My Replikeo Prusa i3 Rework Build

Posted by Trike

|

Re: My Replikeo Prusa i3 Rework Build January 14, 2015 12:38PM |

Registered: 9 years ago Posts: 120 |

Quote

Bratan

You lucky. It's such a pain to adjust bed level, and I have to do it almost every time I print. I made better z-endstop bracket that uses long screw that I can move up or down and it presses on the switch, but nuts on it keep unscrewing from vibration. I'm going to try proximity sensor next...Quote

Blue Ice

Yeah, I only adjusted mine twice over the past six months, so it hasn't really bothered me much. But when I do need to adjust it, it's quite a chore. One thing that I would like to see are captive nuts in the parts- that way you don't have to do all of the painful "hold the nut on one end and screw on the other" work. Instead, you would just screw in the screw. Maybe someday....

You have to adjust the z-endstop mount almost every time you print? Maybe you could try locking nuts on the ends of the endstop screws?

It's really only the jackscrews on the bed that I ever use, and it's pretty infrequently. Usually I just change them on the fly when the printer is doing rings around the part, and that's probably every four prints. After I figured out that all of my slop was coming from loose nuts where the frame is attached to the Y-axis assembly, I just tightened the crap out of them and left them alone. Now all of the issues have disappeared

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build January 14, 2015 12:42PM |

Registered: 9 years ago Posts: 120 |

Quote

pierrehavelaar

@Blue Ice I had inverted Y on my prints at first, so in Marlin I reversed the Y direction, home direction and plugged the endstop into the MAX setting in order to flip it.

Ahh ok- I tried messing with Marlin a bunch but it never occurred to me to change the wiring. That makes a lot of sense.

Quote

pierrehavelaar

The Z-stop is in a really bad spot, I simply cannot access the nuts and bolt properly to fix it in place. I fixed it in place as good as I could and then used the bed screws to do the final leveling. I haven't touched the z-stop since.

I have looked around and I like this z-stop, but I haven't tried it myself yet.

adjustable z-stop

That does look really good! I don't have any problems with mine right now, but maybe I'll change it to that if I run into things.

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build January 16, 2015 04:43PM |

Registered: 9 years ago Posts: 30 |

I have a few questions for you guys:

1: Where are you plugging in your fans? The Replikeo kit fan has bare wires, and I assume they intend for it to be plugged into D9 (I emailed them and they actually said plug it directly into my power supply...?)? The image on the reprap wiki though shows a different location which would require a connector (as this is an extruder fan, right?): Fan Wiring Options.

2: I purchased the LCD from the Replikeo website. Which LCD do I enable in the Marlin firmware, and are there any other lines I need to uncomment?

3: Can someone explain EEPROM to me, and advise if I should be using it?

1: Where are you plugging in your fans? The Replikeo kit fan has bare wires, and I assume they intend for it to be plugged into D9 (I emailed them and they actually said plug it directly into my power supply...?)? The image on the reprap wiki though shows a different location which would require a connector (as this is an extruder fan, right?): Fan Wiring Options.

2: I purchased the LCD from the Replikeo website. Which LCD do I enable in the Marlin firmware, and are there any other lines I need to uncomment?

3: Can someone explain EEPROM to me, and advise if I should be using it?

|

Re: My Replikeo Prusa i3 Rework Build January 18, 2015 12:50PM |

Registered: 9 years ago Posts: 21 |

Quote

underthetire

Worked out in the end, the Replikeo Jhead was VERY loose in the extruder body, and the sainsmart one was not. So i have one close to perfect Jhead now, and no more replikeo ABS. I had also ordered a J head from Banggood US, so I did have a backup, but i sold that one to a guy at work.

How did you fix the loose J-Head in the end? I recieved a kit, buildt it up and now i'm facing the same problem: the J-Head is very loose in the extruder body. This leads to horrible prints !

|

Re: My Replikeo Prusa i3 Rework Build January 18, 2015 07:45PM |

Registered: 9 years ago Posts: 30 |

Quote

BoxSon

Quote

underthetire

Worked out in the end, the Replikeo Jhead was VERY loose in the extruder body, and the sainsmart one was not. So i have one close to perfect Jhead now, and no more replikeo ABS. I had also ordered a J head from Banggood US, so I did have a backup, but i sold that one to a guy at work.

How did you fix the loose J-Head in the end? I recieved a kit, buildt it up and now i'm facing the same problem: the J-Head is very loose in the extruder body. This leads to horrible prints !

Use a slightly larger diameter screw to hold it in place.

|

Re: My Replikeo Prusa i3 Rework Build January 20, 2015 06:35PM |

Registered: 9 years ago Posts: 30 |

I've had a lot of issues with the z-axis not moving high enough up on prints, resulting in the nozzle colliding with layers. I think I have everything fine tuned perfectly now, and should have every mechanical setting in the firmware correct, extruder calibrated, voltages set, and am measuring filament diameter regularly - these things improved it greatly. I have had a couple random instances where the z-axis just simply didn't move upwards during print (but did move just fine manually commanded) though that are puzzling to me, and I'm not sure if they were related to the Vref of the steppers. Another puzzle was during extruder calibration, I would command 100 and get 80, then command 100 and get 100. It was very odd, but seems to have somehow worked itself out - I turned off the thermal runaway option in my firmware, as I think that may have been triggering an off command before extrusion was complete.

Anyhow, the nozzle still seems to be dragging somewhat though (but no longer colliding, at least lately) which is predominantly noticeable when it does the honeycomb infill patterns. It sounds aggressively loud to me and like it is scraping; is this normal? Perimeters look and sound fine. Does everybody else's nozzle touch the previous layer?

An unfortunate side effect of this is that now my hotend is very loose and will cause poor prints, and there are bulges/cracks where the screws hold it in. Every retract command actually jolts the nozzle back about half an inch, and then it returns just in time to start extruding. I had one print earlier with terrible shifting of layers in the x-direction and wasn't sure why, as subsequent prints were fine. I'm sure it was the loose hotend now. I'm afraid to even drill the screws up to a 4mm size now to tighten up the hotend. Any other ideas? All I can think of is to maybe wrap the hotend in some kapton tape and still use the 3mm screws?

Anyhow, the nozzle still seems to be dragging somewhat though (but no longer colliding, at least lately) which is predominantly noticeable when it does the honeycomb infill patterns. It sounds aggressively loud to me and like it is scraping; is this normal? Perimeters look and sound fine. Does everybody else's nozzle touch the previous layer?

An unfortunate side effect of this is that now my hotend is very loose and will cause poor prints, and there are bulges/cracks where the screws hold it in. Every retract command actually jolts the nozzle back about half an inch, and then it returns just in time to start extruding. I had one print earlier with terrible shifting of layers in the x-direction and wasn't sure why, as subsequent prints were fine. I'm sure it was the loose hotend now. I'm afraid to even drill the screws up to a 4mm size now to tighten up the hotend. Any other ideas? All I can think of is to maybe wrap the hotend in some kapton tape and still use the 3mm screws?

|

Re: My Replikeo Prusa i3 Rework Build January 27, 2015 11:08AM |

Registered: 9 years ago Posts: 137 |

Hi guys,

So after having some great success with Repetier host firmware, I'm now trying to get my printer working with Marlin. And it's an Epic Fail

I've read some posts here and tried to follow recommendation about axis and endstop settings, but it's not working. In fact not a single endstop works. I did get movement directions working correctly. Can someone post their Configuration.h file so I can analyze it and adjust? I have Y motor with endstop in the back.

Here's what's happening basically.

1. Z axes:

I can move Z axis up, or down manually. When I try homing Z axes, steppers buzz like crazy and don't move at all. I think it's a feedrate setting or something else. I can never reach endstop manually, because it doesn't doesn't want to go done past some point.

2. X axes:

I can move it manually. When it hits endstop, it doesn't stop moving right, but won't move left anymore, which makes me believe it thinks endstop is at the left postion. Tried changing #define X_HOME_DIR to 1 or -1, makes no difference.

3. Y axes:

Just like X, I can move it manually, but when it hits endstop (at the end, which is at the back of the printer) it continues going, but won't move forward anymore.

Sane person would assume that changing ENDSTOP Settings in the config file would actually yeild some results but it doesn't make any difference... I'm assuming there are other settings somwhere...

Also initially I tried Replikeo's recommended settings, and it didn't work at all (directions were reversed).

Here're my settings (i'm also attaching configuration.h file)

EDIT: I got Y axes to work by changing logic that when it goes toward you it should be -Y and away from you is +Y. Now Y axes is homing correctly. But X and Z still not working...

Edited 2 time(s). Last edit at 01/27/2015 12:11PM by Bratan.

So after having some great success with Repetier host firmware, I'm now trying to get my printer working with Marlin. And it's an Epic Fail

I've read some posts here and tried to follow recommendation about axis and endstop settings, but it's not working. In fact not a single endstop works. I did get movement directions working correctly. Can someone post their Configuration.h file so I can analyze it and adjust? I have Y motor with endstop in the back.

Here's what's happening basically.

1. Z axes:

I can move Z axis up, or down manually. When I try homing Z axes, steppers buzz like crazy and don't move at all. I think it's a feedrate setting or something else. I can never reach endstop manually, because it doesn't doesn't want to go done past some point.

2. X axes:

I can move it manually. When it hits endstop, it doesn't stop moving right, but won't move left anymore, which makes me believe it thinks endstop is at the left postion. Tried changing #define X_HOME_DIR to 1 or -1, makes no difference.

3. Y axes:

Just like X, I can move it manually, but when it hits endstop (at the end, which is at the back of the printer) it continues going, but won't move forward anymore.

Sane person would assume that changing ENDSTOP Settings in the config file would actually yeild some results but it doesn't make any difference... I'm assuming there are other settings somwhere...

Also initially I tried Replikeo's recommended settings, and it didn't work at all (directions were reversed).

Here're my settings (i'm also attaching configuration.h file)

#define INVERT_X_DIR false // for Mendel set to false, for Orca set to true

#define INVERT_Y_DIR false // for Mendel set to true, for Orca set to false

#define INVERT_Z_DIR false // for Mendel set to false, for Orca set to true

#define INVERT_E0_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

// ENDSTOP SETTINGS:

// Sets direction of endstops when homing; 1=MAX, -1=MIN

#define X_HOME_DIR 1

#define Y_HOME_DIR -1

#define Z_HOME_DIR -1

//// MOVEMENT SETTINGS

#define NUM_AXIS 4 // The axis order in all axis related arrays is X, Y, Z, E

#define HOMING_FEEDRATE {50*60, 50*60, 4*60, 0} // set the homing speeds (mm/min)

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,4000,600} // default steps per unit for Ultimaker

#define DEFAULT_MAX_FEEDRATE {500, 500, 5, 25} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {2000,2000,20,1000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for Skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for retracts

EDIT: I got Y axes to work by changing logic that when it goes toward you it should be -Y and away from you is +Y. Now Y axes is homing correctly. But X and Z still not working...

Edited 2 time(s). Last edit at 01/27/2015 12:11PM by Bratan.

|

Re: My Replikeo Prusa i3 Rework Build January 29, 2015 12:19AM |

Registered: 9 years ago Posts: 30 |

Your X setting is going to similarly be what you've discovered for the Y. If your homing directions are correct, then it's your +/- logic that needs to be changed.

The Z axis issue can be solved by 1) increasing the voltage on your stepper motor potentiometer (but not too much as you'll overheat, read up on this and measure it with a voltmeter to make sure you aren't going too high, I think mine is set at around .6-.8, which is I think on the high end even though it maxes out around 1.3 or something. make sure you have your heat sinks installed), and 2) reducing your z-axis default max feedrate.

Edited 1 time(s). Last edit at 01/29/2015 12:21AM by Jonny Five.

The Z axis issue can be solved by 1) increasing the voltage on your stepper motor potentiometer (but not too much as you'll overheat, read up on this and measure it with a voltmeter to make sure you aren't going too high, I think mine is set at around .6-.8, which is I think on the high end even though it maxes out around 1.3 or something. make sure you have your heat sinks installed), and 2) reducing your z-axis default max feedrate.

Edited 1 time(s). Last edit at 01/29/2015 12:21AM by Jonny Five.

|

Re: My Replikeo Prusa i3 Rework Build January 29, 2015 04:03PM |

Registered: 9 years ago Posts: 137 |

Thanks! I'll give it X axes another try today. I think I went thru all possible combinations tho.Quote

Jonny Five

Your X setting is going to similarly be what you've discovered for the Y. If your homing directions are correct, then it's your +/- logic that needs to be changed.

The Z axis issue can be solved by 1) increasing the voltage on your stepper motor potentiometer (but not too much as you'll overheat, read up on this and measure it with a voltmeter to make sure you aren't going too high, I think mine is set at around .6-.8, which is I think on the high end even though it maxes out around 1.3 or something. make sure you have your heat sinks installed), and 2) reducing your z-axis default max feedrate.

About Z-axes, are you sure it's voltage issue? Both Z motors work just find with another firmware... As I mentioned I can also move them with manual commands without any issues. It gotta by feedrate setting then...

|

Re: My Replikeo Prusa i3 Rework Build January 29, 2015 04:37PM |

Registered: 10 years ago Posts: 344 |

|

Re: My Replikeo Prusa i3 Rework Build January 29, 2015 04:39PM |

Registered: 9 years ago Posts: 137 |

Wow, that's genius! I forgot there are different physical connections, I bet it's connected to wrong header! Thank you so much, I'll check tonight!Quote

gforce1

Z-axis: set max feedrate on 2 (standard 5).

X-axis:Your endstop is on the right side, so this is the max.endstop. is it connected on the max position of your (ramps)board?

|

Re: My Replikeo Prusa i3 Rework Build January 29, 2015 05:54PM |

Registered: 9 years ago Posts: 30 |

|

Re: My Replikeo Prusa i3 Rework Build January 29, 2015 05:56PM |

Registered: 9 years ago Posts: 30 |

So the equation for properly calculating the extruder default steps is:

e_steps_per_mm = (motor_steps_per_rev * driver_microstep) * (big_gear_teeth / small_gear_teeth) / (hob_effective_diameter * pi)

e_steps_per_mm = (200 * 16) * (43 / 10) / (7 * 3.14159) = 625.70681

However, it seems as 600 is actually the proper extruder default setting, both from the other config files I've seen online and from my own calibration efforts. What in the equation above is wrong?

e_steps_per_mm = (motor_steps_per_rev * driver_microstep) * (big_gear_teeth / small_gear_teeth) / (hob_effective_diameter * pi)

e_steps_per_mm = (200 * 16) * (43 / 10) / (7 * 3.14159) = 625.70681

However, it seems as 600 is actually the proper extruder default setting, both from the other config files I've seen online and from my own calibration efforts. What in the equation above is wrong?

|

Re: My Replikeo Prusa i3 Rework Build January 30, 2015 06:27AM |

Registered: 9 years ago Posts: 119 |

Hi guys,

I'm entering the i3-Rework club, too =) Am currently building my printer, everything is set up but the heatbed. Some questions came up:

- How did you mount your heatbeds? I only have 4 M3x25 Screws, some nuts and 4 pretty strong springs and I'm wondering what would be the best setup.

- I seem to be unable to get a flat heatbed. The pcb is just bending and the GFK-sheet is following it. So i have about 0,5 to 1mm higher bed in the middle than in the corners. Any advice on that?

Edited 3 time(s). Last edit at 01/31/2015 09:34AM by Ano.

I'm entering the i3-Rework club, too =) Am currently building my printer, everything is set up but the heatbed. Some questions came up:

- How did you mount your heatbeds? I only have 4 M3x25 Screws, some nuts and 4 pretty strong springs and I'm wondering what would be the best setup.

- I seem to be unable to get a flat heatbed. The pcb is just bending and the GFK-sheet is following it. So i have about 0,5 to 1mm higher bed in the middle than in the corners. Any advice on that?

Edited 3 time(s). Last edit at 01/31/2015 09:34AM by Ano.

|

Anonymous User

Re: My Replikeo Prusa i3 Rework Build January 31, 2015 04:08PM |

Ano,

I got mine with a lot of bend rods, GFK-sheet included, and need a lot of work to get things working. For GFK-sheet, I wast hours try to flat it and end up replace it with manually cut 2mm glass.

Check out Jay Gould's channel, there're many useful videos for calibration that I'm working on. Never know the kit need so much instrument to get a good print LOL!

http://youtu.be/hM8OLP1NaHE

Edited 1 time(s). Last edit at 01/31/2015 04:09PM by Infinite.

I got mine with a lot of bend rods, GFK-sheet included, and need a lot of work to get things working. For GFK-sheet, I wast hours try to flat it and end up replace it with manually cut 2mm glass.

Check out Jay Gould's channel, there're many useful videos for calibration that I'm working on. Never know the kit need so much instrument to get a good print LOL!

http://youtu.be/hM8OLP1NaHE

Edited 1 time(s). Last edit at 01/31/2015 04:09PM by Infinite.

|

Re: My Replikeo Prusa i3 Rework Build January 31, 2015 04:24PM |

Registered: 9 years ago Posts: 30 |

|

Re: My Replikeo Prusa i3 Rework Build January 31, 2015 07:07PM |

Registered: 9 years ago Posts: 119 |

Yeah, capacitive sensor for auto-leveling was one of my top-things-to-do, too. I just finished my first print and I'm really impressed. Went much better than I thought. Well, after some troubleshooting (filament not getting into the hotend, because the metal thingy at the top of the hotend-plastic was turned in too much and was blocking the filament).

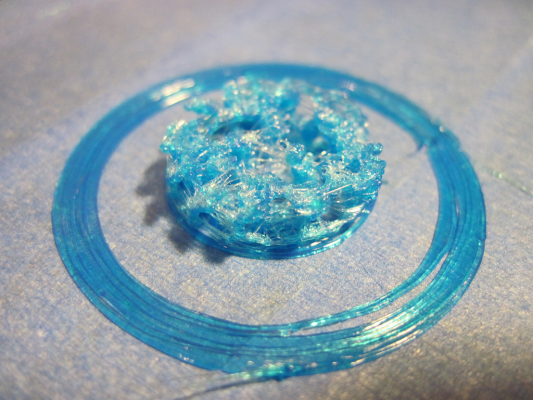

See attached!

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

See attached!

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

|

Re: My Replikeo Prusa i3 Rework Build January 31, 2015 07:15PM |

Registered: 9 years ago Posts: 120 |

Quote

Ano

Yeah, capacitive sensor for auto-leveling was one of my top-things-to-do, too. I just finished my first print and I'm really impressed. Went much better than I thought. Well, after some troubleshooting (filament not getting into the hotend, because the metal thingy at the top of the hotend-plastic was turned in too much and was blocking the filament).

See attached!

That looks really great for a first print! Here was mine

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build January 31, 2015 07:21PM |

Registered: 9 years ago Posts: 119 |

Btw. I used some of your buildlog infos and fotos from your blog to build up my printer, as some infos on the wiki where inaccurate, so thanks for that

Wanted to post a comment there, but I don't want to use google+

My second print, a 20x20x20mm cube (0,4 infill)

Three little questions: My printbed stays at high temperature, even after the print job is finished. It stayed hot for several minutes before I switched it off

manually. Is there some config where I could change this time to a minute or two?

While my dimensions are pretty good for a second try (about 19,8x19,8x19,6), the first 4 layers are being print in 21x21mm. Is this wanted? I mean,

is there a config that makes the first layers larger to better stick on the plate? If you look at my last post, the onewall-test had also the first layer being larger than the rest.

And the second thing: As you may see on the second image, the top layers are not filled 100%, which leads to some little holes. I would think this is due to a extruder rate

not being high enough, is this right? (Hotend temp is at 245°C and I think it is high enoug)

Btw: I seem to be unable to heat my bed to more than 110°C, and reaching the 110 is taking really long. This first pring was with 100°C for first layers, 95°C for the rest.

Could this become a problem? My next steps regarding this would be to change the mosfet for a better one (Texas Instruments is sending me some nice samples^^) and changing the cables,

because they were getting a bit warm (but not really hot, which leads me to think, that this will not change really much)

/edit: First bigger part (170mm length) went horribly wrong. After about 1 hour printing the abs retracted, bent and lost it's grip to the heatbed. 95°C seem to be too cold. Will try 105°C tomorrow.

Edited 6 time(s). Last edit at 02/01/2015 06:45PM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

Wanted to post a comment there, but I don't want to use google+

My second print, a 20x20x20mm cube (0,4 infill)

Three little questions: My printbed stays at high temperature, even after the print job is finished. It stayed hot for several minutes before I switched it off

manually. Is there some config where I could change this time to a minute or two?

While my dimensions are pretty good for a second try (about 19,8x19,8x19,6), the first 4 layers are being print in 21x21mm. Is this wanted? I mean,

is there a config that makes the first layers larger to better stick on the plate? If you look at my last post, the onewall-test had also the first layer being larger than the rest.

And the second thing: As you may see on the second image, the top layers are not filled 100%, which leads to some little holes. I would think this is due to a extruder rate

not being high enough, is this right? (Hotend temp is at 245°C and I think it is high enoug)

Btw: I seem to be unable to heat my bed to more than 110°C, and reaching the 110 is taking really long. This first pring was with 100°C for first layers, 95°C for the rest.

Could this become a problem? My next steps regarding this would be to change the mosfet for a better one (Texas Instruments is sending me some nice samples^^) and changing the cables,

because they were getting a bit warm (but not really hot, which leads me to think, that this will not change really much)

/edit: First bigger part (170mm length) went horribly wrong. After about 1 hour printing the abs retracted, bent and lost it's grip to the heatbed. 95°C seem to be too cold. Will try 105°C tomorrow.

Edited 6 time(s). Last edit at 02/01/2015 06:45PM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

|

Anonymous User

Re: My Replikeo Prusa i3 Rework Build February 02, 2015 03:11AM |

How to Set Up a PCB Heatbed by Alex Franke.

"In this video, Jacob shows an easy way to set up a PCB heatbed for your 3D printer -- a method that allows the entire surface of the heatbed to be used for printing. He also shows how to cut inexpensive certificate frame glass to size with some simple tools. We've had printers with a heatbed setup just like this running without incident for over a year."

Try this first, it's works fopr me. Also, try place cork sheet or insulation on the heat bed when it warm up like a racing car do

"In this video, Jacob shows an easy way to set up a PCB heatbed for your 3D printer -- a method that allows the entire surface of the heatbed to be used for printing. He also shows how to cut inexpensive certificate frame glass to size with some simple tools. We've had printers with a heatbed setup just like this running without incident for over a year."

Try this first, it's works fopr me. Also, try place cork sheet or insulation on the heat bed when it warm up like a racing car do

|

Re: My Replikeo Prusa i3 Rework Build February 02, 2015 04:41PM |

Registered: 9 years ago Posts: 120 |

Quote

Ano

Btw. I used some of your buildlog infos and fotos from your blog to build up my printer, as some infos on the wiki where inaccurate, so thanks for that

Wanted to post a comment there, but I don't want to use google+

That's great! Glad I could help you out. Hopefully I will be moving away from Google's Blogger sometime over the next couple months.

Quote

Ano

My second print, a 20x20x20mm cube (0,4 infill)

Three little questions: My printbed stays at high temperature, even after the print job is finished. It stayed hot for several minutes before I switched it off

manually. Is there some config where I could change this time to a minute or two?

While my dimensions are pretty good for a second try (about 19,8x19,8x19,6), the first 4 layers are being print in 21x21mm. Is this wanted? I mean,

is there a config that makes the first layers larger to better stick on the plate? If you look at my last post, the onewall-test had also the first layer being larger than the rest.

And the second thing: As you may see on the second image, the top layers are not filled 100%, which leads to some little holes. I would think this is due to a extruder rate

not being high enough, is this right? (Hotend temp is at 245°C and I think it is high enoug)

Btw: I seem to be unable to heat my bed to more than 110°C, and reaching the 110 is taking really long. This first pring was with 100°C for first layers, 95°C for the rest.

Could this become a problem? My next steps regarding this would be to change the mosfet for a better one (Texas Instruments is sending me some nice samples^^) and changing the cables,

because they were getting a bit warm (but not really hot, which leads me to think, that this will not change really much)

/edit: First bigger part (170mm length) went horribly wrong. After about 1 hour printing the abs retracted, bent and lost it's grip to the heatbed. 95°C seem to be too cold. Will try 105°C tomorrow.

I think I can help you out with these issues. Are you using Slic3r and Marlin?

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build February 02, 2015 04:43PM |

Registered: 9 years ago Posts: 119 |

That would be great =)Quote

Blue Ice

[...] I think I can help you out with these issues. Are you using Slic3r and Marlin?

Yap newest marlin version and slic3er aswell.

Oh, and I didn't say: My layers were 0,2mm, my hotend 245°C and my heatbed 100°C first layers, then 95°C

And I just tried a print with heatbed temp 105°C for the whole print, still warping.

/edit: Hm. There are some that say a warmer heatbed is better and then there are others that say 90°C is enough: http://voltivo.com/blog/control-pla-and-abs-warping

Any other opinions? ^^

/edit2: Made another print, this time 250°C hotend, 105°C heatbed and 0,3mm layerheight. Warping started after about half the print, but was still able to finish it. It also seems like I have to push my extruder rate a bit higher, as

the strings (on the same layer) aren't connecting so well, which leads to a bad cracking behavior. See here on the left side:

Oh, and could you upload your configuration.h? Just to be able to compare some values =)

/edit3: Well, extruder rate higher was in fact a good point. Extruding 100mm only gave me 79mm of filament. I changed from

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,4000,473}

to#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,4000,598}

Which now outputs 100mm in real.I wonder how my prints could still be this good (like not breaking completely appart) with that high discrepancy?

Edited 6 time(s). Last edit at 02/02/2015 05:57PM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

|

Re: My Replikeo Prusa i3 Rework Build February 02, 2015 06:11PM |

Registered: 9 years ago Posts: 120 |

Could you upload your Configuration.h file instead? It might be easier for me to point out which parts are different and compare.

I also get the cracks between the outer layers and inner layers of parts sometimes with ABS. It's really only on small borders and turning up the extrusion rate usually helps.

I read about this on RichRap's blog and it seems it might help, but I've never tried it. Maybe try that?

About the heated bed- do you have anything on the glass? I use a mixture of 1 parts ABS to 4 parts acetone by weight, and then I let the ABS dissolve in the acetone. After that, I paint it on the bed with a paper towel when the bed is hot, and the parts stick much better.

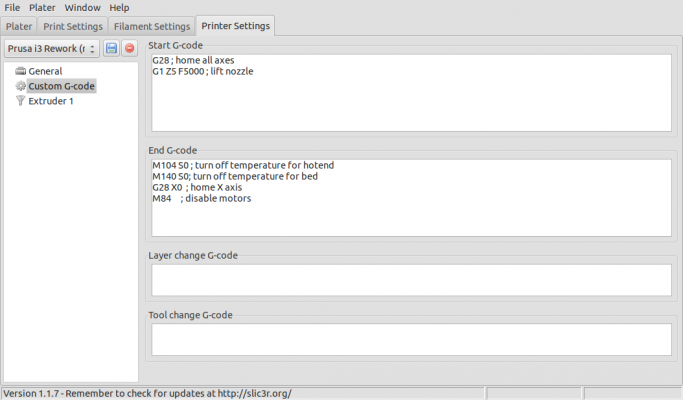

Here are some images of the mixture:

Edited 2 time(s). Last edit at 02/02/2015 06:16PM by Blue Ice.

Blue Ice

blog at [contemporarymaker.com]

I also get the cracks between the outer layers and inner layers of parts sometimes with ABS. It's really only on small borders and turning up the extrusion rate usually helps.

I read about this on RichRap's blog and it seems it might help, but I've never tried it. Maybe try that?

About the heated bed- do you have anything on the glass? I use a mixture of 1 parts ABS to 4 parts acetone by weight, and then I let the ABS dissolve in the acetone. After that, I paint it on the bed with a paper towel when the bed is hot, and the parts stick much better.

Here are some images of the mixture:

Edited 2 time(s). Last edit at 02/02/2015 06:16PM by Blue Ice.

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build February 02, 2015 06:23PM |

Registered: 9 years ago Posts: 119 |

Oh, yeah, I don't know why I didn't think about uploading it myself XD

See attached my configuration.h

As I said, in the meantime I changed my extrusion rate, so this should definitely help.

I am currently printing on the fiberglass plate from replikeo. It works quite well, at least for little prints. It is not flat, but for larger

prints, the first layers (multiple!) are printing pretty good and holding on the plate, till warping begins.

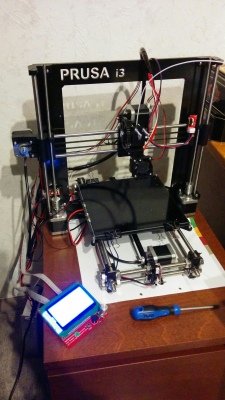

Here is a photo of my setup (everything original-replikeo-kit so far)

I would really like to avoid working with chemicals (I know it's a dumb thing to say, when clearly this seems to be one of the better solutions,

but still^^)

Edited 1 time(s). Last edit at 02/02/2015 06:25PM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

See attached my configuration.h

As I said, in the meantime I changed my extrusion rate, so this should definitely help.

I am currently printing on the fiberglass plate from replikeo. It works quite well, at least for little prints. It is not flat, but for larger

prints, the first layers (multiple!) are printing pretty good and holding on the plate, till warping begins.

Here is a photo of my setup (everything original-replikeo-kit so far)

I would really like to avoid working with chemicals (I know it's a dumb thing to say, when clearly this seems to be one of the better solutions,

but still^^)

Edited 1 time(s). Last edit at 02/02/2015 06:25PM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

|

Re: My Replikeo Prusa i3 Rework Build February 02, 2015 10:39PM |

Registered: 9 years ago Posts: 137 |

Why use those chemicals when you can just easily apply Elmer's blue glue stick? I swear by that stuff, ABS sticks to like crazy when hot and releases when cold... Plus it let's me print at just 90-95C . Never had lift off issues. That's probably the only issues I didn't have, everything else is not so good but that's another story

I just reapply more glue after each print. Eventually I just take glass off and wash it in the sink. Water and paper towels take glue right off.

Edited 1 time(s). Last edit at 02/02/2015 10:41PM by Bratan.

I just reapply more glue after each print. Eventually I just take glass off and wash it in the sink. Water and paper towels take glue right off.

Edited 1 time(s). Last edit at 02/02/2015 10:41PM by Bratan.

|

Re: My Replikeo Prusa i3 Rework Build February 02, 2015 11:37PM |

Registered: 9 years ago Posts: 120 |

Quote

Ano

Three little questions: My printbed stays at high temperature, even after the print job is finished. It stayed hot for several minutes before I switched it off

manually. Is there some config where I could change this time to a minute or two?

Yes. I added this line in Slic3r, under the tab Printer Settings, the option Custom G-code, and the box End G-code:

M140 S0; turn off temperature for bed

This immediately turns off the bed heating when a print has completed. I like it a lot- it allows me to print stuff overnight without the bed being on all night.

Quote

Ano

While my dimensions are pretty good for a second try (about 19,8x19,8x19,6), the first 4 layers are being print in 21x21mm. Is this wanted? I mean,

is there a config that makes the first layers larger to better stick on the plate? If you look at my last post, the onewall-test had also the first layer being larger than the rest.

This is because your hotend is too close to the bed on the starting layers, which causes the filament to be pushed hard into the glass plate for the first couple layers. Try adjusting your bed leveling screws so it is just a bit farther away.

So now I'm looking through your Configuration.h- I'll describe some things that appear to be different and might need to be changed.

You have:

#define TEMP_SENSOR_0 60 //Ano #define TEMP_SENSOR_1 0 #define TEMP_SENSOR_2 0 #define TEMP_SENSOR_BED 60 //Ano

I have:

#define TEMP_SENSOR_0 1 #define TEMP_SENSOR_1 0 #define TEMP_SENSOR_2 0 #define TEMP_SENSOR_BED 1

These values are important and may help with your temperature problems. Basically, they give more exact values for what voltages apply to what temperatures from your thermistors. They are quite useful and I would recommend changing them from 60 to 1.

Your DEFAULT_AXIS_STEPS_PER_MM looks good.

You have:

// Preheat Constants #define PLA_PREHEAT_HOTEND_TEMP 180 #define PLA_PREHEAT_HPB_TEMP 70 #define PLA_PREHEAT_FAN_SPEED 255 // Insert Value between 0 and 255 #define ABS_PREHEAT_HOTEND_TEMP 240 #define ABS_PREHEAT_HPB_TEMP 100 #define ABS_PREHEAT_FAN_SPEED 255 // Insert Value between 0 and 255

I have:

#define PLA_PREHEAT_HOTEND_TEMP 185 #define PLA_PREHEAT_HPB_TEMP 70 #define PLA_PREHEAT_FAN_SPEED 255 // Insert Value between 0 and 255 #define ABS_PREHEAT_HOTEND_TEMP 215 #define ABS_PREHEAT_HPB_TEMP 100 #define ABS_PREHEAT_FAN_SPEED 255 // Insert Value between 0 and 255

Pretty similar, but notice that none of either of our values are over 100 Celsius for the bed. You really should never have to heat it up more than that. Changing the thermistor value as mentioned above should help to solve the problem.

Quote

Ano

And the second thing: As you may see on the second image, the top layers are not filled 100%, which leads to some little holes. I would think this is due to a extruder rate

not being high enough, is this right? (Hotend temp is at 245°C and I think it is high enoug)

Most likely that is too high for ABS. Try 215 degrees Celsius after changing your thermistor values- that should be more accurate. Also try bumping up your infill value in Slic3r to something larger and adding more layers on the top surface.

Quote

Ano

Btw: I seem to be unable to heat my bed to more than 110°C, and reaching the 110 is taking really long. This first pring was with 100°C for first layers, 95°C for the rest.

Could this become a problem? My next steps regarding this would be to change the mosfet for a better one (Texas Instruments is sending me some nice samples^^) and changing the cables,

because they were getting a bit warm (but not really hot, which leads me to think, that this will not change really much)

I usually keep mine at 100 degrees for the whole print, but that is personal preference. Again, changing the thermistor values should help a lot with this issue. In a room-temperature area, my heated bed takes less that 20 minutes but more than 10 minutes to heat up to 100 degrees.

Quote

Ano

/edit: First bigger part (170mm length) went horribly wrong. After about 1 hour printing the abs retracted, bent and lost it's grip to the heatbed. 95°C seem to be too cold. Will try 105°C tomorrow.

Your temps are messed up, as mentioned above- the culprit is likely the thermistor values- again

Good luck and let me know what happens!

Edited 2 time(s). Last edit at 02/02/2015 11:41PM by Blue Ice.

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build February 03, 2015 05:07AM |

Registered: 9 years ago Posts: 119 |

@Bratan: Well, 0.90$ at Amazon.de, nice. But I am living in germany, makes ! 20€ ! for here. I will try another glue stick, though ^^ seems less chemical and aggressive to me than acetone.

@Blue Ice: Thanks for the hint for slic3r. I didn't think of that^^

I copied the thermistor values from a website and tried to check them with another external thermometer. They seemed to be about right (+-3 to 4 °C). Will check that again this evening!

Also will try lifting my nozzle a bit and lowering the hotend temperature. Quite a list to work through =)

Will keep you informed how it went!

/Edit: So, I remeasured the temperatures and both (hotend and hotbed) were only +-2°C off from my other thermometer. So I think that they are pretty much right. I printed the first of the two

pieces for: http://www.thingiverse.com/thing:542892.

My hotend was at 225°C, still extruding quite good. The hotbed was set for 90°C, and even the small object was warping a bit, which leaded to not enough adhesion. No problem, cause I could

still finish the print, but still need to test some temperatures for the heatbed. I readjusted the nozzle height so have a bit more space between the hotend and the bed. The boarder around the

first layers was smaller, but still is there a bit. Need to raise it a bit more (and/or lower the nozzle-temp a bit more).

Edited 2 time(s). Last edit at 02/03/2015 06:05PM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

@Blue Ice: Thanks for the hint for slic3r. I didn't think of that^^

I copied the thermistor values from a website and tried to check them with another external thermometer. They seemed to be about right (+-3 to 4 °C). Will check that again this evening!

Also will try lifting my nozzle a bit and lowering the hotend temperature. Quite a list to work through =)

Will keep you informed how it went!

/Edit: So, I remeasured the temperatures and both (hotend and hotbed) were only +-2°C off from my other thermometer. So I think that they are pretty much right. I printed the first of the two

pieces for: http://www.thingiverse.com/thing:542892.

My hotend was at 225°C, still extruding quite good. The hotbed was set for 90°C, and even the small object was warping a bit, which leaded to not enough adhesion. No problem, cause I could

still finish the print, but still need to test some temperatures for the heatbed. I readjusted the nozzle height so have a bit more space between the hotend and the bed. The boarder around the

first layers was smaller, but still is there a bit. Need to raise it a bit more (and/or lower the nozzle-temp a bit more).

Edited 2 time(s). Last edit at 02/03/2015 06:05PM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

|

Re: My Replikeo Prusa i3 Rework Build February 04, 2015 10:35AM |

Registered: 9 years ago Posts: 120 |

Quote

Ano

@Bratan: Well, 0.90$ at Amazon.de, nice. But I am living in germany, makes ! 20€ ! for here. I will try another glue stick, though ^^ seems less chemical and aggressive to me than acetone.

@Blue Ice: Thanks for the hint for slic3r. I didn't think of that^^

I copied the thermistor values from a website and tried to check them with another external thermometer. They seemed to be about right (+-3 to 4 °C). Will check that again this evening!

Also will try lifting my nozzle a bit and lowering the hotend temperature. Quite a list to work through =)

Will keep you informed how it went!

/Edit: So, I remeasured the temperatures and both (hotend and hotbed) were only +-2°C off from my other thermometer. So I think that they are pretty much right. I printed the first of the two

pieces for: http://www.thingiverse.com/thing:542892.

My hotend was at 225°C, still extruding quite good. The hotbed was set for 90°C, and even the small object was warping a bit, which leaded to not enough adhesion. No problem, cause I could

still finish the print, but still need to test some temperatures for the heatbed. I readjusted the nozzle height so have a bit more space between the hotend and the bed. The boarder around the

first layers was smaller, but still is there a bit. Need to raise it a bit more (and/or lower the nozzle-temp a bit more).

Great! I'm thinking that you should raise the bed temp to 100 degrees. Also, maybe the glue stick method isn't providing enough adhesion?

Blue Ice

blog at [contemporarymaker.com]

|

Re: My Replikeo Prusa i3 Rework Build February 04, 2015 12:38PM |

Registered: 9 years ago Posts: 30 |

I wouldn't raise your hotend to minimize the first layer thickness. You need it very close to the bed to lay down a solid first layer for adhesion - it should be smashed down a bit.

If you think you don't need an extra fat first layer, then you adjust this in slic3r. The default settings are to lay down a thicker layer, which I think is ideal. Anyway, look at print settings -> first layer height (default .35mm for .3mm layer height). Also, Print Settings -> Advanced -> First Layer (default 200%).

If you think you don't need an extra fat first layer, then you adjust this in slic3r. The default settings are to lay down a thicker layer, which I think is ideal. Anyway, look at print settings -> first layer height (default .35mm for .3mm layer height). Also, Print Settings -> Advanced -> First Layer (default 200%).

|

Re: My Replikeo Prusa i3 Rework Build February 04, 2015 01:14PM |

Registered: 9 years ago Posts: 119 |

@Jonny Five: Oh, thanks for that information. I didn't see the advanced settings in slic3r. In fact, the brim would not be an issue for me, but my get a few layers too wide. If it was only the first one, it would not matter, as you can get rid of it pretty easily, but as it is more than one (mostly 4-5 with an exponential decrease in being too wide), it just makes my objects round and not having a 90° wall on the outside. I'll try to raise my z-home a bit and in addition add a brim on the first layer. This should give me enough surface and still get nice 90° walls, at least that's what I hope.

/edit: Just to be clear: The brim option was not activated for the prints so far.

@Blue Ice: Yeah, will get my heatbed back to 100°C for the next print. I didn't try the glue stick method yet.

Edited 2 time(s). Last edit at 02/04/2015 01:16PM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

/edit: Just to be clear: The brim option was not activated for the prints so far.

@Blue Ice: Yeah, will get my heatbed back to 100°C for the next print. I didn't try the glue stick method yet.

Edited 2 time(s). Last edit at 02/04/2015 01:16PM by Ano.

Prusa i3 Rework (from Replikeo.com) & original Prusa i3 MK2 (from shop.prusa3d.com) << the MK2 definitely is worth the higher cost!

Print Troubleshooting Guide // Visual troubleshooting guide

Sorry, only registered users may post in this forum.