My Replikeo Prusa i3 Rework Build

Posted by Trike

|

Re: My Replikeo Prusa i3 Rework Build May 31, 2015 02:28AM |

Registered: 8 years ago Posts: 1 |

|

Re: My Replikeo Prusa i3 Rework Build June 01, 2015 12:51PM |

Registered: 9 years ago Posts: 124 |

Quote

Ano

Quote

lurch68b

Thanks guys, my y end stop is in back. Why did you guys put it int he front?

Well... Don't know =) The pictures I saw had it on the front. Really doesn't matter though. You just need to have the same physical and software configuration.

Should be this lines in marlin:

// ENDSTOP SETTINGS: // Sets direction of endstops when homing; 1=MAX, -1=MIN #define X_HOME_DIR -1 #define Y_HOME_DIR -1 #define Z_HOME_DIR -1So for you I think the y should then be +1 instead of -1.

Conflicting images of where the Y-motor and Y endstop were mounted led me to put it in the front.

[reprap.org]

[reprap.org]

[www.iprintin3d.co.uk]

[i01.i.aliimg.com]

There are numerous images showing the Y-axis endstop and motor in the rear.

Unfortunately, this has led to much confusion when it comes time to configuring the Y endstop, direction of travel and home position.

The manual I followed had the Y-motor at the front at one point and then at the rear in another part of the build. By then, I already had the frame with the longer top rods and tension idler in the rear.

|

Re: My Replikeo Prusa i3 Rework Build June 04, 2015 07:18AM |

Registered: 10 years ago Posts: 444 |

Nice long thread with good info. However, when the thread shows up in your subscribed threads with a "new" flag, how do you just go to the first new post, like most forums can do? I seem to have to go to page 1 first, then to the last page, then scroll up and try to remember what I read last.

And of course I end up reading many things again before realizing I've already read them.

And of course I end up reading many things again before realizing I've already read them.

|

Re: My Replikeo Prusa i3 Rework Build June 04, 2015 08:27AM |

Registered: 9 years ago Posts: 119 |

Sorry, can't help with that^^

Did someone already upgrade this standard wade extruder with an auto bed leveling sensor (capacitive)? That's the next step I would like to try.

I already tried another extruder, but the wade just seems to be quite a good design.

And btw, which layer height do you guys use? I use 0.12mm for the first layer (always) and 0.2mm for the rest. The 0.12mm was a great help for

getting enough adhesion when printing ABS. Before that I used 0.3mm as first layer, but it always warped away... Well, now I'm using PLA

with the same settings (0.12 and 0.2).

Edited 1 time(s). Last edit at 06/04/2015 08:39AM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

Did someone already upgrade this standard wade extruder with an auto bed leveling sensor (capacitive)? That's the next step I would like to try.

I already tried another extruder, but the wade just seems to be quite a good design.

And btw, which layer height do you guys use? I use 0.12mm for the first layer (always) and 0.2mm for the rest. The 0.12mm was a great help for

getting enough adhesion when printing ABS. Before that I used 0.3mm as first layer, but it always warped away... Well, now I'm using PLA

with the same settings (0.12 and 0.2).

Edited 1 time(s). Last edit at 06/04/2015 08:39AM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

|

Re: My Replikeo Prusa i3 Rework Build June 04, 2015 10:12AM |

Registered: 9 years ago Posts: 17 |

Hi Ano,

Im using ABL (AutoBed Leveling) longer time. But im using servo and microswitch. Layer 0.12 (sheet of paper) is fine high and will ensure good ahesion. Im Printing with first layer 0.3 for 0.3 nozzle and 0.2 other layers. And results are superb. What about extruder I can suggest you to use bowden one.Bowden extruder is also good motivation to have dual extrusion

Im using ABL (AutoBed Leveling) longer time. But im using servo and microswitch. Layer 0.12 (sheet of paper) is fine high and will ensure good ahesion. Im Printing with first layer 0.3 for 0.3 nozzle and 0.2 other layers. And results are superb. What about extruder I can suggest you to use bowden one.Bowden extruder is also good motivation to have dual extrusion

|

Re: My Replikeo Prusa i3 Rework Build June 11, 2015 01:26PM |

Registered: 8 years ago Posts: 9 |

Confused has been my middle name when it comes to this thing.  I haven had any time to work on it since my last post. I did talk to some one at work here and he mentions making user the the coordinates system is setup for relative or absolute or some such thing. I think I have been having an issue that it thinks it is at home position when it is turned on no matter where the head is at. So if it is in the middle of the bead it thinks. Have not been able to look at it and check but does that sound right? Sounds right to me but what do I know??

I haven had any time to work on it since my last post. I did talk to some one at work here and he mentions making user the the coordinates system is setup for relative or absolute or some such thing. I think I have been having an issue that it thinks it is at home position when it is turned on no matter where the head is at. So if it is in the middle of the bead it thinks. Have not been able to look at it and check but does that sound right? Sounds right to me but what do I know??

I hope to have time this weekend and next week to work on it.

Anyone have any luck printing from a PC yet, I saw earlier that people had to use an SD card, I need to buy the display/SD card module.

I haven had any time to work on it since my last post. I did talk to some one at work here and he mentions making user the the coordinates system is setup for relative or absolute or some such thing. I think I have been having an issue that it thinks it is at home position when it is turned on no matter where the head is at. So if it is in the middle of the bead it thinks. Have not been able to look at it and check but does that sound right? Sounds right to me but what do I know??

I haven had any time to work on it since my last post. I did talk to some one at work here and he mentions making user the the coordinates system is setup for relative or absolute or some such thing. I think I have been having an issue that it thinks it is at home position when it is turned on no matter where the head is at. So if it is in the middle of the bead it thinks. Have not been able to look at it and check but does that sound right? Sounds right to me but what do I know??I hope to have time this weekend and next week to work on it.

Anyone have any luck printing from a PC yet, I saw earlier that people had to use an SD card, I need to buy the display/SD card module.

|

Re: My Replikeo Prusa i3 Rework Build June 11, 2015 03:55PM |

Registered: 9 years ago Posts: 119 |

Thanks for the info. Well, I tried Bowden (see some of the last pages), but wasn't able to reduce the oozing to an acceptable state. So I went back to the standard direct wade extruder.Quote

tomleeds

...

You mean, when you start your printer, it shows 0|0|0 as position, wherever the nozzle may be at time of starting? That's normal. But when you select the home command, it should go to the corner you chose. What exactly happens, if you chose to activate the homing?Quote

lurch68b

Confused has been my middle name when it comes to this thing.I haven had any time to work on it since my last post. I did talk to some one at work here and he mentions making user the the coordinates system is setup for relative or absolute or some such thing. I think I have been having an issue that it thinks it is at home position when it is turned on no matter where the head is at. So if it is in the middle of the bead it thinks. Have not been able to look at it and check but does that sound right? Sounds right to me but what do I know??

I hope to have time this weekend and next week to work on it.

Anyone have any luck printing from a PC yet, I saw earlier that people had to use an SD card, I need to buy the display/SD card module.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

|

Re: My Replikeo Prusa i3 Rework Build June 15, 2015 08:33AM |

Registered: 9 years ago Posts: 17 |

|

Re: My Replikeo Prusa i3 Rework Build June 15, 2015 03:38PM |

Registered: 8 years ago Posts: 9 |

Quote

Ano

Thanks for the info. Well, I tried Bowden (see some of the last pages), but wasn't able to reduce the oozing to an acceptable state. So I went back to the standard direct wade extruder.Quote

tomleeds

...

You mean, when you start your printer, it shows 0|0|0 as position, wherever the nozzle may be at time of starting? That's normal. But when you select the home command, it should go to the corner you chose. What exactly happens, if you chose to activate the homing?Quote

lurch68b

Confused has been my middle name when it comes to this thing.I haven had any time to work on it since my last post. I did talk to some one at work here and he mentions making user the the coordinates system is setup for relative or absolute or some such thing. I think I have been having an issue that it thinks it is at home position when it is turned on no matter where the head is at. So if it is in the middle of the bead it thinks. Have not been able to look at it and check but does that sound right? Sounds right to me but what do I know??

I hope to have time this weekend and next week to work on it.

Anyone have any luck printing from a PC yet, I saw earlier that people had to use an SD card, I need to buy the display/SD card module.

It does seem to home but it don't stop when it gets to the end stops. And when I try to move them away from the end stops it some times wont move and I get the message, endstop hit.

Edited 1 time(s). Last edit at 06/15/2015 05:05PM by lurch68b.

|

Re: My Replikeo Prusa i3 Rework Build June 15, 2015 10:33PM |

Registered: 8 years ago Posts: 9 |

Quote

lurch68b

Quote

Ano

Thanks for the info. Well, I tried Bowden (see some of the last pages), but wasn't able to reduce the oozing to an acceptable state. So I went back to the standard direct wade extruder.Quote

tomleeds

...

You mean, when you start your printer, it shows 0|0|0 as position, wherever the nozzle may be at time of starting? That's normal. But when you select the home command, it should go to the corner you chose. What exactly happens, if you chose to activate the homing?Quote

lurch68b

Confused has been my middle name when it comes to this thing.I haven had any time to work on it since my last post. I did talk to some one at work here and he mentions making user the the coordinates system is setup for relative or absolute or some such thing. I think I have been having an issue that it thinks it is at home position when it is turned on no matter where the head is at. So if it is in the middle of the bead it thinks. Have not been able to look at it and check but does that sound right? Sounds right to me but what do I know??

I hope to have time this weekend and next week to work on it.

Anyone have any luck printing from a PC yet, I saw earlier that people had to use an SD card, I need to buy the display/SD card module.

It does seem to home but it don't stop when it gets to the end stops. And when I try to move them away from the end stops it some times wont move and I get the message, endstop hit.

Got the endstops working, turns out that I messed up on the wiring. Now to figure out the bow in the heat bed problem.

|

Re: My Replikeo Prusa i3 Rework Build June 17, 2015 01:33AM |

Registered: 10 years ago Posts: 444 |

|

Re: My Replikeo Prusa i3 Rework Build June 18, 2015 12:19AM |

Registered: 8 years ago Posts: 9 |

Hi all, so I thought I had everything ready to go for the calibration print and well something isnt right. The heat bed temp is set for PLA but the temp dont stop at 60C, it will go to 60C and stay there if I manually set the temperature. And now the filament is stuck in the head. Any ideas why the temp keeps going up?

|

Re: My Replikeo Prusa i3 Rework Build June 18, 2015 02:31AM |

Registered: 9 years ago Posts: 120 |

RRuser, sorry, I have the aluminum frame.

lurch68b,

I'm a little confused about what you mean with the heatbed. Are you saying that you set it for a temperature higher that 60 degrees C, but it stops at 60 degrees C? Or are you saying that you set it for 60 degrees C, but it continues to increase even after it reaches 60 degrees C? Either way, it seems like a problem that we can figure out for you. Thanks.

The filament being stuck in the print head should be easily fixed by heating the hotend to ~190 degrees C, and either PLA or ABS should be able to be pulled out from the feed in side.

Blue Ice

blog at [contemporarymaker.com]

lurch68b,

I'm a little confused about what you mean with the heatbed. Are you saying that you set it for a temperature higher that 60 degrees C, but it stops at 60 degrees C? Or are you saying that you set it for 60 degrees C, but it continues to increase even after it reaches 60 degrees C? Either way, it seems like a problem that we can figure out for you. Thanks.

The filament being stuck in the print head should be easily fixed by heating the hotend to ~190 degrees C, and either PLA or ABS should be able to be pulled out from the feed in side.

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build June 18, 2015 11:22AM |

Registered: 8 years ago Posts: 9 |

Quote

Blue Ice

RRuser, sorry, I have the aluminum frame.

lurch68b,

I'm a little confused about what you mean with the heatbed. Are you saying that you set it for a temperature higher that 60 degrees C, but it stops at 60 degrees C? Or are you saying that you set it for 60 degrees C, but it continues to increase even after it reaches 60 degrees C? Either way, it seems like a problem that we can figure out for you. Thanks.

The filament being stuck in the print head should be easily fixed by heating the hotend to ~190 degrees C, and either PLA or ABS should be able to be pulled out from the feed in side.

Sorry, what I mean is that when I try to print that the heat bed seems to go into a thermal run away state, I let it hit 114C and it was still climbing before I aborted. But when I tested to make sure that the hb is working by manual setting it, it maintains the set temperature as expected. I was able to clean the HE, had to pull it apart and clean out the tube manually.

Speaking of printing, when you click print does the print job start after the hb and he reach a stable temprature?

Never mind, the issue was that I didn't have the rite settings in slicer. Now I am having a problem in the Z axis. After homing the z axis goes up, raises the print head, then it acts like it gets stuck. The motors keep trying to raise the axis. I can lift it by hand.

Edited 2 time(s). Last edit at 06/19/2015 09:52PM by lurch68b.

|

Re: My Replikeo Prusa i3 Rework Build June 19, 2015 10:07PM |

Registered: 8 years ago Posts: 5 |

Hi All,

Have been reading this thread for a while now, and have now ordered and build one of these.

Mechanically everything seems to be OK, except the extruder.

I raised the z-axis and am trying to manually extrude ABS, but it always gets jammed. If I set it to extrude by say 50mm, as long as I apply downward pressure on the filament by hand whilst the bolt is turning, it will extrude, but as soon as I release the pressure, it starts slowing down until a complete stop.

Without the downward pressure, the bolt eventually chews up the filament. I have tried increasing the temp to 240degC, tried loosening/tightening the hobbed bolt bearing. When it gets jammed and I pull it out, it appears to bulge. I've attached photos of the bolt chew, ABS bulge and fan position. Anybody have any ideas? Maybe the hotend is partially blocked?? The filament tends to curl up as it comes out of the nozzle. Maybe even the quality of the ABS Replikeo send perhaps?

Any help from experienced extruderists would be greatly appreciated.

Have been reading this thread for a while now, and have now ordered and build one of these.

Mechanically everything seems to be OK, except the extruder.

I raised the z-axis and am trying to manually extrude ABS, but it always gets jammed. If I set it to extrude by say 50mm, as long as I apply downward pressure on the filament by hand whilst the bolt is turning, it will extrude, but as soon as I release the pressure, it starts slowing down until a complete stop.

Without the downward pressure, the bolt eventually chews up the filament. I have tried increasing the temp to 240degC, tried loosening/tightening the hobbed bolt bearing. When it gets jammed and I pull it out, it appears to bulge. I've attached photos of the bolt chew, ABS bulge and fan position. Anybody have any ideas? Maybe the hotend is partially blocked?? The filament tends to curl up as it comes out of the nozzle. Maybe even the quality of the ABS Replikeo send perhaps?

Any help from experienced extruderists would be greatly appreciated.

|

Re: My Replikeo Prusa i3 Rework Build June 19, 2015 10:17PM |

Registered: 8 years ago Posts: 5 |

Quote

lurch68b

Quote

Blue Ice

RRuser, sorry, I have the aluminum frame.

lurch68b,

I'm a little confused about what you mean with the heatbed. Are you saying that you set it for a temperature higher that 60 degrees C, but it stops at 60 degrees C? Or are you saying that you set it for 60 degrees C, but it continues to increase even after it reaches 60 degrees C? Either way, it seems like a problem that we can figure out for you. Thanks.

The filament being stuck in the print head should be easily fixed by heating the hotend to ~190 degrees C, and either PLA or ABS should be able to be pulled out from the feed in side.

Sorry, what I mean is that when I try to print that the heat bed seems to go into a thermal run away state, I let it hit 114C and it was still climbing before I aborted. But when I tested to make sure that the hb is working by manual setting it, it maintains the set temperature as expected. I was able to clean the HE, had to pull it apart and clean out the tube manually.

Speaking of printing, when you click print does the print job start after the hb and he reach a stable temprature?

Never mind, the issue was that I didn't have the rite settings in slicer. Now I am having a problem in the Z axis. After homing the z axis goes up, raises the print head, then it acts like it gets stuck. The motors keep trying to raise the axis. I can lift it by hand.

Yes, I had a similar problem (kinda of opposite) where the printer would never start even when pronterface temp was reached. I have problems inporting STL file to pronterface so made the g-code first in Slic3r, but realised the temps in slic3r were higher so it was never getting to setpoint. With the z-axis, when you lift it out of the nuts, do the motors start to spin freely?

|

Re: My Replikeo Prusa i3 Rework Build June 19, 2015 11:37PM |

Registered: 8 years ago Posts: 9 |

Quote

clone

Quote

lurch68b

Quote

Blue Ice

RRuser, sorry, I have the aluminum frame.

lurch68b,

I'm a little confused about what you mean with the heatbed. Are you saying that you set it for a temperature higher that 60 degrees C, but it stops at 60 degrees C? Or are you saying that you set it for 60 degrees C, but it continues to increase even after it reaches 60 degrees C? Either way, it seems like a problem that we can figure out for you. Thanks.

The filament being stuck in the print head should be easily fixed by heating the hotend to ~190 degrees C, and either PLA or ABS should be able to be pulled out from the feed in side.

Sorry, what I mean is that when I try to print that the heat bed seems to go into a thermal run away state, I let it hit 114C and it was still climbing before I aborted. But when I tested to make sure that the hb is working by manual setting it, it maintains the set temperature as expected. I was able to clean the HE, had to pull it apart and clean out the tube manually.

Speaking of printing, when you click print does the print job start after the hb and he reach a stable temprature?

Never mind, the issue was that I didn't have the rite settings in slicer. Now I am having a problem in the Z axis. After homing the z axis goes up, raises the print head, then it acts like it gets stuck. The motors keep trying to raise the axis. I can lift it by hand.

Yes, I had a similar problem (kinda of opposite) where the printer would never start even when pronterface temp was reached. I have problems inporting STL file to pronterface so made the g-code first in Slic3r, but realised the temps in slic3r were higher so it was never getting to setpoint. With the z-axis, when you lift it out of the nuts, do the motors start to spin freely?

hmm, it got passed the sticking point. I have tried running up to that point several times and it gets stuck most of the time. If I lift it it stays stuck but if I turn the left stepper by hand it moves passed the stuck point. Here is another issue though, it wants to print at like 100mm above the bed. Hmm, looks like there may be some thread damage to the left rod.

|

Re: My Replikeo Prusa i3 Rework Build June 21, 2015 01:31AM |

Registered: 9 years ago Posts: 120 |

lurchb,

My prints start once the hotend and bed reach temperature.

Do you oil your threaded z-axis rods? That might contribute to the problem.

If one is messed up, don't bother contacting Replikeo... they won't want to send you a new one, even after you explain a rod is messed up. If you live in the USA, Fastenal is a great store for metric threaded rod. I'd pick one up there and cut it at home. It will probably be around 5 dollars for a meter.

Not sure why the print would start so high up. Are you toggling the z-endstop at some point?

Blue Ice

blog at [contemporarymaker.com]

My prints start once the hotend and bed reach temperature.

Do you oil your threaded z-axis rods? That might contribute to the problem.

If one is messed up, don't bother contacting Replikeo... they won't want to send you a new one, even after you explain a rod is messed up. If you live in the USA, Fastenal is a great store for metric threaded rod. I'd pick one up there and cut it at home. It will probably be around 5 dollars for a meter.

Not sure why the print would start so high up. Are you toggling the z-endstop at some point?

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build June 21, 2015 01:38AM |

Registered: 9 years ago Posts: 120 |

Quote

clone

Hi All,

Have been reading this thread for a while now, and have now ordered and build one of these.

Mechanically everything seems to be OK, except the extruder.

I raised the z-axis and am trying to manually extrude ABS, but it always gets jammed. If I set it to extrude by say 50mm, as long as I apply downward pressure on the filament by hand whilst the bolt is turning, it will extrude, but as soon as I release the pressure, it starts slowing down until a complete stop.

Without the downward pressure, the bolt eventually chews up the filament. I have tried increasing the temp to 240degC, tried loosening/tightening the hobbed bolt bearing. When it gets jammed and I pull it out, it appears to bulge. I've attached photos of the bolt chew, ABS bulge and fan position. Anybody have any ideas? Maybe the hotend is partially blocked?? The filament tends to curl up as it comes out of the nozzle. Maybe even the quality of the ABS Replikeo send perhaps?

Any help from experienced extruderists would be greatly appreciated.

I had the exact same problem when I started out with my RepRap. I had the same bulging piece on the filament and tried everything, like you did. The only thing that worked at the time for me was pinching the extruder shut more tightly (by hand).

In the end, I decided that the design of the printer was not working for me. Long story short, I ended up switching the long M3 screws with springs that squeeze the extruder shut for shorter M3 x 25mm screws with washers that press directly up against the plastic (no springs). This caused the extruder to pinch tightly enough against the filament, and I continue to use it today with ABS and PLA because it is repeatable and works each time.

I would definitely recommend doing that; it's worked a charm for me so far.

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build June 21, 2015 04:38AM |

Registered: 8 years ago Posts: 5 |

Quote

Blue Ice

Quote

clone

Hi All,

Have been reading this thread for a while now, and have now ordered and build one of these.

Mechanically everything seems to be OK, except the extruder.

I raised the z-axis and am trying to manually extrude ABS, but it always gets jammed. If I set it to extrude by say 50mm, as long as I apply downward pressure on the filament by hand whilst the bolt is turning, it will extrude, but as soon as I release the pressure, it starts slowing down until a complete stop.

Without the downward pressure, the bolt eventually chews up the filament. I have tried increasing the temp to 240degC, tried loosening/tightening the hobbed bolt bearing. When it gets jammed and I pull it out, it appears to bulge. I've attached photos of the bolt chew, ABS bulge and fan position. Anybody have any ideas? Maybe the hotend is partially blocked?? The filament tends to curl up as it comes out of the nozzle. Maybe even the quality of the ABS Replikeo send perhaps?

Any help from experienced extruderists would be greatly appreciated.

I had the exact same problem when I started out with my RepRap. I had the same bulging piece on the filament and tried everything, like you did. The only thing that worked at the time for me was pinching the extruder shut more tightly (by hand).

In the end, I decided that the design of the printer was not working for me. Long story short, I ended up switching the long M3 screws with springs that squeeze the extruder shut for shorter M3 x 25mm screws with washers that press directly up against the plastic (no springs). This caused the extruder to pinch tightly enough against the filament, and I continue to use it today with ABS and PLA because it is repeatable and works each time.

I would definitely recommend doing that; it's worked a charm for me so far.

That's great news, I will definitely try that and see how I go. Also, I was constantly browsing your build thread and crosschecking as I was building the machine, was super helpful. So thank you very much for all the help you have provided.

|

Re: My Replikeo Prusa i3 Rework Build June 21, 2015 02:51PM |

Registered: 9 years ago Posts: 120 |

Quote

clone

Quote

Blue Ice

Quote

clone

Hi All,

Have been reading this thread for a while now, and have now ordered and build one of these.

Mechanically everything seems to be OK, except the extruder.

I raised the z-axis and am trying to manually extrude ABS, but it always gets jammed. If I set it to extrude by say 50mm, as long as I apply downward pressure on the filament by hand whilst the bolt is turning, it will extrude, but as soon as I release the pressure, it starts slowing down until a complete stop.

Without the downward pressure, the bolt eventually chews up the filament. I have tried increasing the temp to 240degC, tried loosening/tightening the hobbed bolt bearing. When it gets jammed and I pull it out, it appears to bulge. I've attached photos of the bolt chew, ABS bulge and fan position. Anybody have any ideas? Maybe the hotend is partially blocked?? The filament tends to curl up as it comes out of the nozzle. Maybe even the quality of the ABS Replikeo send perhaps?

Any help from experienced extruderists would be greatly appreciated.

I had the exact same problem when I started out with my RepRap. I had the same bulging piece on the filament and tried everything, like you did. The only thing that worked at the time for me was pinching the extruder shut more tightly (by hand).

In the end, I decided that the design of the printer was not working for me. Long story short, I ended up switching the long M3 screws with springs that squeeze the extruder shut for shorter M3 x 25mm screws with washers that press directly up against the plastic (no springs). This caused the extruder to pinch tightly enough against the filament, and I continue to use it today with ABS and PLA because it is repeatable and works each time.

I would definitely recommend doing that; it's worked a charm for me so far.

That's great news, I will definitely try that and see how I go. Also, I was constantly browsing your build thread and crosschecking as I was building the machine, was super helpful. So thank you very much for all the help you have provided.

No problem! Let me know how it works out

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build June 27, 2015 01:54AM |

Registered: 8 years ago Posts: 5 |

Hi Blue Ice. I didn't have the correct length screw and just decided to trim the long screw down a bit so the springs would be a lot tighter. This worked well, extruding was much better and uniform. So I started to print a cube, about a third of the way though, the extruder motor started stuttering and would stop the stuttering if I applied a small rotational force to the gear to help. In the end, the filament got chewed again. So I took it out, cleaned all the debris, and increased the motor pot by about an 1/8. Now I tried again and it worked, didn't have any troubles extruding throughout the print. Again thankyou for the advice. Only thing I need to look into now is it printed x and y at more or less 20cm, but only printed 15cm high. Regardless, I am rapped that I have actually finally printed something.

Edit: 20mm I meant. I think all I need to do is modify the steps per mm in the firmware.

Edited 1 time(s). Last edit at 06/27/2015 02:02AM by clone.

Edit: 20mm I meant. I think all I need to do is modify the steps per mm in the firmware.

Edited 1 time(s). Last edit at 06/27/2015 02:02AM by clone.

|

Re: My Replikeo Prusa i3 Rework Build June 28, 2015 09:13PM |

Registered: 8 years ago Posts: 5 |

Greetings!

I'm a aspiring 3d-er with Replikeo's Prusa i3. I'm having a few difficulties that I would love some feedback on, if you have the time.

I've made a youtube video describing my stepper motor issues: [youtu.be]

I am however 100% sure the motors can run as expected. When I initially set up configuration.h, I mistakenly enabled settings for a Delta printer without understanding I didn't have a delta printer (noob me ), which caused the steppers to turn through various revolutions smoothly (and in a completely unexpected manner) when entering commands in Pronterface. I've since disabled delta printer settings and my stepper motor troubles begin.

), which caused the steppers to turn through various revolutions smoothly (and in a completely unexpected manner) when entering commands in Pronterface. I've since disabled delta printer settings and my stepper motor troubles begin.

Please take a look at the attached configuration.h file text and my youtube video. Thanks!

chicky

I'm a aspiring 3d-er with Replikeo's Prusa i3. I'm having a few difficulties that I would love some feedback on, if you have the time.

I've made a youtube video describing my stepper motor issues: [youtu.be]

- Basically, my motors aren't turning when I give the command in Pronterface. They make a whining noise for a certain period of time, depending on whether I select 0.1, 1, or 10 in Pronterface. For example, if I want the x-axis to move 10 (mm, correct?) in the +x direction, the x-axis motor will "try" to move and make the whining sound for about a second or so.

The problem is the same after adjusting the trimpot to all possible currents. With more current, the motors whine louder and maybe even jolt a mm or so. I can get this jolting behavior from a motor by turning up the current and clicking 1 or 10. The motors won't jolt more than about 1 mm, even when I select 10 in Pronterface.

- When I run M119 (Get Endstop Status) in Pronterface, the status of y_min, y_max, z_min and z_max always reads "open", even if the endstops are triggered. The x_min and x_max status will correctly read "open" or "TRIGGERED" depending on the status of the endstop, as expected. I plugged the y and z axis endstops into the x_min and x_max pins on RAMPS, just to make sure they read TRIGGERED when hit (which they do) so there isn't a problem with the endstop or wire. Could it be that the soldering job on RAMPS isn't transmitting the signal? (cold solder) Or is there a problem in my configuration.h file?

I am however 100% sure the motors can run as expected. When I initially set up configuration.h, I mistakenly enabled settings for a Delta printer without understanding I didn't have a delta printer (noob me

), which caused the steppers to turn through various revolutions smoothly (and in a completely unexpected manner) when entering commands in Pronterface. I've since disabled delta printer settings and my stepper motor troubles begin.

), which caused the steppers to turn through various revolutions smoothly (and in a completely unexpected manner) when entering commands in Pronterface. I've since disabled delta printer settings and my stepper motor troubles begin.Please take a look at the attached configuration.h file text and my youtube video. Thanks!

chicky

|

Re: My Replikeo Prusa i3 Rework Build June 28, 2015 11:09PM |

Registered: 9 years ago Posts: 120 |

Quote

clone

Hi Blue Ice. I didn't have the correct length screw and just decided to trim the long screw down a bit so the springs would be a lot tighter. This worked well, extruding was much better and uniform. So I started to print a cube, about a third of the way though, the extruder motor started stuttering and would stop the stuttering if I applied a small rotational force to the gear to help. In the end, the filament got chewed again. So I took it out, cleaned all the debris, and increased the motor pot by about an 1/8. Now I tried again and it worked, didn't have any troubles extruding throughout the print. Again thankyou for the advice. Only thing I need to look into now is it printed x and y at more or less 20cm, but only printed 15cm high. Regardless, I am rapped that I have actually finally printed something.

Edit: 20mm I meant. I think all I need to do is modify the steps per mm in the firmware.

All right! That's awesome that you got it to work!

It seems like your problem with height could be caused by an incorrect value for the DEFAULT_AXIS_STEPS_PER_UNIT value in Marlin. If you get stuck, here's mine:

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,4000,607}

That's great that you're making progress! Calibration is the hard part, and then you have a working 3D printer

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build June 28, 2015 11:41PM |

Registered: 9 years ago Posts: 120 |

Hi, chicky! Welcome to the forum.

First off, I'd like to say that I appreciate the time you took to document the problem. It makes it a lot easier (and more inviting) for people to help you out. Thanks for working on that.

Problem #1:

I've seen the "whining" behavior in stepper motors before (off of a 3D printer) when too many steps are attempted at once with the stepper. In other words, I've seen the whining noise caused by an attempt to rotate the motor too quickly. I think other conditions have an effect on the whining noise as well, such as the amount of current supplied.

I think a good jumping off point for solving your problem would be if you could replicate my software setup with my version of Marlin (which I am certain works properly). From this, we can have a better shot at nailing down whether your problem is caused by software or hardware (or both).

I looked at your config file versus my config file, and they seem to be pretty similar in most aspects. I'd give you mine to try out, but you have a later version of Marlin than I do, so I'm not sure a one-for-one swap will work with config files.

Nevertheless, I have a GitHub repository where I keep all of my Prusa i3 Rework programs available for public view. What I'm thinking is that you could download it and use my Marlin Arduino files exactly like I do. It shouldn't be very hard- you can download the repository with the button on the lower right that says "Download ZIP", and then all you need to do is unpack the ZIP file and open /programs/Marlin-Marlin_v1/Marlin/Configuration.h . Then, you should be able to use the Arduino editor to upload my config file, just like yours.

I've never seen this problem before on a 3D printer, so I don't know if this will work. If it does, I'll look through your config file more closely and help you edit it so you won't have to use mine. If this fix doesn't work, then we can try out other things.

Problem #2:

Interesting. Do the red lights on the Y and Z endstops turn on when they are plugged into the board and triggered? Let's start from there.

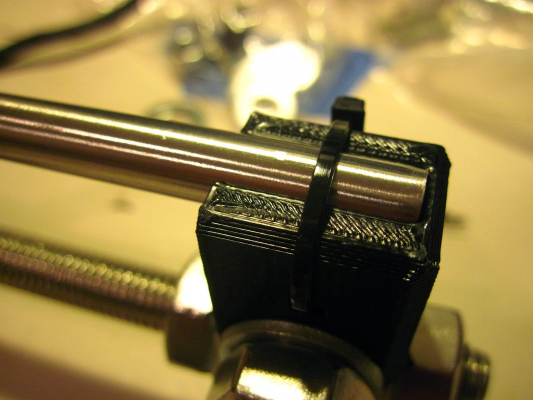

As a side note, your build looks fantastic. One thing that might help with rigidity of the printer the future is to add small zipties at the corners of the printer base, where the smooth rods meet the 3D printed corners.

Here's an image of what the corners look like on my printer:

I'd love to hear what happens- let me know and we can go from there.

Best,

Blue Ice

Edited 1 time(s). Last edit at 06/28/2015 11:43PM by Blue Ice.

Blue Ice

blog at [contemporarymaker.com]

First off, I'd like to say that I appreciate the time you took to document the problem. It makes it a lot easier (and more inviting) for people to help you out. Thanks for working on that.

Problem #1:

I've seen the "whining" behavior in stepper motors before (off of a 3D printer) when too many steps are attempted at once with the stepper. In other words, I've seen the whining noise caused by an attempt to rotate the motor too quickly. I think other conditions have an effect on the whining noise as well, such as the amount of current supplied.

I think a good jumping off point for solving your problem would be if you could replicate my software setup with my version of Marlin (which I am certain works properly). From this, we can have a better shot at nailing down whether your problem is caused by software or hardware (or both).

I looked at your config file versus my config file, and they seem to be pretty similar in most aspects. I'd give you mine to try out, but you have a later version of Marlin than I do, so I'm not sure a one-for-one swap will work with config files.

Nevertheless, I have a GitHub repository where I keep all of my Prusa i3 Rework programs available for public view. What I'm thinking is that you could download it and use my Marlin Arduino files exactly like I do. It shouldn't be very hard- you can download the repository with the button on the lower right that says "Download ZIP", and then all you need to do is unpack the ZIP file and open /programs/Marlin-Marlin_v1/Marlin/Configuration.h . Then, you should be able to use the Arduino editor to upload my config file, just like yours.

I've never seen this problem before on a 3D printer, so I don't know if this will work. If it does, I'll look through your config file more closely and help you edit it so you won't have to use mine. If this fix doesn't work, then we can try out other things.

Problem #2:

Interesting. Do the red lights on the Y and Z endstops turn on when they are plugged into the board and triggered? Let's start from there.

As a side note, your build looks fantastic. One thing that might help with rigidity of the printer the future is to add small zipties at the corners of the printer base, where the smooth rods meet the 3D printed corners.

Here's an image of what the corners look like on my printer:

I'd love to hear what happens- let me know and we can go from there.

Best,

Blue Ice

Edited 1 time(s). Last edit at 06/28/2015 11:43PM by Blue Ice.

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build June 29, 2015 02:36PM |

Registered: 8 years ago Posts: 5 |

Blue Ice

Thank you for your help and friendliness so far. Also for your detailed and quick reply! It's much appreciated.

I added the zip ties at the corners of the printer base. I didn't even realize during assembly that those slots are for zip ties!

Unfortunately uploading your complete firmware (not just configuration.h, but everything in Marlin-Marlin_v1) didn't help. The problem is exactly the same, except maybe that the whining noises are differently pitched with your firmware. I'm also not able to get my update videos uploaded to youtube before I leave for work (I work swing shift). Nevertheless, here is my thought process on the problem:

First, the stepper motors all work, because I checked the resistances on each coil-end pair in each motor. The 4 wires from the stepper motor to the RAMPS board do not have a short either, as I've checked continuity. The firmware (Marlin-Marlin_v1) is yours, which is working properly on your printer. Adjusting the trimpot changes the current but does not correct the motor behavior. 12V are being output and sent to the RAMPS board, so the PSU isn't the problem (checked this with multimeter).This gives us:

Stepper Motors

Stepper Motor Wires

Stepper Motor Wiring

RAMPS/Arduino Electronics

Stepsticks Stepper drivers (I found my exact model here: [www.amazon.com])

Stepstick Current Adjustment

ATX Power Supply

The wiring *could* somehow be incorrect. I mean, I've got it wired according to the female connectors on Replikeo's supplied motor wires, so I don't think this is the problem. Plugging in the black female connector from the motor wires both directions onto RAMPS yields the same problem. I can't say for sure until I saw someone else's setup using the same motors I have.

The stepper drivers could be the problem. I don't however think that each driver would be exhibiting the same problem. If you think it would be worthwhile, I might try testing a stepper driver and motor using my Arduino Uno and breadboard. That way we could eliminate the drivers as the problem.

I think the problem lies in the RAMPS board or Arduino Mega. The Arduino isn't genuine (at least that is my conclusion after close inspection) and it could be eliminated as the problem if I were to check every I/O slot. Ultimately though, I think my RAMPS board is the problem. I can't think of any method to test this other than visually inspecting the board...

For the endstops, the LED comes on when they are plugged into RAMPS and triggered. I am sure the endstops and endstop wires are working, as I've plugged all of them into x_min individually to see if they would read "TRIGGERED" when closed, which they would. At the RAMPS female connector on the endstop wires, ~5V runs into the signal pin when the switch is open and 0V when triggered. This is correct. The "TRIGGERED" status simply never appears in Pronterface for y_min, y_max, z_min, z_max.

Thanks for your diligence on this, hopefully we can get the problem figured out.

Thanks,

chicky

Thank you for your help and friendliness so far. Also for your detailed and quick reply! It's much appreciated.

I added the zip ties at the corners of the printer base. I didn't even realize during assembly that those slots are for zip ties!

Unfortunately uploading your complete firmware (not just configuration.h, but everything in Marlin-Marlin_v1) didn't help. The problem is exactly the same, except maybe that the whining noises are differently pitched with your firmware. I'm also not able to get my update videos uploaded to youtube before I leave for work (I work swing shift). Nevertheless, here is my thought process on the problem:

First, the stepper motors all work, because I checked the resistances on each coil-end pair in each motor. The 4 wires from the stepper motor to the RAMPS board do not have a short either, as I've checked continuity. The firmware (Marlin-Marlin_v1) is yours, which is working properly on your printer. Adjusting the trimpot changes the current but does not correct the motor behavior. 12V are being output and sent to the RAMPS board, so the PSU isn't the problem (checked this with multimeter).This gives us:

Stepper Motor Wiring

RAMPS/Arduino Electronics

Stepsticks Stepper drivers (I found my exact model here: [www.amazon.com])

The wiring *could* somehow be incorrect. I mean, I've got it wired according to the female connectors on Replikeo's supplied motor wires, so I don't think this is the problem. Plugging in the black female connector from the motor wires both directions onto RAMPS yields the same problem. I can't say for sure until I saw someone else's setup using the same motors I have.

The stepper drivers could be the problem. I don't however think that each driver would be exhibiting the same problem. If you think it would be worthwhile, I might try testing a stepper driver and motor using my Arduino Uno and breadboard. That way we could eliminate the drivers as the problem.

I think the problem lies in the RAMPS board or Arduino Mega. The Arduino isn't genuine (at least that is my conclusion after close inspection) and it could be eliminated as the problem if I were to check every I/O slot. Ultimately though, I think my RAMPS board is the problem. I can't think of any method to test this other than visually inspecting the board...

For the endstops, the LED comes on when they are plugged into RAMPS and triggered. I am sure the endstops and endstop wires are working, as I've plugged all of them into x_min individually to see if they would read "TRIGGERED" when closed, which they would. At the RAMPS female connector on the endstop wires, ~5V runs into the signal pin when the switch is open and 0V when triggered. This is correct. The "TRIGGERED" status simply never appears in Pronterface for y_min, y_max, z_min, z_max.

Thanks for your diligence on this, hopefully we can get the problem figured out.

Thanks,

chicky

|

Re: My Replikeo Prusa i3 Rework Build June 29, 2015 04:53PM |

Registered: 9 years ago Posts: 119 |

Hi Chicky,

nice video. As Blue Ice said, really makes it easier to see the problem.

I think the important part of the configuration is the

problem could be a combination of these values not being properly adjusted (aka too high)

and the motors not getting enough power. You could try to turn up the power a bit by turning

the potentiometers on the driver boards. Just try to move it with pronterface, adjust the power

and retry. If you see, that it starts turning a bit, more power could be needed.

I just saw something on the video that seems a bit odd: It seems like your motor cables (at the ramps) are

yellow-blue-green-red in this order from right to left. Could you tell us, which order it is, on both

sides (ramps and motor side)? Mine is (ramps side) Blue-yellow-green-red.

Edited 3 time(s). Last edit at 06/29/2015 05:05PM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

nice video. As Blue Ice said, really makes it easier to see the problem.

I think the important part of the configuration is the

#define DEFAULT_MAX_FEEDRATE {500, 500, 1, 25}

line. If the feedrates are to high, the motor will not turn or turn incorrectely. I think yourproblem could be a combination of these values not being properly adjusted (aka too high)

and the motors not getting enough power. You could try to turn up the power a bit by turning

the potentiometers on the driver boards. Just try to move it with pronterface, adjust the power

and retry. If you see, that it starts turning a bit, more power could be needed.

I just saw something on the video that seems a bit odd: It seems like your motor cables (at the ramps) are

yellow-blue-green-red in this order from right to left. Could you tell us, which order it is, on both

sides (ramps and motor side)? Mine is (ramps side) Blue-yellow-green-red.

Edited 3 time(s). Last edit at 06/29/2015 05:05PM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

|

Re: My Replikeo Prusa i3 Rework Build June 30, 2015 06:35AM |

Registered: 8 years ago Posts: 5 |

Quote

Blue Ice

Quote

clone

Hi Blue Ice. I didn't have the correct length screw and just decided to trim the long screw down a bit so the springs would be a lot tighter. This worked well, extruding was much better and uniform. So I started to print a cube, about a third of the way though, the extruder motor started stuttering and would stop the stuttering if I applied a small rotational force to the gear to help. In the end, the filament got chewed again. So I took it out, cleaned all the debris, and increased the motor pot by about an 1/8. Now I tried again and it worked, didn't have any troubles extruding throughout the print. Again thankyou for the advice. Only thing I need to look into now is it printed x and y at more or less 20cm, but only printed 15cm high. Regardless, I am rapped that I have actually finally printed something.

Edit: 20mm I meant. I think all I need to do is modify the steps per mm in the firmware.

All right! That's awesome that you got it to work!

It seems like your problem with height could be caused by an incorrect value for the DEFAULT_AXIS_STEPS_PER_UNIT value in Marlin. If you get stuck, here's mine:

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,4000,607}

That's great that you're making progress! Calibration is the hard part, and then you have a working 3D printer

Thanks BlueIce, I changed steps per unit and then it printed too high leaving gaps. I realised the original cube layers were more compressed and still had the temp at 240 from when I had extruder problems, put scaling back to close to original, reduced temp to 230 and now it prints fine. Have printed a knight chess piece, notre dame, and currently am now printing an adjustable wrench with a smaller layer height (gone from 0.4 to 0.3 mm) so far looking good.

Chicky, I got the whirring motor noise on my z axis when I increased my steps per unit, I fixed that whirring motor problem by reducing the feedrate to some value between 2.5 and 3. Not sure why this fixed it exactly or if it will help, but worth a try. Just make sure you record all original settings

Edited 1 time(s). Last edit at 06/30/2015 06:36AM by clone.

|

Re: My Replikeo Prusa i3 Rework Build July 05, 2015 01:08AM |

Registered: 10 years ago Posts: 444 |

|

Re: My Replikeo Prusa i3 Rework Build July 16, 2015 09:16AM |

Registered: 10 years ago Posts: 444 |

Sorry, only registered users may post in this forum.