My Replikeo Prusa i3 Rework Build

Posted by Trike

|

Re: My Replikeo Prusa i3 Rework Build February 22, 2015 03:08AM |

Registered: 9 years ago Posts: 120 |

Quote

Ano

Tried to update my printer:

[attachment 49782 IMG_20150222_011708.jpg]

Direct drive extruder at the top frame with 45° mount angle.

Now I just need to fix the extruder:

https://www.youtube.com/watch?v=b4G1odhli3I&feature=youtu.be

I'm not sure what's causing this motor behavior. I would understand the gear not being able to pull/push the filament, but this "jumps"

are a bit strange.

I think you mean bowden, not direct drive

Try playing with the potentiometer controlling amperage on the motor driver on the RAMPS board. I think the motor is missing steps when there is resistance to movement. Also, how hot is the motor getting?

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build February 22, 2015 03:11AM |

Registered: 9 years ago Posts: 120 |

Quote

mr.sneezy

Update on my Prusa i3.

The printed parts on my machine are made of PLA. Yesterday the shed where it's used was 40C ambient in a bit of Aussie hot weather. You'd think that would make for nice printing as the print would not cool so much between layers.

Well about 15 minutes into the print the Wade extruder assembly softened up and drooped by about 10mm, ruined the print of course, and the Wade extruder holder. The X-carriage is also warped.

Now getting those parts reprinted in ABS.

Martin

Wow, that stinks! I wouldn't mind some hot weather in Colorado, though... right now we have about 5 inches of snow

Did the new parts work out? Also, did you manage to remove all of the hardware from the old extruder?

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build February 22, 2015 07:57AM |

Registered: 9 years ago Posts: 59 |

Hey Blue, yes the new parts are working fine, although not without a quick fix for an unforeseen extruder holder issue.

The new mount I used was the Buderschnozzle version of the Gregs Wade reworked version here.

[www.thingiverse.com]

The one I got a friend to print out is the one shown in the last image, in black ABS this time. Unfortunately it's not quite Budaschnozzle compatible without a 9mm spacer between the mount and the X carriage.

It uses a 30mm spacing for the X carriage screws instead of 24mm, so the new X carriage had to match. I also got back 10mm of Z height with the new X carriage BTW, the mounting holes are higher on it than the first one.

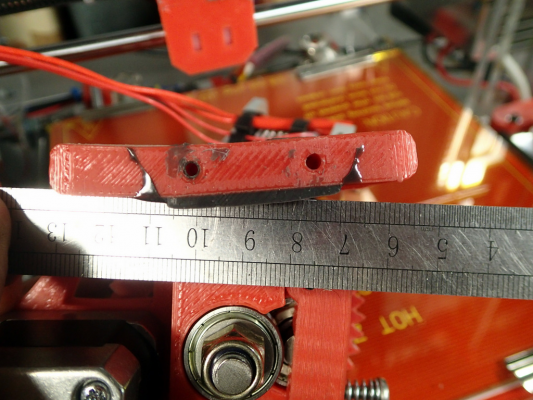

Here's a pic of the warped PLA extruder mount, it should be level across the ruler. The X carriage was also warped, but not as bad as this. The grey stuff is Devcon epoxy, which I hopefully won't need again.

Edited 2 time(s). Last edit at 02/22/2015 08:05AM by mr.sneezy.

The new mount I used was the Buderschnozzle version of the Gregs Wade reworked version here.

[www.thingiverse.com]

The one I got a friend to print out is the one shown in the last image, in black ABS this time. Unfortunately it's not quite Budaschnozzle compatible without a 9mm spacer between the mount and the X carriage.

It uses a 30mm spacing for the X carriage screws instead of 24mm, so the new X carriage had to match. I also got back 10mm of Z height with the new X carriage BTW, the mounting holes are higher on it than the first one.

Here's a pic of the warped PLA extruder mount, it should be level across the ruler. The X carriage was also warped, but not as bad as this. The grey stuff is Devcon epoxy, which I hopefully won't need again.

Edited 2 time(s). Last edit at 02/22/2015 08:05AM by mr.sneezy.

|

Re: My Replikeo Prusa i3 Rework Build February 25, 2015 09:46PM |

Registered: 11 years ago Posts: 76 |

|

Re: My Replikeo Prusa i3 Rework Build February 26, 2015 06:45PM |

Registered: 9 years ago Posts: 120 |

Quote

Michaelj

Does anyone know of a comparable kit in the United States?

Shipping alone is $100.00US unless I wait for 60-90 days

Which is $46.00US.

I just shouldered the cost of the shipping and didn't really worry about it. The kit is a good deal even with the extra $100 for shipping

Also, the box is shipped very nicely and I did not run into any issues at all.

Also, the box is shipped very nicely and I did not run into any issues at all.Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build February 28, 2015 10:33AM |

Registered: 9 years ago Posts: 124 |

Quote

Blue Ice

Hey guys-

Ano, thanks for mentioning the picture confusion with whether the motor should be at the front or the back. I fixed it in the introduction post and added a note that the motor should be at the front as per the build instructions.

I also got the next build log post published, covering the extruder setup. It seems that you won't need it after all, though, because you have a different extruder! But other people might find a use for it at some point, so we'll see.

Hey Blue Ice! I just finished skimming through your latest build blog. Your extruder looks pretty much like mine. I still have to buy a hobbed bolt for it. Do you know what length of hobbed bolt is it and where is the center of the hobbed portion in relation to the bolt head or end?

I am getting ready to buy my heated bed and I'm trying to find the right thermistor to use for a MK2B style HB. In the configurations.h file there is a list of thermistors. I believe you had mentioned before to use either options 1,5 or 8. Is this correct? I am thinking of going with #5 an ATC Semitec 104GT-2. Would that be a good selection?

Edited 1 time(s). Last edit at 02/28/2015 02:55PM by psneddon.

|

Re: My Replikeo Prusa i3 Rework Build March 01, 2015 05:51AM |

Registered: 9 years ago Posts: 59 |

MK3 3mm aluminium heatbed, are any of you guys using one on the Prusa, and have and opinion of the performance ?

I used a FLIR IR camera to confirm that the MK2B and glass plate bed has a 10 degree C roll off at the edges, mainly the last 30mm. This is no big deal for smaller prints, but when using the whole width in ABS it is an issue.

Using a 'brim' helps a LOT but I wonder if I might be better off with the combined aluminium heater/printbed.

Martin

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

Prusa i3 EiNSTeiN Varient - I mounted my Y motor backwards, and loved every minute of it

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

I used a FLIR IR camera to confirm that the MK2B and glass plate bed has a 10 degree C roll off at the edges, mainly the last 30mm. This is no big deal for smaller prints, but when using the whole width in ABS it is an issue.

Using a 'brim' helps a LOT but I wonder if I might be better off with the combined aluminium heater/printbed.

Martin

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

Prusa i3 EiNSTeiN Varient - I mounted my Y motor backwards, and loved every minute of it

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

|

Re: My Replikeo Prusa i3 Rework Build March 01, 2015 07:36AM |

Registered: 11 years ago Posts: 76 |

|

Re: My Replikeo Prusa i3 Rework Build March 01, 2015 08:24AM |

Registered: 9 years ago Posts: 46 |

Have you considered a wilson ts... a full kit is offered by mjrice on ebay for $480 with $20 shipping in the usa. Mine just shipped.

Highlights of this kit

All the parts you need are included

No soldering required! The hot end, heat bed, end stops, stepper motors, and even the fans are all prewired for you and plug-in ready.

No cutting of rods or beams required.

All high quality components, clearly labelled and carefully packed.

Arduino controller comes pre-programmed with Marlin 3D printer firmware for the Wilson printer configuration.

Assembly videos on youtube

What's Included

Complete set of printed plastic parts for the Wilson TS (see photo for color)

Set of 6 precision aluminum extrusions with black matte anodized finish, metric 2020 profile, precut

Set of 6 hardened chrome-finished steel rods, 8mm profile, precut

Five High torque (76 oz-inch) NEMA17 stepper motors

Authentic J-Head hot end by Reifsnyder Precision Works – completely assembled and ready to use (for use with 1.75mm filament)

12V, 30A switching power supply, along with professionally assembled line cord and RAMPS connector assembly.

All electronics, including Arduino Mega, RAMPS 1.4, and A4988 stepper motor drivers.

SMART LCD controller with SD card interface and 4GB memory card.

MK2a heat bed, completely wired up and ready for use, along with the MDF mounting sheet and glass.

Metric 5mm threaded rods

All metric fasteners, nuts & bolts, springs, and bearings (see detailed list below)

Set of 52 t-slot nuts for frame assembly

12 LM8UU linear bearings

End stops, pre-wired and ready to plug in

MK7 stainless steel extruder drive gear

GT2 timing belt and aluminum 20-tooth pulleys

More!

Edited 1 time(s). Last edit at 03/01/2015 08:49AM by bassnfool.

Highlights of this kit

All the parts you need are included

No soldering required! The hot end, heat bed, end stops, stepper motors, and even the fans are all prewired for you and plug-in ready.

No cutting of rods or beams required.

All high quality components, clearly labelled and carefully packed.

Arduino controller comes pre-programmed with Marlin 3D printer firmware for the Wilson printer configuration.

Assembly videos on youtube

What's Included

Complete set of printed plastic parts for the Wilson TS (see photo for color)

Set of 6 precision aluminum extrusions with black matte anodized finish, metric 2020 profile, precut

Set of 6 hardened chrome-finished steel rods, 8mm profile, precut

Five High torque (76 oz-inch) NEMA17 stepper motors

Authentic J-Head hot end by Reifsnyder Precision Works – completely assembled and ready to use (for use with 1.75mm filament)

12V, 30A switching power supply, along with professionally assembled line cord and RAMPS connector assembly.

All electronics, including Arduino Mega, RAMPS 1.4, and A4988 stepper motor drivers.

SMART LCD controller with SD card interface and 4GB memory card.

MK2a heat bed, completely wired up and ready for use, along with the MDF mounting sheet and glass.

Metric 5mm threaded rods

All metric fasteners, nuts & bolts, springs, and bearings (see detailed list below)

Set of 52 t-slot nuts for frame assembly

12 LM8UU linear bearings

End stops, pre-wired and ready to plug in

MK7 stainless steel extruder drive gear

GT2 timing belt and aluminum 20-tooth pulleys

More!

Edited 1 time(s). Last edit at 03/01/2015 08:49AM by bassnfool.

|

Re: My Replikeo Prusa i3 Rework Build March 01, 2015 09:46AM |

Registered: 11 years ago Posts: 76 |

Bassnfool....I just took a look at the Wilson TS. My biggest problem is EBay.

The pricing is only a few dollars different than the Rework after you add the LCD and glass plate.

Cheaper if you get the steel or plexi version and about $35 more for the aluminum frame.

Let's see how well they support the unit once you get it. There are so many people around here

with the Rework, that you can almost always find an answer pretty quickly.

The pricing is only a few dollars different than the Rework after you add the LCD and glass plate.

Cheaper if you get the steel or plexi version and about $35 more for the aluminum frame.

Let's see how well they support the unit once you get it. There are so many people around here

with the Rework, that you can almost always find an answer pretty quickly.

|

Re: My Replikeo Prusa i3 Rework Build March 01, 2015 10:43AM |

Registered: 9 years ago Posts: 46 |

Michialj,

I agree that the pricing is very close... i chose this kit vs other i3 variations for the following reasons:

1. The components seem top notch, for example the high torque nema steppers & genuine j-head

2. I did not want to go with the Plexiglas frame... the extruded aluminum makes adding accessories or making changes easy so that eliminated any price advantage for the Replikeo.

3. No customs or other ship from china hassles ( maybe more imagined than real :-) ).

4. The fantastic build videos from the designer

5. I like the extruded aluminum rather than the threaded rods.

6. Maybe should be #1... read great reviews from other builders on these forums.

Having said that, my second choice was the replikeo i3 steal rework kit. Seems like a great kit. I like the molded plastic parts! People seem really happy with it!

Bassnfool

I agree that the pricing is very close... i chose this kit vs other i3 variations for the following reasons:

1. The components seem top notch, for example the high torque nema steppers & genuine j-head

2. I did not want to go with the Plexiglas frame... the extruded aluminum makes adding accessories or making changes easy so that eliminated any price advantage for the Replikeo.

3. No customs or other ship from china hassles ( maybe more imagined than real :-) ).

4. The fantastic build videos from the designer

5. I like the extruded aluminum rather than the threaded rods.

6. Maybe should be #1... read great reviews from other builders on these forums.

Having said that, my second choice was the replikeo i3 steal rework kit. Seems like a great kit. I like the molded plastic parts! People seem really happy with it!

Bassnfool

|

Re: My Replikeo Prusa i3 Rework Build March 01, 2015 11:02AM |

Registered: 11 years ago Posts: 76 |

Bassnfool, your thought are exactly the way I feel. I was almost ready to get the Replikeo i3 rework aluminum kit with an lcd and a glass plate. You have now thrown a wrench into that. I am tossed between these two now. Well I'm not going to order for a couple of weeks yet, so I'll keep on reading. I'd like to hear how sturdy it turns out and how well the prints are, so please keep us updated on how your build goes. Any one else have any experience with the Wilson TS?

Edited 1 time(s). Last edit at 03/01/2015 11:53AM by Michaelj.

Edited 1 time(s). Last edit at 03/01/2015 11:53AM by Michaelj.

|

Re: My Replikeo Prusa i3 Rework Build March 01, 2015 11:18AM |

Registered: 9 years ago Posts: 46 |

|

Re: My Replikeo Prusa i3 Rework Build March 02, 2015 10:58AM |

Registered: 9 years ago Posts: 137 |

|

Re: My Replikeo Prusa i3 Rework Build March 02, 2015 05:41PM |

Registered: 9 years ago Posts: 120 |

Quote

psneddon

Quote

Blue Ice

Hey guys-

Ano, thanks for mentioning the picture confusion with whether the motor should be at the front or the back. I fixed it in the introduction post and added a note that the motor should be at the front as per the build instructions.

I also got the next build log post published, covering the extruder setup. It seems that you won't need it after all, though, because you have a different extruder! But other people might find a use for it at some point, so we'll see.

Hey Blue Ice! I just finished skimming through your latest build blog. Your extruder looks pretty much like mine. I still have to buy a hobbed bolt for it. Do you know what length of hobbed bolt is it and where is the center of the hobbed portion in relation to the bolt head or end?

I am getting ready to buy my heated bed and I'm trying to find the right thermistor to use for a MK2B style HB. In the configurations.h file there is a list of thermistors. I believe you had mentioned before to use either options 1,5 or 8. Is this correct? I am thinking of going with #5 an ATC Semitec 104GT-2. Would that be a good selection?

Hey psneddon! I can let you know about the hobbed bolt Wednesday night (away from printer right now).

The thermistor that you mentioned sounds great. I just recommended 1,5, or 8 because they are often the correct options for mystery thermistors. Of course, if you just purchase one that you know is a certain number in the table, you will be just fine.

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build March 02, 2015 05:44PM |

Registered: 9 years ago Posts: 120 |

Quote

Michaelj

Blue ice...when you ordered you PRuse i3 Rework from Replikeo, what extras other than the LCD screen and glass heatbed did you order?

That was about it! In terms of consumables, I also ordered some PTFE-infused lubricant for the smooth rods. The other boxes contained misc parts that haven't really been useful yet (heatsink pieces for the stepper drivers, which were already included, and heatsinks for the MOSFETs, which wouldn't fit).

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build March 03, 2015 07:42AM |

Registered: 9 years ago Posts: 59 |

Quote

Bratan

I finally added LCD smart controller (have been printing from PC all this time). I'm a little confused tho, I get no power to the ATMegal when using just PSU. If connect USB everything works. RAMPS doesn't power ATMega?

I have Melzi 2.0 not RAMPS, but I suspect there may be a 5V supply link you need to fit some place on the RAMPS board.

|

Re: My Replikeo Prusa i3 Rework Build March 03, 2015 02:51PM |

Registered: 9 years ago Posts: 124 |

|

Re: My Replikeo Prusa i3 Rework Build March 03, 2015 06:02PM |

Registered: 9 years ago Posts: 120 |

|

Re: My Replikeo Prusa i3 Rework Build March 04, 2015 10:15PM |

Registered: 9 years ago Posts: 120 |

|

Re: My Replikeo Prusa i3 Rework Build March 05, 2015 09:20AM |

Registered: 9 years ago Posts: 124 |

|

Re: My Replikeo Prusa i3 Rework Build March 05, 2015 05:40PM |

Registered: 9 years ago Posts: 119 |

Hi guys,

long time no read. My 40x40mm fan broke =(. It was already damaged when I build my printer, but now it just broke appart. I ordered another one, after the new one from replikeo took too long to arrive,

the Scythe Mini Kaze. It only turns at 3500 rpm, but I think it's still enough air ventilation. And it's so much less noisy. Costed around 7 €, which was a good investment I think.

So, I'm back in business now =)

I try to find a good config for my bowden setup and would be great to get some tips from you =)

I currently have the problem, that after each retract, when the extruder turns back (re-retracts?), there is a blob of abs forming under the nozzle. Someone told me to decrease the retractspeed, I had it at

100mm/s, now it's at 40mm/s but I don't think it helped much. Should I try even lower values, or are there any other things I could do?

I have 5 mm retraction right now, which seems to be not enough, as some strings still appear. Should I try the option "extra lenght on restart"? Like setting it to -1mm, so that it retracts 5mm but only re-retracts 4?

Using slic3r btw. And the "wipe while retract"-option just seems to not change anything.

Also my printer seems to retract really often. Set the minimum travel after retraction to 1mm, should I raise it a bit?

Btw, my extruder works just fine now. Raised the motor current a bit and adjusted the tension of the screw to hold the filament.

When I ordered my printer at replikeo, I just added the LCD screen. It's the full pixel-matrix screen now, even if they didn't upgrade their page. And having all the parts (appart from wade extruder) as injection molded

pieces is kind of nice =)

Does anyone use cablechaines for the Prusa i3 rework? I would like to add some, I like the style =) Will try to add one from the electronics to the left z-axis-guide and another one from the guide to the hotend.

@psneddon:

My hobbed bolt (original from replikeo) is:

total length: 65mm

centered 30mm from the top of the bold head

the hobbed area is about 3,5mm wide

Edited 4 time(s). Last edit at 03/05/2015 05:55PM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

long time no read. My 40x40mm fan broke =(. It was already damaged when I build my printer, but now it just broke appart. I ordered another one, after the new one from replikeo took too long to arrive,

the Scythe Mini Kaze. It only turns at 3500 rpm, but I think it's still enough air ventilation. And it's so much less noisy. Costed around 7 €, which was a good investment I think.

So, I'm back in business now =)

I try to find a good config for my bowden setup and would be great to get some tips from you =)

I currently have the problem, that after each retract, when the extruder turns back (re-retracts?), there is a blob of abs forming under the nozzle. Someone told me to decrease the retractspeed, I had it at

100mm/s, now it's at 40mm/s but I don't think it helped much. Should I try even lower values, or are there any other things I could do?

I have 5 mm retraction right now, which seems to be not enough, as some strings still appear. Should I try the option "extra lenght on restart"? Like setting it to -1mm, so that it retracts 5mm but only re-retracts 4?

Using slic3r btw. And the "wipe while retract"-option just seems to not change anything.

Also my printer seems to retract really often. Set the minimum travel after retraction to 1mm, should I raise it a bit?

Btw, my extruder works just fine now. Raised the motor current a bit and adjusted the tension of the screw to hold the filament.

When I ordered my printer at replikeo, I just added the LCD screen. It's the full pixel-matrix screen now, even if they didn't upgrade their page. And having all the parts (appart from wade extruder) as injection molded

pieces is kind of nice =)

Does anyone use cablechaines for the Prusa i3 rework? I would like to add some, I like the style =) Will try to add one from the electronics to the left z-axis-guide and another one from the guide to the hotend.

@psneddon:

My hobbed bolt (original from replikeo) is:

total length: 65mm

centered 30mm from the top of the bold head

the hobbed area is about 3,5mm wide

Edited 4 time(s). Last edit at 03/05/2015 05:55PM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

|

Re: My Replikeo Prusa i3 Rework Build March 06, 2015 04:10PM |

Registered: 9 years ago Posts: 124 |

Blue Ice

Thanks again. I'll check mine over once I receive it in the mail.

I received my MK2B heated bed and hooked up the wires to it and measured the resistance and I'm getting 2.6 ohms. Most of the information I've read about this heated bed states that the resistance should be 1.2 to 1.3 ohms. Is this correct?

I have the negative lead hooked to pad #1 and the positive lead hooked to pad #2 for a 12 volt supply - as stenciled on the heated bed.

I haven't hooked it up to any power yet and definitely not to my Ramps board until I test it. I have a DC power supply that can put out 3 amps of power at 12 volts, but I think the bed can take a higher current - is that so?

Thanks again. I'll check mine over once I receive it in the mail.

I received my MK2B heated bed and hooked up the wires to it and measured the resistance and I'm getting 2.6 ohms. Most of the information I've read about this heated bed states that the resistance should be 1.2 to 1.3 ohms. Is this correct?

I have the negative lead hooked to pad #1 and the positive lead hooked to pad #2 for a 12 volt supply - as stenciled on the heated bed.

I haven't hooked it up to any power yet and definitely not to my Ramps board until I test it. I have a DC power supply that can put out 3 amps of power at 12 volts, but I think the bed can take a higher current - is that so?

|

Re: My Replikeo Prusa i3 Rework Build March 06, 2015 04:36PM |

Registered: 9 years ago Posts: 120 |

Quote

psneddon

Blue Ice,

Yes please! I never say no to information!

The hobbed bolt I'm waiting on supposedly has the center of the hobbed portion at around 28.5 mm from the bottom of the bolt head.

Mine was about that much as well, so you should be OK.

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build March 06, 2015 05:01PM |

Registered: 9 years ago Posts: 124 |

Quote

Blue Ice

Quote

psneddon

Blue Ice,

Yes please! I never say no to information!

The hobbed bolt I'm waiting on supposedly has the center of the hobbed portion at around 28.5 mm from the bottom of the bolt head.

Mine was about that much as well, so you should be OK.

Sounds good! Thanks again.

|

Re: My Replikeo Prusa i3 Rework Build March 06, 2015 05:17PM |

Registered: 9 years ago Posts: 137 |

|

Re: My Replikeo Prusa i3 Rework Build March 07, 2015 09:16PM |

Registered: 9 years ago Posts: 120 |

Quote

Ano

Hi guys,

long time no read. My 40x40mm fan broke =(. It was already damaged when I build my printer, but now it just broke appart. I ordered another one, after the new one from replikeo took too long to arrive,

the Scythe Mini Kaze. It only turns at 3500 rpm, but I think it's still enough air ventilation. And it's so much less noisy. Costed around 7 €, which was a good investment I think.

So, I'm back in business now =)

Nice! i don't mind the noise, and my fan is in good shape, so I haven't replaced mine for something else.

Quote

Ano

I try to find a good config for my bowden setup and would be great to get some tips from you =)

I currently have the problem, that after each retract, when the extruder turns back (re-retracts?), there is a blob of abs forming under the nozzle. Someone told me to decrease the retractspeed, I had it at

100mm/s, now it's at 40mm/s but I don't think it helped much. Should I try even lower values, or are there any other things I could do?

I have 5 mm retraction right now, which seems to be not enough, as some strings still appear. Should I try the option "extra lenght on restart"? Like setting it to -1mm, so that it retracts 5mm but only re-retracts 4?

Using slic3r btw. And the "wipe while retract"-option just seems to not change anything.

Also my printer seems to retract really often. Set the minimum travel after retraction to 1mm, should I raise it a bit?

I really don't know a lot about bowden setups. Maybe you could start a new thread here and ask about it?

Quote

Ano

Btw, my extruder works just fine now. Raised the motor current a bit and adjusted the tension of the screw to hold the filament.

When I ordered my printer at replikeo, I just added the LCD screen. It's the full pixel-matrix screen now, even if they didn't upgrade their page. And having all the parts (appart from wade extruder) as injection molded

pieces is kind of nice =)

That's good. I've had a screen for my printer for quite a while now, and it is very handy.

Quote

Ano

Does anyone use cablechaines for the Prusa i3 rework? I would like to add some, I like the style =) Will try to add one from the electronics to the left z-axis-guide and another one from the guide to the hotend.

I haven't, but it looks like someone has!

I guess someone on Thingiverse thought it was a good idea like you did

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build March 07, 2015 09:38PM |

Registered: 9 years ago Posts: 119 |

Oh nice, thanks for that link!

I tried some more settings for my bowden setup, but I think I'll change back to the direct method. But I will replace the wade extruder for a direct drive one, just for the looks of it ^^

Thinking about letting the PTFE tube in place to guide my filament from the spool to the extruder, though.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

I tried some more settings for my bowden setup, but I think I'll change back to the direct method. But I will replace the wade extruder for a direct drive one, just for the looks of it ^^

Thinking about letting the PTFE tube in place to guide my filament from the spool to the extruder, though.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

|

Re: My Replikeo Prusa i3 Rework Build March 07, 2015 09:42PM |

Registered: 9 years ago Posts: 120 |

Quote

psneddon

Blue Ice

Thanks again. I'll check mine over once I receive it in the mail.

I received my MK2B heated bed and hooked up the wires to it and measured the resistance and I'm getting 2.6 ohms. Most of the information I've read about this heated bed states that the resistance should be 1.2 to 1.3 ohms. Is this correct?

I have the negative lead hooked to pad #1 and the positive lead hooked to pad #2 for a 12 volt supply - as stenciled on the heated bed.

I haven't hooked it up to any power yet and definitely not to my Ramps board until I test it. I have a DC power supply that can put out 3 amps of power at 12 volts, but I think the bed can take a higher current - is that so?

Hmm. My heated bed has a resistance of about 1.7 ohms. Also, by the information that you stated for the average heated bed, the heated bed pulls about 9.23 A:

V = 12 volts

R = 1.3 ohms

V = I * R

V / R = I

12 / 1.3 = 9.23

For your own heated bed, it would draw about 4.62 amps.

12 / 2.6 = 4.62

So I don't think the power supply will work- the heated bed will pull more amps than the power supply can supply.

Where did you buy the heated bed from? Can you post a link?

Edited 2 time(s). Last edit at 03/07/2015 09:45PM by Blue Ice.

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build March 07, 2015 09:48PM |

Registered: 9 years ago Posts: 120 |

Quote

Bratan

What do you guys think about using MK8 hobbed pulley instead of hobbed bolt? This completely eliminates all the gears from extruder! All you need is bearing pushing filment onto pulley. Of course this requires different design for extruder but I'm sure there are many on Thingiverse...

I don't know. My extruder is working great with the hobbed bolt and the gears, ever since I put in spacers instead of springs

Are you having issues with yours?

Are you having issues with yours?Blue Ice

blog at [contemporarymaker.com]

Sorry, only registered users may post in this forum.