Folger Prusa i3 Kit from ebay

Posted by Waltermixx

|

Re: Folger Prusa i3 Kit from ebay October 25, 2014 10:08AM |

Registered: 9 years ago Posts: 208 |

Did you adjust your vref. on each of the stepper motor driver modules? You dont mention it, so I thought I would ask

Did you read through this thread, we discuss reference voltages we have tried, the ones Folgertech recommends, etc.

There is also some discussion on motor wires, the kit came with a jst connector on one end, and lose wires on the other end to put in the RAMPS motor jumpers,

could it be the wiring is not consistent? I'm guessing Vref. issue...

Did you read through this thread, we discuss reference voltages we have tried, the ones Folgertech recommends, etc.

There is also some discussion on motor wires, the kit came with a jst connector on one end, and lose wires on the other end to put in the RAMPS motor jumpers,

could it be the wiring is not consistent? I'm guessing Vref. issue...

|

Re: Folger Prusa i3 Kit from ebay October 25, 2014 12:08PM |

Registered: 9 years ago Posts: 4 |

Just a few questions.

Does this kit contain the rework version of the I3? Or the original?

Is there a summary of suggestions for this specific machine? I noticed a comment asking if someone actually used the original bearings. Is there a reason to not?

What extruder and hot end come in the kit? I don't see it listed on eBay or in this thread.

I'm really interested in this machine as the low price point and great prints you guys are getting. But just want to make sure I know what I'm getting into.

Thanks to everyone on here walking through their issues.

Edited 2 time(s). Last edit at 10/25/2014 02:42PM by BgHurt.

Does this kit contain the rework version of the I3? Or the original?

Is there a summary of suggestions for this specific machine? I noticed a comment asking if someone actually used the original bearings. Is there a reason to not?

What extruder and hot end come in the kit? I don't see it listed on eBay or in this thread.

I'm really interested in this machine as the low price point and great prints you guys are getting. But just want to make sure I know what I'm getting into.

Thanks to everyone on here walking through their issues.

Edited 2 time(s). Last edit at 10/25/2014 02:42PM by BgHurt.

|

Re: Folger Prusa i3 Kit from ebay October 25, 2014 12:48PM |

Registered: 9 years ago Posts: 9 |

Quote

Waltermixx

Yes it's a great kit.

did you give the lcd more thought? I only print from the sd card via the lcd...

I'm trying to learn custom gcodes to add to gcode that is generated,

something to set the bed, then the fan on the extruder, then the hot end...

keeps the extruder cooler...

I asked the Folger guys what they had their Vref set to for their printers, and this is what they sent back:

"The larger bed motor I set it to 0.55V, the Z's are .35V, X is 0.33V, Extruder 0.35V

Thanks!

John"

man of few words... but then again most folks are compared to me

I set the vref to these amounts. I was able to get the X and Z axis to work. I changed the infeed values to something lower in pronterface, then I went and changed the vref and it all got a lot smoother. However the Y axis still is having problems. It just keeps jittering instead of moving to a direction. I know the ramps board cam with a bunch of jumpers and I used none of them(was i suppose to put them somewhere?) I havn't checked the wire yet. That is the next step. Anymore ideas tho?

Thank you for your help so far.

|

Re: Folger Prusa i3 Kit from ebay October 25, 2014 01:46PM |

Registered: 9 years ago Posts: 6 |

|

Re: Folger Prusa i3 Kit from ebay October 25, 2014 03:10PM |

Registered: 9 years ago Posts: 7 |

Quote

NukedWorker

I ordered my i3 a few weeks ago (around 60 had been purchased I think), but because real life kept getting in the way, amongst the difficulties I had getting it together, I'm only now getting close. However, I'm a little baffled at the difficulty I'm having with my X carriage. I've finally got my Y and Z moving, but when the X motor picks up (i.e. if I hit the home button) the motor vibrates like anything without moving the carriage anywhere, and then, just before it stops, it moves back and forth about 1/2 cm each direction, without having any results. Until I hit "motors off" the motor is still tight. I started using the different v-ref settings different people have posted here, then gave up and started at 0.07 V (where it vibrated, but didn't dance at the end) moving up by around 0.03 V until I got to 0.47 V where it seemed to dance a little more during the cycle, but I always ended up in the same place. I figured v-ref was the issue because my Z reacted kind of similar until I used Mr.Folger's settings, and away she went. My X still doesn't like me (for the record, I'm still married to my first wife of almost 17 years, I'm not giving up).

Am I barking up the wrong tree, or is it most likely that the v-ref is the problem, and I need to start over at the bottom and work my way up again? I am so close to getting somewhere, and yet so far.

I had the exact same issue with my X motor. I played with the v-ref for a while and got nowhere. I then connected the X motor to the Y plug on the RAMPS and the motor worked fine. So my fix was to swap the A4988 for the X axis with the extra that was in the kit. Everything was fin after that.

|

Re: Folger Prusa i3 Kit from ebay October 25, 2014 07:56PM |

Registered: 9 years ago Posts: 208 |

Quote

BgHurt

Just a few questions.

Does this kit contain the rework version of the I3? Or the original?

Is there a summary of suggestions for this specific machine? I noticed a comment asking if someone actually used the original bearings. Is there a reason to not?

What extruder and hot end come in the kit? I don't see it listed on eBay or in this thread.

I'm really interested in this machine as the low price point and great prints you guys are getting. But just want to make sure I know what I'm getting into.

Thanks to everyone on here walking through their issues.

There are plenty of pictures of the kit in my flickr feed, including pictures of the printer from many angles. There are also detailed pictures of the extruder as well. A makerbot style of extruder I think would best describe the type of extruder....

Like the ones found in the replicator and clones... Single extruder, but 12volts, and with a termister not a thermocouple.

One additional note, is that the extruder is not spring loaded, but seems to do a very good job...

There are links to my pics in the thread at various points.

Cheers hope thy his helps...

Edited 1 time(s). Last edit at 10/25/2014 09:56PM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay October 25, 2014 09:59PM |

Registered: 9 years ago Posts: 208 |

Here is the link to pictures, but I do encourage folks to read through the thread as there are a good learning points in it...

(Thanks again folks for your help in getting me up and running and sharing your experiences while building this very cool and inexpensive kit.)

[www.flickr.com]

(Thanks again folks for your help in getting me up and running and sharing your experiences while building this very cool and inexpensive kit.)

[www.flickr.com]

|

Re: Folger Prusa i3 Kit from ebay October 25, 2014 11:42PM |

Registered: 9 years ago Posts: 14 |

Quote

zorg1179

Quote

NukedWorker

I've finally got my Y and Z moving, but when the X motor picks up (i.e. if I hit the home button) the motor vibrates like anything without moving the carriage anywhere, and then, just before it stops, it moves back and forth about 1/2 cm each direction, without having any results. Until I hit "motors off" the motor is still tight. I started using the different v-ref settings different people have posted here, then gave up and tried to find a v-ref on my own, but I always ended up in the same place. I figured v-ref was the issue because my Z reacted kind of similar until I used Mr.Folger's settings, and away she went. My X still doesn't like me (for the record, I'm still married to my first wife of almost 17 years, I'm not giving up).

Am I barking up the wrong tree, or is it most likely that the v-ref is the problem, and I need to start over at the bottom and work my way up again? I am so close to getting somewhere, and yet so far.

I had the exact same issue with my X motor. I played with the v-ref for a while and got nowhere. I then connected the X motor to the Y plug on the RAMPS and the motor worked fine. So my fix was to swap the A4988 for the X axis with the extra that was in the kit. Everything was fine after that.

Well zorg, it appears you are correct - or so it seems at least. However, this is not good news in the least. I did the test as you suggested, and bammo, X drove smoothly! So I promptly, and excitedly swapped in the spare thinking I FINALLY HAVE IT! and nothing

; no movement at all this time, not even a twitch. So just to ensure, I then swapped the connections back, and swapped the X and Y A4988 instead. Apparently, I have not 1, but 2 bad chips in my kit - the X now worked, and the Y did not. I'm thinking someone doesn't like me somewhere.

; no movement at all this time, not even a twitch. So just to ensure, I then swapped the connections back, and swapped the X and Y A4988 instead. Apparently, I have not 1, but 2 bad chips in my kit - the X now worked, and the Y did not. I'm thinking someone doesn't like me somewhere.Thanks muchly for the assistance. Now for the painful process of waiting to get my hands on some new chips, as if the waiting hasn't been painful already.

|

Re: Folger Prusa i3 Kit from ebay October 26, 2014 02:07AM |

Registered: 9 years ago Posts: 58 |

|

Re: Folger Prusa i3 Kit from ebay October 26, 2014 02:04PM |

Registered: 9 years ago Posts: 58 |

Quote

NukedWorker

Quote

zorg1179

Quote

NukedWorker

I've finally got my Y and Z moving, but when the X motor picks up (i.e. if I hit the home button) the motor vibrates like anything without moving the carriage anywhere, and then, just before it stops, it moves back and forth about 1/2 cm each direction, without having any results. Until I hit "motors off" the motor is still tight. I started using the different v-ref settings different people have posted here, then gave up and tried to find a v-ref on my own, but I always ended up in the same place. I figured v-ref was the issue because my Z reacted kind of similar until I used Mr.Folger's settings, and away she went. My X still doesn't like me (for the record, I'm still married to my first wife of almost 17 years, I'm not giving up).

Am I barking up the wrong tree, or is it most likely that the v-ref is the problem, and I need to start over at the bottom and work my way up again? I am so close to getting somewhere, and yet so far.

I had the exact same issue with my X motor. I played with the v-ref for a while and got nowhere. I then connected the X motor to the Y plug on the RAMPS and the motor worked fine. So my fix was to swap the A4988 for the X axis with the extra that was in the kit. Everything was fine after that.

Well zorg, it appears you are correct - or so it seems at least. However, this is not good news in the least. I did the test as you suggested, and bammo, X drove smoothly! So I promptly, and excitedly swapped in the spare thinking I FINALLY HAVE IT! and nothing; no movement at all this time, not even a twitch. So just to ensure, I then swapped the connections back, and swapped the X and Y A4988 instead. Apparently, I have not 1, but 2 bad chips in my kit - the X now worked, and the Y did not. I'm thinking someone doesn't like me somewhere.

Thanks muchly for the assistance. Now for the painful process of waiting to get my hands on some new chips, as if the waiting hasn't been painful already.

I'm sure you already checked this but just in case. If you are using the small heat sinks that came with the stepper drivers (recommended) then make sure that they are not shorting any of the other components on the drivers. Also, it sounds like you may have eliminated this but when I first put my kit together one of my stepper motor wires was not terminated properly at the motor side connector. (Wire was not crimped properly). This gave very similar behavior and took a bit to figure out. I wound up removing the crimp from the connector and soldering the wire onto it and then putting it back.

When you switched to your spare did you try adjusting the vref on the spare when it wouldn't work?

|

Re: Folger Prusa i3 Kit from ebay October 26, 2014 02:10PM |

Registered: 9 years ago Posts: 36 |

Quote

czmorris

Second mod to the bearing holder. When I got a chance to look at it closely it looked like there would be clearance issues. I Modified it to work with zip ties instead as suggested. Instead of making it such that the ties have to go through the bed I added a channel in the back of the part that connects to the bed for the tip tie to rest in. I have no plans to change mine currently as it isn't giving me any issues. Again if someone tries it out and it works let me know and I will see what I can do about posting it on Thingiverse. I'm sure the source files are under an open source license but I'm not sure of the original source. If anyone knows if Folger got these from somewhere that I can source please let me know.

Here is the link

I have now also experienced the problem with one of the Y carriage bearings popping out of the holder. I'm running with a piece of reflective firewall insulation under the heated bed plate, so I'm not convinced this is a heat issue - I wonder if it is just vibration that is shaking the bearing slowly free?

What is your latest and greatest design for an upgraded holder? I'll print out a set and replace mine.

|

Re: Folger Prusa i3 Kit from ebay October 26, 2014 02:23PM |

Registered: 9 years ago Posts: 58 |

Quote

jjbunn

Quote

czmorris

Second mod to the bearing holder. When I got a chance to look at it closely it looked like there would be clearance issues. I Modified it to work with zip ties instead as suggested. Instead of making it such that the ties have to go through the bed I added a channel in the back of the part that connects to the bed for the tip tie to rest in. I have no plans to change mine currently as it isn't giving me any issues. Again if someone tries it out and it works let me know and I will see what I can do about posting it on Thingiverse. I'm sure the source files are under an open source license but I'm not sure of the original source. If anyone knows if Folger got these from somewhere that I can source please let me know.

Here is the link

I have now also experienced the problem with one of the Y carriage bearings popping out of the holder. I'm running with a piece of reflective firewall insulation under the heated bed plate, so I'm not convinced this is a heat issue - I wonder if it is just vibration that is shaking the bearing slowly free?

What is your latest and greatest design for an upgraded holder? I'll print out a set and replace mine.

I haven't done anything else with it since the pictures except uploading to thingiverse. Here is the thingiverse link. It shows around 40 downloads so far but no feed back. I haven't needed them so I am not using them myself. Let me know how it goes.

|

Re: Folger Prusa i3 Kit from ebay October 26, 2014 05:42PM |

Registered: 9 years ago Posts: 14 |

Quote

czmorris

Quote

NukedWorker

Well zorg, it appears you are correct - or so it seems at least. However, this is not good news in the least. I did the test as you suggested, and bammo, X drove smoothly! So I promptly, and excitedly swapped in the spare thinking I FINALLY HAVE IT! and nothing; no movement at all this time, not even a twitch. So just to ensure, I then swapped the connections back, and swapped the X and Y A4988 instead. Apparently, I have not 1, but 2 bad chips in my kit - the X now worked, and the Y did not. I'm thinking someone doesn't like me somewhere.

Thanks muchly for the assistance. Now for the painful process of waiting to get my hands on some new chips, as if the waiting hasn't been painful already.

I'm sure you already checked this but just in case. If you are using the small heat sinks that came with the stepper drivers (recommended) then make sure that they are not shorting any of the other components on the drivers. Also, it sounds like you may have eliminated this but when I first put my kit together one of my stepper motor wires was not terminated properly at the motor side connector. (Wire was not crimped properly). This gave very similar behavior and took a bit to figure out. I wound up removing the crimp from the connector and soldering the wire onto it and then putting it back.

When you switched to your spare did you try adjusting the vref on the spare when it wouldn't work?

I appreciate all the input people have offered. It does look most likely to be the A4988's. I had similar problems with my pins too, and had to solder at least 2 of them on the RAMPs side. Seeing as how I was able to get each stepper running with different drivers, I'm 99.999999% sure that's what it is now. After your comment I rechecked all of the drivers, and the heat sinks appear to be floating nicely without making contact. When I tested the 'spare' driver, I did alter the v-ref first, but thanks for asking. When I switched the X (not working) and Y (working) drivers, after having 2 that didn't work for X, it was a check to make sure it wasn't the RAMPs board. X worked when the driver I had put into Y was in the X spot, and Y stopped working.

Sadly now, the nearest place with these (slightly different) are about 150km away, and $13.50 (A2A Printer) for a $3 component - plus gas and time. That said, I went there for my materials, and they were very pleasant. In an attempt to be patient, albeit frustrated, I've ordered some off eBay, and will get in touch with Mr.Folger tomorrow to see if there's anything he can/will do for me.

Thanks again.

|

Re: Folger Prusa i3 Kit from ebay October 26, 2014 05:49PM |

Registered: 9 years ago Posts: 9 |

Just finished my first successful hollow cube and the dimensions line up exactly.

So my problem ended up being a combination between the vref not being set correctly and the connectors that you have to make yourself(the 4 prong black ones) had a few wires loose. Still not sure that the reflective tape is for.

As a side note, does anyone elses X axis motor get VERY hot. Toward the of the (20 min) long print, it was to hot to touch. The Y and Z motors were cold and the Extruder motor was warm but nothing to bad I don't think. Could this be a bad stepper motor or is the normal?

So my problem ended up being a combination between the vref not being set correctly and the connectors that you have to make yourself(the 4 prong black ones) had a few wires loose. Still not sure that the reflective tape is for.

As a side note, does anyone elses X axis motor get VERY hot. Toward the of the (20 min) long print, it was to hot to touch. The Y and Z motors were cold and the Extruder motor was warm but nothing to bad I don't think. Could this be a bad stepper motor or is the normal?

|

Re: Folger Prusa i3 Kit from ebay October 26, 2014 06:12PM |

Registered: 9 years ago Posts: 208 |

hey there are you in Ontario? I'm in York Region myself...

A2A is a nice shop I've been there, I was going to buy a Prusa i3 from them, but found the Folger one for less.

I'm sure they can ship the components to you within a week...

also www.creatroninc.com also in toronto [www.creatroninc.com]

[www.a2aprinter.ca]

what direction are you? there is a place in St. Catherines that sells repraps, so they must also carry these little motor drivers...

[www.eckertech.com]

Edited 2 time(s). Last edit at 10/26/2014 06:15PM by Waltermixx.

A2A is a nice shop I've been there, I was going to buy a Prusa i3 from them, but found the Folger one for less.

I'm sure they can ship the components to you within a week...

also www.creatroninc.com also in toronto [www.creatroninc.com]

[www.a2aprinter.ca]

what direction are you? there is a place in St. Catherines that sells repraps, so they must also carry these little motor drivers...

[www.eckertech.com]

Edited 2 time(s). Last edit at 10/26/2014 06:15PM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay October 26, 2014 10:03PM |

Registered: 9 years ago Posts: 36 |

Quote

czmorris

Quote

jjbunn

Quote

czmorris

Second mod to the bearing holder. When I got a chance to look at it closely it looked like there would be clearance issues. I Modified it to work with zip ties instead as suggested. Instead of making it such that the ties have to go through the bed I added a channel in the back of the part that connects to the bed for the tip tie to rest in. I have no plans to change mine currently as it isn't giving me any issues. Again if someone tries it out and it works let me know and I will see what I can do about posting it on Thingiverse. I'm sure the source files are under an open source license but I'm not sure of the original source. If anyone knows if Folger got these from somewhere that I can source please let me know.

Here is the link

I have now also experienced the problem with one of the Y carriage bearings popping out of the holder. I'm running with a piece of reflective firewall insulation under the heated bed plate, so I'm not convinced this is a heat issue - I wonder if it is just vibration that is shaking the bearing slowly free?

What is your latest and greatest design for an upgraded holder? I'll print out a set and replace mine.

I haven't done anything else with it since the pictures except uploading to thingiverse. Here is the thingiverse link. It shows around 40 downloads so far but no feed back. I haven't needed them so I am not using them myself. Let me know how it goes.

I printed a couple off. Mr printer had some trouble with the overhang, but overall they looked good: new holders

However, after fitting, the new lips foul on the frame just slightly: holder against frame

Perhaps instead of the lips, there should be a ridge/edge around each end opening, which would prevent the bearing moving out of the holder laterally? The downside would be that the bearing would have to be pressed in from the top, rather than slid in from the end.

I may have a go at fabricating something like that, as a test.

|

Re: Folger Prusa i3 Kit from ebay October 26, 2014 10:35PM |

Registered: 9 years ago Posts: 19 |

So I finally read all the way through, and I have to admit it helped during the assembly. Everything went together fairly smoothly, with the exception of the hours wasted trying to figure out why the motors only stuttered no mater the v-ref. After checking on here, I noticed my error with the wiring.

I rotated the hotend to the threaded boss and spaced it with some spacers, seems to keep the extruder motor a little cooler. Just wondering for those of you that have been happy with there prints, what are your go to settings in repitier host or what ever software you use?

By the way Waltermixx, where in York Region? I am not too far from A2A.

Thanks for logging all of your discussion on this forum! I found it was a huge help!

I rotated the hotend to the threaded boss and spaced it with some spacers, seems to keep the extruder motor a little cooler. Just wondering for those of you that have been happy with there prints, what are your go to settings in repitier host or what ever software you use?

By the way Waltermixx, where in York Region? I am not too far from A2A.

Thanks for logging all of your discussion on this forum! I found it was a huge help!

|

Re: Folger Prusa i3 Kit from ebay October 26, 2014 10:49PM |

Registered: 9 years ago Posts: 208 |

I've been very happy with my prints. If I notice something in the layers, that usually means I have to tighten a screw here or there...

the screws on the Y belt holder are the ones that usually loosen after a few hours of printing... I have lock nuts on them and used some

Lock Tight, and it's helped a great deal...

I use Repetier host, and Slic3r i created a few profiles for 15% fill, 20% fill, 40%fill etc. all at .200mm printing layer resolution.

I print with a 100 degree heated build plate and 220 on the nozzle.

I'm not sure if those settings are saved in a file somewhere on my mac, but if I find them I would be happy to post them.

I am in Woodbridge.

my favorite print is also most likely my most useless print... a chest buster from the Alien Movies. i like it because it was an 8 hour print that printed without issue. it was pretty smooth as well,

i like it because it was an 8 hour print that printed without issue. it was pretty smooth as well,

but not as smooth as the active cooling nozzle i just printed last night. not sure how to mount it yet, or weather or not i will

not sure how to mount it yet, or weather or not i will  but it was a very nice print.

but it was a very nice print.

[www.flickr.com]

Edited 1 time(s). Last edit at 10/26/2014 10:51PM by Waltermixx.

the screws on the Y belt holder are the ones that usually loosen after a few hours of printing... I have lock nuts on them and used some

Lock Tight, and it's helped a great deal...

I use Repetier host, and Slic3r i created a few profiles for 15% fill, 20% fill, 40%fill etc. all at .200mm printing layer resolution.

I print with a 100 degree heated build plate and 220 on the nozzle.

I'm not sure if those settings are saved in a file somewhere on my mac, but if I find them I would be happy to post them.

I am in Woodbridge.

my favorite print is also most likely my most useless print... a chest buster from the Alien Movies.

i like it because it was an 8 hour print that printed without issue. it was pretty smooth as well,

i like it because it was an 8 hour print that printed without issue. it was pretty smooth as well,but not as smooth as the active cooling nozzle i just printed last night.

not sure how to mount it yet, or weather or not i will

not sure how to mount it yet, or weather or not i will  but it was a very nice print.

but it was a very nice print.

[www.flickr.com]

Edited 1 time(s). Last edit at 10/26/2014 10:51PM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay October 27, 2014 12:55PM |

Registered: 9 years ago Posts: 58 |

Quote

jjbunn

Quote

czmorris

Quote

jjbunn

Quote

czmorris

Second mod to the bearing holder. When I got a chance to look at it closely it looked like there would be clearance issues. I Modified it to work with zip ties instead as suggested. Instead of making it such that the ties have to go through the bed I added a channel in the back of the part that connects to the bed for the tip tie to rest in. I have no plans to change mine currently as it isn't giving me any issues. Again if someone tries it out and it works let me know and I will see what I can do about posting it on Thingiverse. I'm sure the source files are under an open source license but I'm not sure of the original source. If anyone knows if Folger got these from somewhere that I can source please let me know.

Here is the link

I have now also experienced the problem with one of the Y carriage bearings popping out of the holder. I'm running with a piece of reflective firewall insulation under the heated bed plate, so I'm not convinced this is a heat issue - I wonder if it is just vibration that is shaking the bearing slowly free?

What is your latest and greatest design for an upgraded holder? I'll print out a set and replace mine.

I haven't done anything else with it since the pictures except uploading to thingiverse. Here is the thingiverse link. It shows around 40 downloads so far but no feed back. I haven't needed them so I am not using them myself. Let me know how it goes.

I printed a couple off. Mr printer had some trouble with the overhang, but overall they looked good: new holders

However, after fitting, the new lips foul on the frame just slightly: holder against frame

Perhaps instead of the lips, there should be a ridge/edge around each end opening, which would prevent the bearing moving out of the holder laterally? The downside would be that the bearing would have to be pressed in from the top, rather than slid in from the end.

I may have a go at fabricating something like that, as a test.

Interesting that the lips ran into clearance issues still. I made them smaller than the gap and as short as possible just for that reason. In theory you can likely get by without the lips at all so long as there is clearance enough for the zip tie that you are using. (Either cut them off or slice them off in software and reprint).

Personally I would hesitate to cap the ends and press it on. Just seems like that is asking to break or weaken something. However... Along the same thought. It might be a good idea to cut off half of the cylinder on the bottom and cap the ends. Then all you would have to do is set the bearing holder on top of the bearing and zip tie it into place. Then you have something to hold it in place from the ends and you do not have to force snap it into to place. That should leave plenty of room for clearance as well. If I have time this evening when I get home I may give it a try.

|

Re: Folger Prusa i3 Kit from ebay October 27, 2014 01:51PM |

Registered: 12 years ago Posts: 76 |

Does anyone know if any of the other iterations of the i3 have a similiar issue with these mounts?

I'm wondering if a better solution would be to fill in the point where the circle meets the flat mount so that the stress on that area from the press fit of the bearing would be spread out a bit more. You would still need a zip tie for backup.

I'm wondering if a better solution would be to fill in the point where the circle meets the flat mount so that the stress on that area from the press fit of the bearing would be spread out a bit more. You would still need a zip tie for backup.

|

Re: Folger Prusa i3 Kit from ebay October 27, 2014 02:14PM |

Registered: 9 years ago Posts: 58 |

Before I saw your last post I modified the bearing mount during my lunch hour for the half cylinder idea I was talking about. Added the update as another file on Thingiverse. I will do a test print just to confirm the model when I get home.

http://www.thingiverse.com/thing:513656

http://www.thingiverse.com/thing:513656

|

Re: Folger Prusa i3 Kit from ebay October 27, 2014 02:59PM |

Registered: 9 years ago Posts: 705 |

I have the Aurora Prusa i3. Worst instructions ever but does come with video instructions and a full set of STL kit parts. If you guys would like manual or stl files just let me know. Email me at rb3d@msn.com. I hope it's ok to list email address. If not, sorry. Brian.

|

Re: Folger Prusa i3 Kit from ebay October 27, 2014 03:05PM |

Registered: 9 years ago Posts: 705 |

|

Re: Folger Prusa i3 Kit from ebay October 27, 2014 03:23PM |

Registered: 9 years ago Posts: 208 |

Quote

czmorris

Before I saw your last post I modified the bearing mount during my lunch hour for the half cylinder idea I was talking about. Added the update as another file on Thingiverse. I will do a test print just to confirm the model when I get home.

http://www.thingiverse.com/thing:513656

i have zip ties on the original clips, i just drilled holes through them and the acrylic bed... (ok a bit barbarian, but I did not want to take it all appart,)

so I can confirm that zip ties on bearing holders with no "lips" will work fine and pass through the Acrylic frame

i like your design, however i would move the zip tie holes tight up against the curve of the bearing holder.

that is where I drilled the holes and it seemed to work out well

that is where I drilled the holes and it seemed to work out well

Edited 2 time(s). Last edit at 10/27/2014 04:24PM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay October 27, 2014 03:42PM |

Registered: 9 years ago Posts: 705 |

|

Re: Folger Prusa i3 Kit from ebay October 27, 2014 04:35PM |

Registered: 9 years ago Posts: 58 |

Thanks waltermixx. I was thinking about moving those in a bit more. I am not sure that it is necessary but it couldn't hurt. One of the things I was going for is to remove the need to drill the bed acrylic. Sure it is a simple task to do but it also adds another place someone might make a mistake. I suppose if it helps someone out it is worth it. One less tool needed.

One of the things I like about the half cylinder idea if it works out is that it makes itis little easier to remove the bed if needed without having to remove screws or slide out bearings.

I like the idea about filling in between the cylinder and the flat for more strength. Seems like a simple enough mod. if I have time I will try it out. It may require increasing the bearing hole diameter a bit to keep from breaking things with that stretching gone.

One of the things I like about the half cylinder idea if it works out is that it makes itis little easier to remove the bed if needed without having to remove screws or slide out bearings.

I like the idea about filling in between the cylinder and the flat for more strength. Seems like a simple enough mod. if I have time I will try it out. It may require increasing the bearing hole diameter a bit to keep from breaking things with that stretching gone.

|

Re: Folger Prusa i3 Kit from ebay October 27, 2014 07:58PM |

Registered: 9 years ago Posts: 208 |

"Thanks waltermixx. I was thinking about moving those in a bit more. I am not sure that it is necessary but it couldn't hurt. One of the things I was going for is to remove the need to drill the bed acrylic."

you are absolutely right Mr. Morris, i was just being lazy I think anyone building the kit who has access to a printer before hand would do well to print your version of the clips

I think anyone building the kit who has access to a printer before hand would do well to print your version of the clips

Cheers.

you are absolutely right Mr. Morris, i was just being lazy

I think anyone building the kit who has access to a printer before hand would do well to print your version of the clips

I think anyone building the kit who has access to a printer before hand would do well to print your version of the clips

Cheers.

|

Re: Folger Prusa i3 Kit from ebay October 27, 2014 08:42PM |

Registered: 9 years ago Posts: 58 |

Quote

Waltermixx

"Thanks waltermixx. I was thinking about moving those in a bit more. I am not sure that it is necessary but it couldn't hurt. One of the things I was going for is to remove the need to drill the bed acrylic."

you are absolutely right Mr. Morris, i was just being lazyI think anyone building the kit who has access to a printer before hand would do well to print your version of the clips

Cheers.

Haha, I don't know that I would say lazy. Your pictures and extruder research is some of the best stuff here. Nothing wrong with using a simple solution especially when it works well. I haven't even bothered messing with mine as it hasn't given me this particular issue as of yet. Anyway, hopefully some of the ideas we come up with here can make their way back into the kit to make life a bit easier for folks in the future.

Curious, About how much clearance do you have between the zip ties and the frame on your setup?

A bit of irony: As I was writing this post I was running a test print of the latest bearing holder. One of my bearings just started slipping out.

Looks like I get to try out the new design after all.

Looks like I get to try out the new design after all.

|

Re: Folger Prusa i3 Kit from ebay October 27, 2014 10:05PM |

Registered: 9 years ago Posts: 208 |

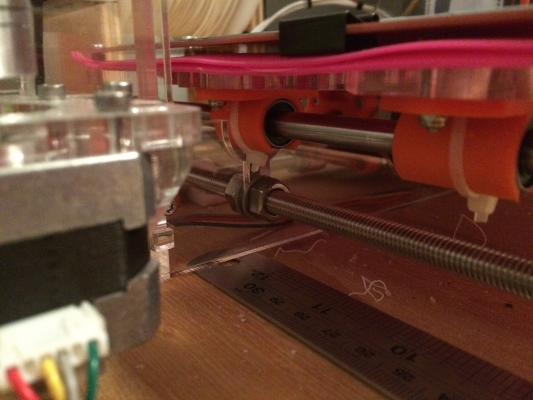

as you can see it's pretty tight.

i hope some of the Idea's make it to the next kit too.

the Y belt holder with the 3 screw holes that match this kit, ( I sent them the .stl for that, so they should have what they need if they choose to include it, saves drilling a hole

)

)Edited 1 time(s). Last edit at 10/27/2014 10:07PM by Waltermixx.

|

Re: Folger Prusa i3 Kit from ebay October 27, 2014 11:06PM |

Registered: 9 years ago Posts: 58 |

"I sent them the .stl for that, so they should have what they need if they choose to include it, saves drilling a hole"

Awesome, that was one of the things I had on my list. Easy fix but useful. I am thinking about trying to do something with the Z-axis nuts as well when I get a chance. A few folks have complained about that and someone suggested modding them to prevent it from moving.

I am currently testing the "half" style bearing holders. They clicked in place very tight so I decided to try them first without any zip ties at all just to see how it goes. So far so good. Fairly quick and easy swap. If I did not already have this thing put together I think I would reprint the plastic parts in color. That orange looks awesome. I was thinking about using some fluorescent green that I like to use. No practical purpose I suppose but it adds to what my wife calls the "nerdtasticness" of my work area. lol.

Awesome, that was one of the things I had on my list. Easy fix but useful. I am thinking about trying to do something with the Z-axis nuts as well when I get a chance. A few folks have complained about that and someone suggested modding them to prevent it from moving.

I am currently testing the "half" style bearing holders. They clicked in place very tight so I decided to try them first without any zip ties at all just to see how it goes. So far so good. Fairly quick and easy swap. If I did not already have this thing put together I think I would reprint the plastic parts in color. That orange looks awesome. I was thinking about using some fluorescent green that I like to use. No practical purpose I suppose but it adds to what my wife calls the "nerdtasticness" of my work area. lol.

Sorry, only registered users may post in this forum.