My Replikeo Prusa i3 Rework Build

Posted by Trike

|

Re: My Replikeo Prusa i3 Rework Build June 29, 2014 02:12AM |

Registered: 11 years ago Posts: 661 |

Quote

gadget_greg

Thanks for all that! I'm printing with PLA, my fan is on D9, and it is running non-stop.

Also, I did an extrusion test and no matter how high I seem to set the steps-per-mm I'm still getting between 73mm and 82mm when I call for 100mm. I must be missing something.

The options for fan tuning are in your slicer. There should be an option for always on or auto cool. Where and how you set it depends on the slicer.

Not responding to your changes means the firmware likely isn't seeing your changes. It could mean that if you are sending them via gcode the EEPROM feature isn't active. If you are saving them in a config file and recompiling the firmware make sure if are saving the file if you are using an external editor before you compile it. Also make sure the motor is connected to the right driver and that you are editing it to the proper place in the file.

|

Re: My Replikeo Prusa i3 Rework Build June 29, 2014 02:50PM |

Registered: 10 years ago Posts: 197 |

Thanks for the input.

I'm making the changes in the Marlin firmware via the Arduino IDE. The changes have been compiled and uploaded and are present and visible on the printer's LCD.

I'm not sure what's up with the fan since Slic3r appears to be configured properly using auto-cool and, IIRC, default settings. I'm not terribly concerned with the fan running all the time unless it's going to affect my print quality.

I'm making the changes in the Marlin firmware via the Arduino IDE. The changes have been compiled and uploaded and are present and visible on the printer's LCD.

I'm not sure what's up with the fan since Slic3r appears to be configured properly using auto-cool and, IIRC, default settings. I'm not terribly concerned with the fan running all the time unless it's going to affect my print quality.

|

Re: My Replikeo Prusa i3 Rework Build June 30, 2014 08:26AM |

Registered: 9 years ago Posts: 15 |

|

Re: My Replikeo Prusa i3 Rework Build June 30, 2014 02:29PM |

Registered: 10 years ago Posts: 197 |

Several people have gotten broken or defective parts and Replikeo has sent out replacements right away from what I understand. I had one minor broken part, the z-endstop holder, but I didn't bother to ask for a replacement because I found one with a better design and just printed that instead.

Good luck on your voyage. The folks in this thread are very helpful.

Good luck on your voyage. The folks in this thread are very helpful.

|

Re: My Replikeo Prusa i3 Rework Build June 30, 2014 03:19PM |

Registered: 9 years ago Posts: 137 |

Thanks for the lube advise!Quote

gadget_greg

For lubrication: [www.reprap.org]

I've been using a silicone lube or Duralube. The silicone is more of a penetrating-type lube, whereas the Duralube is more of a PTFE-type lube.

I'm not sure where you're talking about on the spool holder but there was a light layer printed adjacent to the bearing, creating a barrier between the bearing and where the shaft runs. I just cut it away. I also had to trim with my dremel to get the bearing to fit properly. It works get though!

Did you have any luck getting your extrusion right? I'm getting between 72 and 82 mm extruded when I called for 100, no matter how I set the steps per mm. :/

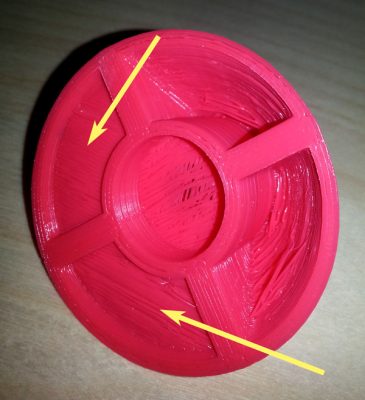

No, besides that shaft barrier on mine it printed another 2 layer barrier between 2 ridges where should not be a barrier there. it doesn't obstruct anything, but just looks like a glitch, not sure why Slic3r generated it. I'll post picture later on. Do you remember how long it took you to print that hub piece? Cause for me it took 1h:50m, kind of long...

I never got my extrusion exactly right, best I could get is 28mm instead of 30mm. After some point increasing extrusion steps doesn't yield any noticeable result, maybe there's firmware limit or something else I don't understand. But it prints just fine, if a little thick. I'm probably wasting more PLA than needed, but I don't care at this point. Extruder idler came out great and I already replaced broken one.

Check/redo your header connectors. I had headers broken/loose on 3!!! stepper motors.Quote

esponda

I received my kit last week, finally. Everything is ok, I just got a bad stepper ( no continuity in 1 coil) ; anyone received a bad part and got a replacement as soon as you report it to them?

|

Re: My Replikeo Prusa i3 Rework Build June 30, 2014 04:39PM |

Registered: 9 years ago Posts: 6 |

I am considering buying a replikeo iron kit, but I saw on the wiki page that the single sheet frame is supposed to be 6 mm thick and the iron one is only 3 mm thick. I was wondering if the iron frame has proven to be sturdy and hold up well. This will my be my first time building/buying a 3d printer, and I am trying to keep it as cheap as possible while still getting a decent/good product which is why I am looking at replikeo. If anyone has any other comments or suggestions, those are greatly appreciated as well. Thank you so much

|

Re: My Replikeo Prusa i3 Rework Build June 30, 2014 05:05PM |

Registered: 9 years ago Posts: 137 |

|

Re: My Replikeo Prusa i3 Rework Build June 30, 2014 05:23PM |

Registered: 9 years ago Posts: 6 |

|

Re: My Replikeo Prusa i3 Rework Build June 30, 2014 05:25PM |

Registered: 9 years ago Posts: 137 |

Yes, I had some issues, but considering price I'd say it's worth it.Quote

Rayton

Thanks. Has the kit in general worked out well for you?

I had bad connectors on 3 stepper motors, bad header on one of the thermistors, bad connection on the hotend, and as almost everyone else here mentioned carbon fiber sheet for the heatbed is garbage, you'll need to get a piece of glass if you want bed to be evenly leveled.

Greg, here's the glitch I was talking about. See those two planes are not supposed to be there, but Slic3r generated them for some reason ...

Edit: Ok I printed second one, and it didn't happen this time. So bizarre...

Edited 2 time(s). Last edit at 07/01/2014 01:59PM by Bratan.

|

Re: My Replikeo Prusa i3 Rework Build July 01, 2014 05:26PM |

Registered: 9 years ago Posts: 137 |

I modified MarkBenson's spool holder to work with 3mm Iron/Steel frame sold by Replikeo. [www.thingiverse.com]

|

Re: My Replikeo Prusa i3 Rework Build July 02, 2014 03:49AM |

Registered: 10 years ago Posts: 197 |

That IS weird. Slic3r has a mind of its own. I'm considering trying others but I haven't heard anything particularly good about any of them, frankly.

I lowered my acceleration to 1000 on x and y and my prints are starting to look better. I tweaked the steps per mm for x and y slightly, I'll see if the help tomorrow. I printed supports for the z-axis plate but they don't fit properly. Unless I find another style I'm going to have to modify the the one I found. I've gone through about a half of a spool of PLA and I'm still not thrilled with my print quality... :/

I lowered my acceleration to 1000 on x and y and my prints are starting to look better. I tweaked the steps per mm for x and y slightly, I'll see if the help tomorrow. I printed supports for the z-axis plate but they don't fit properly. Unless I find another style I'm going to have to modify the the one I found. I've gone through about a half of a spool of PLA and I'm still not thrilled with my print quality... :/

|

Re: My Replikeo Prusa i3 Rework Build July 03, 2014 12:30AM |

Registered: 11 years ago Posts: 661 |

|

Re: My Replikeo Prusa i3 Rework Build July 03, 2014 02:07AM |

Registered: 10 years ago Posts: 197 |

|

Re: My Replikeo Prusa i3 Rework Build July 04, 2014 01:54AM |

Registered: 11 years ago Posts: 661 |

RichRap has some great posts on calibration and other issues. Here is one with failed print examples and tips...[richrap.blogspot.com]

Here is one with printing tips for Slic3r... [richrap.blogspot.com]

Surf around over there as there is a great deal of info.

Here is one with printing tips for Slic3r... [richrap.blogspot.com]

Surf around over there as there is a great deal of info.

|

Re: My Replikeo Prusa i3 Rework Build July 05, 2014 06:28AM |

Registered: 9 years ago Posts: 37 |

Posted another video with progress updates YouTube Video

Close to being really great, just have to sort out some z-axis banding appearing on the surface of fine prints. The video doesn't show the distortions that well but you get the idea. Here's a link to what others have done to correct it: http://forums.reprap.org/read.php?1,148833,148836,quote=1

Close to being really great, just have to sort out some z-axis banding appearing on the surface of fine prints. The video doesn't show the distortions that well but you get the idea. Here's a link to what others have done to correct it: http://forums.reprap.org/read.php?1,148833,148836,quote=1

|

Re: My Replikeo Prusa i3 Rework Build July 05, 2014 12:44PM |

Registered: 10 years ago Posts: 197 |

Nice vid there Tech2C. Thanks for that link about the z-banding too.

My print quality is slowly increasing but I still have a shift occurring in the x-y at a certain level. I'm still not sure why.

I like your idea with the long nut, I may try that too!

I found a few z-frame stabilizers but none fit my setup. It looks like yours will though. Any chance you'd post those models? Maybe the y-endstop extender too...

Maybe the y-endstop extender too...

My print quality is slowly increasing but I still have a shift occurring in the x-y at a certain level. I'm still not sure why.

I like your idea with the long nut, I may try that too!

I found a few z-frame stabilizers but none fit my setup. It looks like yours will though. Any chance you'd post those models?

Maybe the y-endstop extender too...

Maybe the y-endstop extender too...

|

Re: My Replikeo Prusa i3 Rework Build July 05, 2014 10:20PM |

Registered: 9 years ago Posts: 37 |

Here they are gadget_greg

I've noticed one of my z-axis stepper motors has a bend in the shaft. This is definately contributing to the banding issue. Not sure if it has been like that since purchase tho.

I've noticed one of my z-axis stepper motors has a bend in the shaft. This is definately contributing to the banding issue. Not sure if it has been like that since purchase tho.

|

Re: My Replikeo Prusa i3 Rework Build July 05, 2014 11:35PM |

Registered: 9 years ago Posts: 15 |

|

Re: My Replikeo Prusa i3 Rework Build July 06, 2014 04:47AM |

Registered: 10 years ago Posts: 197 |

|

Re: My Replikeo Prusa i3 Rework Build July 06, 2014 01:31PM |

Registered: 10 years ago Posts: 197 |

|

Re: My Replikeo Prusa i3 Rework Build July 06, 2014 08:08PM |

Registered: 9 years ago Posts: 71 |

|

Re: My Replikeo Prusa i3 Rework Build July 07, 2014 03:47AM |

Registered: 10 years ago Posts: 14 |

Happy ! I'm happy !

I print my first calibration cube last day ! It is so far of perfection, but not bad at all !

I encouter many problems with the building of my replikeo printer : many disconnected connectors (for E thermistance and stepper motors), 0 ohm HB thermistance, wrong marlin config, ... like everyone ! For the price, Replikeo's kit is very attractive ! But you have to be good for soldering !

I print my first calibration cube last day ! It is so far of perfection, but not bad at all !

I encouter many problems with the building of my replikeo printer : many disconnected connectors (for E thermistance and stepper motors), 0 ohm HB thermistance, wrong marlin config, ... like everyone ! For the price, Replikeo's kit is very attractive ! But you have to be good for soldering !

|

Re: My Replikeo Prusa i3 Rework Build July 07, 2014 12:09PM |

Registered: 10 years ago Posts: 197 |

|

Re: My Replikeo Prusa i3 Rework Build July 07, 2014 11:30PM |

Registered: 9 years ago Posts: 71 |

|

Re: My Replikeo Prusa i3 Rework Build July 08, 2014 12:48AM |

Registered: 10 years ago Posts: 197 |

|

Re: My Replikeo Prusa i3 Rework Build July 08, 2014 01:16PM |

Registered: 10 years ago Posts: 197 |

So I tried ABS for the first time last night and it was like night and day, my print quality with the ABS was MUCH better than with PLA. I'm having trouble with the heatbed temperature so I'm going to insulate it underneath with either cork or self-adhesive rubber pipe insulation. I'll also cover the top of the bed until I'm up to temp. I could only reliably get to 105C and adhesion was ok (a small section didn't adhere that well). I also used hairspray as I did for PLA but on my next print I'll try just the glass cleaned well with acetone.

Any other suggestions? My extruder was set to 230C, what are you all using for Replikeo's ABS?

Any other suggestions? My extruder was set to 230C, what are you all using for Replikeo's ABS?

|

Re: My Replikeo Prusa i3 Rework Build July 08, 2014 02:44PM |

Registered: 9 years ago Posts: 124 |

|

Re: My Replikeo Prusa i3 Rework Build July 08, 2014 08:20PM |

Registered: 10 years ago Posts: 197 |

|

Re: My Replikeo Prusa i3 Rework Build July 09, 2014 07:18AM |

Registered: 9 years ago Posts: 124 |

No just some regular natural cork. I was looking on some number about rubber pipe insulation and technically it can handle 150°C (I don´t know what type you have) so you can try use it. IMHO just put in under your HB and don´t attach HB to mount, heat it up and in case of some problem, just take HB away.

|

Re: My Replikeo Prusa i3 Rework Build July 09, 2014 02:10PM |

Registered: 9 years ago Posts: 71 |

They sent me a tracking number the same day, said the head is on its way. Electronics went fairly smooth, I have it moving around with the LCD, and homing. Had to move the Y switch one header over, and reverse the motor connectors, but that was it. Wanted to get more done last night, but Deadliest Catch was on, so lost an hour there.

Might try a welders mat for insulation, you can find it at any hardware store for torch sweating copper pipe. Im going to my local ACE to get glass cut and will probably pick one up myself. They can handle a lot of heat.

Might try a welders mat for insulation, you can find it at any hardware store for torch sweating copper pipe. Im going to my local ACE to get glass cut and will probably pick one up myself. They can handle a lot of heat.

Sorry, only registered users may post in this forum.