on my Ramps board.

This one from thingiverse will work with a 60mm fan. The 60mm will move more air than the 40mm and the fan i have is

about as quite as the 40mm i have.

[www.thingiverse.com] (it's customizable... no I did not create it, but it's very cool, you can pick a fan size,

the height you want the fan to be at etc. it's very well done )

)

Edited 1 time(s). Last edit at 10/20/2014 11:43PM by Waltermixx.

This one from thingiverse will work with a 60mm fan. The 60mm will move more air than the 40mm and the fan i have is

about as quite as the 40mm i have.

[www.thingiverse.com] (it's customizable... no I did not create it, but it's very cool, you can pick a fan size,

the height you want the fan to be at etc. it's very well done

)

)Edited 1 time(s). Last edit at 10/20/2014 11:43PM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay October 22, 2014 03:29AM |

Registered: 9 years ago Posts: 1 |

Hi all,

I've been reading this thread very carefully since last week Tuesday when my Folger kit arrived.

Thank you very much guys for important information covered in this thread! Based on this I could complete and setup my printer last weekend.

It is my first very personal experience with 3D printing and I'm amused by built of printer itself as well as first printing results.

My prints are just PLA yet. Temperature settings for bed is 60/50 and hot-end 210/200. Layer width 0.2mm. Vrefs are set slightly less than suggested earlier in this thread: X & Z 260mV, Y 490mV, E 290mV. Everything works great with these settings.

As Folger guys are now reading this too, I'd like to thank them for such great kit at the right price level.

Photos are published here: [picasaweb.google.com]

I've been reading this thread very carefully since last week Tuesday when my Folger kit arrived.

Thank you very much guys for important information covered in this thread! Based on this I could complete and setup my printer last weekend.

It is my first very personal experience with 3D printing and I'm amused by built of printer itself as well as first printing results.

My prints are just PLA yet. Temperature settings for bed is 60/50 and hot-end 210/200. Layer width 0.2mm. Vrefs are set slightly less than suggested earlier in this thread: X & Z 260mV, Y 490mV, E 290mV. Everything works great with these settings.

As Folger guys are now reading this too, I'd like to thank them for such great kit at the right price level.

Photos are published here: [picasaweb.google.com]

|

Re: Folger Prusa i3 Kit from ebay October 22, 2014 05:16PM |

Registered: 12 years ago Posts: 2 |

I've just built an I3 (not from a Folger kit) and am having a problem that I hope someone may be able to help with.

I notice that when the extruder is next to the Y-axis stepper motor and hence all the weight is at the left hand end of the Yaxis, that the right hand end lifts slightly and there is play in the Z-axis nut on the right side. As the Yaxis moves across to the right then the extruder weight moves the right Yaxis block down slightly getting rid of the play in the nut.

Now, I am not sure if this is a problem - I have other extruder problems at the moment to be bale to see if it affects the print quality- but has anyone else noticed this? the left hand Z-axis nut stays firmly seated due to the weight of the Y-axis stepper.

Peter

I notice that when the extruder is next to the Y-axis stepper motor and hence all the weight is at the left hand end of the Yaxis, that the right hand end lifts slightly and there is play in the Z-axis nut on the right side. As the Yaxis moves across to the right then the extruder weight moves the right Yaxis block down slightly getting rid of the play in the nut.

Now, I am not sure if this is a problem - I have other extruder problems at the moment to be bale to see if it affects the print quality- but has anyone else noticed this? the left hand Z-axis nut stays firmly seated due to the weight of the Y-axis stepper.

Peter

|

Re: Folger Prusa i3 Kit from ebay October 22, 2014 08:35PM |

Registered: 9 years ago Posts: 208 |

i secured my 5M nuts in the x-motor and x-idler parts using 15minute epoxy. they are in there good... so the only thing moving the x axis is the stepper motors, nothing left to chance...

some folks heat the nuts up and press them into the x-idler/motor printed parts, but I was paranoid I might come in at an odd angle and then they would be stuck in there... so I opted for

a very nicely printed x idler and x motor mount the nut fit nicely on its own, and then I epoxied the hell out of it so it's very very secure

so it's very very secure  hope this helps... this was the black and silver syringe

hope this helps... this was the black and silver syringe

mix of 15 minute epoxy and it works great. I would suggest that as a way to secure the nut in place.

I would suggest that as a way to secure the nut in place.

some folks heat the nuts up and press them into the x-idler/motor printed parts, but I was paranoid I might come in at an odd angle and then they would be stuck in there... so I opted for

a very nicely printed x idler and x motor mount the nut fit nicely on its own, and then I epoxied the hell out of it

so it's very very secure

so it's very very secure  hope this helps... this was the black and silver syringe

hope this helps... this was the black and silver syringe mix of 15 minute epoxy and it works great.

I would suggest that as a way to secure the nut in place.

I would suggest that as a way to secure the nut in place.

|

Re: Folger Prusa i3 Kit from ebay October 23, 2014 06:43AM |

Registered: 12 years ago Posts: 2 |

Thanks Waltermixx

Peter

Peter

Quote

Waltermixx

i secured my 5M nuts in the x-motor and x-idler parts using 15minute epoxy. they are in there good... so the only thing moving the x axis is the stepper motors, nothing left to chance...

some folks heat the nuts up and press them into the x-idler/motor printed parts, but I was paranoid I might come in at an odd angle and then they would be stuck in there... so I opted for

a very nicely printed x idler and x motor mount the nut fit nicely on its own, and then I epoxied the hell out of itso it's very very secure

hope this helps... this was the black and silver syringe

mix of 15 minute epoxy and it works great.I would suggest that as a way to secure the nut in place.

|

Re: Folger Prusa i3 Kit from ebay October 23, 2014 03:50PM |

Registered: 9 years ago Posts: 208 |

Found this on thingiverse for those folks who only want to print PLA, this would not work for ABS for obvious reasons.

it utilizes the existing fan to both cool the extruder, and the PLA print area. Have a look... it prints in 3 pieces making it

Have a look... it prints in 3 pieces making it

easy to print.

[www.thingiverse.com]

I think when my Roll of ABS is all gone, I may start dipping into my PLA reserves...

it utilizes the existing fan to both cool the extruder, and the PLA print area.

Have a look... it prints in 3 pieces making it

Have a look... it prints in 3 pieces making it easy to print.

[www.thingiverse.com]

I think when my Roll of ABS is all gone, I may start dipping into my PLA reserves...

|

Re: Folger Prusa i3 Kit from ebay October 24, 2014 05:58PM |

Registered: 9 years ago Posts: 6 |

Hi Everyone!

Just wanted to give a shout out to all that have been active in this thread. I got my kit a couple weeks ago and have finally got it dialed in as good as its going to be for right now. Many Thanks for all of the information in this thread!!!

My first real print is the case for the full graphic lcd..

Folger did miss the two belt guide pulleys in my kit but luckly I have a metal lathe so I turned some aluminum pulleys so I could get the printer up and running.

I need to print a spool holder next, Any tips on a good holder for the Folger i3?

Just wanted to give a shout out to all that have been active in this thread. I got my kit a couple weeks ago and have finally got it dialed in as good as its going to be for right now. Many Thanks for all of the information in this thread!!!

My first real print is the case for the full graphic lcd..

Folger did miss the two belt guide pulleys in my kit but luckly I have a metal lathe so I turned some aluminum pulleys so I could get the printer up and running.

I need to print a spool holder next, Any tips on a good holder for the Folger i3?

|

Re: Folger Prusa i3 Kit from ebay October 24, 2014 08:06PM |

Registered: 9 years ago Posts: 14 |

I ordered my i3 a few weeks ago (around 60 had been purchased I think), but because real life kept getting in the way, amongst the difficulties I had getting it together, I'm only now getting close. However, I'm a little baffled at the difficulty I'm having with my X carriage. I've finally got my Y and Z moving, but when the X motor picks up (i.e. if I hit the home button) the motor vibrates like anything without moving the carriage anywhere, and then, just before it stops, it moves back and forth about 1/2 cm each direction, without having any results. Until I hit "motors off" the motor is still tight. I started using the different v-ref settings different people have posted here, then gave up and started at 0.07 V (where it vibrated, but didn't dance at the end) moving up by around 0.03 V until I got to 0.47 V where it seemed to dance a little more during the cycle, but I always ended up in the same place. I figured v-ref was the issue because my Z reacted kind of similar until I used Mr.Folger's settings, and away she went. My X still doesn't like me (for the record, I'm still married to my first wife of almost 17 years, I'm not giving up).

Am I barking up the wrong tree, or is it most likely that the v-ref is the problem, and I need to start over at the bottom and work my way up again? I am so close to getting somewhere, and yet so far.

Thanks,

Tyler

================================================================================================

This whole XYZ thing is strange. When you drive around a nuclear reactor face, X and Y are the face, and Z moves in and out.

Y and Z are completely confused on printers

Then again, on a reactor face, the "nozzle" faces the reactor, not the floor.

Edited 1 time(s). Last edit at 10/24/2014 08:07PM by NukedWorker.

Am I barking up the wrong tree, or is it most likely that the v-ref is the problem, and I need to start over at the bottom and work my way up again? I am so close to getting somewhere, and yet so far.

Thanks,

Tyler

================================================================================================

This whole XYZ thing is strange. When you drive around a nuclear reactor face, X and Y are the face, and Z moves in and out.

Y and Z are completely confused on printers

Then again, on a reactor face, the "nozzle" faces the reactor, not the floor.

Edited 1 time(s). Last edit at 10/24/2014 08:07PM by NukedWorker.

|

Re: Folger Prusa i3 Kit from ebay October 24, 2014 08:58PM |

Registered: 9 years ago Posts: 36 |

Quote

DMAN120

I need to print a spool holder next, Any tips on a good holder for the Folger i3?

I'm not totally happy with my spool holder, but it does work.

Folger i3 with spool holder

I modified existing designs for the arms, and designed the spindle and cap myself.

|

Re: Folger Prusa i3 Kit from ebay October 25, 2014 12:06AM |

Registered: 9 years ago Posts: 9 |

Just finished putting mine together, Didn't take as long as I thought it would but I guess the real fun is in the calibration.

Speaking of which, I decided to try and connect my laptop up to it an use pronterface to move the extruder around a bit. However it is acting really strange.

Whenever I tell it to step in a direction of 1mm it seems to move fine in all the directions, but when I try to move anything more (10 or 100 mm) there is a squealing noise(sounding like it from the motor) and at the end of it the motors axle shakes a little. To me this seems like this would happen if there was to much resistance but it does move when i tell it to move 1mm. Also only the X axis motor gets really hot, the other 3 axis motors are still cold to the touch.

Is there some setup that I am missing? I did not play with the code at all yet I only grabbed what was on the google drive and uploaded it to the arduino.

And what is the reflective tape for? I can't figure out what it is suppose to be for.

Speaking of which, I decided to try and connect my laptop up to it an use pronterface to move the extruder around a bit. However it is acting really strange.

Whenever I tell it to step in a direction of 1mm it seems to move fine in all the directions, but when I try to move anything more (10 or 100 mm) there is a squealing noise(sounding like it from the motor) and at the end of it the motors axle shakes a little. To me this seems like this would happen if there was to much resistance but it does move when i tell it to move 1mm. Also only the X axis motor gets really hot, the other 3 axis motors are still cold to the touch.

Is there some setup that I am missing? I did not play with the code at all yet I only grabbed what was on the google drive and uploaded it to the arduino.

And what is the reflective tape for? I can't figure out what it is suppose to be for.

Sorry, only registered users may post in this forum.